page 6

6.Wiring.

Modifications not approved by the party responsible for compliance

could void the user's authority to operate the equipment.

*NOTE:This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules.These limits are designed to provide

reasonable protection against harmful interference in a residential installation.This

equipment generates,uses and can radiate radio frequency energy and,if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

* Reorient or relocate the receiving antenna.

* Increase the separation between the equipment and receiver.

* Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

black

black

white

white

black supply wire

ground

(green

or bare)

white supply wire

from

ceiling

from

fan

ground

(green or bare)

(wiring for fan) *

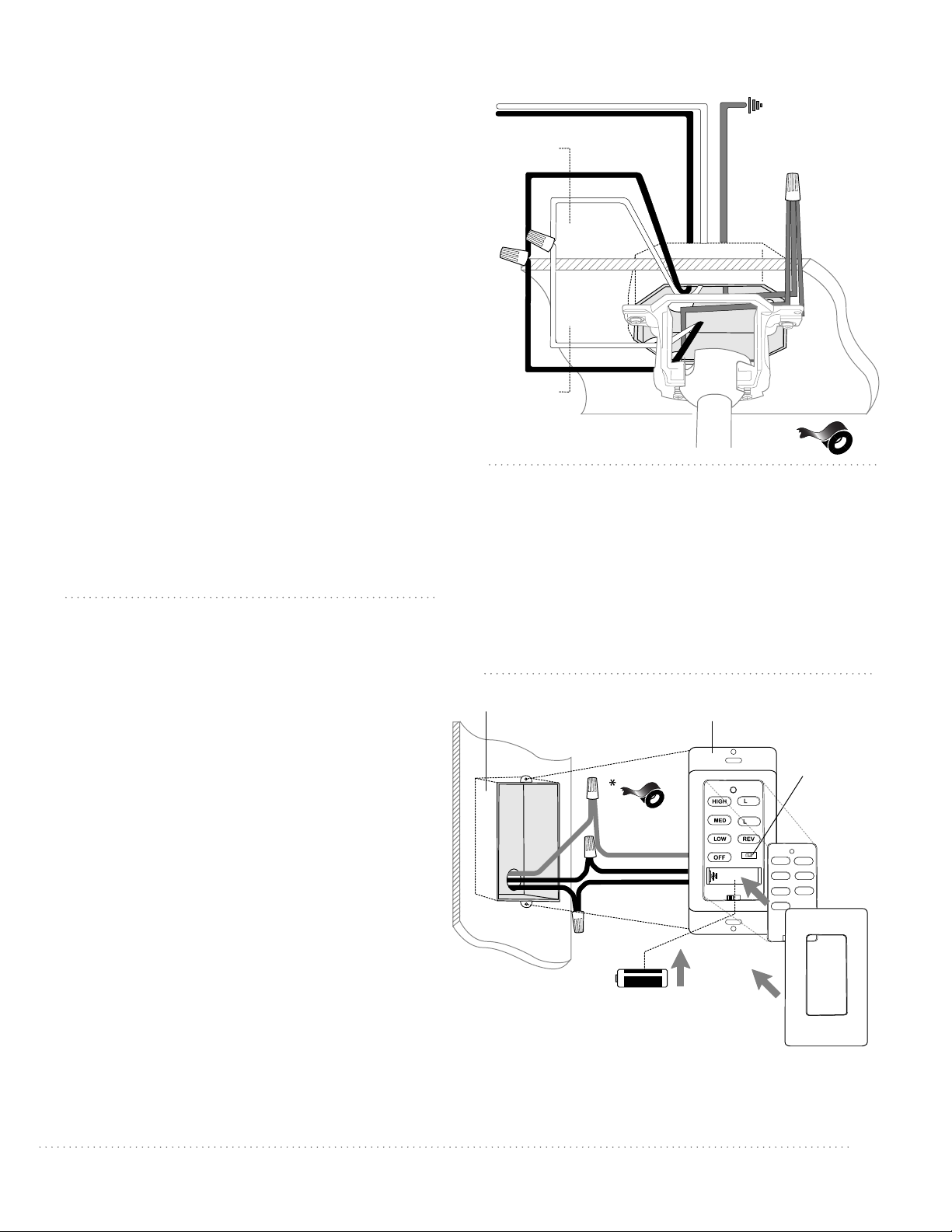

[PLEASE NOTE:Wall and/or handheld remote

control must be used for fan to operate. If you do

not wish to use the wall control,please proceed to

Section 7 below to continue with fan installation.]

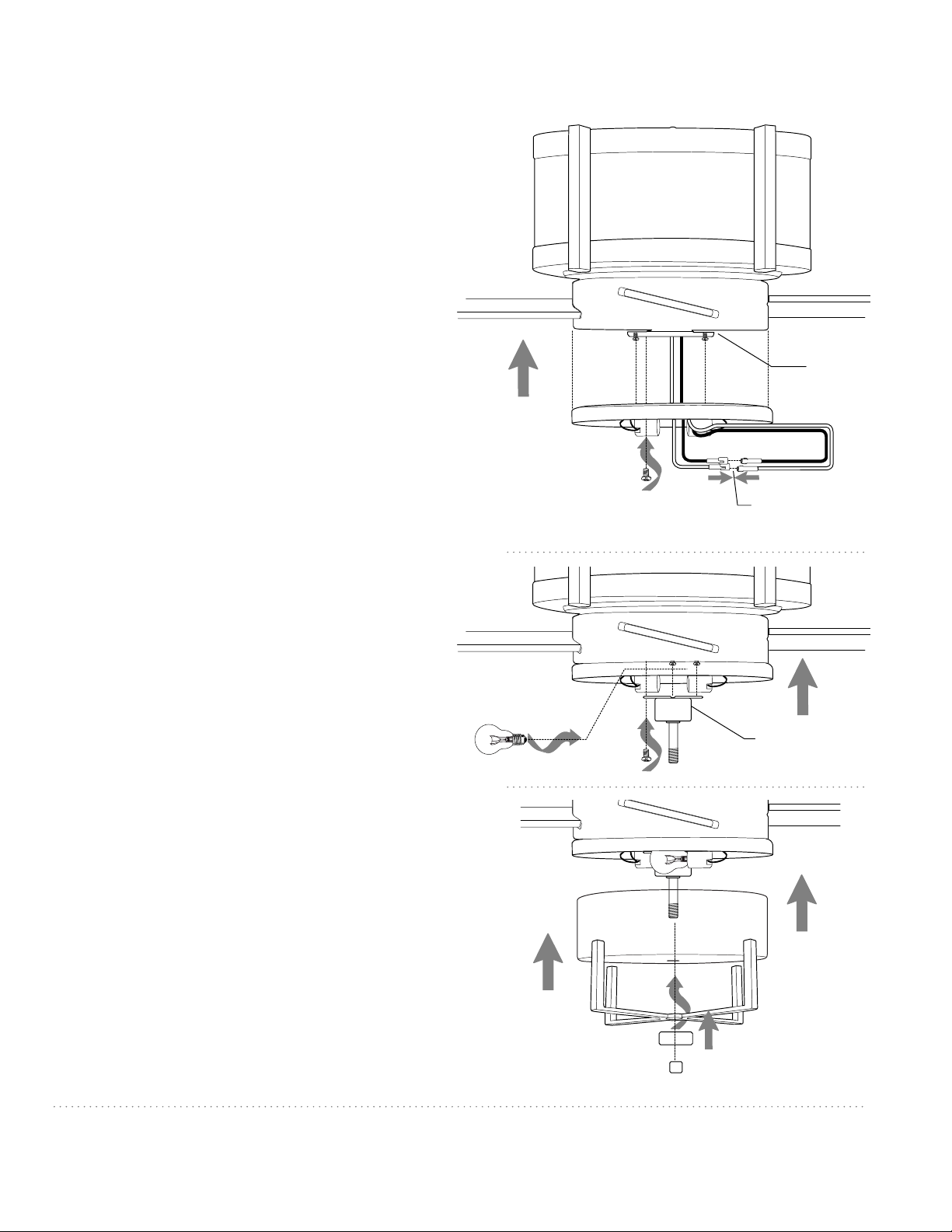

To install wall control, remove existing wall switch.

Wire one of the wall controls with wire connectors

provided as shown in diagram at right.

*Wrap each wire connector separately with

electrical tape as an extra safety measure. Gently

push wires and taped wire connectors into outlet

box.

Install one 12-volt battery (included) in wall control.

IMPORTANT:Wall control will not function unless

battery is installed.

Since this fan comes with incandescent bulbs, the

dimmer switch (labeled DIM and ON) has been

pre-set to the "ON" position (DIM). If you do not

wish to have dimming capability, please move the

switch to the "OFF" position (ON).

Select a faceplate (almond or white) and press

firmly onto front of wall control.Attach wall control

to outlet box and secure with screws from original

wall switch. Attach plate (included) to wall control

using 2 screws provided with the wall control.

(wiring for wall control)

black (OUT to fan)

green

black

(AC IN from

breaker box)

black

(TO POWER supply)

black

green/

bare

ground

green/

bare

ground

outlet box wall

control

face-

plate

12V battery

dimmer

switch

plate

11

-

22

-

DIM ON

CAUTION: Be sure outlet box is properly grounded and

that a ground wire (GREEN or Bare) is present.

Make sure all electrical connections comply with Local

Codes or Ordinances and the National Electrical Code.

If you are unfamiliar with electrical wiring or if the

house/building wires are different colors than those

referred to in the instructions below,please use a

qualified electrician.

Note: Excess lead wire length from the fan can be cut

to the desired length and then stripped.

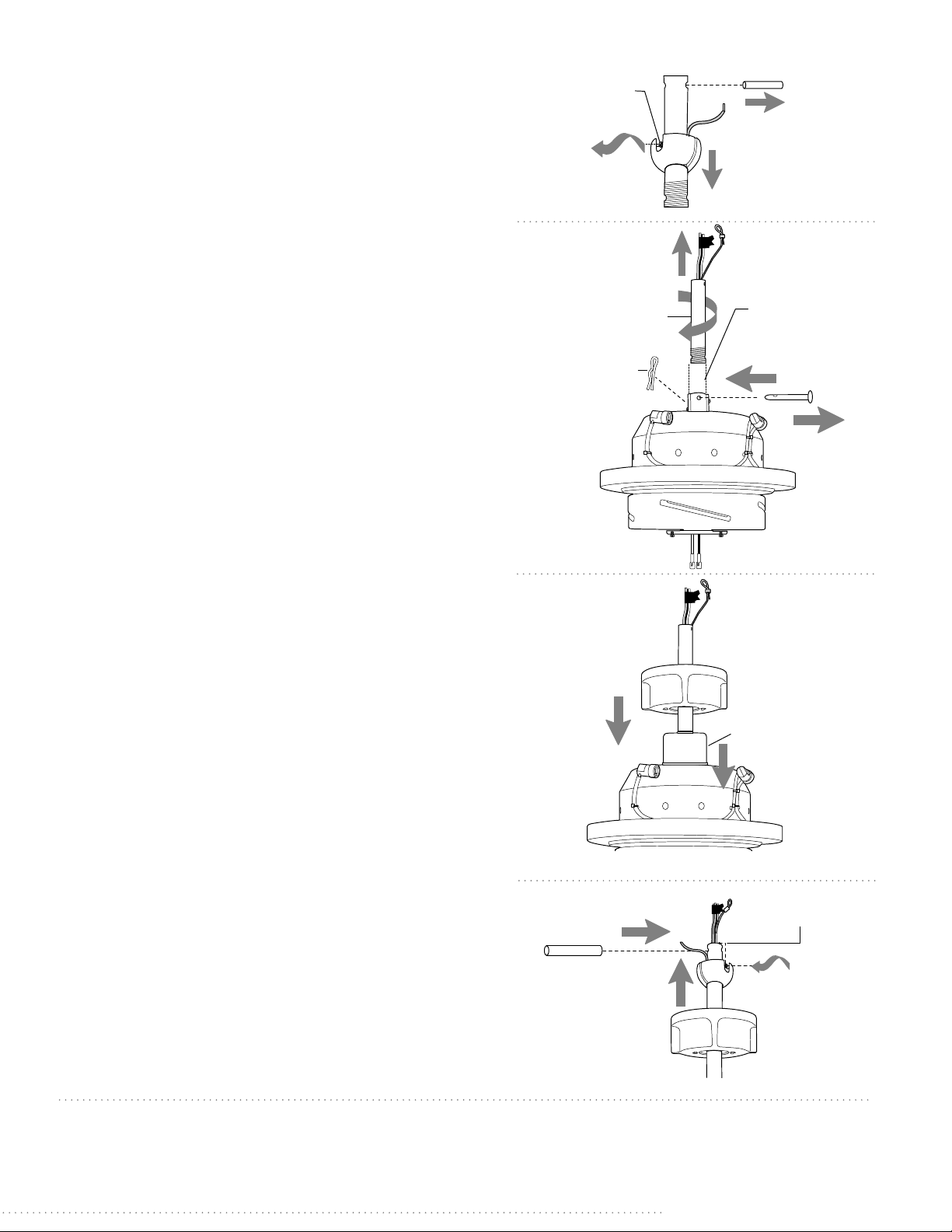

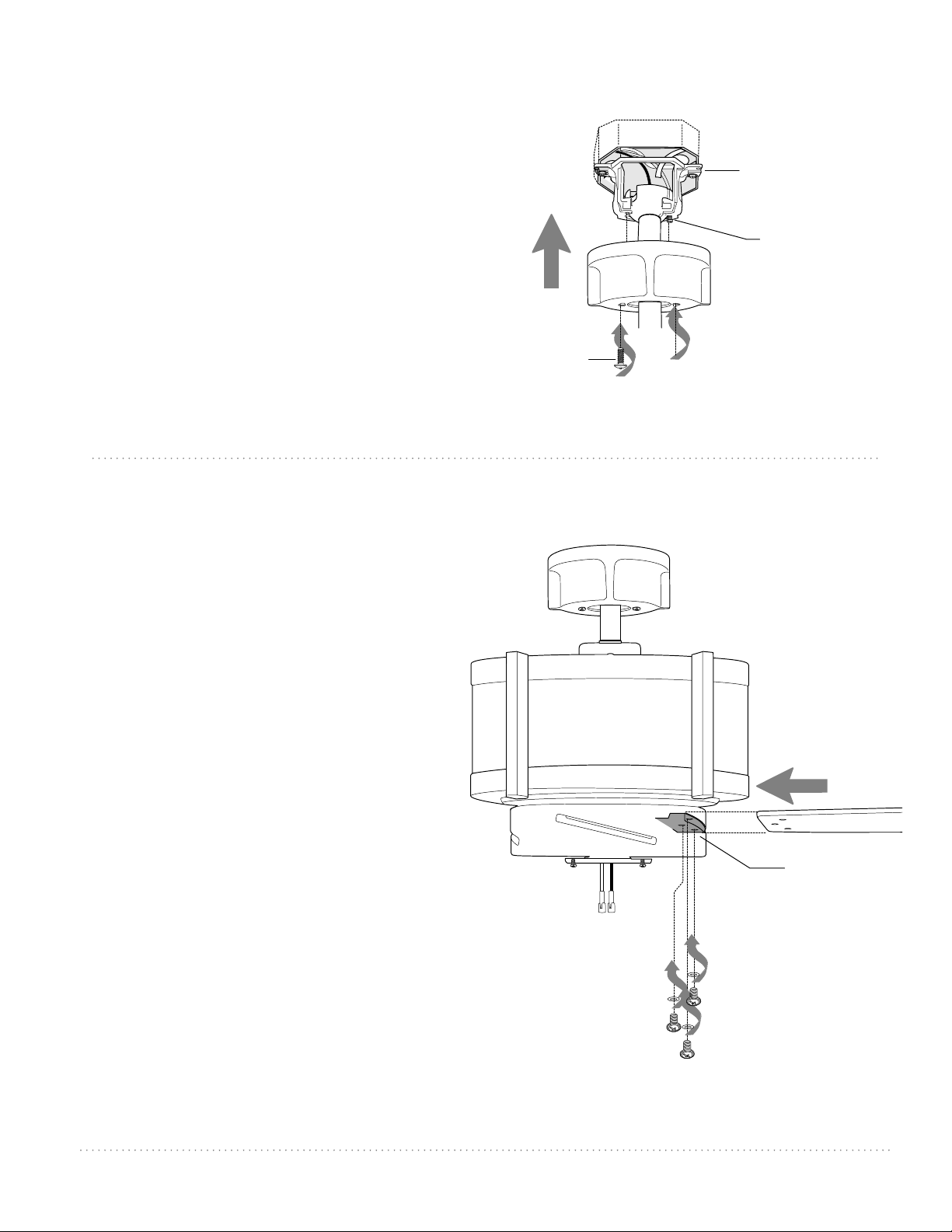

When fan is secured in place on the hanging

bracket, electrical wiring can be made as follows:

Connect BLACK wire from fan to BLACK wire from

ceiling with wire connector provided.

Connect WHITE wire from fan to WHITE wire from

ceiling with wire connector provided.

Connect all GROUND (GREEN) wires together from

fan to BARE/GREEN wire from ceiling with wire

connector provided.

* Wrap each wire connector separately with

electrical tape as an extra safety measure.