3

This jack features a 6,000 lbs. maximum load

capacity. Lifting range for this jack is 5-3/8

inches to 19-1/2 inches. Jack features an

overload valve bypass system to prevent jack

damage and user injury.

Specications

Compact design allows use in conned spaces

Maximum load capacity........3 tons (6,000 lbs.)

Service jack lift range.....5-3/8 to 19-1/2 inches

Weight....................................................75 lbs.

WARNING: This product contains chemicals

known to the state of California to cause

cancer and birth defects or other reproductive

harm. www.P65Warnings.ca.gov

SAFETY INSTRUCTIONS CRAFTSMAN LIMITED WARRANTY

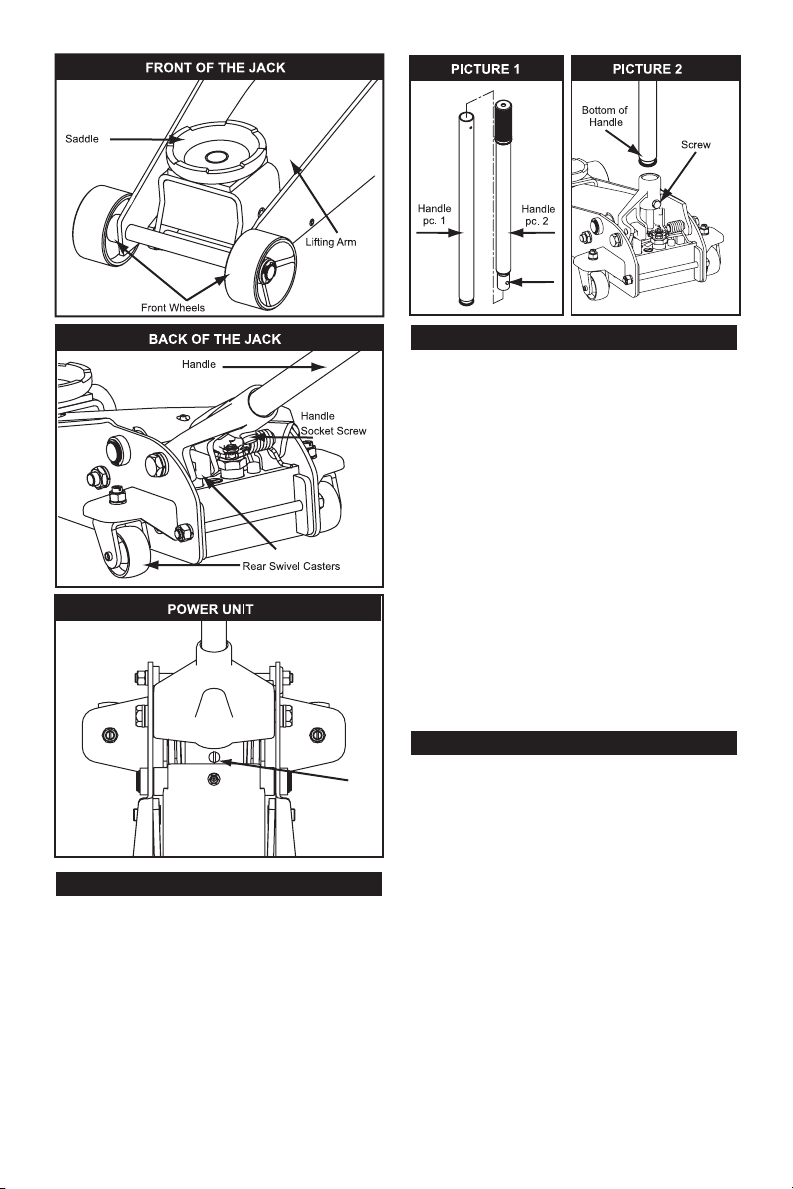

DESCRIPTION

Read Operating Instructions

Study, understand and follow all instructions in

this manual before operating the jack. Failure

to heed these warnings may result in loss of

load, damage to the jack and/or jack failure

resulting in personal injury or property damage.

Position the Jack

This jack is designed only for lifting part of

the total vehicle. Position the jack to only lift

on the areas of the vehicle specied by the

vehicle manufacturer.

Use Support Stands

After lifting the vehicle always support the

load with appropriately rated vehicle support

stands before working on the vehicle.

Do Not Overload Jack

Do not overload this jack beyond its rated

capacity. Overloading this jack beyond its

rated capacity can cause damage to or failure

of the jack.

Use on Hard Level Surface

This jack is designed only for use on hard level

surfaces capable of sustaining the load. Use

on other than hard level surfaces can result in

jack instability and possible loss of load.

Center Load on Jack Saddle

Center load on jack saddle before lifting

vehicle. O-center loads and loads lifted

when the jack is not level can cause loss

of load or damage to the jack. Only use on

vehicles whose lift points t well with saddle

of this jack.

Do Not Use Jack as Dolly

Do not move or dolly the vehicle while it is on

the jack. Do not use this jack to lift or move

a building, mobile home or travel trailer of

any type.

KEEP HANDS AND FEET CLEAR OF

THE JACK HINGE MECHANISM AND

GROUND CONTACT AREA WHEN

LOWERING THE LOAD!

CRAFTSMAN LIMITED WARRANTY

FOR ONE YEAR from the date of sale this

product is warranty against defects in material

or workmanship. WITH PROOF OF SALE

a defective product will be replaced free of

charge.

For warranty coverage details to obtain

free replacement, visit the web page: www.

craftsman.com/warranty

This warranty applies for only 90 days from

the date of sale if this product is ever used

while providing commercial services or if

rented to another person.

This warranty gives you specic legal rights,

and you may also have other rights which vary

from state to state.

Sears Brands Management Corporation,

Homan Estates, IL 60179

THIS IS A LIFTING DEVICE ONLY!

DO NOT work on vehicle supported by jack.

Immediately after lifting, support load with

appropriately rated vehicle support stands before

working on vehicle.