3q5o fzlrnn lr4oroA. dl L" P,Ju1€V

SPEED

For best perf ormance this tool should run at 8p-

proximately 2700 R.P.M. This speed is attained by

using a 2 inch diameter motor pulley with a Yz inch

V-groove.

Be sure to specify the shaft diameter of your motor

when ordering the motor pulley.

BETT

Use a standard % inch V-belt. To determine the

belt length place rhotor and tool in operati.g posi-

tion and measure around the outside of the pulleys

with a steel tape. Do not measure in the grooves.

TUBRICATION

This sander is equipped with precision type, sealed

ball bearings. These bearings were packed with

grease at the factory and require no additional lubri-

cation for the life of the bearing.

To maintain smooth and easy operation of the

controls, oil the following parts occasionally with any

good grade machine oil:

| . Belt adjusting knobs Nos. 23 and 33 where

they enter the casting.

2. Pulley support pins Nos. 25 and 29 where they

enter the casting.

coNTROTS

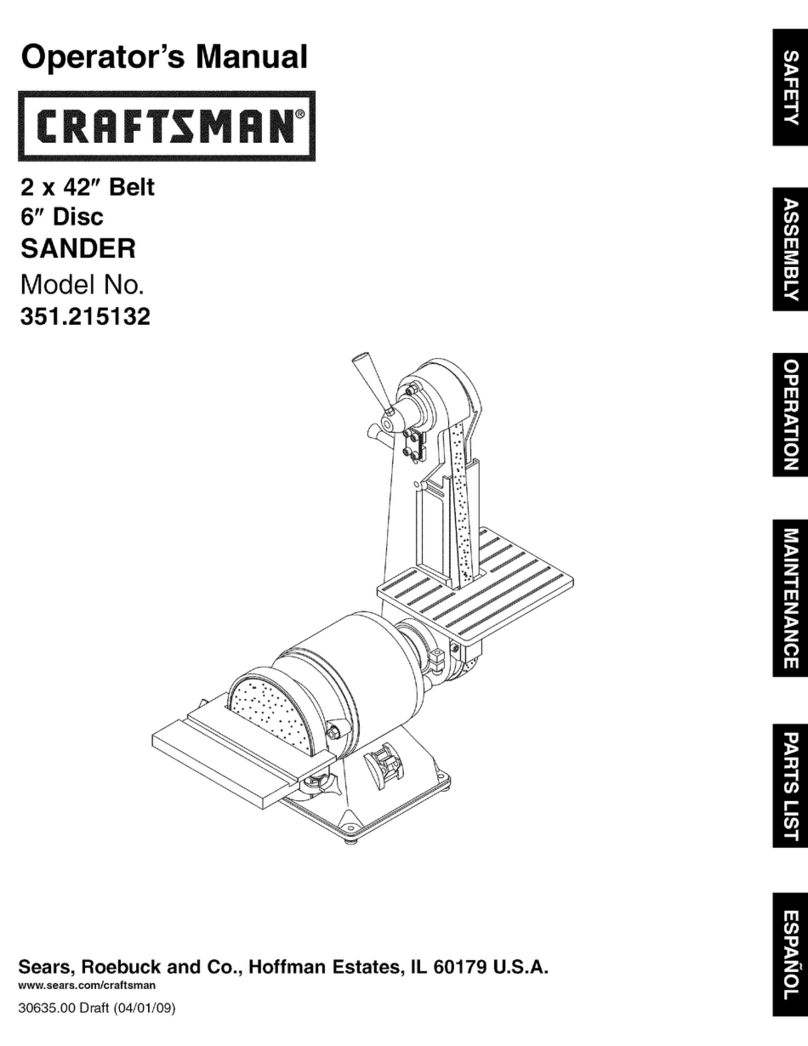

The sanding belt may be raised from horizontal to

vertical position after loosenittg the two belt table

pivot lock bolts, No. I 0. Always tighten these bolts

securely before operation in any position.

The belt adjustir,g knobs align the iCler pulley, No.

27 , to keep the sanding belt running true over. the

pulleys and centered on the belt table. These knobs

also control the tension of the sanding belt.

The table tilt lock knob locks the work table at any

desired degree of tilt from 0o to 45".

The belt table fence provides a backup for the

work piece when using the sanding belt.

T-t(e RPA wl z'i, faufrl oil.) :roaL

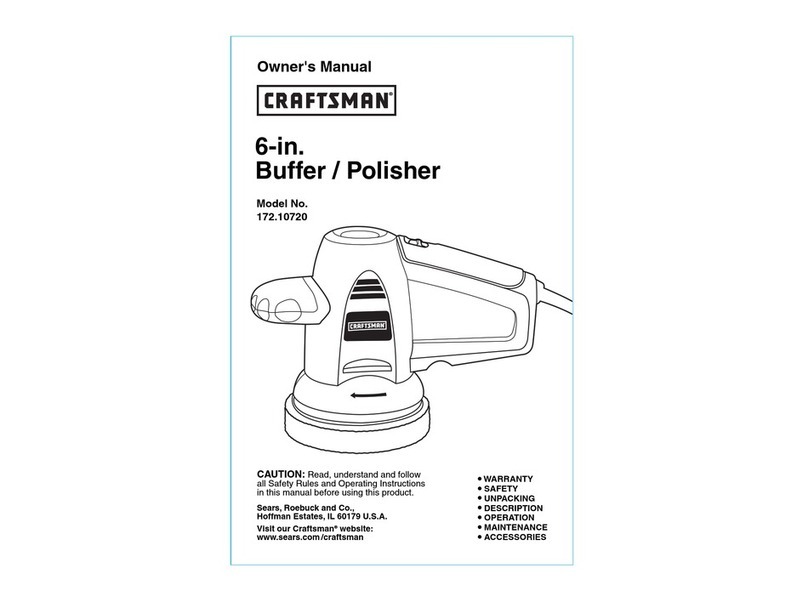

2. Apply belt tension by turning the two belt ad-

justing knobs clockwise. While applying ten-

sion keep the idler pulley approximately p?r-

allel with the drive pulley. When proper ten-

sion has been applied you should be able to

deflect the belt, as shown in Fig. 2, ErpproX-

imately Yz of an inch.

Align the sanding belt so that it will track on the

approximate centers of the two pulleys and remain in

one position on the pulleys, as follows:

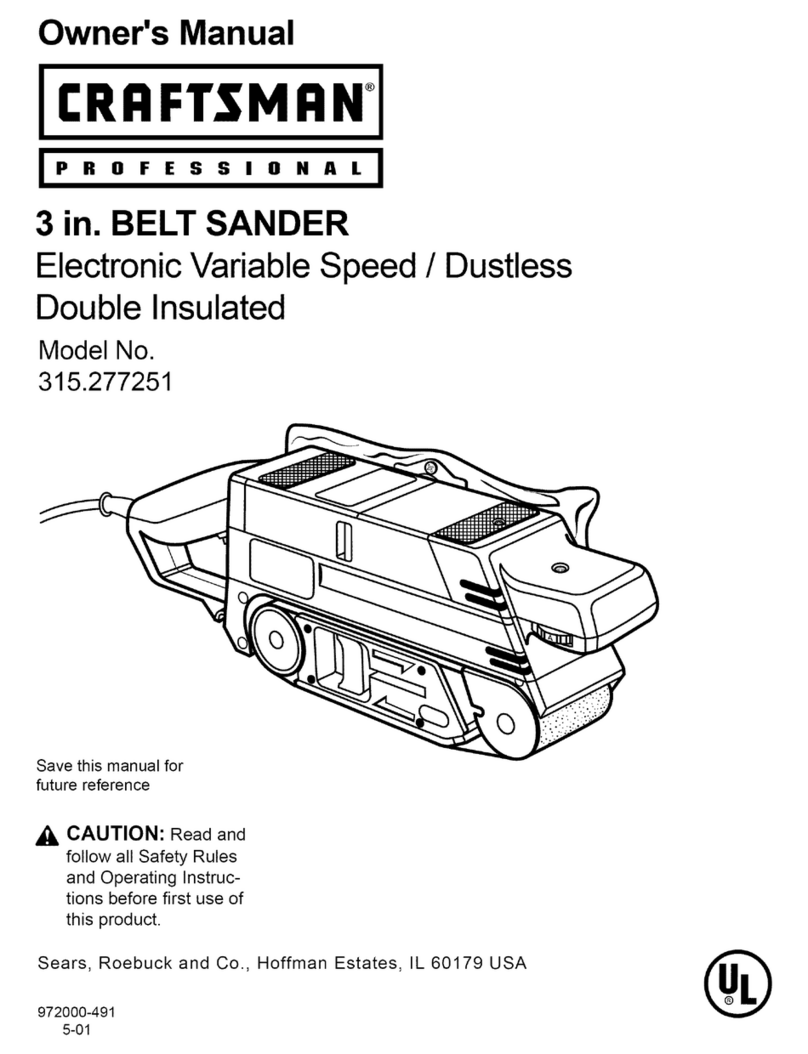

| . Rotate the belt bv hand in the correct direc-

tion, as shown in Fig. | .

2. If the belt tends to run off to the right, turn

the right hand knob clockwise. If the belt tends

to run off to the left, turn the left hand knob

clockwise.

3. Recheck the belt tension and adjust if fi€c€s-

sary by turning both knobs an equal amount.

4. The tool should now be ready to operate. If,

under power, the belt does not track propetly,

make very minor adjustment of the knobs

while the tool is in operation.

When installirg new sanding belts follow the

above steps. Be sure the arrow on the inside of the

belt points in the same direction as the rotation

arrow shown in Fig. l.

NOTE: Tighten all pulley set scre\ rs after a few

hours of operation.

The work table stop screws may require adjust-

ment to obtain the 90" and 45" settings. If adjust-

ment is necessary, it may be accomplished as f ollows:

| . Loosen the table tilt lock knob, No. 5 3, and

using a combination square set the work table

exactly square with the sanding ciisc. R e-

tighten knob.

2. Loosen hex nut, No. 50, and turn the square

head set scr€w, No. 5 | , until it contacts tlre rib

on the underside of the table. Re-tighten the

hex nut, while holding screw in this ptsition.

3. Repeat the above procedure f or the 45 " stop

screw, No. 59.

CAUTION: In placing the work table assemblv on

the tool, keep the edge of the table as close as pos-

sible to the sanding surface to eliminate the J.rr-

ger of thin work becomittg wedged between the

table and the sanding surface.

The socket head set screw, No. 5 5 , secures the

table support, No. 49, to the support rod, No. 52,

and also serves as the lock stud for the table tilt lock

knob. If adjustment of this stud is necessary loosen

the tilt knob and tighten securely with the Allen

wrench provided.

The sanding belt table when used in the vertical

position should be set square with the work table, as

follows:

l. After the work table has been installed for use

with the belt, loosen the two belt table pivot

Iock bolts, No. | 0.

2. Place a combination square on the work table

and pivot the belt table until the two tables are

90" to each other.

3. Re-tighten pivot lock bolts.

This procedure must be repeated each time the

position of the belt table has been changed.

* "i:;.* ;:' il"?T: ;:T ?:,'ff" n :::",|;ni ff^r:

FIGURE 2

ADJUSTMENTS

Tension the sanding belt before operatirg, as fol-

lows:

l. Face the end of the tool with rotation arrow,

see Fig. l, pointing away from you.