Cray CX1000 Operating instructions

Site Preparation Guide

The following copyright notice protects this book under Copyright laws which prohibit such actions

as,

but not

limited to, copying, distributing, modifying,

and

making derivative

works.

Trademarks and

Acknowledgements

W

e

acknowledge the right of proprietors of trademarks mentioned

in

this

manual.

All

brand names and software and hardware product names

are

subject to trademark and/or patent

protection.

Quoting of brand and product names is for information purposes only and does not represent trademark

misuse.

The information in this document is subject to

change

without notice. Craywill not be liable for errors

contained

herein, or for incidental or

consequential damages

in connection with the use of this

material.

T

able

of Contents

Legal Information

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Regulator

y

Declarations

and

Disclaimers

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Declaration

of

the Manufacturer

or

Importer

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Safety Compliance Statement

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

European Community

(EC)

Council Directives

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Electromagnetic Compatibility

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Low

Voltage .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

EC

Conformity

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Telecommunications Terminal Equipment

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Mechanical

Structures

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

FCC

Declaration

of

Conformity

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Canadian Compliance

Statement (Industry

Canada) .

. . . . . . . . . . . . . . . . . . . . . . . .

.

Laser Compliance Notice (if applicable)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Safety Information

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Definition

of

Safety

Notices .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Electrical

Safety .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Laser Safety Information (if applicable)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Data Integrity

and

Verification

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

W

aste

Management

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

viii

viii

viii

viii

viii

viii

viii

viii

viii

viii

ix

ix

ix

x

x

x

xi

xi

xi

Preface

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Intended Readers

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Highlighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

xii

xii

xii

Chapter

1.

Fitting out the Premises

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

1-1

1-2

1-3

1-3

1-4

1-4

1-5

1-5

1-5

1-6

1-7

1-7

1-7

1-8

1-8

1-8

1-9

1-9

1.1.

1.2.

1.3.

1.4.

1.5.

1.5.1.

General

Recommendations

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Delivery Conditions

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Carry-In Route

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Data Center

Layout .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Planning Installation

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Cabinet Cut-outs

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

1.5.1.1.

1.5.1.2.

1.5.1.3.

1.5.2.

1.5.2.1.

1.5.2.2.

Standard

1100

Cabinet Cut-outs

.

. . . . . . . . . . . . . . . . . . . . .

.

Standard

1200

Cabinet Cut-outs

.

. . . . . . . . . . . . . . . . . . . . .

.

W

ater

-Cooled

1200

Cabinet Cut-outs

.

. . . . . . . . . . . . . . . . .

.

Service

Clearance .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Standard Cabinet Service Clearance (Single

and

Dual)

.

.

.

.

.

W

ater

-Cooled

Cabinet Service Clearance (Single

and Dual)

1.6.

1.7.

1.7.1.

1.7.2.

1.7.3.

Electrical

/

Electromagnetic Interference

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Fire Protection

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Fire Detection

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Extinguishing

Procedure .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Extinguishing

Agent

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Contents

iii

1.7.4.

1.8.

1.9.

1.9.1.

1.9.2.

1.10.

1.11.

Alarms

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

1-9

1-10

1-10

1-10

1-10

1-12

1-12

1-12

1-12

1-13

1-13

1-13

W

ater

Damage .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Computer Room Floor

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Primary

Floor .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Raised

Floor .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Computer Room Ceiling

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Computer Room Environment

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

1.11.1.

1.11.2.

1.11.3.

Sound-Proofing

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Protection from Sunlight

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Cleaning

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

1.12.

1.13.

Media

Storage

Room .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Printing Room

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Chapter

2.

Air-Conditioning

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

2-1

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-4

2-5

2-5

2.1.

2.1.1.

2.1.2.

2.1.3.

2.2.

2.2.1.

2.2.2.

2.2.3.

2.2.4.

2.3.

Air-Conditioning System Features

and

Functions

.

. . . . . . . . . . . . . . . . . . . .

.

Temperature

Control .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Hygrometr

y Control .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Heat Dissipation

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Air-Conditioning System Specifications

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Air Renewal .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Air

Distribution

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Air

Circulation

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Air

Pollutants

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Checks

and

Alarms

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Chapter

3.

Power

Supply .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

3-1

3-2

3-3

3-3

3-3

3-4

3-6

3-6

3-7

3-8

3-9

3-9

3-9

3.1.

3.2.

3.2.1.

3.2.2.

3.3.

3.4.

3.4.1.

3.4.2.

3.5.

3.6.

3.6.1.

3.6.2.

Power Supply

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Cabling Requirements

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Power Cables

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Network Cables

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Power Supply

Cable

Sockets

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Grounding Circuit

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Electric Protection

Wire

Characteristics

.

. . . . . . . . . . . . . . . . . . . . . .

.

Grounding the Raised Floor

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Neutral Power

System .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Non-Computing Power

Supply .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Ambient Lighting

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Emergency Lighting

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Chapter

4.

Water

Supply

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

4-1

4-2

4-3

4-4

4-4

4.1.

4.2.

4.3.

4.4.

Chilled

W

ater

Requirements

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

W

ater

-Cooled

Cabinet Chilled

W

ater

Supply Requirements

.

. . . . . . . . . . .

.

Preparing the Cooling Unit for the Connection of

W

ater

-Cooled

Cabinets

Cooling Unit Fixtures for

W

ater

-Cooled

Cabinets .

. . . . . . . . . . . . . . . . . . .

.

iv

-

Site Preparation

Guide

Appendix

A.

Notices

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

A-1

A-2

A-3

A-5

A-6

A-8

A.1.

A.2.

A.3.

A.4.

A.5.

DANGER Notices .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

CAUTION Notices .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

WARNING

Notices .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

IMPOR

T

ANT

Notices .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

NOTES

Notices

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Index

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

x‐1

Contents

v

List

of

Figures

Figure

1.

Figure

2.

Figure

3.

Figure

4.

Figure

5.

Figure

6.

Figure

7.

Figure

8.

Figure

9.

Figure

10.

Figure

11.

Figure

12.

Figure

13.

Figure

14.

Figure

15.

Standard

1100

installation cable cut-out

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Standard

1200

installation cable cut-out

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

W

ater

-cooled

1200

cabinet cable

and

water supply cut-outs

.

. . . . . . . . . . . . . . . . . . . . .

.

Example of standard cabinet service clearance (single

and

dual)

.

. . . . . . . . . . . . . . . . . .

.

Example

of

water-cooled service clearance (single

and dual) .

. . . . . . . . . . . . . . . . . . . . .

.

Raised floor cross-section

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Raised floor structure

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Example

of

poor

air

distribution

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Example

of

obstacles that may obstruct

air

circulation

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Plug

and

socket

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

US

plug characteristics

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

PDU/UPS

Power socket

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Raised floor equipotentiality method

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Grounding circuit diagram for

a

TN-S neutral point connection

.

. . . . . . . . . . . . . . . . . . .

.

W

ater

-cooled

cabinet connection (example)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

1-5

1-5

1-6

1-7

1-7

1-11

1-11

2-4

2-4

3-4

3-4

3-5

3-7

3-8

4-4

vi

-

Site Preparation

Guide

List

of

Tables

Table

1.

Table

2.

Chilled water characteristics

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

W

ater

treatment recommendations

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

4-2

4-3

Contents

vii

Legal

Infor

mation

Regulatory Declarations and

Disclaimers

Declaration of the Manufacturer or

Importer

W

e

hereby certify that this product is in compliance

with:

•

European Union

EMC

Directive

2004/108/EC,

using standards

EN55022

(Class

A) and

EN55024

and Low Voltage Directive

2006/95/EC,

using standard

EN60950

•

International Directive

IEC 60297

and

US ANSI

Directive EIA-310-E

Safety Compliance Statement

•

•

•

UL

60950 (USA)

IEC 60950

(International)

CSA 60950 (Canada)

European Community (EC) Council

Directives

This product is in conformity with the protection requirements of the following

EC Council

Directives:

Electromagnetic Compatibility

•

2004/108/EC

Low

Voltage

•

2006/95/EC

EC

Conformity

•

93/68/EEC

Telecommunications

T

erminal

Equipment

•

1999/5/EC

Neither the provider nor the manufacturer can accept responsibility for

any

failure to satisfy

the protection requirements resulting from

a

non‐recommended modification of the

product.

Compliance with these directives

requires:

•

•

•

An EC

declaration of conformity from the manufacturer

An EC

label on the

product

Technical

documentation

Mechanical

Str

uctures

•

IEC 60297

•

EIA-310-E

viii

-

Site Preparation

Guide

FCC Declaration of

Conformity

This device complies with

Par

t

15

of the

FCC

Rules. Operation is subject to the following

two

conditions:

(1)

this device may not cause harmful interference, and

(2)

this device must

accept

any

interference received, including interference that may cause undesired

operation.

Federal Communications Commission (FCC)

Statement

This equipment has been tested and found to comply with the limits for

a

Class

A digital

device, pursuant to

Par

t

15

of the

FCC

Rules. These limits

are

designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance

with the instruction manual, may cause

har

mful

interference to radio communications. Operation of this equipment in

a

residential

area

is

likely

to cause harmful interference in which case the user will

be

required to correct the

interference

at

their own

expense.

Properly shielded and grounded cables and connectors must

be

used in order to meet

FCC

emission limits. Neither the provider nor the manufacturer

are

responsible for

any

radio

or

television interference caused

by

using other than recommended cables and connectors or

by

unauthorized changes or modifications to this equipment. Unauthorized changes

or

modifications could void the user's authority to operate the

equipment.

Pursuant to

Par

t

15.21

of the

FCC

Rules,

any

changes or modifications to this equipment not

expressly approved

by Cray, Inc

may cause harmful interference and void the

FCC

authorization to operate this

equipment.

An FCC

regulatory label is affixed to the

equipment.

Canadian Compliance Statement (Industry

Canada)

This Class

A

digital apparatus meets

all

requirements of the

Canadian

Interference

Causing

Equipment

Regulations.

Cet appareil numérique

de la

classe

A

est conforme

à la

norme NMB-003 du

Canada.

This product is in conformity with the protection requirements of the

following standards:

•

ICES-003

•

NMB-003

Laser Compliance Notice (if

applicable)

This product that uses laser technology complies with Class

1

laser requirements.

A CLASS 1

LASER PRODUCT label is affixed to the laser

device.

Legal

Infor

mation

ix

Class 1 Laser

Product

Luokan 1 Laserlaite

Klasse 1 Laser

Apparat

Laser Klasse

1

Safety

Information

Definition of Safety Notices

DANGER

A Danger

notice indicates the presence of

a

hazard that has the potential of causing death

or

serious personal

injury.

CAUTION

A Caution

notice indicates the presence of

a

hazard that has the potential of causing moderate

or minor personal

injury.

W

ARNING

A Warning

notice indicates

an

action that could cause damage to

a

program, device, system,

or

data.

Electrical

Safety

The following safety instructions shall

be

observed when connecting or disconnecting

devices

to the

system.

DANGER

The Customer is responsible for ensuring that the AC electricity supply is compliant

with

national and local recommendations, regulations, standards and codes of

practice.

An incorrectly wired and grounded electrical outlet may place hazardous voltage on

metal

parts of the system or the devices that attach to the system and result in

an

electrical shock.

It is mandatory to remove power cables from electrical outlets

before relocating the system.

CAUTION

This unit has more than one power supply cable. Follow procedures for removal of

power

from the system when

directed.

x

-

Site Preparation

Guide

Laser Safety Information (if

applicable)

The optical drive in this system unit is classified

as a

Class

1

level Laser product. The

optical

drive has

a

label that identifies its

classification.

The optical drive in this system unit is certified in the

U.S.

to conform to the requirements of the

Department of Health and Human Services

21

Code of Federal Regulations (DHHS

21 CFR)

Subchapter

J

for Class

1

laser products. Elsewhere, the drive is certified to conform to the

requirements of the International Electrotechnical Commission

(IEC)

60825-1:

2001 and

CENELEC EN

60825-1:

1994

for Class

1

laser

products.

CAUTION

Invisible laser radiation when open. Do not stare into beam or view directly with optical

instruments.

Class

1

Laser products

are

not considered to

be

hazardous. The optical drive

contains

internally

a

Class

3B

gallium-arsenide laser that is nominally

30

milliwatts

at 830

nanometers.

The design incorporates

a

combination of enclosures, electronics, and redundant

interlocks

such that there is no exposure to laser radiation above

a

Class

1

level during

normal

operation, user maintenance, or servicing

conditions.

Data Integrity and Verification

W

ARNING

Cray product

are

designed to reduce the risk of undetected data corruption or loss. However,

if

unplanned outages or system failures occur, users

are

strongly advised to check the

accuracy

of the

operations performed and the data saved or transmitted

by

the system

at

the time

of

outage or

failure.

Waste

Management

This product has been built to comply with the Restriction of

Certain Hazardous Substances

(RoHS) Directive

2002/95/EC.

This product has been built to comply with the

W

aste

Electrical and Electronic

(WEEE)

Directive

2002/96/EC.

Legal

Infor

mation

xi

Preface

Intended

Readers

This

Site Preparation Guide

explains how to prepare

a

Data Processing Center for Cray

equipments, in compliance with the standards in force. It is to

be

used

by all

personnel

and

trade representatives involved in the site preparation

process.

Highlighting

The following highlighting conventions

are

used in this

guide:

Bold

Identifies the

following:

•

Interface objects such

as

menu names, labels, buttons

and

icons.

File, directory and path

names.

Keywords

to which particular attention must

be paid.

•

•

Italics

Identifies references such

as

manuals or URLs.

monospace

Identifies portions of program codes, command lines, or messages

displayed in command

windows.

<

>

Identifies parameters to

be

supplied

by

the

user

.

xii

-

Site Preparation

Guide

Chapter

1.

Fitting out the Premises

This chapter explains how to plan

and

fit out your premises to receive your equipment. It

includes the following

topics:

•

•

•

•

•

•

•

•

•

•

•

•

•

General Recommendations,

on page

1-2

Delivery Conditions, on

page

1-3

Carry-In Route, on

page

1-3

Data Center Layout, on

page

1-4

Planning Installation, on

page

1-4

Electrical

/

Electromagnetic Interference, on

page

1-8

Fire Protection, on

page

1-8

W

ater

Damage, on

page

1-10

Computer Room Floor, on

page

1-10

Computer Room Ceiling, on

page

1-12

Computer Room Environment, on

page

1-12

Media

Storage Room, on

page

1-13

Printing Room, on

page

1-13

Chapter

1.

Fitting out the Premises

1-1

1.1.

General Recommendations

mpor

t

a

nt

It is

mandatory

to comply with the

procedures,

design

requirements

and

recommendations

set out in this guide. All

the standards referred to

in

this

guide

are

applicable

in

France. Equivalent standards must

be

applied

and

complied with

in

other

countries.

The construction

of

the Data Processing Center

and

the installation

of

ancillary facilities must

meet the level of safety required

by

the standards

and

laws

in

force

in

the country where the

equipment is to

be

installed

and

the Customer's requirements

in

terms

of

continuity

of

ser

vice.

Site preparation must take

all

the following aspects into account:

•

•

•

•

•

•

•

•

•

•

•

safety

of personnel,

primary

/

raised

floor

,

suspended

ceiling,

sound-proofing,

protection from sunlight,

access

control,

fire

protection,

water protection,

air

-conditioning,

power

supply,

water

supply.

W

ARNING

The installation

of an

“on-line" Uninterruptible Power Supply (UPS) is strongly recommended

to ensure continuity of service and to protect the equipment

in

the event of

a

mains

failure.

Note

In the case of

a

water-cooled equipement installation, the customer is

responsible

for supplying the complete water installation, from the water supply station through

to the water pipe outlets

at

the base of the cabinets. The water installation must

comply with the standards

in force.

Site preparation

must

be

completed

by

the pre-arranged delivery date.

Any

delay due to

non-completion of the site

by

the pre-arranged date will

be

considered

as

the Customer's

responsibility.

The Customer shall bear the cost of the works to

be

carried out to attain stipulated safety

and

continuity

of

operation

requirements.

On

request, your Customer Service Representative

can

supply you with

a

list of the

services

available for your equipment. These services include

Data

Processing Center site assessment

and

conformity

inspections.

1-2

-

Site Preparation

Guide

1.2.

Deliver

y Conditions

The equipment is delivered

24

hours

in

advance of the scheduled installation date.

On

arrival, the equipment must

be

placed,

in

its packing,

in

the Computer Room so that it

reaches room temperature before powering up (optimum operating temperature =

22° C

+

3° C,

hygrometry =

50%

+

5%).

W

ARNING

To avoid incorrect handling, the equipment must

be

removed from its packing

by

authorized

Customer Service Engineers

only.

1.3.

Carr

y-In

Route

The route from the unloading

bay

to the Computer Room must

be

checked to ensure that the

equipment

can be

carried into the premises easily

and

that floors

can

suppor

t

temporary

overloads.

mportant

Access doors must be at least 2.10 meters high to allow

rack-mounted

equipment to be

transported vertically.

CAUTION

The equipment must

be

transported

as

indicated on packing

labels.

The equipment

may

be extremely heavy and require the use of

an elevator.

The Data Processing Site manager must allocate enough personnel to ensure safe handling

of

the

equipment.

Chapter

1.

Fitting out the Premises

1-3

1.4.

Data Center Layout

mpor

t

a

nt

Site layout must provide sufficient

clearance around

equipment for

easy

access, addition of extensions and protection from direct

sunlight.

Wall

and floor carpets must not to be used

in

the Data Processing Center

.

When

planning layout, the following criteria must

be

taken into

account:

•

•

•

•

•

•

resistance

of

primary

floors,

headroom (at least

2.50

meters

high),

easy access,

exposure

and

location

of

windows

and doors,

location

of

electrical

and

telephone

sockets,

location

of

pillars

and radiators.

CAUTION

It is mandatory for layout to take the safety of personnel into account. Access for stretchers

must

be

provided around equipment and

cabinets.

Note

It is recommended to make room for the removal of packing items

in

the Computer

Room

and

ancillary

premises.

1.5.

Planning

Installation

Installation must

be

planned so that

any

changes

and / or

extensions may

be

implemented

with minimum service disruption. It is recommended to plan installation

of

the

following

elements:

•

•

•

•

•

•

cabinets

and equipment,

cableways,

extension

cables,

power

and

telephone sockets,

storage

cabinets,

water supply

connection.

The requirements

are

different according to the type of the system which is going to

be

installed, particularly if it is

a

water cooled

equipment.

Note

In the case of

a

water--cooled equipment installation, you

are

advised to

separate

water supply aisles (cold aisles) from cable aisles (hot

aisles).

1-4

-

Site Preparation

Guide

1.5.1.

Cabinet Cut-outs

According to requirements,

a

cable

cut-out must

be

provided

at

the front and/or rear base

of

cabinets.

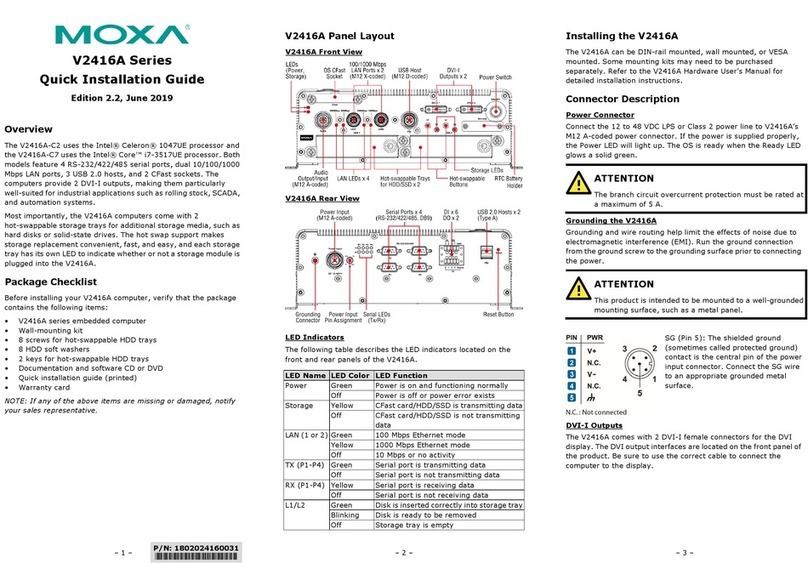

1.5.1.1.

Standard 1100 Cabinet Cut-outs

The standard

cut-out

for cables is shown

in

the following

figure:

15 cm

(6 in)

35 cm

(14 in)

<

>

Figure

1.

Standard

1100

installation cable cut-out

1.5.1.2.

Standard 1200 Cabinet Cut-outs

The standard

cut-out

for cables is shown

in

the following

figure:

Figure

2.

Standard

1200

installation cable cut-out

Chapter

1.

Fitting out the Premises

1-5

<

<

Cable cut−out

1.5.1.3.

W

ater

-Cooled

1200 Cabinet Cut-outs

When a

cooling unit is installed to supply water to water-cooled cabinets,

cut-outs must

be

made

in

the raised floor slabs to allow correct water circulation,

as

shown

in

the following

figure.

mpor

t

a

nt

The water-cooled cabinet must

be

aligned with slab sides.

Figure

3.

W

ater

-cooled

1200

cabinet cable

and

water supply cut-outs

1-6

-

Site Preparation

Guide

1.5.2.

Service

Clearance

According to cabinet model, it is mandatory to comply with the service

clearance

requirements indicated

in

the following

figures.

mpor

t

a

nt

•

When

a

cabinet is

equipped

with

a

Cool

Cabinet

Door, more

service

clearance

is required as shown

below.

Aisles must be at least 80 cm wide to allow

passageway

for

stretchers.

Fullaccess to equipment is

mandatory

for

maintenance operations.

Customers are

advised

to plan

ahead

and to provide

space

for

extenstions.

•

•

•

1.5.2.1.

Standard Cabinet Service Clearance (Single and Dual)

150 cm

100 cm

Figure

4.

Example of standard cabinet service clearance (single

and dual)

1.5.2.2.

W

ater

-Cooled

Cabinet Service Clearance (Single and

Dual)

(59 in)

cm

Rear

(59 in)

Figure

5.

Example

of

water-cooled service clearance (single

and dual)

Chapter

1.

Fitting out the Premises

1-7

150 cm

Front

in)

300 cm

(118,2 in)

100

(39.4

150 cm

150 cm

Front

(59 in)

300 cm

(118,2 in)

100 cm

(39.4 in)

150 cm

(59 in) Rear

Front

(59 in)

100 cm

(39.4 in)

100 cm

(39.4 in)

Rear

(39.4 in)

Front

150 cm

(59 in)

100 cm

(39.4 in)

100 cm

(39.4 in)

Rear

100 cm

(39.4 in)

1.6.

Electrical

/

Electromagnetic

Interference

Generators

of

electromagnetic interference may adversely affect equipment operation. The

following sources

of

electrical

and / or

electromagnetic interference must not

be

located

in

the immediate vicinity of the Data Processing

Center:

•

•

•

high-voltage

lines,

radars,

radios

or

other transmitters.

Equipment must not

be

subjected to electric

/

magnetic fields

in

excess

of:

•

electric field

(E): 3

V/m

,

•

magnetic field

(H): 30

A/m.

W

ARNING

The installation

of an

“on-line” Uninterruptible Power Supply (UPS) is strongly recommended

to ensure continuity of service and to protect equipment

in

the event of

a

mains

failure.

The

UPS may

be installed

in

the Computer Room

or in an

ancillary

room.

1.7.

Fire

Protection

For effective fire protection, the fire detection

and

extinction system must

be specially

designed for the Data Processing Center, which must

be

located

in a

fire

area

surrounded

by

fire-protection walls, partitions

and doors.

1.7.1.

Fire

Detection

The Customer must ensure that the following areas

are

monitored:

•

•

•

•

the raised floor

plenum,

the Computer Room

environment,

the suspended ceiling plenum

(where applicable),

adjacent

and

ancillary

rooms.

Commonly used fire detectors

are:

•

•

•

ionic,

optic,

thermovelokinetic.

The detection circuit must comprise

at

least two independent loops, each of which must

be

equipped with different

detectors.

1-8

-

Site Preparation

Guide

Other manuals for CX1000

1

Table of contents

Other Cray Desktop manuals