Cray T3E User manual

HMM-168-A.1 Cray Research/Silicon Graphics Proprietary 1

AC Repair and Adjustment Procedures

HMM-168-A.1

CRAY T3E™ Air-cooled Systems

Last Modified: January 1998

Record of Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety and ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Field-replaceable Units (FRUs), On-site Spares, and Tools . . . . . . . . . . . . . . . 5

Cabinet Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Doors and Panels

FRP 1: Opening and Removing the Cabinet Doors . . . . . . . . . . . . . . . . . . . . . . 13

FRP 2: Removing the Cabinet Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Module Power Supplies, Modules, Daughter Cards, and Rails

FRP 3: Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FRP 4: Auxiliary Clock Power Supply Replacement . . . . . . . . . . . . . . . . . . . . 29

FRP 5: Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

FRP 6: Daughter Card Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

FRP 7: Power Supply Rail Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

FRP 8: Top Module Rail Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

FRP 9: Bottom Module Rail Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Cables

FRP 10: Logic Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

FRP 11: GigaRing Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

FRP 12: Clock Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

FRP 13: Boundary Scan Cable/Wire Replacement . . . . . . . . . . . . . . . . . . . . . . 87

FRP 14: Module-to-WACS Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . 99

Warning and Control System (WACS) and Switches

FRP 15: WACS Microprocessor (EPROM) Replacement . . . . . . . . . . . . . . . . . 109

FRP 16: WACS Scanner Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 113

FRP 17: WACS Display Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

FRP 18: WACS Panel Switch (SW6, SW7, SW8) Replacement . . . . . . . . . . . . 120

FRP 19: Blower Controller Bypass Switch (SW3) Replacement . . . . . . . . . . . 122

AC Repair and Adjustment Procedures

2 CrayResearch/SiliconGraphicsProprietary HMM-168-A.1

FRP 20: Cabinet Power Switch (SW2) Replacement . . . . . . . . . . . . . . . . . . . . 124

FRP 21: Clock Switch Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

FRP 22: Module Thermistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

FRP 23: Inlet Air Thermistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

FRP 24: Exhaust Air Thermistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 136

FRP 25: Thermostat Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Fuses and Circuit Breakers

FRP 26: WACS Scanner Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

FRP 27: Power Supply Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

FRP 28: Blower Control Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

FRP 29: Main Disconnect Circuit Breaker (CB1) Replacement . . . . . . . . . . . . 152

FRP 30: WACS Panel Circuit Breaker (CB8, CB9, or CB10) Replacement . . . 156

FRP 31: Power Supply Circuit Breaker (CB2 through CB7) Replacement . . . 160

Power Box Components

FRP 32: Voltage Selector Switch (SW1) Replacement . . . . . . . . . . . . . . . . . . . 164

FRP 33: Time-delay Relay Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

FRP 34: Line Filter (FL1) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

FRP 35: Contactor (CT1) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

FRP 36: Resistor (R1) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Cooling Components

FRP 37: Air Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

FRP 38: Blower Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

FRP 39: Blower Controller (SCR1) Replacement . . . . . . . . . . . . . . . . . . . . . . . 187

FRP 40: Transformer (T1) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

FRP 41: Run Capacitor (C1) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Preventive Maintenance and Adjustment Procedures . . . . . . . . . . . . . . . . . . . . 197

Cleaning the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Cleaning the EMI Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Adjusting the Module Power Supply Output Voltage . . . . . . . . . . . . . . . . . 197

AC Repair and Adjustment Procedures Record of Revision

HMM-168-A.1 Cray Research/Silicon Graphics Proprietary 3

Record of Revision

September 1996

Original printing.

January 1998

Revision A. Added information on module pin protectors. Added steps for

packing a module in a shipping container to the module replacement procedure.

Made minor technical corrections elsewhere.

March 1998

Revision A.1. Updated the power supply removal procedure with information

about the appropriate tools to use in order to avoid stripping hex bolts.

Introduction AC Repair and Adjustment Procedures

4 CrayResearch/SiliconGraphicsProprietary HMM-168-A.1

Introduction

This document guides you in removing and replacing the field replaceable units

(FRUs) of the CRAY T3E air-cooled (AC) cabinet. This document includes a

list of FRUs, on-site spares, and tools for the CRAY T3E AC cabinet. It also

includes procedures for parts that need periodic maintenance.

This document does not contain power-on and power-off procedures. Refer to

the AC Power, Control, and Electromechanical Troubleshooting document,

Cray Research publication HMM-169-0, for power-on and power-off

procedures.

NOTE: Service personnel who are not Cray Research employees should

perform only procedures that are specified in their maintenance

agreements.

The following general instructions apply to all procedures in this document:

•Review the entire procedure before you perform any steps.

•Remember that the tools list for a given procedure does not include the

hex wrench required to open cabinet doors or the tools required to

complete additional tasks that are documented under a different

procedure.

•Label, or otherwise record the locations of, every wire or cable that you

disconnect during a procedure.

•Inspect all replacement parts for evidence of physical damage when you

receive them.

Safety and ESD Precautions

ObservesafetyandESDprecautionsduringallreplacementprocesses.Required

apparel includes an ESD smock, ESD wrist strap, and ESD shoes or shoe straps.

For further information on safety and ESD, read the Safety and ESD Guidelines,

Cray Research publication HGM-016-A.

Most CRAY T3E AC repair procedures require that you unplug the cabinet and

install, lock, and tag the plug with an electrical plug lockout device

(P/N 15255100).

AC Repair and Adjustment Procedures Field-replaceable Units (FRUs), On-site Spares, and Tools

HMM-168-A.1 Cray Research/Silicon Graphics Proprietary 5

Field-replaceable Units (FRUs), On-site Spares, and Tools

Table 1 lists the field-replaceable units (FRUs) for the CRAY T3E air-cooled

(AC) cabinet at the time of publication.

Table 1. Mainframe FRUs

Part Number Description Cabinet

Quantity Return for

Repair

Power Supplies

13264101 Power Supply, 3.3V with Thermal Pad 1/Module Yes

57170001 Cordset, IEC320 20A 250V W/Ferrite 1/Module No

57252400 Rail Assy, Power Supply Bottom 1/Supply Yes

57252500 Rail Assy, Power Supply Top 1/Supply Yes

15258000 Power Supply, Dual Output (auxiliary clock supply) 1/Clock Yes

Modules and Daughter Boards

Variable

(refer to

FN 2290)

Module Assy, Air-Cooled PEM Variable Yes

Variable

(refer to

FN 2290)

Module Assy, Clock Variable Yes

15107601 Daughter Board Assy, 1/2 pop 16Meg 70 NS (32MB) Variable Yes

15158500 Daughter Board Assy, 1/2 pop 16Meg 60 NS (32MB) Variable Yes

15104601 Daughter Board Assy, Single Hi 16Meg 70 NS (64MB) Variable Yes

15158100 Daughter Board Assy, Single Hi 16Meg 60 NS (64MB) Variable Yes

15104001 Daughter Board Assy, 2Hi Stack 16Meg 70 NS (128MB) Variable Yes

15158300 Daughter Board Assy, 2Hi Stack 16Meg 60 NS (128MB) Variable Yes

15148500 Daughter Board Assy, 1/2 pop 64Meg 60 NS (128MB) Variable Yes

15148700 Daughter Board Assy, Single Hi 64Meg 60 NS (256MB) Variable Yes

15108200 Daughter Board Assy, 2Hi Stack 64Meg 60 NS (512MB) Variable Yes

15108400 Daughter Board Assy, 4Hi Stack 64Meg 60 NS (1GB) Variable Yes

57163500 Handle, Module 1/Module No

57251800 Rail Assy, Clock Module-Top 1/Clock Yes

57251900 Rail Assy, Clock Module-Bottom 1/Clock Yes

57255300 Rail Assy, PEM Top 1/Module Yes

57255000 Rail Assy, PEM Bottom 1/Module Yes

Cables and Wires

15112904 Cable Assy, Ribbon (X dimension) 4/Module No

15112905 Cable Assy, Ribbon (Z dimension) 8/Module No

15112906 Cable Assy, Ribbon (Y dimension) 4/Module No

Field-replaceable Units (FRUs), On-site Spares, and Tools AC Repair and Adjustment Procedures

6 CrayResearch/SiliconGraphicsProprietary HMM-168-A.1

Cables and Wires (continued)

15200500 Cable Assy, GigaRing to Bulkhead 4/Module No

15214200 Cable Assy, PEM to WACS 1/Module No

15214300 Cable Assy, PEM to Scan 1/Module No

15223701 Wire Assy, Clock (system clock) 2/Module No

15223802 Cable Assy, Scan Jumper 120-in. 1 No

15224008 Wire Assy, 34 AWG 100 Ohm 120-in. (GigaRing Clock) 1/Module No

15224009 Wire Assy, 34 AWG 100 Ohm 144-in. 1 No

15237601 Cable Assy, 2 POS Skt to Pigtail (boundary scan) 2 No

15237701 Wire Assy, 4 POS Pin to Pigtail (boundary scan) 1/Module No

15237801 Cable Assy, 2 POS Pin to Pigtail (boundary scan) 2 No

15244601 Wire Assy, Clock Shielded w/ Drain (master clock) 1/Module No

57244600 Cable Assy, AUI 12 Foot 1 No

57251100 Couple, In-line 8 wire RJ45 5 No

57263800 Cable Assy, clock to WACS T3E-AC 1 No

WACS Components

15135901 IC, Micro T3E Air WACS 1 Yes

15130000 Thermistor Assy, Module Temperature 4 No

31445000 Module Assy, Disk IOSF Display 1 Yes

31504104 Module Assy, IOSF/T3E Air WACS (scanner) 2 Yes

57199600 Thermistor Assy, Air Flow 4 No

57199700 Thermostat, 65 Degree C 2 No

Switches

57185700 Switch, 600V 40A 5 Stage (Voltage Selector) 1 No

57186400 Switch, PB Gold Contacts (Restart) 1 No

57186500 Switch, Rocker Green LED (Remote Enable) 1 No

57186700 Switch, Rocker Green LED (PS Margin) 1 No

57199100 Switch, Rocker (Cabinet Power / Emergency) 1 No

57199101 Switch, Rocker Silver Contacts (Blower Bypass) 1 No

57253600 PC Board Assy, T3E Switch (Clock Switches) 1 No

Fuses

01134006 Fuse, 250V 1/2 Amp (0.5-A WACS scanner fuse) 2 No

01158809 Fuse, Ceramic 250V 15 Amp (power supply fuse) 2/PS No

57084701 Fuse, 250V 2/10 Amp (0.2-A blower control fuse) 2 No

Table 1. Mainframe FRUs (continued)

Part Number Description Cabinet

Quantity Return for

Repair

AC Repair and Adjustment Procedures Field-replaceable Units (FRUs), On-site Spares, and Tools

HMM-168-A.1 Cray Research/Silicon Graphics Proprietary 7

Circuit Breakers

57168600 Circuit Breaker Assy, 40A 480V (CB1) 1 No

57176100 Circuit Breaker, 20 Amp 480V (power supply) 6 No

57176101 Circuit Breaker, 10 Amp (blower) 1 No

57176102 Circuit Breaker, 3 Amp (WACS and auxiliary) 2 No

Power Box Components

55091902 Relay, Time Delay 1 No

57168800 Filter, Power 45 Amp 1 No

57186100 Contactor, 4 Pole 65 Amp 600V 1 No

57185400 Resistor, 50W 330 Ohm 1 No

57185700 Switch, 600V 40A 5 Stage (Voltage Selector) 1 No

57186100 Contactor, 4 Pole 65 Amp 600V 1 No

57170001 Cordset, IEC320 20A 480V 1 No

Blower, Blower Speed Control Components, and Air Filter

57067701 Controller, Power SCR 20A W/ XFMER (transformer) 1 No

57081901 Capacitor, Run 20MFD 1 No

57178900 Blower Assy, 18 Inch 1 Yes

57188100 Filter, Air Intake 1 No

Table 1. Mainframe FRUs (continued)

Part Number Description Cabinet

Quantity Return for

Repair

Field-replaceable Units (FRUs), On-site Spares, and Tools AC Repair and Adjustment Procedures

8 CrayResearch/SiliconGraphicsProprietary HMM-168-A.1

Table 2 lists on-site spares for the CRAY T3E AC cabinet.

Table 2. On-site Spares (57247700)

Part Number Description

01134006 Fuse, Glass 1/2 Amp (WACS scanner)

01158809 Fuse, Ceramic 250V 15 Amp (power supply)

01158900 Fuse, Glass 250V 1/16A

01158907 Fuse, Glass 250V 1A

01577002 Screw, Cap SCH BTNHD 6-32

01675100 Nut, Retainer 10-32

01775900 Lock, Pin Connector

12755600 Spacer, Connector

13033501 Screw, SCH Conn Mtg

13158903 Screw, Mach PNH PHH M3 8MM

13159002 Screw, Mach PNH PHH M4 6MM

13159003 Screw, Mach PNH PHH M4 8MM

13159004 Screw, Mach PNH PHH M4 10MM

13160602 Washer, Plain M3

13160603 Washer, Plain M4

13161502 Washer, Lock M3

13161503 Washer, Lock M4

13249901 IC, Micro PWR Subrack

13264101 Power Supply, T3E FRU

15130000 Thermistor Assembly, Module Temperature

15135901 IC, Micro T3E Air WACS

15215600 Spring, Rail

15223701 Wire Assy, Clock

15224008 Wire Assy, 34 AWG 100 Ohm 120”

15224009 Wire Assy, 34 AWG 144”

15237701 Wire Assy, 4 POS Pin to Pigtail

57084701 Fuse, 250V 2/10 Amp

(0.2-A blower control fuse)

57174200 Plug, Module Rail

57176200 Plug, Module Rail

57188100 Filter, Air

57199600 Thermistor Assembly, Air Flow

57199700 Thermostat, 65 Degree C

57253000 Screw, Mach PNH PHH Wshr M4 8MM

57264700 Filter Assy, Power Supply

AC Repair and Adjustment Procedures Field-replaceable Units (FRUs), On-site Spares, and Tools

HMM-168-A.1 Cray Research/Silicon Graphics Proprietary 9

Formore information on AC spares,refer to the CRAYT3E Spares Support Plan

athttp://www.csd.sgi.com/spo/T3E/t3espare.htm,whichcontainslistsofcountry

spares, parts bank spares, and central Logistics spares.

Table 3 lists the CRAY T3E AC tool kit at the time of publication.

Table 3. Tool Kit (57247800)

Part Number Description

01140800 Kit, Solderless Terminal

01263600 Multimeter, Digital

01523100 Cutter, Diagonal

01523700 Pliers, 6”

01524502 Wrench, Adjustable 12”

01524800 Wrench Set, Combination

01524900 Screwdriver Set, Phillips

01524901 Screwdriver Set, Flat Blade

01525001 Wrench Set, 1/4” Drive

01525400 Screwdriver Set, Torque

01529400 Holder, Hemostat Curved

01529401 Holder, Hemostat Straight

01529903 Battery, D Cell

01531200 Mirror, Inspection TLSCP

01531700 Tweezers, Micro

01532400 Magnet, Parts Pick-up

01563600 Screwdriver, PH Hard Tip

01596700 Probe Kit

12277700 Cable Assy, Test Lead Ohming

12804700 Connector, DB25 Loopback

12889800 Cam Tool, Shuttle Conn Actuator

13170700 Wire Stripper, Variable

13267200 Socket Set, Metric Hex Bit 2mm-6mm

13267300 Socket Set, Metric 1/4-in. Drive 4mm-12mm

13267400 Wrench Set, Metric 7 pc. 7mm-15mm

15252100 Pencil, Mechanical. 3mm

15252200 Dental Pick, Curved

15252400 Balldriver Set, Metric Hex 1.5-10mm

15255000 Extractor, PLCC 20-84 Pin

15255100 Lockout Device, Electric Plug

15255200 Tool Case, 7 1/2” Deep

Field-replaceable Units (FRUs), On-site Spares, and Tools AC Repair and Adjustment Procedures

10 CrayResearch/SiliconGraphicsProprietary HMM-168-A.1

NOTE: You can modify CRAY Y-MP carts for use with both CRAY Y-MP

and CRAY T3E modules by installing two rails, P/N 13267700.

15255800 Flashlight

15256900 Flashlight, NightHawk Microlight

35717400 Wrench Set, Balldriver Hex .050-5/32

51908400 Pliers, Needle Nose

90334800 Tape, Cleaner HD 4MM

ME107389 Tool Assy, Daughter Board Removal

Table 3. Tool Kit (57247800)

Part Number Description

AC Repair and Adjustment Procedures Cabinet Overview

HMM-168-A.1 Cray Research/Silicon Graphics Proprietary 11

Cabinet Overview

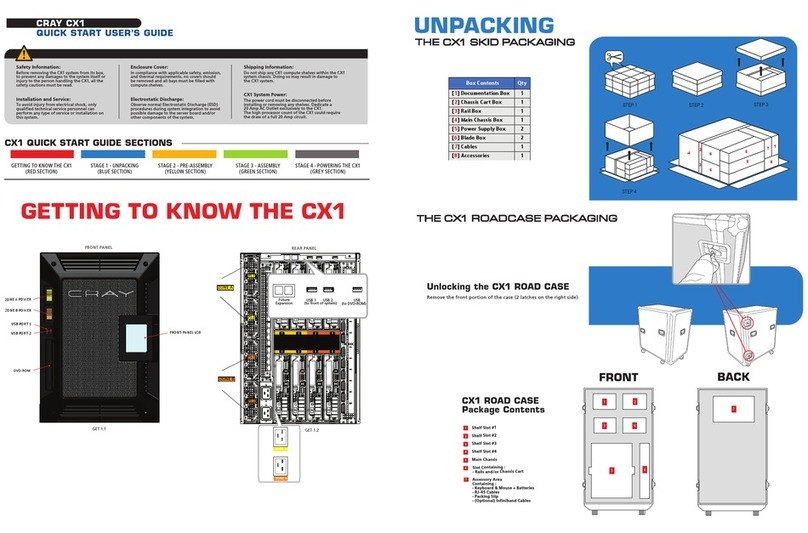

Figure 1 shows a front left view of the CRAY T3E AC cabinet without aesthetic

panels (i.e., trim or skins) or door. The figure shows access panels, wire ducts,

and various cabinet components.

Figure 1. Access Panels, Ducts, and Components (Front Left View)

Upper Logic

Panel

Logic Wire

Duct

Logic Wire

Duct with

Frame Joiner

Duct Attached

Lower Logic

Panel

Restart, Remote

Enable, and

Margin Switches

WACS

Panel

Power

Supply

Power

Supply

Breakers

Power Box Main

Disconnect

(CB1)

Blower (Fan)

Inlet

Thermistors

(on wire duct

cover)

Circuit

Breakers

WACS

Display

Cabinet Overview AC Repair and Adjustment Procedures

12 CrayResearch/SiliconGraphicsProprietary HMM-168-A.1

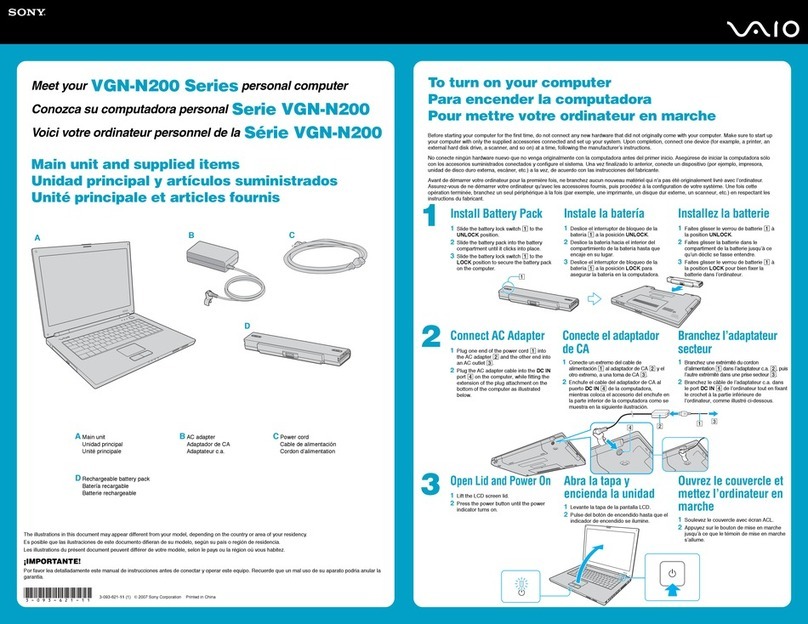

Figure 2 shows a rear left view of the cabinet without aesthetic panels or door.

The figure shows access panels that you must remove to replace modules or

cables and it shows wire duct covers that you must remove in order to add

cabinets or remove aesthetic panels. The figure also shows the locations of the

wrist-strap plugs, which are near the modules.

Figure 2. Access Panels (Rear Left View)

Lower Logic

Panel

Blower

Exhaust

Shield

Upper

Plenum

Panel

Lower

Plenum

Panel

Module

Panel

I/O Panel

Upper Rear

Wire Duct

Cover

Wrist-strap

Plugs

AC Repair and Adjustment Procedures FRP 1: Opening and Removing the Cabinet Doors

HMM-168-A Cray Research/Silicon Graphics Proprietary 13

FRP 1:Opening and Removing the Cabinet Doors

For all field replacement procedures (FRPs), you must open at least one of the

cabinet doors. In rare cases, you must also remove a door.

Tools Required

•Door opening tool (4-mm ball-end hex [allen] wrench)

•#2 Phillips screwdriver

Opening Procedure

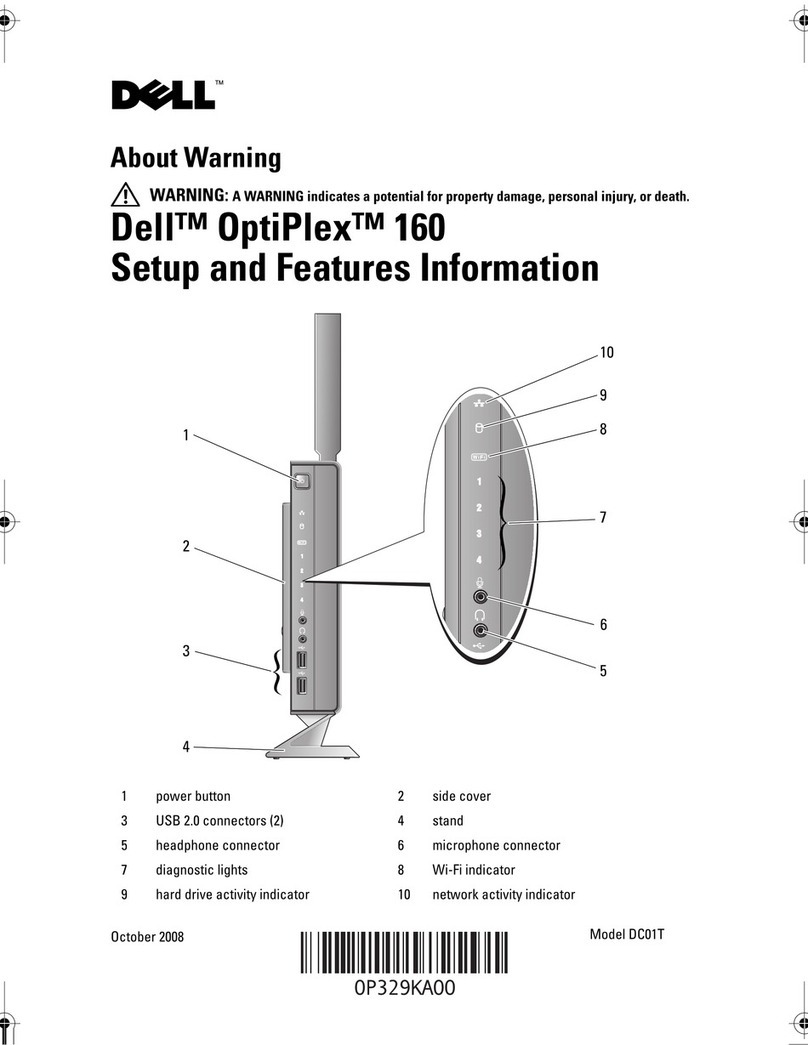

1. Each door contains two 1/4-turn latches: top and bottom. For each latch,

insert the hex wrench into the latch and turn the latch counterclockwise

1/4 turn. Refer to Figure 3.

2. Grasp the door and swing the door open.

Each door contains a hole that aids in door opening. You may insert a

tool, such as a #2 Phillips screwdriver, in the hole to improve your grip

and serve as a door handle.

•On the front door, the hole is on the top of a raised panel near the

middle/right side of the door, as shown in Figure 3.

•On the rear door, the hole is on the bottom of a raised panel near the

middle/right side of the door.

CAUTION

If you insert a tool in a door opening hole, ensure that the tool

does not touch and exert force on the fiberglass. Pressure

against the fiberglass will cause it to crack and chip.

FRP 1: Opening and Removing the Cabinet Doors AC Repair and Adjustment Procedures

14 CrayResearch/SiliconGraphicsProprietary HMM-168-A

Figure 3. Door Latches and “Handle” (Front Door)

Door Removal Procedure

1. Open the door.

2. Use a Phillips screwdriver to disconnect one end of the ground wire that

connects to the top of the door.

3. Disconnect the Cabinet Power switch connector (front door only). The

connection is near the top left corner of the front door.

Door Latch

(1/4-turn)

Door Latch

(1/4-turn)

Insert

Tool Here

and Pull

AC Repair and Adjustment Procedures FRP 1: Opening and Removing the Cabinet Doors

HMM-168-A Cray Research/Silicon Graphics Proprietary 15

NOTE: The Cabinet Power switch is normally open; therefore,

disconnecting it should not trip CB1.

4. Carefully lift the door straight up about 1 in. (2.54 cm) until the door

hardware clears the frame hinge, then remove the door.

5. Set the door in a protected location.

Door Replacement Procedure

1. Ensure that all washers are in place. (The washers are located on the

vertical studs of the chassis hinge assembly.)

2. Carefully position the door’s hinge hardware directly above the frame

hinge pins.

NOTE: You may need to flex the door slightly to align the hardware.

3. Carefully lower the door onto the frame hinge pins.

4. Ensure that the door opens and closes properly.

5. Connect the Cabinet Power switch connector (front door only) and the

ground wire, then close the door for normal operation.

WARNING

Thedoor isheavyand willcause injury

if it falls on someone.

CAUTION

The edges of the fiberglass door panel are fragile. Be careful

not to drop the door. When you set the door aside, ensure that

the weight is supported by portions of the fiberglass that can

bear the weight.

FRP 2: Removing the Cabinet Side Panel AC Repair and Adjustment Procedures

16 CrayResearch/SiliconGraphicsProprietary HMM-168-A

FRP 2:Removing the Cabinet Side Panel

For system upgrades and other procedures, you may need to remove at least one

side panel to gain access to the logic cables, etc. Four bolts hold each panel to

the frame – one bolt in each corner of the frame.

Tools Required

•Small flatblade screwdriver

•#2 (M4) Phillips screwdriver

•Socket wrench with 10-mm socket

Side Panel Removal Procedure

NOTE: This procedure requires two people.

1. Open the front cabinet door.

2. Open the cabinet’s main disconnect circuit breaker (CB1) and unplug the

cabinet. Place a lockout device over the cabinet’s plug and lock/tag it.

You may also open, lock, and tag the customer’s wall breaker(s).

3. Open the rear cabinet door.

4. Disconnect the cable from the clock switch board. Two flathead screws

secure the cable to the board.

5. Remove the blower exhaust shield. Six #2 (M4) Phillips screws secure the

shield to the cabinet.

WARNING

Ensure that the electrical plug for the

equipment that you service is

unplugged,locked,andtagged.Failure

to do so could result in severe shock

and burns.

AC Repair and Adjustment Procedures FRP 2: Removing the Cabinet Side Panel

HMM-168-A Cray Research/Silicon Graphics Proprietary 17

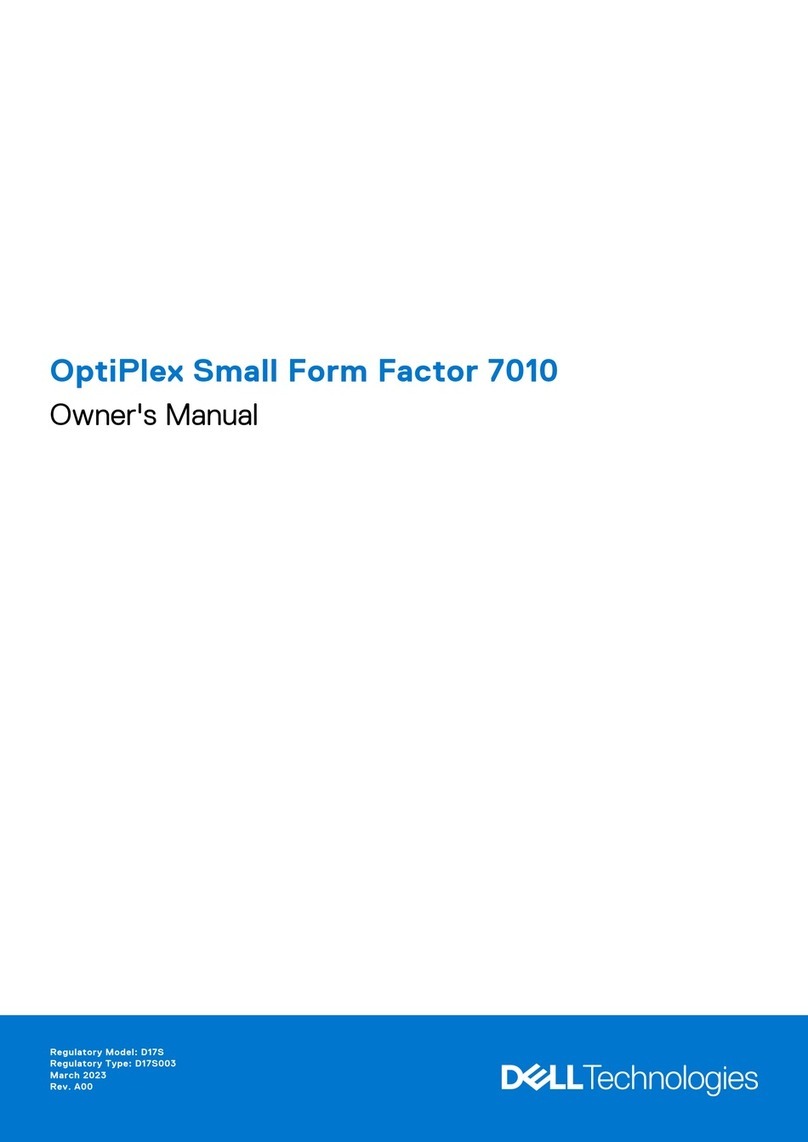

6. Remove the bottom wire-duct covers and the top rear wire-duct covers to

expose the retaining studs that hold the panel to the frame. Eight #2 (M4)

Phillips screws secure each panel. (Refer to Figure 4.)

NOTE: You may not be able to remove the bottom front wire-duct

covers unless you remove the power box cover or the input

power access plate. However, if you loosen the bottom center

screw on the wire-duct cover, you may be able to rotate the

wire-duct cover out of the way.

7. If you plan to remove the left panel, disconnect the connector for the

Cabinet Power switch (SW2). The connection is located near the top stud

(retaining bolt) on the power-supply end of the left panel.

Figure 4. Side Panel Bolt and Wire Duct Locations

8. Use a 10-mm socket to remove the nuts and washers from the bottom

retaining studs. (Be careful not to drop any nuts or washers into the wire

channels.)

Holes for Bottom

Retaining Bolts

Holes for Top

Retaining Bolts

Wire

Duct

Covers

FRP 2: Removing the Cabinet Side Panel AC Repair and Adjustment Procedures

18 CrayResearch/SiliconGraphicsProprietary HMM-168-A

9. While someone else holds the panel in place, remove the nuts and washers

from the top retaining studs. (Again, be careful not to drop any nuts or

washers.)

10. Remove the panel:

a. With a partner, carefully lift the panel slightly, then pull it straight out

from the side of the cabinet. Keep the panel in a vertical position.

b. Set the panel in a protected location.

WARNING

Remove the panel carefully; the side

panel may start tipping. The panel is

heavy and will cause injury if it falls on

someone.

AC Repair and Adjustment Procedures FRP 2: Removing the Cabinet Side Panel

HMM-168-A Cray Research/Silicon Graphics Proprietary 19

Figure 5. Removing Side Panels

Spacer

(Stand-off)

Spacer

(Stand-off)

Stud

FRP 2: Removing the Cabinet Side Panel AC Repair and Adjustment Procedures

20 CrayResearch/SiliconGraphicsProprietary HMM-168-A

Side Panel Replacement Procedure

1. Replace the panel on the frame:

a. With a partner, carefully position the retaining studs in line with the

corresponding holes in the frame.

Push the studs through the holes until the panel contacts the frame.

2. While your partner holds the panel in position, replace the washers and

nuts on the retaining studs. Secure the nuts.

3. Reconnect the Cabinet Power switch (SW2) if necessary.

4. Replace the wire duct panels.

5. Replace the blower exhaust shield and connect the clock switches.

6. Return the cabinet to operation, and close the front and rear cabinet doors.

WARNING

Replace the panel carefully; the side

panel may start tipping. The panel is

heavy and will cause injury if it falls on

someone.

Other manuals for T3E

2

Table of contents

Other Cray Desktop manuals