Cray XC30-LC Manual

XC30-LC and XC40-LC Repair Procedures

(2.0) H-8002 Rev A

Contents

1 About the XC30-LC and XC40-LC Repair Procedures...........................................................................................6

1.1 Safety Information.....................................................................................................................................7

1.2 XC30-LC and XC40-LC Spare Part Numbers.........................................................................................10

2 System Cabinet Procedures.................................................................................................................................20

2.1 Power Down a System Cabinet...............................................................................................................20

2.2 Power Up a System Cabinet...................................................................................................................20

2.3 Power Supply Replacement....................................................................................................................21

2.3.1 Remove a Power Supply............................................................................................................21

2.3.2 Install a Power Supply................................................................................................................22

2.4 Operator Interface Replacement.............................................................................................................23

2.4.1 Remove an Operator Interface...................................................................................................23

2.4.2 Install an Operator Interface.......................................................................................................25

2.5 Environmental Distribution Board Replacement......................................................................................26

2.5.1 Remove an Environmental Distribution Board...........................................................................26

2.5.2 Install an Environmental Distribution Board...............................................................................27

2.6 Liquid Sensor Replacement....................................................................................................................29

2.6.1 Remove a Liquid Sensor............................................................................................................29

2.6.2 Install a Liquid Sensor................................................................................................................30

2.7 Chassis Backplane Replacement............................................................................................................31

2.7.1 Remove a Chassis Backplane...................................................................................................31

2.7.2 Install a Chassis Backplane.......................................................................................................36

2.8 Power Distribution Unit (PDU) Replacement...........................................................................................41

2.8.1 Remove a Power Distribution Unit (PDU)..................................................................................41

2.8.2 Install a Power Distribution Unit (PDU)......................................................................................43

2.9 Power Supply Rack Replacement...........................................................................................................45

2.9.1 Remove a Power Supply Rack...................................................................................................45

2.9.2 Install a Power Supply Rack.......................................................................................................48

2.10 Cabinet Controller Replacement...........................................................................................................52

2.10.1 Remove a Cabinet Controller...................................................................................................52

2.10.2 Install a Cabinet Controller.......................................................................................................53

2.11 Cabinet Controller Backplane Replacement..........................................................................................54

2.11.1 Remove a Cabinet Controller Backplane.................................................................................54

2.11.2 Install a Cabinet Controller Backplane.....................................................................................56

2.12 Cabinet Controller DIMM Replacement.................................................................................................58

2.12.1 Remove a Cabinet Controller DIMM........................................................................................58

Contents

2

2.12.2 Install a Cabinet Controller DIMM............................................................................................59

2.13 Chassis Host Replacement...................................................................................................................61

2.13.1 Remove a Chassis Host...........................................................................................................61

2.13.2 Install a Chassis Host...............................................................................................................62

2.14 Optical Network Cable Replacement.....................................................................................................64

2.14.1 Remove an Optical Network Cable (AOC)...............................................................................64

2.14.2 Install an Optical Network Cable (AOC)...................................................................................65

2.15 Copper Network Cable Replacement....................................................................................................66

2.15.1 Remove a Copper Network Cable............................................................................................66

2.15.2 Install a Copper Network Cable................................................................................................67

2.16 Temperature and Humidity Sensor Replacement..................................................................................68

2.16.1 Remove a Temperature and Humidity Sensor.........................................................................68

2.16.2 Install a Temperature and Humidity Sensor.............................................................................70

2.17 Coil Control Board Replacement...........................................................................................................71

2.17.1 Remove a Coil Control Board...................................................................................................71

2.17.2 Install a Coil Control Board.......................................................................................................73

2.18 Non-spring Returned Water Valve Actuator Replacement....................................................................75

2.18.1 Remove a Non-Spring Returned Water Valve Actuator...........................................................75

2.18.2 Install a Non-Spring Returned Water Valve Actuator...............................................................77

2.19 Spring Returned Water Valve Actuator Replacement............................................................................80

2.19.1 Remove a Spring Returned Water Valve Actuator...................................................................80

2.19.2 Install a Spring Returned Water Valve Actuator.......................................................................82

2.20 Redesigned Water Pressure Transducer Replacement........................................................................83

2.20.1 Remove a Redesigned Water Pressure Transducer................................................................84

2.20.2 Install a Redesigned Water Pressure Transducer....................................................................85

2.21 Original Water Pressure and Temperature Transducer Replacement...................................................86

2.21.1 Remove an Original Water Pressure and Temperature Tranducer..........................................86

2.21.2 Install an Original Water Pressure and Temperature Transducer.............................................87

2.22 Return or Supply Temperature Sensor Replacement............................................................................88

2.22.1 Remove a Return or Supply Temperature Sensor...................................................................88

2.22.2 Install a Return or Supply Temperature Sensor.......................................................................89

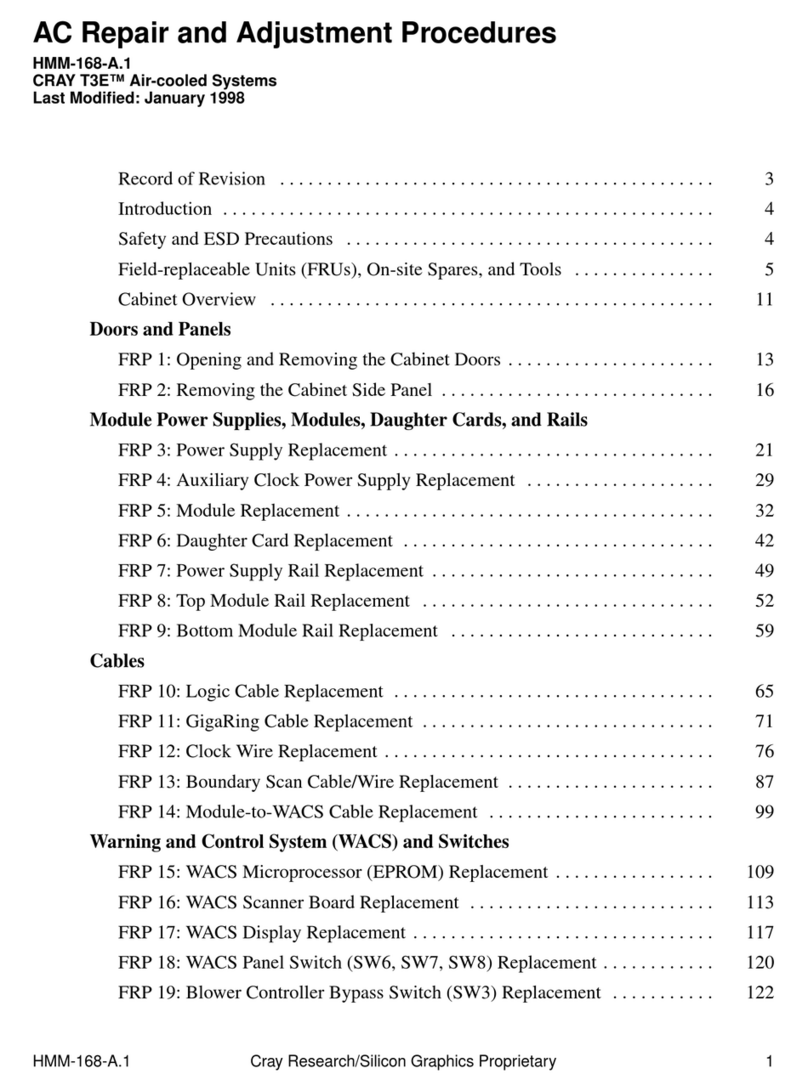

3 Blower Cabinet Procedures..................................................................................................................................92

3.1 Blower Assembly Replacement...............................................................................................................92

3.1.1 Remove a Blower Assembly......................................................................................................92

3.1.2 Install a Blower Assembly..........................................................................................................93

3.2 Blower Control Assembly Replacement..................................................................................................94

3.2.1 Remove a Blower Control Assembly..........................................................................................94

3.2.2 Install a Blower Control Assembly..............................................................................................95

Contents

3

3.3 Blower PDU Replacement.......................................................................................................................97

3.3.1 Remove a Blower Power Distribution Unit (PDU)......................................................................97

3.3.2 Install a Blower Power Distribution Unit (PDU)..........................................................................99

4 Preconditioner Cabinet Procedures....................................................................................................................103

4.1 Preconditioner Liquid Sensor Replacement..........................................................................................103

4.1.1 Remove a Preconditioner Liquid Sensor..................................................................................103

4.1.2 Install a Preconditioner Liquid Sensor......................................................................................104

4.2 Non-Spring Returned Preconditioner Water Valve Actuator Replacement............................................106

4.2.1 Remove a Non-Spring Returned Preconditioner Water Valve Actuator...................................106

4.2.2 Install a Non-Spring Returned Preconditioner Water Valve Actuator.......................................107

4.3 Spring Returned Preconditioner Water Valve Actuator Replacement...................................................109

4.3.1 Remove a Spring Returned Preconditioner Water Valve Actuator...........................................109

4.3.2 Install a Spring Returned Preconditioner Water Valve Actuator...............................................111

4.4 Original Preconditioner Water Pressure and Temperature Transducer Replacement...........................113

4.4.1 Remove an Original Preconditioner Water Pressure and Temperature Transducer................113

4.4.2 Install an Original Preconditioner Water Pressure and Temperature Transducer....................114

4.5 Redesigned Preconditioner Water Pressure Transducer Replacement................................................115

4.5.1 Remove a Redesigned Preconditioner Water Pressure Transducer........................................115

4.5.2 Install a Redesigned Preconditioner Water Pressure Transducer............................................116

4.6 Preconditioner Return or Supply Temperature Sensor Replacement....................................................118

4.6.1 Remove a Preconditioner Return or Supply Temperature Sensor...........................................118

4.6.2 Install a Preconditioner Return or Supply Temperature Sensor...............................................119

4.7 Preconditioner Air Temperature Sensor Replacement..........................................................................121

4.7.1 Remove a Preconditioner Air Temperature Sensor..................................................................121

4.7.2 Install a Preconditioner Air Temperature Sensor......................................................................122

4.8 Preconditioner Temperature and Humidity Sensor Replacement..........................................................122

4.8.1 Remove a Preconditioner Temperature and Humidity Sensor.................................................122

4.8.2 Install a Preconditioner Temperature and Humidity Sensor.....................................................124

4.9 Preconditioner Coil Control Board Replacement...................................................................................126

4.9.1 Remove a Preconditioner Coil Control Board..........................................................................126

4.9.2 Install a Preconditioner Coil Control Board..............................................................................127

5 Compute and IO Blade Procedures....................................................................................................................129

5.1 Remove a Blade Using xtwarmswap.....................................................................................................129

5.2 Install a Blade Using xtwarmswap.........................................................................................................131

5.3 Remove a Compute or IO Blade...........................................................................................................133

5.4 Install a Compute or IO Blade...............................................................................................................134

5.5 Blade Memory DIMM Replacement.......................................................................................................135

5.5.1 Remove a Blade Memory DIMM..............................................................................................135

Contents

4

5.5.2 Install a Blade Memory DIMM..................................................................................................136

5.6 Voltage Module (VRM, VIVOC, and HIVOC) Replacement...................................................................137

5.6.1 Remove a Voltage Module (VRM, VIVOC, and HIVOC)..........................................................137

5.6.2 Install a Voltage Module (VRM, VIVOC, and HIVOC)..............................................................138

5.7 Processor Replacement........................................................................................................................139

5.7.1 Remove a Processor................................................................................................................140

5.7.2 Install a Processor....................................................................................................................142

5.8 KPDC Processor Replacement.............................................................................................................146

5.8.1 Remove a Processor on an KPDC...........................................................................................146

5.8.2 Install a Processor on a KPDC.................................................................................................149

5.9 KPDC Replacement..............................................................................................................................153

5.9.1 Remove a KPDC......................................................................................................................153

5.9.2 Install a KPDC..........................................................................................................................154

5.10 QPDC Replacement............................................................................................................................156

5.10.1 Remove a QPDC....................................................................................................................157

5.10.2 Install a QPDC........................................................................................................................158

5.11 XPDC Replacement............................................................................................................................159

5.11.1 Remove a XPDC....................................................................................................................159

5.11.2 Install an XPDC......................................................................................................................160

5.12 SGDC Replacement............................................................................................................................161

5.12.1 Remove a SGDC....................................................................................................................161

5.12.2 Install a SGDC........................................................................................................................162

5.13 GPDC Replacement............................................................................................................................163

5.13.1 Remove a GPDC....................................................................................................................163

5.13.2 Install a GPDC........................................................................................................................164

5.14 HPDC Replacement............................................................................................................................165

5.14.1 Remove a HPDC....................................................................................................................165

5.14.2 Install a HPDC........................................................................................................................166

5.15 PCI Card Replacement........................................................................................................................167

5.15.1 Remove a PCI Card...............................................................................................................167

5.15.2 Install a PCI Card...................................................................................................................169

5.16 IO Base Board (IOBB) Component Replacement...............................................................................170

5.16.1 Remove Components from an IO Base Board (IOBB)...........................................................170

5.16.2 Install Components on an IO Base Board (IOBB)..................................................................170

6 System Maintenance Workstation (SMW)..........................................................................................................172

7 Boot RAID Cabinet.............................................................................................................................................173

Contents

5

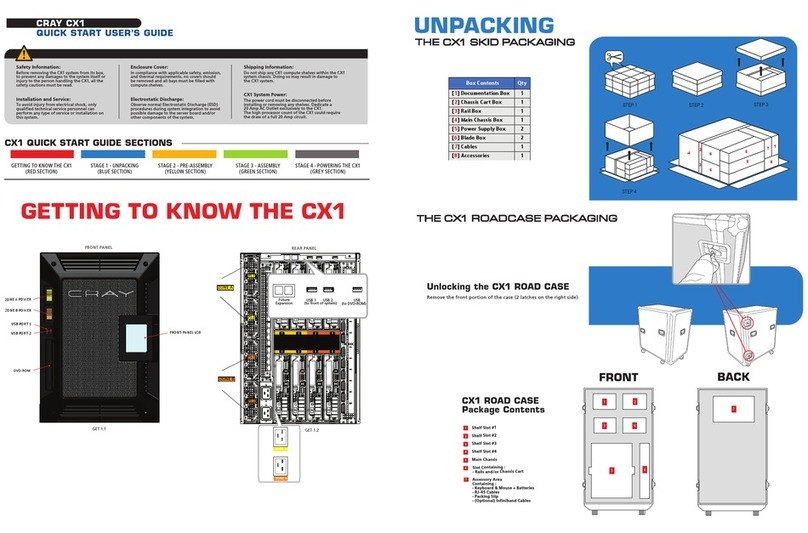

1About the XC30-LC and XC40-LC Repair Procedures

This publication describes how to remove and replace the field replaceable units (FRUs) in Cray® XC30-LC and

XC40-LC systems.

Release Information

Table 1. Record of Revision

Publication Title Publication Number Date

XC30-LC and XC40-LC Repair

Procedures

H-8002 December 2016

XC Series-LC Repair Procedures December 2015

Maintenance and Replacement

Procedures for Cray XC30 Systems

H80-8002-B January 2014

Maintenance and Replacement

Procedures for Cray XC30 Systems

H80-8002-A September 2013

Maintenance and Replacement

Procedures for Cray XC30 Systems

H80-8002 October 2012

Typographic Conventions

Monospace Indicates program code, reserved words, library functions, command-line prompts,

screen output, file/path names, key strokes (e.g., Enter and Alt-Ctrl-F), and

other software constructs.

Monospaced Bold Indicates commands that must be entered on a command line or in response to an

interactive prompt.

Oblique or Italics Indicates user-supplied values in commands or syntax definitions.

Proportional Bold Indicates a graphical user interface window or element.

\ (backslash) At the end of a command line, indicates the Linux® shell line continuation character

(lines joined by a backslash are parsed as a single line). Do not type anything after

the backslash or the continuation feature will not work correctly.

Scope and Audience

This publication is intended for Cray service personnel. Personnel must complete XC30-LC and XC40-LC

hardware training before performing these maintenance and replacement procedures.

About the XC30-LC and XC40-LC Repair Procedures

6

Torx Fasteners

The XC Series cabinet and blades contain both Torx and Torx+ fasteners. The drivers and bits in the tool kit are

Torx. Torx drivers and bits work with both Torx and Torx+ fasteners.

HSS Component Naming Conventions

This publication refers to the HSS ID of the target component as the hostname. The man pages for the various

commands refer to the target component as the hostname, physIDlist, id-list, or some other name; these

names all refer to the standard HSS ID for the target component. The procedures include an example of the HSS

ID for each command.

Feedback

Visit the Cray Publications Portal at http://pubs.cray.com and make comments online using the Contact Us button

in the upper-right corner or Email pubs@cray.com. Your comments are important to us and we will respond within

24 hours.

Trademarks

The following are trademarks of Cray Inc. and are registered in the United States and other countries: CRAY and

design, SONEXION, URIKA, and YARCDATA. The following are trademarks of Cray Inc.: APPRENTICE2,

CHAPEL, CLUSTER CONNECT, CRAYDOC, CRAYPAT, CRAYPORT, DATAWARP, ECOPHLEX, LIBSCI,

NODEKARE. The following system family marks, and associated model number marks, are trademarks of Cray

Inc.: CS, CX, XC, XE, XK, XMT, and XT. The registered trademark LINUX is used pursuant to a sublicense from

LMI, the exclusive licensee of Linus Torvalds, owner of the mark on a worldwide basis. Other trademarks used in

this document are the property of their respective owners.

1.1 Safety Information

Read and comply with the following safety information while servicing XC30-LC and XC40-LC systems.

DANGER:

● Electrocution Hazard

● Cray requires the power to be disconnected from the PDU when working on components inside the

PDU chassis. If it is necessary to work on components in the PDU with power applied, a minimum 36-

in working clearance must be maintained in front of the PDU. This workspace is required and must be

maintained around all electrical equipment where parts of an energized system may be serviced. To

maintain this clearance, remove the door from the cabinet facing the energized parts, and install an

insulating barrier to prevent any grounded equipment from coming in contact with the energized

components in the PDU. Failure to do so could result in serious injury or death.

WEEE Directive

The Waste Electrical and Electronic Equipment (WEEE) directive of the European Union (EU) is designed to

reduce waste management problems linked to heavy metals and flame retardants. It attempts to limit the amount

of electrical and electronic equipment that enters landfills by encouraging reuse, recycling, and separate

collection. Components that bear the crossed-out wheelie bin symbol require special disposal.

About the XC30-LC and XC40-LC Repair Procedures

7

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE), the

presence of the crossed-out wheelie bin symbol on a product or on its packaging indicates that you must not

dispose of that item in the normal unsorted municipal waste stream. Instead, it is your responsibility to dispose of

that product by returning it to a collection point that is designated for the recycling of electrical and electronic

equipment waste. Separate collection of this waste helps to optimize the recovery and recycling of any

reclaimable materials and reduces the impact on human health and the environment.

ESD Precautions

Observe electrostatic discharge (ESD) precautions during any maintenance or repair of Cray systems. Required

apparel includes an ESD smock, ESD shoes, and an ESD wrist strap. ESD and Safety Guidelines H-0016,

contains information about safety procedures and potential hazards. Read these guidelines before servicing any

Cray systems.

CAUTION:

● Equipment damage

● Observe all ESD precautions. Failure to do so can result in damage to the equipment.

ESD Smock

Wear a Cray approved static-dissipative smock while servicing or handling an ESD-sensitive device. Completely

button the smock and wear it as the outermost layer of clothing. A portion of the smock’s sleeves must be in direct

contact with the skin of the arms. Skin contact is essential for a dissipative path-to-earth ground. Tuck hair that

exceeds shoulder length inside the back of the smock.

ESD Shoes

Wear approved static-dissipative shoes or approved dissipative heel straps on both shoes while servicing or

handling an ESD-sensitive device. When sensitive equipment is exposed to static discharge, ESD shoes help

prevent an excessive charge from building up.

About the XC30-LC and XC40-LC Repair Procedures

8

Blade Handling

Each blade weighs approximately 29 lbs (13 kg). Blades can be removed or installed using a lift.

WARNING:

● Personal injury

● Use and proper lifting techniques when handling blades. Failure to do so could result in serious

personal injury.

CAUTION:

● Equipment damage

● Always observe the ESD and safety precautions described in the previous section when handling

blades. Failure to do so could result in equipment damage.

Safety Measures

Observe the following safety measures to remove, install, repair, or maintain the system.

● Do not wear watches or jewelry while working on a system cabinet.

● Keep fingers and conductive tools away from high-voltage areas and from high-current areas.

DANGER:

● Serious injury or death

● Keep fingers and conductive tools away from high-voltage areas. Serious injury or death will occur if

these precautions are not followed.

WARNING:

● Severe personal injury

● Ensure that the electrical circuit breakers for the equipment being serviced are off, locked, and

tagged. Failure to do so could result in severe shock and burns.

● Remove all tools from the system cabinets after performing service.

● Replace all covers and panels that were removed from the system during servicing.

● Some procedures require powering off the system; power off the system only after shutting down the system

software in an orderly manner.

CAUTION:

● Loss of data

● Do not power off the system before halting the operating system. Failure to do so could result in loss

of data.

Cray systems may reach noise levels where the use of hearing protection is required. The need for this protection

depends on such factors as the number of installed cabinets, the speed of the blowers, and the physical design

and the materials used in the computer room. The use of hearing protection is highly recommended for all

About the XC30-LC and XC40-LC Repair Procedures

9

personnel when working in computer rooms, even if noise exposure dosimetry results are below the USA OSHA

or other country's regulatory levels.

1.2 XC30-LC and XC40-LC Spare Part Numbers

Table 2. Tools

Part Number Description

80299500 Adjustable Torque Driver, 5-40 in-lbs.

100737101 Torque Wrench, 1/4" Drive 30-150 in-lbs.

80294700 Adaptor, 1/4in. hex male to 1/4in. square male

100784000 Balldriver Set, 11 Piece 5/64-3/8"

80263400 Dusting gas

100117500 Thermal grease

Table 3. XC Series-LC System Cabinet

Part Number Description Procedure

100790601 POWER SUPPLY, 52VDC 3KW

230-277VAC (RECTIFIER)

Install a Power Supply

100648000 INTERFACE MODULE,

OPERATOR

Install an Operator Interface on

page 25

100692802 ENVIRONMENTAL CONTROL

ASSY

Install an Environmental Distribution

Board on page 27

100673900 SENSOR ASSY, LIQUID SENSE

(INC. 100208502 WATER 4WIRE

5VDC SENSOR)

Install a Liquid Sensor on page 30

100931500 BACKPLANE ASSY AND

REPLACEMENT KIT

Install a Chassis Backplane on

page 36

100542901 PDU ASSY, COMPUTE CABINET Install a Power Distribution Unit

(PDU) on page 43

100826600 BUS BAR ASSY, POWER RACK

AND HORIZONTAL, 105KW

ELTEK/VALERE

Install a Power Supply Rack on

page 48

100697500 MODULE ASSY, CABINET

CONTROLLER CS

Install a Cabinet Controller

100727500 BACKPLANE ASSY, CABINET

CONTROLLER

Install a Cabinet Controller

Backplane

About the XC30-LC and XC40-LC Repair Procedures

10

Part Number Description Procedure

100189300 DIMM, 2GB PC-6400

(CONTROLLER DIMM)

Install a Cabinet Controller DIMM

100697801 MODULE ASSY, CHASSIS HOST Install a Chassis Host

100424807 CABLE ASSY, 12.5GBS OPTICAL

CXP 10.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424808 CABLE ASSY, 12.5GBS OPTICAL

CXP 12.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424809 CABLE ASSY, 12.5GBS OPTICAL

CXP 15.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424810 CABLE ASSY, 12.5GBS OPTICAL

CXP 17.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424811 CABLE ASSY, 12.5GBS OPTICAL

CXP 20.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424803 CABLE ASSY, 12.5GBS OPTICAL

CXP 25.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424813 CABLE ASSY, 12.5GBS OPTICAL

CXP 28.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424814 CABLE ASSY, 12.5GBS OPTICAL

CXP 30.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424815 CABLE ASSY, 12.5GBS OPTICAL

CXP 35.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424800 ABLE ASSY, 12.5GBS OPTICAL

CXP 4.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424816 CABLE ASSY, 12.5GBS OPTICAL

CXP 40.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424817 CABLE ASSY, 12.5GBS OPTICAL

CXP 45.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424801 CABLE ASSY, 12.5GBS OPTICAL

CXP 5.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424804 CABLE ASSY, 12.5GBS OPTICAL

CXP 50.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424805 CABLE ASSY, 12.5GBS OPTICAL

CXP 55.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100424802 ABLE ASSY, 12.5GBS OPTICAL

CXP 6.0M AOC

Install an Optical Network Cable

(AOC) on page 65

100659005 CABLE ASSY, NETWORK XCEDE

18PR 40"

Install a Copper Network Cable on

page 67

100659006 CABLE ASSY, NETWORK XCEDE

18PR 55"

Install a Copper Network Cable on

page 67

About the XC30-LC and XC40-LC Repair Procedures

11

Part Number Description Procedure

100659007 CABLE ASSY, NETWORK XCEDE

18PR 61"

Install a Copper Network Cable on

page 67

100659008 CABLE ASSY, NETWORK XCEDE

18PR 65"

Install a Copper Network Cable on

page 67

100659009 CABLE ASSY, NETWORK XCEDE

18PR 79"

Install a Copper Network Cable on

page 67

100856102 BLOWER FAN ASSY, 280MM EC

FOR BLOWER CAB

Install a Blower Assembly on page

93

100513700 SENSOR, HUMIDITY/TEMP Install a Temperature and Humidity

Sensor on page 70

100625803 PCA, CABINET BLOWER

CONTROL

Install a Blower Control Assembly

on page 95

100588003 PDU ASSY, BLOWER CABINET Install a Blower Power Distribution

Unit (PDU) on page 99

100692700 COIL CONTROL ASSY (ON

SYSTEMS SHIPPED PRIOR TO

01/2014)

Install a Coil Control Board on page

73

100692701 COIL CONTROL ASSY (SYSTEMS

SHIPPED AFTER 12/2013)

Install a Coil Control Board on page

73

Table 4. XC Series-LC System Cabinet Redesigned Components

Part Number Description Procedure

100681000 Actuator Assy, Control ARB24-SR Install a Non-Spring Returned

Water Valve Actuator on page 77

100681001 ACTUATOR ASSY, CONTROL

ARB24-SR W/PLUG SPRING RTN

Install a Spring Returned Water

Valve Actuator on page 82

100950500 TRANSDUCER, PRESSURE

100PSIG Install a Redesigned Water

Pressure Transducer on page

85

Remove an Original Water

Pressure and Temperature

Tranducer on page 86

100950600 CABLE ASSY, WATER CONTROL

PCA TO PRESSURE SENSOR Install a Redesigned Water

Pressure Transducer on page

85

Remove an Original Water

Pressure and Temperature

Tranducer on page 86

About the XC30-LC and XC40-LC Repair Procedures

12

Part Number Description Procedure

100797100 TRANSDUCER, PRESSURE/

TEMPERATURE 100PSIG Remove a Redesigned Water

Pressure Transducer on page

84

Install an Original Water

Pressure and Temperature

Transducer on page 87

100950700 CABLE ASSY, WATER CONTROL

PCA TO TEMP RTD

Install a Return or Supply

Temperature Sensor on page 89

Table 5. XC Series-LC Prconditioner

Part Number Description Procedure

100673900 SENSOR ASSY, LIQUID SENSE

(INC. 100208502 WATER 4WIRE

5VDC SENSOR)

Install a Liquid Sensor on page 30

100681001 ACTUATOR ASSY, CONTROL

ARB24-SR W/PLUG SPRING RTN

Install a Non-Spring Returned

Preconditioner Water Valve

Actuator on page 107

100797100 TRANSDUCER, PRESSURE/

TEMPERATURE 100PSIG

Install an Original Preconditioner

Water Pressure and Temperature

Transducer on page 114

100513700 SENSOR, HUMIDITY/TEMP Install a Preconditioner Temperature

and Humidity Sensor on page 124

100692700 COIL CONTROL ASSY (ON

SYSTEMS SHIPPED PRIOR TO

01/2014)

Install a Preconditioner Coil Control

Board on page 127

100692701 COIL CONTROL ASSY (SYSTEMS

SHIPPED AFTER 12/2013)

Install a Preconditioner Coil Control

Board on page 127

Table 6. XC Series-LC Prconditioner Redesigned Components

Part Number Description Procedure

100681001 ACTUATOR ASSY, CONTROL

ARB24-SR W/PLUG SPRING RTN

Install a Spring Returned

Preconditioner Water Valve

Actuator on page 111

100950500 TRANSDUCER, PRESSURE

100PSIG

Install a Redesigned Preconditioner

Water Pressure Transducer on page

116

100950600 CABLE ASSY, WATER CONTROL

PCA TO PRESSURE SENSOR

Install a Redesigned Preconditioner

Water Pressure Transducer on page

116

About the XC30-LC and XC40-LC Repair Procedures

13

Part Number Description Procedure

100797100 TRANSDUCER, PRESSURE/

TEMPERATURE 100PSIG

Remove a Redesigned

Preconditioner Water Pressure

Transducer on page 115

100950700 CABLE ASSY, WATER CONTROL

PCA TO TEMP RTD

Install a Preconditioner Return or

Supply Temperature Sensor on

page 119

101009400 PCA, TEMPERATURE SENSOR

ASSY

Install a Preconditioner Air

Temperature Sensor on page 122

Table 7. Compute and IO Blades

Part Number Description Procedure

100923801 BLADE ASSY FRU, ANC

COMPUTE RIGHT Install a Blade Using

xtwarmswap on page 131

Install a Compute or IO Blade on

page 134

100923701 BLADE ASSY FRU, ANC

COMPUTE LEFT Install a Blade Using

xtwarmswap on page 131

Install a Compute or IO Blade on

page 134

100697700 Module Assy, I/O Left Install a Blade Using

xtwarmswap on page 131

Install a Compute or IO Blade on

page 134

100872201 DIFFUSSER MODULE ASSY,

RIGHT ANC/QPDC

Install a Blade Using xtwarmswap

on page 131

100872701 DIFFUSSER MODULE ASSY, LEFT

ANC/QPDC

Install a Blade Using xtwarmswap

on page 131

101304000 DIFFUSSER MODULE ASSY, HP

LEFT ANC/HPDC 145W

Install a Blade Using xtwarmswap

on page 131

101304100 DIFFUSSER MODULE ASSY, HP

RIGHT ANC/HPDC 145W

Install a Blade Using xtwarmswap

on page 131

100609602 DIMM, 4GB PC3-12800 REG DUAL

RANK ECC

Install a Blade Memory DIMM on

page 136

100609603 DIMM, 4GB PC3-12800 REG DUAL

RANK ECC

Install a Blade Memory DIMM on

page 136

100609701 DIMM, 8GB PC3-12800 REG DUAL

RANK ECC

Install a Blade Memory DIMM on

page 136

100609702 DIMM, 8GB PC3-12800 REG DUAL

RANK ECC

Install a Blade Memory DIMM on

page 136

About the XC30-LC and XC40-LC Repair Procedures

14

Part Number Description Procedure

100609703 DIMM, 8GB PC3-12800 REG DUAL

RANK ECC

Install a Blade Memory DIMM on

page 136

100730401 DIMM, 16GB PC3-12800 Reg Dual

Rank ECC (Hynix)

Install a Blade Memory DIMM on

page 136

100730403 DIMM, 16GB PC3-12800 REG

DUAL RANK ECC

Install a Blade Memory DIMM on

page 136

100860201 DIMM, 8GB DDR3 PC3-14900 REG

DUAL-RANK ECC

Install a Blade Memory DIMM on

page 136

100860202 DIMM, 8GB DDR3 PC3-14900 REG

DUAL-RANK ECC

Install a Blade Memory DIMM on

page 136

100860203 DIMM, 8GB DDR3 PC3-14900 REG

DUAL-RANK ECC

Install a Blade Memory DIMM on

page 136

100860501 DIMM, 16GB PC3-14900 REG

DUAL-RANK ECC

Install a Blade Memory DIMM on

page 136

100860502 DIMM, 16GB PC3-14900 REG

DUAL-RANK ECC

Install a Blade Memory DIMM on

page 136

100860503 DIMM, 16GB PC3-14900 REG

DUAL-RANK ECC

Install a Blade Memory DIMM on

page 136

100961801 DIMM, 16GB DDR4-2133 REG

DUAL RANK ECC

Install a Blade Memory DIMM on

page 136

100961802 DIMM, 16GB DDR4-2133 REG

DUAL RANK ECC

Install a Blade Memory DIMM on

page 136

100982901 DIMM, 16GB DDR4-2400 REG

DUAL RANK ECC 1.2V 1GX4

Install a Blade Memory DIMM on

page 136

100982902 DIMM, 16GB DDR4-2400 REG

DUAL RANK ECC 1.2V 1GX4

Install a Blade Memory DIMM on

page 136

100961000 DIMM, 32GB DDR3L-1333 REG

QUAD RANK ECC

Install a Blade Memory DIMM on

page 136

101107701 DIMM, 32GB DDR4-2133 REG

DUAL RANK ECC 1.2V 1GX4

Install a Blade Memory DIMM on

page 136

101107702 DIMM, 32GB DDR4-2133 REG

DUAL RANK ECC 1.2V 1GX4

Install a Blade Memory DIMM on

page 136

101131101 DIMM, 32GB DDR4-2400 REG

DUAL RANK ECC 1.2V 2GX4

Install a Blade Memory DIMM on

page 136

101131103 DIMM, 32GB DDR4-2400 REG

DUAL RANK ECC 1.2V 2GX4

Install a Blade Memory DIMM on

page 136

100944701 DIMM, 8GB DDR4-2133 REG ECC Install a Blade Memory DIMM on

page 136

100944702 DIMM, 8GB DDR4-2133 REG ECC Install a Blade Memory DIMM on

page 136

About the XC30-LC and XC40-LC Repair Procedures

15

Part Number Description Procedure

100812302 PCA, IR ARIES VRM (IBB / ANC) Install a Voltage Module (VRM,

VIVOC, and HIVOC) on page 138

100684401 VOLTAGE CONVERTER MOD,

VERT 300W 52-13VDC (VIVOC)

Install a Voltage Module (VRM,

VIVOC, and HIVOC) on page 138

100824500 VOLTAGE CONVERTER MOD,

VERT 300W 48-12VDC (VIVOC)

Install a Voltage Module (VRM,

VIVOC, and HIVOC) on page 138

100824600 VOLTAGE CONVERTER MOD,

HORIZ 456W 48-12VDC (HIVOC)

Install a Voltage Module (VRM,

VIVOC, and HIVOC) on page 138

100684501 VOLTAGE CONVERTER MOD,

HORIZ 430W 52-13VDC (HIVOC

FOR XPDC)

Install a Voltage Module (VRM,

VIVOC, and HIVOC) on page 138

100635202 PCA, INTEL SOCKET R VOLTERA

VRM FOR XPDC

Install a Voltage Module (VRM,

VIVOC, and HIVOC) on page 138

100874601 IC, INTEL 8-CORE E5-2670

2.6GHZ FOR QPDC

Install a Processor on page 142

100881001 IC, INTEL 8-CORE E5-2680

2.7GHZ 20M CACHE

Install a Processor on page 142

100960200 IC, INTEL 10-CORE E5-2670

2.5GHZ 25M CACHE 115W C1

Install a Processor on page 142

100960500 IC, INTEL 10-CORE E5-2680

2.8GHZ 25M CACHE 115W C1

Install a Processor on page 142

100960600 IC, INTEL 10-CORE E5-2690

3.0GHZ 25M CACHE 115W C1

Install a Processor on page 142

101079100 IC, INTEL 10-CORE E5-2650V3

2.5GHZ 105W M1 HPDC

Install a Processor on page 142

100944500 IC, INTEL 12-CORE E5-2695

2.4GHZ 30G CACHE 115W C0

QPDC

Install a Processor on page 142

100944501 IC, INTEL 12-CORE E5-2695

2.4GHZ 30G CACHE 115W C1

QPDC

Install a Processor on page 142

100944400 IC, INTEL 12-CORE E5-2697

2.7GHZ 30G CACHE 130W C0

QPDC

Install a Processor on page 142

100944401 IC, INTEL 12-CORE E5-2697

2.7GHZ 30G CACHE 130W C1

QPDC

Install a Processor on page 142

101078600 IC, INTEL 12-CORE E5-2670V3

2.3GHZ 120W M1 HPDC

Install a Processor on page 142

101078700 IC, INTEL 12-CORE E5-2680V3

2.5GHZ 120W M1 HPDC

Install a Processor on page 142

About the XC30-LC and XC40-LC Repair Procedures

16

Part Number Description Procedure

101078900 IC, INTEL 12-CORE E5-2690V3

2.6GHZ 135W M1 HPDC

Install a Processor on page 142

101079000 IC, INTEL 14-CORE E5-2695V3

2.3GHZ 120W C1 HPDC

Install a Processor on page 142

101120400 IC INTEL 16-CORE E5-2698V3

2.3GHZ 135W C1 HPDC

Install a Processor on page 142

101433000 IC, INTEL 18-CORE E5-2695V4

2.1GHZ 120W 45M B0

Install a Processor on page 142

101485200 IC, INTEL 18-CORE E5-2697V4

2.3GHZ 145W 45M

Install a Processor on page 142

101485400 IC, INTEL 20-CORE E5-2698V4

2.2GHZ 135W 50M

Install a Processor on page 142

101485500 IC, INTEL 22-CORE E5-2699V4

2.2GHZ 145W 50M

Install a Processor on page 142

101026800 IC, INTEL XEON PHI W/

HEATSINKS FRU GPDC

Install a Processor on page 142

101534100 IC, INTEL 68-CORE 215W 1.4GHZ

TDP 7250

Install a Processor on page 142

101534400 IC, INTEL 64-CORE 215W 1.3GHZ

TDP 7210

Install a Processor on page 142

101534200 IC, INTEL 64-CORE 215W 1.3GHZ

TDP 7230

Install a Processor on page 142

100845900 DAUGHTER CARD, QPDC Install a QPDC on page 158

100845901 DAUGHTER CARD, QPDC Install a QPDC on page 158

100752100 DAUGHTER CARD, XPDC SIO

(FOR IO BLADE)

Install an XPDC on page 160

100953000 DAUGHTER CARD, SGDC Install a SGDC on page 162

100950200 DAUGHTER CARD, GPDC Install a GPDC on page 164

100938700 DAUGHTER CARD, HPDC W/

HIVOC

Install a HPDC on page 166

101319700 DAUGHTER CARD, HPDC-HP W/

HIVOC'S

Install a HPDC on page 166

101144701 DAUGHTER CARD, KPDC

100923700 BLADE ASSY FRU, ANC

COMPUTE LEFT

Install Components on an Aries

Network Card (ANC)

100923800 BLADE ASSY FRU, ANC

COMPUTE RIGHT

Install Components on an Aries

Network Card (ANC)

100924900 BLADE ASSY FRU, IO LEFT

(SUPPORTS IO AND IO-HP)

Install Components on an IO Base

Board (IOBB) on page 170

About the XC30-LC and XC40-LC Repair Procedures

17

Part Number Description Procedure

100509801 PCIE, GEN2 8GB DUAL-PORT FC

LOW PROFILE

Install a PCI Card on page 169

100629501 PCIE, GEN2 1GBE QUAD-PORT

COPPER INTERFACE

Install a PCI Card on page 169

100900200 PCIE, GEN2 10GBE DUAL-PORT

CX4 INTERFACE

Install a PCI Card on page 169

100610400 PCIE, GEN2 10GBE DUAL-PORT

LR

Install a PCI Card on page 169

100688600 PCIE, GEN2 10GBE DUAL-PORT

LR

Install a PCI Card on page 169

100610500 SFP+ SR TRANSCEIVER,

MYICOM DUAL PORT 10GBE

Install a PCI Card on page 169

100826300 PCIE, GEN2 6GB DUAL-PORT

SAS-2

Install a PCI Card on page 169

100882000 PCIE, GEN3 14GB DUAL-PORT IB

HCA FDR W/QSFP

Install a PCI Card on page 169

100882500 PCIE, GEN3 40GB DUAL-PORT

ETHERNET OPTICAL

Install a PCI Card on page 169

100900200 PCIE, GEN2 10GBE DUAL-PORT

CX4 INTERFACE

Install a PCI Card on page 169

System Maintenance Workstation (SMW)

Replacement procedures for the Dell PowerEdge R815 workstation are contained in the hardware owner’s

manual that is available on the Dell Website at http://www.dell.com/support/. Dell system workstation parts may be

under warranty.

Table 8. System Maintenance Workstation (SMW)

Part Number Description

100762104 SMW SERVER, 2ND GENERATION LOW END

100862201 SMW SERVER, 2ND GENERATION HIGH END

101017100 KVM CONSOLE/SHELF, 1U, 17 INCH LCD SCREEN,

KEYBOARD, TOUCH PAD

100800200 DIMM, DELL 2GB 1333MHZ DELL R815 SMW

101088500 DISK DRIVE, DELL 7K2 SATA 2.5" 250GB FOR DELL

POWEREDGE R815

100792000 DISK DRIVE, DELL 7K2 SATA 2.5" 500GB FOR DELL

POWEREDGE R815

100792100 DISK DRIVE, DELL 7K2 SATA 2.5" 1TB FOR DELL

POWEREDGE R815

About the XC30-LC and XC40-LC Repair Procedures

18

Part Number Description

100791800 POWER SUPPLY, DELL POWEREDGE R815 SMW2

1100W FRU

100823900 ADAPTER, USB TO PS/2

Boot RAID Cabinet

Replacement procedures for the NetApp E2600 are available for download at the NetApp support website at

http://www.netapp.com. To access the documentation, register for a NetApp account.

Table 9. Boot RAID Cabinet

Part Number Description

100786601 Disk Drive FRU, SAS-2.0 450GB 15K7 FDE 3 1/2" For

12-Bay Tray

100786801 Disk Drive FRU, SAS-2.0 1TB 7K2FDE 3 1/2" For 12-

Bay Tray (Replaced by 100846001)

100786901 Disk Drive FRU, SAS-2.0 2TB 7K2 FDE 3 1/2" For 12-

Bay Tray (Replaced by 100846201)

100787101 Disk Drive FRU, SAS-2.0 600GB 10K4 FDE 2 1/2" For

24-Bay Tray

100787201 Disk Drive FRU, SAS-2.0 1TBB 7K2 FDE 2 1/2" For

24-Bay Tray

100787300 Controller Assy, FRU 2600 2-6gbs SAS Ports & 4-8gbs

FC Ports

100775200 Controller FRU Assy, Netapp 2600 SAS 2-6GBS SAS

Ports

100775800 Power Supply, Netapp 585W 2U12 & 2U24 Disk Tray

(For use with 2600 Controllers)

100587300 SFP Transceiver 2, 4, 8GBIT

100775400 Battery, Netapp CDE2600

About the XC30-LC and XC40-LC Repair Procedures

19

2System Cabinet Procedures

2.1 Power Down a System Cabinet

Prerequisites

Time:

2-3 minutes

Tools

None

Procedure

1. Enter the following command in a terminal window on the SMW:

smw$ xtcli power down hostname

Hostname is the cabinet, system, or partition ID; examples include c0-0 (for a cabinet), s0 (for a system),

or p0 (for a partition). The Cabinet ID can be found on the operator interface.

2. Open the rear door of the cabinet.

3. For compute cabinets, place main circuit breakers CB1 and CB2 in the OFF (down) position.

4. For blower cabinets, place the MAIN DISCONNECT switch on the rear panel of the blower cabinet PDU in the

OFF (down) position.

Figure 1. Cabinet (left) and Blower (right) Circuit Breaker

System Cabinet Procedures

20

This manual suits for next models

1

Table of contents

Other Cray Desktop manuals