CRE Technology GENSYS 2.0 Guide

A53 Z0 9 0020 I En - Technical documentation.doc 1/182

Generator management module

Technical Documentation

CRE Technology believes that all information provided herein is correct and reliable and reserves the right to update at

any time. CRE Technology does not assume any responsibility for its use. E & O E.

CRE Technology

130 Allée Charles-Victor Naudin

Zone des Templiers - Sophia Antipolis

06410 BIOT - FRANCE

Phone: + 33 (0)4.92.38.86.82 - Fax: + 33 (0)4.92.38.86.83

www.cretechnology.com - info@cretechnology.com

SARL au Capital de 300.000 Euros - RCS Antibes: 7488 625 000 15 N°TVA FR54 488 625 583

GENSYS 2.0

A53 Z0 9 0020 I En - Technical documentation.doc 2/182

Date

Version

Comments

Par

Nov 12th 2008

A

Derived from GENSYS documentation. Starting point.

LB

Jan 6th 2008

B

Correction and full explanation of several features.

LB

Feb 19th 2008

C

Added menu references. Global revision by all the team.

LB

Mar 13th 2009

D

Details added for the reset of alarms, faults, and data logging.

Details added for the semi auto mode.

JFB

July 21st 2009

E

J1939 details added.

Modification of general wiring diagram.

Removal of USB connection.

Addition of Ethernet connection.

JFB

Sept 25th 2009

F

Firmware update using SD card added.

Chapter on GENSYS 1.0/GENSYS 2.0 compatibility added.

Extra information concerning analogue sensors.

Information concerning CEM compliance added.

Ethernet connection added and USB connection chapter updated.

Digital input parameter errors corrected.

JFB

Feb 2nd 2010

G

Two phase/three phase system management added.

SD card archiving added.

Breaker management info added.

SD card flashing removed.

Start sequence.

JFB

July 12th 2010

H

GENSYS 2.0 firmware v2.05

IP address can now be changed.

Support of Modbus TCP.

J1939 compatibility with Cummins QSX15G8.

Automatic shutdown of the horn.

Corrections on PWM 500Hz documentation.

CANopen example changed.

JFB

April 2011

I

Enhanced semi-automatic mode description.

New chapter concerning optional power tank capacitor.

New: minimum wiring diagram.

Updated static paralleling diagram.

Updated maintenance cycles chapter.

Updated reference of digital input variables.

Updated custom logo size.

Updated CAN bus good practices.

Updated technical support contact.

Updated external automatic start module setup description

Additional features starting from firmware v3.00:

CRE Config software compatibility.

Assisted manual mode.

Front panel button inhibition.

Firmware upgrade using SD card.

Generating an empty file template.

Import/Export/Delete TXT files on SD card.

Resetting factory parameters.

New methods to permanently store parameters in memory.

JFB

A53 Z0 9 0020 I En - Technical documentation.doc 3/182

You can download the most up-to-date version of this documentation and different other documentations relating to

GENSYS 2.0 on our web site: http://www.cretechnology.com/ .

Documentations available on CRE technology Web site:

A53 Z0 9 0020 x-EN is the GENSYS 2.0 technical documentation (this manual). This documentation is generally used

for product integration.

A53 Z0 9 0014 x-EN is the GENSYS 2.0 Menu reference manual: this is a Windows help file (.chm). This file contains

all references to the man-machine interface (local and html pc web site). This documentation is generally used

as reference during the

A53 Z0 9 0020 x-EN is the Complete variable list with labels, units and limits (see §15 below) in English, in PDF

format. This documentation is generally used as reference during the integration phase.

A53 Z0 9 0020 x- is the Complete variable list with labels, units and limits (see §15 below) in all languages, in EXCEL

WORKBOOK format. This documentation is generally used as reference during the installation phase. It is

NOTE:

Read this entire manual and all other publications pertaining to the work to be performed before

installing, operating, or servicing this equipment. Apply all plant and safety instructions and precautions.

Failure to follow instructions can cause personal injury and/or property damage.

Contact your CRE technology distributor for course training.

A53 Z0 9 0020 I En - Technical documentation.doc 4/182

Table of contents

1Overview ....................................................................................................................................10

1.1 European Union Directive Compliance CE..........................................................................................10

1.2 Environment .....................................................................................................................................10

1.3 Characteristics ..................................................................................................................................10

1.4 Panel cut-out: ...................................................................................................................................10

2Description .................................................................................................................................11

2.1 Front panel .......................................................................................................................................11

2.2 Rear panel - Connectors ....................................................................................................................16

3User interface .............................................................................................................................22

3.2 Local navigation ................................................................................................................................24

3.3 Remote control using a PC (Ethernet connection)..............................................................................25

4Operating modes........................................................................................................................31

4.1 Manual mode....................................................................................................................................31

4.2 Automatic mode ...............................................................................................................................31

4.3 Test mode.........................................................................................................................................32

4.4 Semi-automatic mode.......................................................................................................................32

4.5 Assisted manual mode ......................................................................................................................33

5Start sequence ............................................................................................................................35

6Predefined configurations ..........................................................................................................36

6.1 Single generator in change-over mode ..............................................................................................36

6.2 Single generator in no-change-over mode.........................................................................................38

6.3 Generators paralleling with digital bus ..............................................................................................39

6.4 Generators paralleling with GENSYS 2.0 and parallel line modules.....................................................40

6.5 Multiple generators with static paralleling ........................................................................................41

6.6 Single generator paralleled with mains..............................................................................................43

6.7 Power plant paralleled with mains using MASTER 2.0 or GCR ............................................................46

6.8 Power plant paralleled with several mains using MASTER 2.0 or GCR ................................................48

7Installing and commissioning a GENSYS 2.0 application ............................................................49

7.1 Minimum wiring diagram ..................................................................................................................49

7.2 Complete wiring diagram ..................................................................................................................50

7.3 Before commissioning (before going on site).....................................................................................52

7.4 During commissioning.......................................................................................................................53

8Dedicated I/O lines .....................................................................................................................56

8.1 Speed governor interface..................................................................................................................56

8.2 Speed and voltage control with Contacts / Pulses..............................................................................59

8.3 Analogue AVR (Auto Voltage Regulator) control ................................................................................61

8.4 Relay outputs....................................................................................................................................64

8.5 Crank / Fuel / Starter 2 / Starter 3 functions......................................................................................66

8.6 Water preheat / Pre-lubrication / Pre-glow functions........................................................................67

8.7 Air fan...............................................................................................................................................68

8.8 Fuel filling / Coolant filling / Oil filling................................................................................................68

8.9 Analogue load sharing lines...............................................................................................................69

8.10 Watchdog output ..........................................................................................................................70

9I/O lines ......................................................................................................................................71

9.1 Digital input ......................................................................................................................................71

9.2 Digital outputs ..................................................................................................................................75

9.3 Analogue input..................................................................................................................................78

10 Protections ..............................................................................................................................82

A53 Z0 9 0020 I En - Technical documentation.doc 5/182

10.1 Disable...........................................................................................................................................82

10.2 Generator electrical fault...............................................................................................................82

10.3 Mains electrical fault .....................................................................................................................82

10.4 Alarm.............................................................................................................................................82

10.5 Fault (Soft Shut down) ...................................................................................................................82

10.6 Security (Hard Shutdown) ..............................................................................................................82

10.7 Help + Fault (Soft Shut down) ........................................................................................................82

10.8 Help + Gen. Electrical fault.............................................................................................................82

11 Additional functions ................................................................................................................83

11.1 Load sharing using integral (de-drooping)......................................................................................83

11.2 Operator controlled return to mains..............................................................................................84

11.3 Mains & Generator electrical fault options.....................................................................................85

11.4 Generator electrical fault...............................................................................................................87

11.5 GENSYS 2.0 with external automatic start module .........................................................................88

11.6 Remote start upon external pulse..................................................................................................89

11.7 Safety Inhibitions...........................................................................................................................90

11.8 Use of BSM II with GENSYS 2.0.......................................................................................................91

11.9 GENSYS 2.0 with TEM compact ......................................................................................................94

11.10 Presetting counters / G59 parameters (Access level -1)..................................................................95

11.11 Scada.............................................................................................................................................96

11.12 How to set a GPID..........................................................................................................................96

11.13 Automatic load / unload ................................................................................................................96

11.14 Heavy consumer (marine sequence) ..............................................................................................98

11.15 Non essential consumer trip (marine sequence) ..........................................................................100

11.16 Phase offset (Dyn11 and other)....................................................................................................103

11.17 120° three phase and 180° two phase systems ............................................................................105

11.18 Front panel inhibition ..................................................................................................................105

12 Text file & PLC .......................................................................................................................107

12.1 Introduction ................................................................................................................................107

12.2 Variable naming...........................................................................................................................107

12.3 Text file description .....................................................................................................................107

12.4 PLC programming language .........................................................................................................114

12.5 Variables......................................................................................................................................116

12.6 Syntax examples..........................................................................................................................117

12.7 GENSYS 1.0 GENSYS 2.0 compatibility .......................................................................................118

12.8 Firmware upgrade using SD card..................................................................................................119

12.9 Resetting to factory parameters ..................................................................................................121

13 Communication .....................................................................................................................122

13.1 CAN bus good practices ...............................................................................................................122

13.2 COM1: Inter GENSYS 2.0 CAN bus ................................................................................................123

13.3 COM2: CAN protocols (CANopen, J1939, MTU MDEC):.................................................................131

13.4 COM3: USB..................................................................................................................................142

13.5 COM4: ETHERNET........................................................................................................................142

13.6 COM5: MODBUS RTU on serial port RS485...................................................................................143

13.7 COM6: SD card ............................................................................................................................144

14 Troubleshooting ....................................................................................................................149

15 Menu overview......................................................................................................................151

15.1 Menu introduction.......................................................................................................................151

15.2 DISPLAY Menu .............................................................................................................................151

15.3 CONFIGURATION Menu ...............................................................................................................156

15.4 - Basic Configuration Menu..........................................................................................................156

15.5 - Enhanced Configuration Menu ..................................................................................................161

15.6 SYSTEM Menu .............................................................................................................................170

A53 Z0 9 0020 I En - Technical documentation.doc 6/182

15.7 Dedicated screens........................................................................................................................173

16 Useful Information ................................................................................................................176

17 Variables ...............................................................................................................................178

18 Precautions............................................................................................................................179

19 References.............................................................................................................................181

19.1 Options........................................................................................................................................181

19.2 Accessories..................................................................................................................................181

20 Company Information ...........................................................................................................182

A53 Z0 9 0020 I En - Technical documentation.doc 7/182

List of illustrations

Figure 1 - Panel cut-out .................................................................................................................................................. 10

Figure 2 - Rear panel ...................................................................................................................................................... 16

Figure 3 - COM1 pin out ................................................................................................................................................. 20

Figure 4 - COM2 pin out ................................................................................................................................................. 20

Figure 5 - COM4 pin out ................................................................................................................................................. 21

Figure 6 - COM5 pin out ................................................................................................................................................. 21

Figure 7 - User interface ................................................................................................................................................. 22

Figure 8 Default screen saver....................................................................................................................................... 22

Figure 9 - Password input mode display.......................................................................................................................... 23

Figure 10 - Main menu ................................................................................................................................................... 24

Figure 11- Browser link description................................................................................................................................. 24

Figure 12 - Contextual keys for Input Mode .................................................................................................................... 24

Figure 13 Typical menu................................................................................................................................................ 29

Figure 14 Typical configuration page............................................................................................................................ 30

Figure 15 - Typical start sequence for fuel engines.......................................................................................................... 35

Figure 16 - Power plant in change-over mode without paralleling................................................................................... 36

Figure 17 - Power plant in change over without paralleling ............................................................................................. 38

Figure 18 - Power plant with several generators ............................................................................................................. 39

Figure 19 - Static paralleling with 4 generators coupled together in emergency situation................................................ 41

Figure 20 - Example with 4 generators paralleled together in emergency situation. ........................................................ 41

Figure 21 - Paralleling with mains ................................................................................................................................... 43

Figure 22 - Typical sequence in No Break CO mode......................................................................................................... 44

Figure 23 - Typical sequence in permanent mode ........................................................................................................... 45

Figure 24 - Power plant paralleling with mains................................................................................................................ 46

Figure 25 - GCR GENSYS 2.0 wiring diagram ............................................................................................................... 47

Figure 26 - Power plant paralleling with several mains.................................................................................................... 48

Figure 27 - Power plant paralleling with several mains configuration .............................................................................. 48

Figure 28 - Mounting kit ................................................................................................................................................. 51

Figure 29 - Mounting brackets on GENSYS 2.0................................................................................................................. 51

Figure 30 - Earth grounding ............................................................................................................................................ 51

Figure 31 - Interconnection of all battery negatives ........................................................................................................ 52

Figure 32 - Speed output ................................................................................................................................................ 56

Figure 33 Connexion avec un EFC Cummins.......................................................................................................... 58

Figure 34 - PWM dynamic............................................................................................................................................... 58

Figure 35 Speed and voltage control pulses.................................................................................................................. 61

Figure 36 - Voltage output.............................................................................................................................................. 62

Figure 37 - Connections for water preheat, pre lubrication and pre glow ........................................................................ 67

Figure 38 - Connection for air fans.................................................................................................................................. 68

Figure 39 - Connections for filling ................................................................................................................................... 68

Figure 40 - Fuel filling diagram........................................................................................................................................ 69

Figure 41 - Wiring parallel lines....................................................................................................................................... 70

Figure 42 - Change over with one digital input programmed as "Mains electrical fault"................................................... 85

Figure 43 - Permanent mains paralleling with one digital input programmed as "Mains electrical fault".......................... 86

Figure 44 - Permanent mains paralleling with one digital input programmed as "Mains electrical fault".......................... 86

Figure 45 - Permanent mains paralleling with one input as "Mains electrical fault" ......................................................... 87

Figure 46 - Permanent mains paralleling and generator electrical fault ........................................................................... 87

Figure 47 - Wiring GENSYS 2.0 Auto Start Module...................................................................................................... 88

Figure 48 Wiring GENSYS 2.0 to BSM II......................................................................................................................... 92

Figure 49 - Wiring GENSYS 2.0 TEM........................................................................................................................... 94

Figure 50 - Typical GPID controller.................................................................................................................................. 96

Figure 51 Automatic load/unload sequence ................................................................................................................. 97

Figure 52 - Automatic load/unload arbitration................................................................................................................ 98

Figure 53 - Heavy consumer validation ........................................................................................................................... 99

Figure 54 - Heavy Consumer Control with active power analysis ..................................................................................... 99

Figure 55 - Heavy Consumer Control with number of gensets analysis .......................................................................... 100

Figure 56 - Configuration of the heavy consumer confirmation output.......................................................................... 100

Figure 57 - Non essential consumer trip settings........................................................................................................... 101

Figure 58 - Non essential consumer trip alarm (1)......................................................................................................... 101

Figure 59 - Non essential consumer trip alarm (2)......................................................................................................... 102

A53 Z0 9 0020 I En - Technical documentation.doc 8/182

Figure 60 - Non essential consumer trip output setting................................................................................................. 102

Figure 61 - Non essential consumer trip timers............................................................................................................. 103

Figure 62 - Non essential consumer trip diagram .......................................................................................................... 103

Figure 63 Phase offset example ................................................................................................................................. 104

Figure 65 - CAN Bus wiring............................................................................................................................................ 123

Figure 66 - GENSYS 2.0 GENSYS 2.0.......................................................................................................................... 123

Figure 67 - GENSYS 2.0 GENSYS 2.0 GENSYS 2.0 .......................................................................................... 124

Figure 68 - Mobile generator sets................................................................................................................................. 124

Figure 69 - Connecting J6 to broadcast variables........................................................................................................... 128

Figure 70 - Connecting Magnetic pick up for speed broadcast....................................................................................... 128

Figure 71 - CAN bus inhibition schematic (example)...................................................................................................... 130

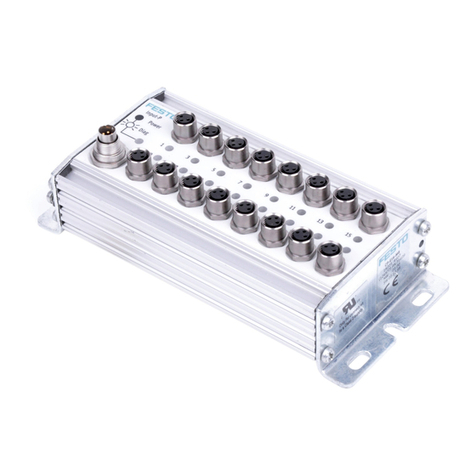

Figure 72 - Modular remote CANopen I/O extension module........................................................................................ 132

Figure 73 - CANopen coupler wiring.............................................................................................................................. 132

Figure 74 MDEC Screens............................................................................................................................................ 137

Figure 75 Virtual input screen.................................................................................................................................... 138

Figure 76 - Wiring diagram for Volvo EMS2................................................................................................................... 142

Figure 77 - GENSYS 2.0 GENSYS 2.0 GENSYS 2.0 BUS).......................................................................... 144

Figure 78 Generator global view ................................................................................................................................ 151

Figure 79 Mains/Busbars global view ......................................................................................................................... 152

Figure 80 Synchroscope............................................................................................................................................. 153

Figure 81 Engine meters ............................................................................................................................................ 155

Figure 82 GPID factory setting.................................................................................................................................... 159

Figure 83 Cos phi PID................................................................................................................................................. 159

Figure 84 kVAR shar. gain .......................................................................................................................................... 160

Figure 85 Timers........................................................................................................................................................ 161

Figure 86 kW sharing GPI........................................................................................................................................... 163

Figure 87 P=const PI .................................................................................................................................................. 163

Figure 88 Synchro volt PID ......................................................................................................................................... 164

Figure 89 Synchroscope frequency & phase PID......................................................................................................... 165

Figure 90 Modification by variable number................................................................................................................ 168

Figure 91 Com ports .................................................................................................................................................. 172

Figure 92 Compilation result screen........................................................................................................................... 173

Figure 93 Download screen........................................................................................................................................ 173

Figure 94 Fault screen................................................................................................................................................ 174

Figure 95 Information screen..................................................................................................................................... 175

Figure 96 Speed regulation details ............................................................................................................................. 176

Figure 97 Voltage regulation details........................................................................................................................... 177

Figure 98 - Several generators warning......................................................................................................................... 179

Figure 99 - One generator with mains warning ............................................................................................................. 179

Figure 100 - Standard cables......................................................................................................................................... 181

Figure 101 - Access to CRE Technology in Sophia Antipolis. ........................................................................................... 182

A53 Z0 9 0020 I En - Technical documentation.doc 9/182

List of tables

Table 1 - GENSYS 2.0 Front Panel.................................................................................................................................... 11

Table 2 - LCD screen characteristics ................................................................................................................................ 11

Table 3 - Display Panel keys............................................................................................................................................ 12

Table 4 - Control Panel keys............................................................................................................................................ 14

Table 5 - Control Panel LEDs ........................................................................................................................................... 15

Table 6 - Inputs/Outputs description .............................................................................................................................. 21

Table 7 - Authorization levels and passwords.................................................................................................................. 23

Table 8- Typical basic change over configuration ............................................................................................................ 36

Table 9 - Typical sequence in change over mode............................................................................................................. 37

Table 10- Typical no change over basic configuration...................................................................................................... 38

Table 11 - Typical basic multi Generator configuration.................................................................................................... 39

Table 12 - Generator paralleling with parallel lines ......................................................................................................... 40

Table 13 - Typical basic configuration for GENSYS 2.0 with parallel line modules............................................................. 40

Table 14 - Typical basic mains paralleling configuration .................................................................................................. 43

Table 15 - Paralleling with mains configuration............................................................................................................... 46

Table 16 - GENSYS 2.0 /GCR configuration ...................................................................................................................... 47

Table 17 - Speed governor parameters ........................................................................................................................... 57

Table 18 - PWM parameters........................................................................................................................................... 58

Table 19 - AVR parameters ............................................................................................................................................. 63

Table 20 - Breaker control configuration......................................................................................................................... 65

Table 21 - Fuel/cooling/oil filling parameters .................................................................................................................. 69

Table 22 - Input parameters ........................................................................................................................................... 71

Table 23 - Input validity domain...................................................................................................................................... 72

Table 24 - Input direction domain................................................................................................................................... 72

Table 25 - Input functions............................................................................................................................................... 75

Table 26: Oil pressure calibration points......................................................................................................................... 79

Table 27: Water Temp calibration points: ....................................................................................................................... 80

Table 28 - Wiring GENSYS 2.0 Auto Start Module ....................................................................................................... 88

Table 29 - Wiring GENSYS 2.0 TEM............................................................................................................................. 95

Table 30- Label definition bloc...................................................................................................................................... 110

Table 31 - Custom logo labels ....................................................................................................................................... 110

Table 32 - Valid units and accuracy codes ..................................................................................................................... 111

Table 33 - Variables with customizable unit/accuracy values......................................................................................... 114

Table 34 Available instructions .................................................................................................................................. 116

Table 35 DB9 pin out ................................................................................................................................................. 122

Table 36 - Broadcast variables sent over inter GENSYS 2.0 CAN bus............................................................................... 126

Table 37 Broadcast variables received by BROADCAST DATA from inter GENSYS 2.0 CAN bus..................................... 127

Table 38 - CAN bus inhibition variables......................................................................................................................... 130

Table 39 - CAN bus inhibition parameters ..................................................................................................................... 131

Table 40 - CANopen input and output variables ............................................................................................................ 133

Table 41 - CANopen configuration example .................................................................................................................. 134

Table 42 - MDEC connection......................................................................................................................................... 135

Table 43 - Important parameters.................................................................................................................................. 136

Table 44 - J1939 message actions (protections) ............................................................................................................ 139

Table 45 - COM5 pin out............................................................................................................................................... 143

Table 46 - Power plant configuration ............................................................................................................................ 157

Table 47 - Breaker settings ........................................................................................................................................... 162

Table 48 - Screensaver modes ...................................................................................................................................... 171

A53 Z0 9 0020 I En - Technical documentation.doc 10/182

1Overview

1.1 European Union Directive Compliance CE

The EMC Directive (89/336/EEC) deals with electromagnetic emissions and immunity. This product is tested by applying

the standards, in whole or in part, which are documented in the following technical construction file:

CEM 2004/108/EC, which replaces directive CEM (89/336/EEC) relative to electromagnetic emissions as from July 20th

2009.

This product is developed to respect harmonized norms:

EN 55099:2009

EN 55099:2010

EN 55088:2008

2006/95/EC (replaced directive 73/23/EEC since January 16th 2007).

SAE J1939/71, /73, /31

Other norms:

EN 61326-1: 2006 (Industrial location)

EN 55011

EN 61000-3-2

EN 61000-3-3

Note: This is a class A product. In a domestic environment this product may cause radio interference. The user is

responsible for taking the necessary precautions.

1.2 Environment

Temperature

Operating: 055°C

Storage: -30+70°C

Humidity: 5 to 95%

Tropic proof circuits for normal operation in humid conditions.

Front panel: IP65 protection.

Back panel: IP20 protection.

1.3 Characteristics

Size: 248x197x57mm (9.76x7.76x2.24in)

Weight: 1.9kg (4.2oz)

1.4 Panel cut-out:

Figure 1 - Panel cut-out

Note:Cut-out must be cleaned and de-burred before mounting.

228 mm /

8.98 in

177 mm /

6.97 in

A53 Z0 9 0020 I En - Technical documentation.doc 11/182

2Description

2.1 Front panel

Table 1 - GENSYS 2.0 Front Panel

The display panel allows setting up and monitoring of the GENSYS 2.0 configuration and the power plant it controls. It

provides a large LCD display and a keypad. See "User interface" chapter, page 22, for more details about the functions of

LEDs & Keys.

LCD characteristics

Value

Unit

Viewing area

240x128

dots

114x64 (4.49x2.52)

mm (in)

30x16

Characters

Character size (small font)

2.7x3.6 (0.1x0.14)

mm (in)

(standard font)

3.6x3.6 (0.14x0.14)

mm (in)

(large font)

9.45x9.45 (0.37x0.37)

Back light

60

cd/m²

LCD mode

STN

Table 2 - LCD screen characteristics

A53 Z0 9 0020 I En - Technical documentation.doc 12/182

2.1.1 Display panel

The five dedicated keys of the display panel allow direct access to special menus or functions. See "User interface"

chapter, page 22, for more details about the functions of LEDs & Keys.

Table 3 - Display Panel keys

Key

Navigation mode

Input mode

(during parameter modification)

Navigation bar

Scroll / select menus and parameters.

Change parameter value.

Enter

E

Shift

Used with other keys only ([+], [-], I).

Not used.

+

Shortcut to special function.

Increase speed in manual mode.

Increase voltage when associated with

Shift key in manual mode.

Not used.

-

Shortcut to special function.

Decrease speed in manual mode.

Decrease voltage when associated with

Shift key in manual mode.

Not used.

Esc

Return to parent menu.

Discard parameter changes and return to

A53 Z0 9 0020 I En - Technical documentation.doc 13/182

2.1.2 Service panel

Key

Function

Buzzer

This key will stop the alarm horn.

Fault

Direct access to the Fault menu.

An associated red LED indicates the Fault status of the generator.

Pressing this key will switch to the associated menu, showing active faults.

Pressing a second time on the same key will switch back to the menu displayed beforehand.

Fault archive can be deleted in the System/ Date Time meter/. Data logging --reset menu

Alarm

Direct access to the Alarm menu.

An associated orange LED indicates the Alarm status of the generator.

Pressing this key will switch to the associated menu, showing active alarms.

Pressing a second time on the same key will switch back to the menu displayed beforehand.

Alarm archive can be deleted in the System/ Date Time meter/. Data logging --reset menu

Info

1. Direct access to global monitoring page (user configurable).

-

Pressing this key will switch to the associated menu, which is custom made and contains

parameters the user wants to monitor easily.

Pressing a second time on the same key will switch back to the menu displayed beforehand.

Bulb

LED test: pressing this key will turn on all GENSYS 2.0 LEDs. It is a simple test to check the LEDs

and the keypad.

Table 4 - Service Panel keys

A53 Z0 9 0020 I En - Technical documentation.doc 14/182

2.1.3 Control panel

The control panel allows the user to pilot and control the generator. See "User interface" chapter, page 22, for more

details about the functions of LEDs & Keys.

Key

Function

upper

right

LED

2.0

This LED is illuminated when a key is pressed and is switched off when all keys are

released. This LED also stays on during a save parameters command (see SHIFT-I

above). It is also used to indicate SD card accesses.

Auto

Switches the system to automatic mode. The associated LED is ON when AUTO

mode is activated.

Test

Switches the system to test mode. The associated LED is ON when TEST mode is

activated.

Manu

Switches the system to manual mode. The associated LED is ON when MANU mode

is activated.

Start

Starts the generator (only available in manual mode).

Stop

Stops the generator (only in manual mode).

O/I

Closes/opens the generator breaker (only in manual mode).

O/I

Closes/opens the mains breaker if available (only in manual mode).

Table 4 - Control Panel keys

A53 Z0 9 0020 I En - Technical documentation.doc 15/182

2.1.4 Control panel LEDs

Led

Function

Engine

Green LED lit when engine is running.

Alternator

Green LED lit when generator voltage is present.

Genset

breaker

Green LED lit when generator breaker is closed.

Mains

breaker

Green LED lit when mains breaker is closed.

Mains /

Bus voltage

Green LED lit when voltage is present at Mains/bus input

Table 5 - Control Panel LEDs

2.1.5 Upper panel LED

There is an orange LED in the dot of the 2.0logo on the upper right corner. This LED lights up when a key is pressed or

when the firmware is accessing the SD card.

A53 Z0 9 0020 I En - Technical documentation.doc 16/182

2.2 Rear panel - Connectors

2.2.1 Overview

Figure 2 - Rear panel

A53 Z0 9 0020 I En - Technical documentation.doc 17/182

2.2.2 Inputs/Outputs

Terminal

Description

Terminal

capacity

(mm² /

AWG)

Comment

A1

Crank relay out

Output 6

2.5 / 12

Supplied via emergency stop input at battery positive voltage;

can also be used as configurable relay output.

240VAC, 5A max. Details in §8.4.2

A2

Fuel relay out

Output 7

2.5 / 12

Supplied via emergency stop input at battery positive voltage;

can also be used as configurable relay output.

240VAC, 5A max. Details in §8.4.2

A3

Emergency stop

2.5 / 12

To battery positive, normally closed; direct supply to crank and

fuel relay outputs.

B1

Generator N

2.5 / 12

Not necessarily connected: if not connected, GENSYS 2.0 will

calculate a virtual neutral voltage.

B2

Generator L1

2.5 / 12

Generator voltage measurement.

100 to 480 VAC line to line. Frequency: 50 or 60Hz.

These lines must be protected externally with 100mA / 600VAC

fuses.

B3

Generator L2

2.5 / 12

B4

Generator L3

2.5 / 12

B5

Mains L1

2.5 / 12

Mains voltage measurement.

100 to 480VAC line to line. Frequency: 50 or 60Hz.

These lines must be protected externally with 100mA / 600VAC

fuses.

B6

Mains L2

2.5 / 12

B7

Mains L3

2.5 / 12

C1 to C5

Output 1 to 5

2.5 / 12

<350mA. Over current protected. Reactive load.

Each output can be configured with a specific function or

programmed with an equation, see details in §9.2.1

C5 can also be used as a watchdog output (contact CRE

Technology for more info).

D1

Generator I1-

2.5 / 12

Generator current measurement 0 to 5A. Maximum rating: 15A

during 10s.

1VA consumption.

External current transformer is normally used.

D2

Generator I1+

2.5 / 12

D3

Generator I2-

2.5 / 12

D4

Generator I2+

2.5 / 12

D5

Generator I3-

2.5 / 12

D6

Generator I3+

2.5 / 12

D7

Not connected

2.5 / 12

E1

Mains open breaker

2.5 / 12

Two configurable relays with one in common, one for closing,

and one for opening. 240VAC, 5A.

Isolated contact. Details in §8.4.1

E2

Mains close breaker

2.5 / 12

E3

Mains common

2.5 / 12

E4

Bus bar open breaker

2.5 / 12

Two configurable relays with one in common, one for closing,

and one for opening. 240VAC, 5A.

Isolated contact. Details in §8.4.1

E5

Bus bar close breaker

2.5 / 12

E6

Bus bar common

2.5 / 12

A53 Z0 9 0020 I En - Technical documentation.doc 18/182

Terminal

Description

Terminal

capacity

(mm² /

AWG)

Comment

F1

Engine meas. 1-

2.5 / 12

(shielded)

0 to 10 resistive sensors with programmable gain. Details in

§9.3

F2

Engine meas. 1+

2.5 / 12

(shielded)

F3

Engine meas. 2-

2.5 / 12

(shielded)

0 to 10 resistive resistive sensors with programmable gain. All

Details can be found in §9.3

F4

Engine meas. 2+

2.5 / 12

(shielded)

F5

Shield

2.5 / 12

Must be used to protect shielded signals.

F6

Water temp meas. -

2.5 / 12

(shielded)

0 to 400resistive sensors. Details in §9.3

F7

Water temp meas. +

2.5 / 12

(shielded)

F8

Oil pressure meas. -

2.5 / 12

(shielded)

0 to 400resistive sensors. Details can be found in §9.3

F9

Oil pressure meas. +

2.5 / 12

(shielded)

G1

±20mA +

2.5 / 12

(shielded)

±10V (20kinput) or ±20mA (50input).

Used as Mains power input measurement with single generator.

Used as synchronization input from GCR External analogue

synchronizer (ex: GCR terminal 42 or MASTER 2.0 by parallel

lines) when several generators parallel with mains.

G2

Shield

2.5 / 12

G3

±20mA -

2.5 / 12

(shielded)

G4

Parallel. -

2.5 / 12

(shielded)

5V (10) compatible parallel lines.

Load sharing and power set level (kW only).

Compatibility with traditional analogue load share lines (often

called Parallel Lines).

Compatibility with Wheatstone bridge.

Only used if GCR or old ILS

Isolated. Details in §8.9

G5

Shield

2.5 / 12

G6

Parallel. +

2.5 / 12

(shielded)

G7

Pickup -

2.5 / 12

50Hz to 10kHz. Maximum voltage: 40VAC

Used for speed regulation, crank drop out and over-speed (see

Cautions in §18).

If not wired, the speed measurement can be made by the

alternator voltage. But pickup is recommended.

Details in speed settings §8.1.1.

G8

Pickup +

2.5 / 12

G9

Speed out +

2.5 / 12

G9: ±10V analogue outputs to speed governor.

G11: ±10V reference input from speed governor (ESG)

Compatibility with most speed governors. Details in §8.1.1

G10

Shield

2.5 / 12

G11

Speed ref

2.5 / 12

H1

Not connected

2.5 / 12

Analogue output ±5V isolated.

Automatic voltage regulator (AVR) control. Compatible with most

regulators. Details in §8.3

H2

AVR out +

2.5 / 12

H3

Shield

2.5 / 12

H4

AVR out -

2.5 / 12

A53 Z0 9 0020 I En - Technical documentation.doc 19/182

Terminal

Description

Terminal

capacity

(mm² /

AWG)

Comment

J1

Mains breaker in

2.5 / 12

Digital input with 10pull-up.

Dedicated input for mains breaker feedback.

Accepts NO or NC contact to 0V.

Not isolated.

J2

Gen breaker in

2.5 / 12

Digital input with 10pull-up.

Dedicated input for generator breaker feedback.

Accepts NO or NC contact to 0V.

Not isolated.

J3

Remote start/stop

2.5 / 12

Digital input with 10pull-up.

Dedicated input for remote start/stop request in Auto mode.

Accepts NO or NC contact to 0V.

Not isolated.

J4

Oil pressure

Spare input

2.5 / 12

Digital input with 10pull-up.

Default factory setting is input for oil pressure fault.

Accepts NO or NC contact to 0V.

Not isolated. Can be programmed as a spare input. Details in §9.1

J5

Water temp

Spare input

2.5 / 12

Digital input with 10pull-up.

Default factory setting is input for water temperature fault.

Accepts NO or NC contact to 0V.

Not isolated. Can be programmed as a spare input. Details in §9.1

J6 to J15

Spare Input

1 to 10

2.5 / 12

Digital input with 10pull-up.

10 inputs can be configured with a specific function or

programmed with PLC equations.

Accepts NO or NC contact to 0V.

Not isolated. Details in §9.1

K1

Power Tank

2.5 / 12

Used for 12V power supply backup during crank time. An

externally supplied capacitor can be connected externally

between ground and this line for better tolerance to power drop.

A value of 1µF per 50µs is a good value. Thus, 47.000µF will add a

50ms delay to power down. Can be adjusted. More is better.

K2

Power supply +

2.5 / 12

9 to 40V, 10W consumption.

Polarity inversion protection.

Note:

The "Power supply -" must be wired from the speed governor via

4 mm² wires. See "state of the art" rules wiring diagram.

External 5A / 40VDC fuse recommended.

K3

Power supply -

2.5 / 12

K4

PWM output

2.5 / 12

500Hz PWM output.

Compatible with Caterpillar and Perkins PWM controlled units. 0-

5V protected against short-circuits to 0V. Details in §8.1.2

L1

Bus/Mains I3+

2.5 / 12

Bus/Mains current measurement.

1 to 5A. Maximum rating: 15A during 10s.

1VA consumption.

External current transformer is normally used.

L2

Bus/Mains I3-

2.5 / 12

L3

Bus/Mains I2+

2.5 / 12

L4

Bus/Mains I2-

2.5 / 12

L5

Bus/Mains I1+

2.5 / 12

L6

Bus/Mains I1-

2.5 / 12

A53 Z0 9 0020 I En - Technical documentation.doc 20/182

Terminal

Description

Terminal

capacity

(mm² /

AWG)

Comment

COM1

CAN1 inter GENSYS 2.0

Male DB9

(shielded)

Isolated CAN© bus.

Proprietary protocol to communicate with other GENSYS

2.0/MASTER 2.0 units and share data/information.

Details in §13.2

SHIELD

SHIELD

PIN 1

NC

PIN 2

CAN-L

PIN 3

GROUND-1

PIN 4

NC

PIN 5

GROUND-2

PIN 6

GROUND-1

PIN 7

CAN-H

PIN 8

NC

PIN 9

NC

Figure 3 - COM1 pin out

COM2

CAN2 options

J1939

CANopen

MTU MDEC

Male DB9

(shielded)

Isolated CAN bus (125kb/s factory setting).

See details in §13.3.

Used to communicate with remote I/O (see remote I/O

CANopen© chapter 13.3.1) and J1939 ECU or MTU MDEC

protocol (electronic MDEC engine): details in §13.3.2

SHIELD

SHIELD

PIN 1

NC

PIN 2

CAN-L

PIN 3

GROUND-1

PIN 4

NC

PIN 5

GROUND-2

PIN 6

GROUND-1

PIN 7

CAN-H

PIN 8

NC

PIN 9

NC

Figure 4 - COM2 pin out

COM3

USB

USB

Type B

High Quality

GENSYS 2.0 with firmware v2.00 (or later) :

This port is replaced by Ethernet communication.

GENSYS 2.0 with firmware v1.xx :

Type B standard USB connector. Use a standard USB A to B cable

to connect with PC.

Used for configuration, parameters, file downloading and

uploading. Uses TCP/IP protocol to communicate with modem

emulation.

Not to be used while engine is running.

Isolated. Details in §13.4

Other manuals for GENSYS 2.0

1

Table of contents

Other CRE Technology Control Panel manuals

Popular Control Panel manuals by other brands

ABB

ABB CP420 Installation and operation manual

BFT

BFT ALTAIR-P installation manual

Dahua Technology

Dahua Technology VTH5422HB-W user manual

Mitsubishi Electric

Mitsubishi Electric E1000 series Service and maintenance manual

K-TRON

K-TRON KSU-II/KCM Programming instructions

Beckhoff

Beckhoff CPX29 0000 Series Installation and operating instructions