Fike CIE-A-200 User manual

Engineering and Commissioning Manual

26-0xxx Issue 1

Fire Detection & Alarm System Control Panel

(Suitable for Sita Devices)

SOLUTIONS

Fire Protection

Explosion Protection

Overpressure Protection

Pressure Activation

26-1746 Issue 1

CIE-A-200 Control Panel Engineering and Commissioning Manual

2

Fike’s policy is one of continual improvement and the right to change a specification at any time without notice is reserved. Whilst every care has

been taken to ensure that the contents of this document are correct at time of publication, Fike shall be under no liability whatsoever in respect of

such contents.

Due to the complexity and inherent importance of a life risk type system, training on this equipment is essential and commissioning should only be

carried out by competent persons.

Fike cannot guarantee the operation of any equipment unless all documented instructions are complied with, without variation.

E&OE.

Mulitpoint, Fike and Fike Corporation are registered trademarks of Fike Corporation and its subsidiaries. All other trademarks, trade names or

company names referenced herein are the property of their respective owners.

Fike equipment is protected by one or more of the following patent numbers: GB2426367, GB2370670, EP1158472, PT1035528T, GB2346758,

EP0917121, GB2329056, EP0980056, GB2325018, GB2305284, EP1174835, EP0856828, GB2327752, GB2313690

© 2018 Fike Safety Technology Ltd. All rights reserved. Document revised March 2020

CIE-A-200 Control Panel Engineering and Commissioning Manual

3

Contents

Introduction.................................................................................................................................6

System Design..................................................................................................................................................6

Equipment Guarantee ......................................................................................................................................6

Anti-Static Handling Guidelines........................................................................................................................6

Warning ............................................................................................................................................................6

EMC..................................................................................................................................................................6

The CIE-A-200 System................................................................................................................7

Advantages of Addressable Systems...............................................................................................................7

Control Panel ..............................................................................................................................8

Mounting the Control Panel..............................................................................................................................8

The General Assembly with front door removed..............................................................................................8

Control Panel Disassembly ..............................................................................................................................9

Physical Dimensions ........................................................................................................................................9

Cabinet Installation.........................................................................................................................................10

Surface Mounting ..............................................................................................................................10

Flush Mounting..................................................................................................................................10

Cable Entry........................................................................................................................................11

Mounting Data ...................................................................................................................................11

Control Panel Assembly....................................................................................................................11

Addressable Circuit Wiring......................................................................................................12

Topology & Cabling ........................................................................................................................................12

Cable Specification.........................................................................................................................................12

Loop Loading..................................................................................................................................................13

General System Schematic............................................................................................................................14

Control Panel Main PCB - Control & Indicating Equipment (CIE)..................................................................15

Panel Backplane Layout.................................................................................................................................16

Peripheral Bus (PB_1 & PB_2)..........................................................................................................17

Monitored Inputs (MON_IN_1 & 2)....................................................................................................18

Relay Outputs 1, 2 & Fault Relay Volt Free Contacts: NO, NC, COM..............................................20

Addressable Loop: END1+, END1-, SCRN, END2+, END2-, SCRN................................................21

Auxiliary Power: 30V, 0V, SCRN......................................................................................................22

32V Power Input................................................................................................................................23

CIE door USB Port: User_USB .........................................................................................................24

Back Board ENG LOOP USB Port....................................................................................................24

Mains Supply & Batteries ..................................................................................................................25

Fuses 1 and In Line Battery Fuse .....................................................................................................26

Battery Temperature Probe...............................................................................................................27

CIE-A-200 Control Panel Engineering and Commissioning Manual

4

General Operation of Control Panel........................................................................................28

Control Panel Front........................................................................................................................................ 28

LED Indication................................................................................................................................................ 29

Fire Alarm Controls........................................................................................................................................ 30

System Controls............................................................................................................................................. 31

User .................................................................................................................................................. 31

Supervisor......................................................................................................................................... 31

Engineer............................................................................................................................................ 31

Access Levels and Codes ................................................................................................................ 32

Access Level 0 (Normal): Controls Enabled LED off........................................................................ 32

Access Level 1 (User): Controls Enabled LED on............................................................................ 33

Access Level 2 (Supervisor): Controls Enabled LED flashing slowly............................................... 34

Access Level 3 (Engineer): Controls Enabled LED flashing quickly ................................................ 40

Alarm Confirmation Technology .............................................................................................45

Alarm Confirmation Delay.............................................................................................................................. 46

Selecting the Devices .................................................................................................................................... 46

Commissioning.........................................................................................................................47

Installation 1st Stage ...................................................................................................................................... 47

Installation 2nd Stage...................................................................................................................................... 47

Initialisation.................................................................................................................................................... 47

Commissioning .............................................................................................................................................. 48

Configuration Example .................................................................................................................................. 49

End User Training.....................................................................................................................49

Good Practice ...........................................................................................................................50

Number of Devices ........................................................................................................................................ 50

Label the Loop Ends...................................................................................................................................... 50

Note the Loop Readings................................................................................................................................ 50

Configuration Printout and Drawings............................................................................................................. 51

Initialisation...............................................................................................................................52

Normal Readings........................................................................................................................................... 52

Initialisation Process...................................................................................................................................... 52

Initialisation Faults ......................................................................................................................................... 54

Earth Faults.................................................................................................................................................... 56

General............................................................................................................................................. 56

General Fault Finding...............................................................................................................57

Common Faults.............................................................................................................................................. 57

Intermittent and Recurring Faults .................................................................................................................. 58

IMPORTANT NOTE....................................................................................................................................... 59

Advanced Connections............................................................................................................60

Monitored Relays........................................................................................................................................... 60

CIE-A-200 Control Panel Engineering and Commissioning Manual

5

Technical Data ..........................................................................................................................61

Control Panel..................................................................................................................................................61

Control Panel Fuses and Protection...............................................................................................................62

Resistor Colour Codes ...................................................................................................................................62

Battery Calculations.................................................................................................................62

Installation Checklist................................................................................................................63

Stage 1 ...........................................................................................................................................................63

Stage 2 ...........................................................................................................................................................63

Commissioning Checklist........................................................................................................64

Step 1 .............................................................................................................................................................64

Step 2 .............................................................................................................................................................64

Step 3 .............................................................................................................................................................64

Step 4 .............................................................................................................................................................64

Loop Continuity and Insulation Test Results.........................................................................65

FIRE ALARM SYSTEM NOTICE ...................................................................................................................66

To Enable the Control Panel Keypad.............................................................................................................66

To Manually Operate the Fire Alarm Sounders..............................................................................................66

Following a Detector or Manual Call Point Operation ....................................................................................66

Following a Fault Condition............................................................................................................................66

To Test the Indication LEDs...........................................................................................................................66

To Disable the Control Panel Keypad ............................................................................................................66

Important Notes..............................................................................................................................................66

Device Details.................................................................................................................................................68

Engineers Notes........................................................................................................................69

Index ..........................................................................................................................................72

Important Points .......................................................................................................................72

CIE-A-200 Control Panel Engineering and Commissioning Manual

6

Introduction

This Manual is intended as a guide to the engineering and commissioning principles of the CIE-A-200

Addressable Intelligent Fire Alarm and Detection system, and covers the system hardware information only.

Due to the complexity and inherent importance of a system covering a ‘Life Protection Risk’, training on this

equipment is essential, and commissioning should only be carried out by competent and approved persons.

For further details of the availability of commissioning services contact your supplier.

System Design

This document does not cover Fire Alarm system design, and a basic understanding is assumed.

Knowledge of the current BS5839: Pt 1 Fire Detection and Alarm Systems for Buildings is

essential.

It is strongly recommended that a suitably qualified and competent person is consulted in

connection with the Fire Alarm System design and that the entire system is commissioned in

accordance with the current national standards and specifications.

Equipment Guarantee

The equipment carries no warranty unless the system is installed, commissioned and serviced

in accordance with this manual and the relevant standards by a suitably qualified and competent

person or organisation.

Anti-Static Handling Guidelines

Immediately prior to handling any PCBs or other static sensitive devices, it is essential to ensure

that a personal connection to earth is made with an anti-static wrist-strap or similar

apparatus.

Always handle PCBs by their sides and avoid touching any components. PCBs should also be

stored in a clean dry place, which is free from vibration, dust and excessive heat, and protected

from mechanical damage.

Warning

Do not attempt to install this equipment until you have fully read and understood this

manual.

Failure to do so may result in damage to the equipment and could invalidate the warranty.

Technical support will not be available if the instruction manual has not been read and

understood. Please have this instruction manual available whenever you call for technical

support.

For further technical support please contact your distributor. Do not call the Fike Safety

Technology support department unless your distributor has first given their advice and attempted

to rectify the issue.

EMC This equipment when installed is subject to the EMC Directive 2014/30/EU. It is also subject to

UK Statutory Instrument 2006 No. 3418.

To maintain EMC compliance this system must be installed as defined within this manual. Any

deviation from this renders the installer liable for any EMC problems that may occur either to the

equipment or to any other equipment affected by the installation.

!

!

!

!

!

CIE-A-200 Control Panel Engineering and Commissioning Manual

7

The CIE-A-200 System

The CIE-A-200 system is an addressable intelligent detector system, with many advantages over traditional

addressable analogue sensor systems. In order to understand the benefits, let us look more closely at the

terms Fire Detector and Fire Sensor. These terms are often used interchangeably but actually have quite

different meanings. A fire detector is the device (component as defined in EN54) which automatically detects

a fire. In the majority of addressable fire detection systems, the fire devices are in fact fire sensors which only

transfer data relating to smoke and heat levels to the control panel, and the fire decision is made by the panel.

Nearly all current addressable systems are Addressable Analogue Detector Systems where the control

panel continually scans the fire sensors, processes the returned data, and makes decisions about fires and

faults.

The CIE-A-200 system is defined as an Addressable Intelligent Detector System or an Addressable Fire

Detection and Alarm System with Independent Distributed Intelligence. Distributed intelligence signifies

that the signal processing is spread throughout the system, in order that the decisions about fires and faults

are taken within the detector itself. The detector is capable of being remotely programmed for different modes

of detection.

Thus the CIE-A-200 system is an analogue addressable system, but with the processing power distributed

across the entire system. This dramatically reduces the complexity of the control panel and the data traffic,

and improves the efficiency of the system.

The system addressing is carried out automatically upon initialisation from the control panel, and does not

need to be programmed manually at each device.

Each device has a built in isolator. When the loop is initialising the panel addresses each device on the loop

starting with the first device connected to Loop End 1, when the first device has been addressed it will close

its isolator and allow the second device to be addressed. This process will carry on and finish with the last

device connected to Loop End 2. When the last device is addressed and closes its isolator power is applied

to Loop End 2, the panel detects this and reports Loop Complete.

The panel will then check for addressable spurs on each device. Addressable spurs are no longer used; this

operation is only to allow for backward compatibility where this panel may be used to replace an old system

which is using addressable spurs.

Advantages of Addressable Systems

The nature of a microprocessor control system with individually identified devices means that the precise

location of fires and faults may be indicated, more complex actions may be implemented, system flexibility is

improved and installation and cabling costs are reduced.

In the CIE-A-200 system, very efficient communications mean that very low quiescent power consumption

maximises the standby capacity, high power transfer capabilities allow more sounders to be connected to the

loop, and a very fast response to events is achieved as the control panel does not have to poll every device

for status data.

CIE-A-200 Control Panel Engineering and Commissioning Manual

8

Control Panel

Mounting the Control Panel

First, identify the proposed location for the control panel. Ensure that the control panel will be easily

accessible, and that account is taken of any subsequent work that may affect access. It should be located at

the most likely point of access for the fire services.

The control panel should be mounted on a flat, vertical wall at a height where the indicators may be seen

without difficulty.

Do not locate the control panel at high level where stepladders or other access equipment may be

required, in spaces with restricted access, or in a position that may require access panels to be

removed.

Do not locate the control panel where extremes of temperature or humidity may occur, or where there

is any possibility of condensation or water ingress.

Like all electronic equipment, the control panel may be affected by extreme environmental conditions. The

position selected for its installation should therefore be clean and dry, not subjected to high levels of vibration

or shock and at least 2 metres away from any pager or radio transmitting equipment. Ambient temperatures

should be within the range given within the Technical Data section, i.e. not directly over a radiator or heater

or in direct sunlight.

In common with all microprocessor-controlled panels, the control panel may operate erratically or may be

damaged if subjected to lightning induced transients. Proper earth/ground connections will greatly reduce

susceptibility to this problem.

The General Assembly with front door removed

CIE-A-200 Control Panel Engineering and Commissioning Manual

9

Control Panel Disassembly

The backboard assembly is attached to the panel back box by two brackets on the bottom of the assembly,

the two brackets hook into the back box. There is a single captive knurled screw in the centre at the top of

the assembly which holds it in.

Disconnect the ribbon cable that goes to the CIE board, unplug all cables and disconnect the earth strap.

Unscrew the single knurled screw in the centre at the top of the assembly, tip the assembly forward and lift it

out from the two lower brackets.

If it is necessary to remove the door that houses the CIE in order to replace the CIE, the door must be opened

to its full extent and the ribbon cable unplugged from the main backplane.

Then the two hinge screws must be removed. The door can then be completely removed.

Physical Dimensions

CIE-A-200 Control Panel Engineering and Commissioning Manual

10

Cabinet Installation

Surface Mounting

The three mounting holes should be used to secure the cabinet to a solid wall using suitable screws of at

least 50mm in length. Ensure that a minimum gap of 50mm is left between the sides of the back box and any

wall or projection (such as another box).

Flush Mounting

A cradle, part number 23-0239 (sold separately) must be used when flush mounting the panel. The flush

mounting hole size is 354mm wide x 334mm high.

When flush mounted the panel will sit at a depth of 83mm into cavity and have 36mm protruding from surface.

SURFACE MOUNT FIXING HOLES

SURFACE MOUNT FIXING HOLES

CIE-A-200 Control Panel Engineering and Commissioning Manual

11

Cable Entry

The cable entry locations are provided by two rows of knockouts at the top, six on the back and one on the

bottom.

The bottom knockout should be used if the 12Ah battery box is used.

The rear bottom half of the panel must be kept clear for mounting the 7Ah internal batteries.

It is recommended that fire rated cable glands are used to ensure that the characteristics of the enclosure

can be maintained adequately.

Mounting Data

Panel Dimensions: Width x Height 353mm x 333mm

Depth 117mm

Flush Mount Hole Size: Width x Height (with cradle) 354mm x 334mm

Depth 83mm

Control Panel Assembly

The backboard assembly is attached to the panel back box by two brackets on the bottom of the assembly,

the two brackets hook into the back box. There is a single captive knurled screw in the centre at the top of

the assembly which holds it in.

To fit the backboard assembly, tip the assembly forward and hook the two lower brackets into the back box

then bring the assembly upright and then secure it with the knurled screw.

To refit the front door which houses the panel controls, line up the top & bottom threaded holes in the left

hand side of the door with the hinge bracket on the back box and fit the two hinge screws.

Connect the ribbon cable to the back board and CIE.

CIE-A-200 Control Panel Engineering and Commissioning Manual

12

Addressable Circuit Wiring

Topology & Cabling

All system wiring should be installed to comply with the current BS 5839: Pt 1 and BS 7671 (wiring regulations)

and any other standards relevant to the area or type of installation. A cable complying with the current BS

5839: Pt 1: Category 1 (cables required to operate for prolonged periods during fire conditions) is required.

This must be a 2-core 1.5mm2screened fire resistant cable (ie.FP200, Firetuff, Firecell, Lifeline or equivalent).

Cable Specification

Max Capacitance Core to Screen...................................................180pF / m

Max Capacitance Core to Core.......................................................100pF / m

Max Inductance...............................................................................1.0mH / km

Max Resistance Two Core Screened 1.5mm²................................12.1Ω / km

Fire Proof ........................................................................................BS5839: Pt1: Category 1

Example..........................................................................................FP200, Firetuff, Firecell

The addressable circuit must be installed as a loop with a maximum length of up to 2 km.

Spur circuits are NOT permitted with this system.

In order to protect against possible data corruption, it is important ensure the following points are adhered to:

1. The addressable circuit cable screen must be connected to the loop SCRN terminal at the

control panel. Both ends must be connected using the terminals provided.

2. The addressable circuit cable screen must not be connected to earth/ground at any point other

than the control panel (at the SCRN terminal provided, not at any earthing point). Do not connect

the screen to a device back box (flush).

3. The addressable circuit cable screen continuity must be maintained at every point of the loop,

using the terminals provided or a suitable connection block.

4. Do not use a 4-core cable as a loop feed & return due to the possibility of data corruption. It is

essential that two 2-core cables are used if this is required.

5. Excess cable lengths must not be coiled as coiling will increase the inductance and cause

communication problems.

6. Fire alarm addressable circuit cabling must be separated from other building system cables by

at least 300mm and not run within 500mm of any mains power cables.

7. Avoid running fire alarm addressable circuit cables in parallel with mains power or any other

building system cables. Where a cross-over between fire alarm addressable circuit cables and

mains power or other building system cables is unavoidable, the cables should be arranged to

cross at right angles with as much separation as possible.

8. Fire alarm cabling should not be run in any cable management system such as trunking, conduit

or on cable trays that are being used by mains power or other building system cables.

CIE-A-200 Control Panel Engineering and Commissioning Manual

13

Loop Loading

In order to allow a method of calculating the maximum loop loading that the system will support, each device

has a rating assigned in Device Loading Units (DLUs). This relates to the load presented in alarm. A maximum

of 450 DLUs are permissible on each loop (subject also to a maximum of 200 addressable devices, whichever

limit is reached first).

The DLUs of the current models of devices as at October 2018 are as follows:

PRODUCT DESCRIPTION

DLU RATING

Type

Product

Code

Subtype

SP0-Off

Low

Medium

High

MP

203 0003

Multipoint Mk3

1

-

-

-

205 0003

ASD Mk3

1

-

-

-

MPS

203 0001

Multipoint with Sounder Mk3

1

1.5

4.5

6

205 0001

ASD with Sounder Mk3

1

1.5

4.5

6

205 0012

ASD with Sounder/Strobe Mk3

4.5

5

8

10

MCP

403 0006

403 0007

Manual Call Point Mk3

3

-

-

-

SOUNDER

313 0001

313 0002

Soundpoint Mk3

1.5

2

4

5.5

323 0001

Hipoint Mk3

1.5

2

4

5.5

303 0012

303 0022

Flashpoint

1.5

4.5

6.5

8

326 0021

326 0023

Sounder/Strobe

9

9.5

11.5

13

326 0001

326 0003

Sounder

1.5

2

4

5.5

326 0015

Strobe

9

-

-

-

I/O

803 0006

Loop I/O Module Mk2

10.5

-

-

-

CZM

803 0010

Conventional Zone Module

(Loop Powered)

23.5

-

-

-

803 0010

Conventional Zone Module

(Ext PSU)

3.5

-

-

-

ANCILLARY

803 0003

803 0005

Multipoint I/O Module (in Relay

Base)

Multipoint I/O Module (in Box)

3

-

-

-

600 0092

Remote Indicator

0.5

-

-

-

The CIE-A-200 OSP programming software v1.00 automatically keeps control of the quantities and DLU

ratings of devices on the loop and will warn the engineer if the limit is reached. It will not allow a system to be

programmed to exceed the maximum DLU rating.

It can detect the type of the device and, in the case of devices manufactured from March 2010, the subtype

from the above list as well. For devices manufactured prior to this date, the CIE-A-200 OSP will attempt to

detect the subtype and use the appropriate DLUs. The engineer can override the automatically detected

subtype if required i.e. if the OSP cannot correctly identify an older device, the engineer can tell the system

that the device is a different subtype to the one OSP has selected (e.g. a Soundpoint instead of Flashpoint)

within the same main type. The OSP can also work out the standby battery calculations.

Note: An Excel spreadsheet (document no. 26-1765) is also available to automatically work out both

standby battery calculations and loop loading calculations based on the quantities entered. This

includes ratings for legacy devices as the above current models.

CIE-A-200 Control Panel Engineering and Commissioning Manual

14

General System Schematic

Sita Multipoint / ASD Sita MP I/O

Sita MCP Remote Indicator

Sita Loop I/O Module

SINGLE LOOP

CONTROL

PANEL

Loop End 2

Loop End 1

CIE-A-200 Control Panel Engineering and Commissioning Manual

15

Control Panel Main PCB - Control & Indicating Equipment (CIE)

The Control Panel PCB is located on the inside of the front inner door.

USB for OSP Programming

The USB for OSP Programming is used to connect a computer to the CIE. CIE-A-200 OSP and a USB-A to

USB-B lead is required in order to program the CIE via a computer. Please note that an Earth Fault may be

present when a computer is connected. This fault will clear when the USB cable is removed.

LCD Contrast

The LCD contrast may be adjusted by rotating the screw on the variable resistor located near the centre of

the main PCB. This is set at the factory but can be adjusted if required.

CIE-A-200 Control Panel Engineering and Commissioning Manual

16

Control Panel Backplane & Terminals

The Termination PCB (also known as the backplane) is located at the rear of the main control panel back

box.

Panel Backplane Layout

The connections on the top from left to right:

PB_1 Peripheral bus 1 for repeater connection

PB_2 Not yet implemented

MON_IN_1 Monitored input 1

MON_IN_2 Monitored input 2

MON_OUT_1 Monitored output 1

MON_OUT_2 Monitored output 2

RELAY_1 Default setting - Fire output 1

RELAY_2 Default setting - Fire output 2

FAULT_RELAY Default setting - Fault output general panel fault notification

END_1 Loop end 1

END_2 Loop end 2

AUX_OUT Auxiliary power output, 30V DC 450mA

32V_INPUT Main power input from PSU

The connections on the bottom from left to right:

ENGR_LOOP_USB Factory use only

BATT Battery connection

CIE-A-200 Control Panel Engineering and Commissioning Manual

17

Peripheral Bus (PB_1 & PB_2)

Communications between the panel and repeater is via a multi-drop RS-485 Peripheral Bus.

2-core 1.5mm2screened fire resistant cable (i.e. FP200, Firetuff, Firecell) cable should be used for

communications to the repeater.

The maximum total cable length from the control panel to a repeater is 500 metres.

Up to 8 repeaters can be used but they must all be within the maximum 500 metres cable length and are

wired + to +, - to -, the screen must be connected to the control panel at one end only using the terminals

provided. Terminate the unused end in a connector block as shown below and so on up to the maximum of

8 repeaters.

The peripheral bus must be run from the panel to the first repeater then the second repeater and so on; the

peripheral bus must not be spurred from one point.

The jumpers are fitted to impedance match the cable with the driver ICs & prevent signal reflections down

the cable. The jumpers must be changed on the CIE and last RDU.

Terminal

Description

+

Connects to the + connection on the repeaters

-

Connects to the - connection on the repeaters

SCRN

Field cable screen connection

PB 2 is not currently used and is for future development.

CIE-A-200 Control Panel Engineering and Commissioning Manual

18

Monitored Inputs (MON_IN_1 & 2)

Monitored input set as a normally open input

Maximum Voltage at contacts, 3.3 Volts. Maximum current 10mA.

Monitored Inputs 1 & 2 will monitor for open and short circuit faults using a 3k3 EOL resistor. To activate the

input, connect a 680R or 470R ‘triggering’ resistor across + & -.

Terminal

Description

+

Monitored Input positive connection

-

Monitored Input 0V connection

SCRN

Field cable screen connection

CIE-A-200 Control Panel Engineering and Commissioning Manual

19

Monitored Outputs (MON_OUT_1 & 2)

Outputs 1 and 2 are monitored circuits which are monitored for open and short circuit faults with a 10k EOL

resistor. Sounders used on monitored outputs must be 24v conventional type sounders.

Any relays must be dioded for polarisation and suppression. Diodes are usually incorporated in fire

relays but if they are not incorporated use diodes part number 1N4002.

The diagram below shows the diode arrangement required if non-dioded relays are used on monitored

outputs.

The default setting for monitored output 1 is a Monitored Sounder Output and the default setting for

monitored output 2 is a Common Fire Output.

The maximum continuous output current for each output is 500mA.

Monitored Outputs can be set as follows: Not Configured

Fire Output

Sounder Output

Sounder Output Cadence

Common Fault

Terminal

Description

+

Monitored Output positive connection

-

Monitored Output 0V connection

SCRN

Field cable screen connection

CIE-A-200 Control Panel Engineering and Commissioning Manual

20

Relay Outputs 1, 2 & Fault Relay Volt Free Contacts: NO, NC, COM

Relays 1, 2 and the Fault Relay are derived from single pole change over ‘volt-free’ relay contacts which are

not fault monitored. The relay contacts are rated at 1A @ 30VDC. All inductive loads should be diode

protected to prevent back EMF. However, if this is not done, the load should be limited to 200mA to reduce

the likelihood of back EMF causing damage to the relay contacts.

The default setting for Relay Outputs 1 & 2 is as Common Fire outputs where the relay is energised in the

fire condition.

Relays 1 & 2 can be set as follows: Not Configured

Fire Output (Common)

Fire Output (Zonal)

Common Fault

The Fault Relay cannot be configured and will always operate as a Common Fault output where the relay is

de-energised in the fault condition.

In order to meet the requirements of EN54-2, one relay must be left as a fire output.

Terminal

Description

NO

Normally open contact

NC

Normally closed contact

COM

Common contact

Other manuals for CIE-A-200

2

Table of contents

Other Fike Control Panel manuals

Fike

Fike FCP-2100ECS User manual

Fike

Fike TWINFLEXpro User manual

Fike

Fike FCP-75 User manual

Fike

Fike Quadnet User manual

Fike

Fike FIK-RA2000 Technical manual

Fike

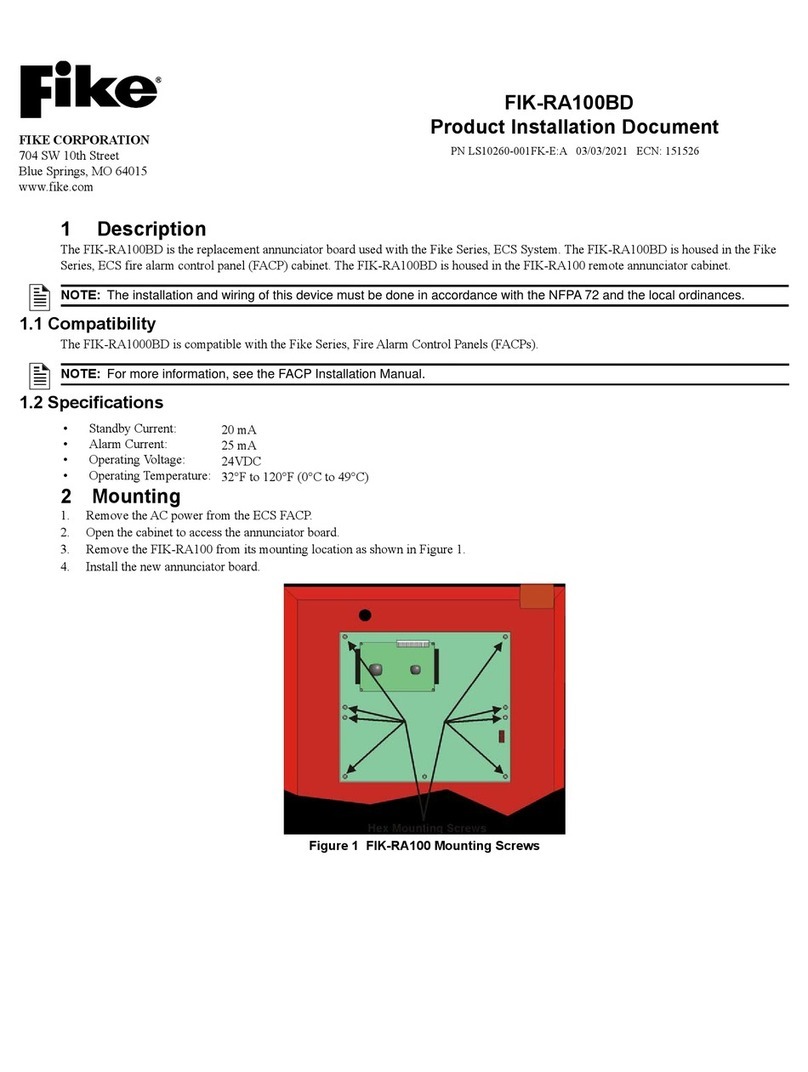

Fike FIK-RA100BD Technical manual

Fike

Fike FCP-75 User manual

Fike

Fike FCP-300 User manual

Fike

Fike FCP-2100 User manual

Fike

Fike TWINFLEXpro User manual

Popular Control Panel manuals by other brands

ZKaccess

ZKaccess Inbio460 installation guide

Potter

Potter PFC-6075 Installation, operation, & programming manual

Bosch

Bosch DS7200V2-EXP installation guide

Eaton

Eaton XV-112 operating instructions

Vivo

Vivo STAND-E-102B instruction manual

Johnson Controls

Johnson Controls FRICK QUANTUM LX/HD installation instructions