Cristofoli Autoclave Quadra 54 User manual

Autoclave Quadra 54

Cristófoli, Brazilian company importer and manufacturer of health products

certified by ISO 9001 - Quality Management System, ISO 13485 - Medical

Devices - Quality Management System - Requirements for Regulatory

Purposes, ISO 14001 - Environmental Management and *BPF - Boas

Práticas de Fabricação - ANVISA.

CRISTÓFOLI’S MISSION

CRISTÓFOLI QUALITY AND ENVIRONMENTAL POLICY

Cristófoli Equipamentos de Biossegurança Ltda., established at Rodovia BR-158, nº 127, Jardim Curitiba in Campo

Mourão, Paraná, Brasil, manufactures biosafety equipment to assist the health field having as policy: “Develop innovative

solutions for the health field by using agile, robust and objective processes to better serve its clients. Fulfill the requirements

for regulatory purposes of the applicable standards, promote the continuous improvement of its quality and environmental

systems, prevent pollution, reduce its environmental impacts and continuous training of its employees, achieving this way, a

sustainable profitability and the maximization of the company’s value”. Rev. 2.

Develop innovative solutions to protect life and promote health.

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

O

I

S

*BPF - Boas Práticas de Fabricação: Brazilian standard similar to the GMP - Good Manufacturing Practices (FDA / US).

“Cristófoli. Valuing Life!”

2

Thanks for choosing us. You, our clients, are the reason of Cristófoli’s commitment.

We put together this manual to guide you as best as possible, in the use and maintenance of your Cristófoli Autoclave.

We would like to thank all our customers, partners and employees for helping us to continually improve and innovate our

products and services. Special thanks to Liliana J.P. Donatelli, Cristófoli’s Biosafety Consultant who provides a valuable

assistance in the coordination of Cristófoli’s Biosafety Project; complementary products research; training of our

employees, representatives and technicians; and as a lecturer of Biosafety Courses for professionals, academics and

assistants.

For any commentaries or suggestions about our products, please get in touch with our CSD - Customer Service

Department, through the address below.

Docs/Layouts Informativos/Manual Quadra 54/Quadra 54 Ing. Rev.1-2015

Cristófoli Equipamentos de Biossegurança Ltda.

Rodovia BR-158, nº127, Campo Mourão, Paraná - Brasil.

CEP 87309-650

E-mail: cac@cristofoli.com

CSD - CUSTOMER SERVICE DEPARTMENT

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

3

Legend of Symbols ......................................................................................................................................

Introduction .................................................................................................................................................

Date and Time Setting .................................................................................................................................

Important Safety Information .......................................................................................................................

Installation Instructions ..................................................................................................................................

Autoclave Components Identification .........................................................................................................

Safety Devices .............................................................................................................................................

Cycles and Messages .................................................................................................................................

Safety Notes .................................................................................................................................................

How to Use the Autoclave Quadra 54 .........................................................................................................

Quality Control .............................................................................................................................................

Adverse Situations ........................................................................................................................................

How to Identify your Autoclave ....................................................................................................................

Time x Pressure Graphs ................................................................................................................................

Technical Data ............................................................................................................................................

Preventive Maintenance ..............................................................................................................................

Preventive Maintenance Table ....................................................................................................................

Troubleshooting ............................................................................................................................................

How to Proceed When Service is Needed ...................................................................................................

Guidance for Final Disposal of the Equipment ............................................................................................

Warranty Terms .............................................................................................................................................

INDEX

04

05

06

07

08

10

12

13

14

14

16

17

18

18

19

20

21

22

24

24

25

PLEASE, READ ALL THE INSTRUCTIONS IN THIS MANUAL BEFORE USING YOUR

AUTOCLAVE, INCORRECT USE MAY RESULT IN STERILIZATION FAILURE AND/OR ACCIDENTS!

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

4

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

Tinta

com propriedade

antimicrobiana.

~

This side up

Maximum

pile

Caution! Consult

accompanying

documents

Manufacturer

Alternate Current

Grounding

Protection Terminal

Fusible

Autoclavable

Date of

manufacture

*Boas Práticas

de Fabricação

4

P

BF

LOT

SN

Fragile - Handle

with care

Dangerous

Electrical Tension

Serial Number

Batch code

Keep away from

sunlight

Recyclable

Keep dry

ISO 13485

ISO 14001

ISO 9001

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

O

I

S

Class ll

Equipment

Antimicrobial

Painting

135 ºC

*BPF: Brazilian standard similar to the GMP - Good Manufacturing Practices (FDA / US)

LEGEND OF SYMBOLS

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

This equipment was developed to assist you in the procedure of steam sterilization of articles/instruments by using steam

under pressure. . We hope in this way to We have intensively dedicated ourselves in order to guarantee your total safety

obtain your full satisfaction.

The purpose of this manual is to familiarize you with the features and proper operation of your autoclave so you know

how to take good care of it, obtain the best results in sterilization and drying, as well as increase the equipment's life span.

For those who have used only the dry heat sterilizer (Pasteur’s oven) for sterilization, we recommend extra attention to this

manual. Autoclave sterilization, although quicker and more efficient, requires totally different procedures and handling,

while still keeping a simple operation.

It is important to know some aspects that can jeopardize this warranty as a result of negligence, improper use,

unauthorized repairs, etc.

The Warranty Terms can be found on page 25.

1 autoclave - 1 power cable - 1 tray holder - 4 trays - 1 clamp - 1 heating element protector - 1 flash drive Box contents:

memory - 1 hose (1,5 m) and 1 instruction manual.

MANUFACTURER

Cristófoli Equipamentos de Biossegurança Ltda.

Rod. BR 158, nº127 - Campo Mourão - PR - Brasil

CEP 87309-650

CNPJ 01.177.248/0001-95 - Inscr. Est. 90104860-65

Website: www.cristofoli.com - e-mail: [email protected]

Responsible Technician

Eder William Costa Camacho

CREA/PR – 87826/D

INTRODUCTION

5

6

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

Whenever the autoclave is unplugged and reconnected, the system will prompt you to set the date and time by

showing the message DATE/TIME? on the display. SET

Setting procedure:

1. To set, press START. Note: To skip this step, press CANCEL, the data will not be set and the standard values will be

applied (January 1st, 2009, 12 am).

2. The display will show next INSERT DATE and the standard date (JAN/01/2009). The piece of information to be set will be

flashing.

3.Press MODE or CANCEL to set the data.

4. Press START quickly to alternate the target information (day, month and year) and keep it pressed until you hear the

confirmation beep of the data you have entered.

5. Next, the display will show INSERT TIME and the standard time (12:00 am). Again, the piece of information to be set will

be flashing.

6. Press MODE or CANCEL to set the data. Note: The am/pm mode cannot be set directly.

7. Press START quickly to alternate between hours and minutes and keep it pressed until you hear the confirmation beep

of the data you have entered.

DATE AND TIME SETTING

7

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

WARNINGS!

Before sterilizing any articles, make sure you first check with their manufacturer if they are autoclavable (resistant to

the temperature of 135ºC and the presence of steam and pressure);

Do not allow patients or especially children to get close to the autoclave;

Install the autoclave in an exclusive sterilization room;

Never warm up or sterilize any kind of food in the autoclave;

Never make any kind of experiment with animals in the autoclave;

Never make any kind of use of this equipment other than the ones described in this manual.

ATTENTION DURING THE INSTALLATION:

Use only the heat resistant hose supplied with your autoclave for water supplying. For external steam exit, use a heat

resistant hose according to the sample provided. Never use a plastic hose on the external steam exit, as the

autoclave reaches temperatures higher than those supported by this material. See “Installation Instructions” topic

“Hydraulic Installation” (Page 9).

SPECIAL MEASURES AND OBSERVATIONS DURING THE USE OF THE AUTOCLAVE:

Always make sure the door handle is properly locked before switching the autoclave on Not following this .

procedure may prevent the autoclave start the cycle, the display will show the message: CLOSE THE DOOR!. See

“How to Use the Autoclave Quadra 54 ”, (Item b, page 14).

When sterilizing simultaneously instruments that have different autoclaving specifications, as instruments that support

2

different levels of pressure (1.2 or 2.1 kgf/cm ) or temperature (121 or 135ºC) the operator must choose the cycle of

lower temperature/pressure offered by autoclave.

When unlocking the handle, the autoclave door should open easily. Never force the door to open the autoclave!

When the door is opened at the end of the cycle to accelerate the cooling process, it is normal that some steam

comes out through the door.

IMPORTANT! Always make sure you have unplugged your autoclave before performing any kind of maintenance,

(even if it’s just an everyday cleaning).

We recommend reading this manual until it is fully understood. Keep it at hand and use it as a constant reference

source.

ATTENTION! TO OPEN THE AUTOCLAVE

1 - Press the door forward; 2 - Slide the handle upwards.

IMPORTANT SAFETY INFORMATION

Quadra 54 . Before using your autoclave it is necessary to observe some safety measures Autoclaves are equipment

which work at high temperature and pressure, therefore they must be handled by qualified and well-informed personnel,

regarding their features and functioning It is essential for such qualification that the operators read all the instructions .

carefully before using the autoclave to make sure to understand them correctly The intended use of this equipment is to .

perform sterilization on dental, medical and hospital instruments/articles resistant to the temperature of 135ºC, steam and

pressure.

8

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

Table 1

The electrical installation must follow the data from table below.

Quadra 54 - 220 V

8,2 A 220 V AC » 198 V - 242 V

For distance up to 5 m (16 ft) from the

circuit breaker to the outlet used to

connect the equipment, use 2,5 mm wiring.

From 5 to 15 m (16 to 46 ft) use 4 mm,

and from 15 to 50 m (46 to 164 ft) 6 mm.

1 Breaker15 A.

MODEL NOMINAL

CURRENT WIRING GAUGECIRCUIT BREAKER VOLTAGE

INSTALLATION INSTRUCTIONS

ELECTRICAL INSTALLATION

ou are going to install it. To do that, simply Check if the voltage of the autoclave is the same of the place where y

look at the identification label in the back of the autoclave. See “How to Identify your Autoclave” (Fig. 14, page 18).

For the installation use a grounded, three-pin outlet (2P + G, 20A) connecting phase/neutral or phase/phase on the

side pins and grounding on the central pin (Fig. 2, page 9). Never connect grounding to neutral.

ATTENTION! As in any other electrical device, grounding is very important for the safety of the operator and the warranty

of your equipment. Therefore, never remove or cut the plug’s central (grounding) pin off. Non-compliance with this

requirement may damage your autoclave. Cristófoli is not responsible for damages caused by inadequate

installations and/or voltage.

Never use extensions, voltage transformers or any kind of adapters (Fig. 3, page 9).

For the proper functioning of your autoclave, the electrical voltage must be stable, in other words, without

oscillations Consult a professional electrician to check the electrical wiring in your building/workplace and make .

sure they are according to the specifications required It is mandatory the use of an exclusive circuit breaker for .

the outlet where you intend to install your autoclave. If after following all the specifications, the electrical current is

still oscillating, contact your local electricity company for repairs.

The equipment must be always carried by three or four people to prevent it from falling or causing an accident. The

storage/installation must be done in a place protected from the weather action (indoors) in normal temperature conditions

on a counter that can bear the weight of the autoclave.

Although simple, the installation of the Autoclave Cristófoli Quadra 54 must be performed by an authorized Cristófoli’s

technician, who will check whether the wiring and voltage of your building are in accordance with the required

specifications in this manual, failure to observe this recommendation will cause immediate warranty cancellation. In

order to have your equipment installed, please contact your local dealer. See also “Warrant Terms” (Page 25) and “How to

Proceed When Service is Needed” (Page 24).

PHYSICAL INSTALLATION

Install the autoclave on a flat, leveled and firm surface at a proper height for the operator to handle it

(approximately 80 cm / 2.6 feet from the ground) (72,5 kg), on a counter that can support the weight of the equipment

as well as its dimensions (54 x 54 x 75 cm - W x H x D). Leave enough room close to the autoclave for the proper

handling of the materials to be sterilized Install the autoclave in a ventilated and clean place, apart from the room .

where the patients are treated. The ideal place for the installation of the autoclave should be a separate sterilization

room Important! Install your autoclave where it can be easily unplugged..

Note: In areas where voltage is 220V:

PP (Phase-Phase) use a “bipolar” breaker

PN (Phase-Neutral) use a “unipolar” breaker connected to Phase.

1

2

4

3

9

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

HYDRAULIC INSTALLATION

IMPORTANT! . For the correct connection of the components, it is essential to read the instruction manual

Connect the (Fig. 1) heat resistant rubber hose (5/16", 300 psi) provided to the external steam exit located in the back

part of the autoclave put the clamp on (also provided and fasten it with a screwdriver The other end must , , Fig. 12, page 11) .

be connected to the plumbing system which (212ºF) or put into an open must tolerate the temperature of at least 100ºC

container located about 40 cm below the level of the autoclave with water inside for steam discharge in this case, the hose ,

must be above the water level with a “V” cut on its end. The gallon used as a reservoir for the distilled water can be placed

next to the autoclave and must be refilled manually by the user whenever the water reaches the minimum level of 1.5 liters

(Fig. 1). .Do not let the water supply hose to touch the bottom of the reservoir! That may jeopardize the water supply

Both hoses must be attached to the lids of the reservoirs, the lids must have 2 flow in and out extra orifices for the air to

easily. The hoses must be inspected yearly for obstructions and general condition.

NOTE: To replace the hose of the external steam exit, make sure the autoclave is cold and unplugged from the electrical

outlet, loosen the clamp, remove the old hose and replace it by the new one, following the same installation procedure

described above.

WARNING! Never use a plastic hose, the heat will melt it causing an obstruction of the external steam exit and possible

damages to the equipment.

Neutral Pin 1

Phase Pin 2

Fig. 3

X

Fig. 1

External Steam Exit

Water inlet

VSPF Valve (internal)

Power Connector

Identification

Label

Power Cable

Circuit Breaker

Power Supply

Buzzer

“V” cut

Hose for the external steam exit.

Keep it attached to the lid

above the water level.

Use a lid with holes so

the steam flows out

Reservoir with water for

steam discharge

Grounding (do not connect

grounding on neutral)

Reservoir for distilled

water supply.

Do not let the hose

touch the bottom!

Never cut or remove

the central pin off

0 1 2 3 4 5 6 7 8 9

0 1 2 3 4 5 6 7 8 9

LOT

SN

01 02 03 04 05 06 2010

07 08 09 10 11 12 2011

220V ~ - 2,8 kW - 8,2A

230V ~ - 2,8 kW - 8,2A

POTÊNCIA / POWER /

POTENCIA

- Europa / Europe

- Brasil/Brazil

REGISTRO ANVISA /

ANVISA REGISTER

10363350011

54 L

CAPACIDADE / CAPACITY / CAPACIDAD

TEMPO MÁXIMO DE AQUECIMENTO /

MAXIMUM HEATING TIME /

TIEMPO MÁXIMO DE CALENTAMIENTO

50 Min.

RESPONSÁVEL TÉCNICO / RESPONSIBLE TECHNICIAN /

RESPONSABLE TÉCNICO

PRESSÃO MÁXIMA /

MAXIMUM PRESSURE /

PRESIÓN MÁXIMA

EDER WILLIAM COSTA CAMACHO - CREA/PR – 87826/D

280 kPa

AÇO INOX /

STAINLESS STEEL

AUTOCLAVE CRISTÓFOLI

QUADRA 54

MODELO / MODEL

CONFORMIDADE / CONFORMITY / CONFORMIDAD

NORMA / STANDARD - NBR 11817

PRODUTO: AUTOCLAVE CRISTÓFOLI PARA ESTERILIZAÇÃO A VAPOR.

PRODUCT: CRISTÓFOLI STEAM STERILIZATION AUTOCLAVE.

PRODUCTO: AUTOCLAVE CRISTÓFOLI PARA ESTERLIZACIÓN POR VAPOR.

INSTRUÇÕES DE USO, PRECAUÇÕES, CONSERVAÇÃO E ARMAZENAMENTO: CONSULTE O MANUAL DE INSTRUÇÕES.

USE INSTRUCTIONS, PRECAUTIONS, CONSERVATION AND STORAGE: SEE INSTRUCTION MANUAL.

INSTRUCCIONES DE USO, PRECAUCIONES, CONSERVACIÓN Y ALMACENAMIENTO : LEA EL MANUAL DE INSTRUCCIONES.

FREQUÊNCIA / FREQUENCY / FRECUENCIA

50/60 Hz

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA

ROD BR 158 Nº 127 - CAMPO MOURÃO - PR - BRASIL

CEP 87309-650 - FONE: 55 44 3518 - 3401

CNPJ 01.177.248/0001-95 - INSCR. EST. 90.104.860-65

INDÚSTRIA BRASILEIRA / MADE IN BRAZIL

5 liters

distilled

water

Fig. 2

A T T E N T I O N !

GROUNDING IS

ESSENTIAL

Table 2

Bipolar plug and wall outlet with grounding

(three-pin or 2P+G) 15 A.

CONNECTION

220 V

220 V NEUTRAL PHASE (220 V)

PHASE (127 V)PHASE (127 V)

PIN 1 PIN 2

5 liters

discharge

10

3

AUTOCLAVE COMPONENTS IDENTIFICATION

2

1CIRCUIT BREAKER - It is located in the back part of the autoclave, its function is to turn it on and off, as well as

protect the equipment and building electrical wiring against peaks of energy or short circuits (Fig. 1, page 9);

WATER RESERVOIR - Plastic container which must be provided by the user (it is not included with the equipment). As a

suggestion, any clean 5-liter plastic gallon may be used, make sure it is suitable for this purpose. The reservoir

supplies the chamber with approximately 1 liter of distilled water before each sterilization cycle (Fig. 1, page 9);

PANEL - It is located in the front part of the autoclave, It’s made with ABS injected plastic, it is where the keyboard

and the display are (Fig. 4);

LID - Located right behind the panel, it is made of stainless steel 304 and it’s responsible for closing the autoclave

chamber (Fig. 8, page 11);

KEYBOARD - Located on the panel, it’s where the controls keys, USB port and the display of the autoclave are (Figs. 4

and 5);

USB PORT* - It is used to transfer the data collected during the operation of the autoclave, as the variations of time,

temperature and pressure to an external device (Fig. 5);

DISPLAY - It is where all the functions/messages of the autoclave are shown, it has two lines with 16 characters each.

It’s located on the keyboard (Fig. 5);

HANDLE - Located in the right side of the autoclave panel (Figs. 8 and 9, page 11). It’s used to open, close and lock

the autoclave door (panel/lid set). To check the correct locking position of the door see Fig. 6 (Page 11);

DOOR GASKET Attached to the door, its function is to seal it with the chamber it also works - (Figs. 7 and 8, page 11),

as a safety device Safety Devices It requires weekly maintenance. See “Preventive . See “ ” (Item 2, page 12).

Maintenance” (Item 4, page 20);

VSPF VALVE - The VSPF valve (patent pending) is one of the devices responsible for relieving the pressure inside the

2

chamber in case it goes beyond 2.7 kgf/cm or eliminate vacuum from the chamber when it is formed (Fig. 1,

page 9);

INTERNAL STEAM EXIT - Orifice located inside the chamber (Fig. 9, page 11) which works as a conduit for the steam

from the chamber to the solenoid valve. It must be inspected daily to be kept free from obstructions;

WATER INLET - Located in the back of the autoclave (Fig. 1, page 9 and Fig. 9, page 11). It is through this connection

that the water reservoir supplies the necessary quantity of water (approximately 1 liter) at the beginning of each

cycle. See “Installation Instructions” topic “Hydraulic Installation” (Page 9);

4

5

6

7

9

8

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

QUADRA 54

Cancela

Cancel

Modo

Mode

Início

Start

Keyboard

Panel

QUADRA 54

Cancela

Cancel

Modo

Mode

Início

Start

Start Key

Display

USB Port

Cancel Key

Mode Key

Fig. 5

Fig. 4

10

11

12

11

14

15

Fig. 9

Fig. 10

Fig. 11

Sterilization

Chamber

Door open

Handle

Water Inlet Orifice

Temperature

Sensor Connection

Internal

Heating Element

Fig. 12

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

Steam Internal Exit

Cover

Base

EXTERNAL STEAM EXIT - Located in the back of the autoclave (Fig. 1, page 9), it has a diameter of 5/16” for the

connection of the discharge hose, which is then connected to the plumbing system or proper container for this

purpose. It releases the cold air in the beginning of the cycle and the steam at the end of it. See “Installation

Instructions” topic “Hydraulic Installation” (Page 9);

SOLENOID VALVES - Internal components of the equipment responsible for the deareration, depressurization and

water supplying. The valves open the beginning of the heating stage eliminating the cold air from the chamber, then

it shuts down to allow pressure build up for the sterilization and opens again at the end of the cycle for the

depressurization of the chamber;

SOLENOID PUMP - Internal device responsible for transporting the water from the reservoir to the chamber during the

automatic water supply;

Fig. 7 Fig. 8

Door gasket

Lid

Handle

Fig. 6

TRAYS HOLDER - It's provided 1 tray holder for 4 trays (Fig. 11);

TRAYS - Provided are 4 trays (Fig. 10), to keep the instruments to be sterilized free from any direct contact with the water

and internal surface of the autoclave chamber;

HEATING ELEMENT - Electrical device responsible for heating the chamber (Fig. 9);

16

17

18

Heating Element Protector

13

12

The autoclaves Quadra 54 have the following safety devices:

TEMPERATURE X PRESSURE DATA CROSSING ELECTRONIC SYSTEM - Internal system of the equipment which will check

the cycle, in case any problem is detected while reading the pressure in the chamber or if it exceeds the safety

limit, the cycle will be cancelled automatically;

2

DOOR GASKET - In case the pressure goes beyond 3 kgf/cm or 294 kPa, the door gasket will detach from the edge

of the door making a loud noise. See “Autoclave Components Identification” (Figs. 7 and 8, page 11);

VSPF* VALVE - Valve that works as an anti-vacuum system (Fig. 1, page 9 - * Patent pending);

CIRCUIT BREAKER - Safety device which purpose is to protect the building electrical wiring against peaks of energy

(Fig. 1, page 9). the breaker used is the 15A/250V as shown on the table below;

SAFETY DEVICES

1

2

3

4

Table 3

HEATING ELEMENT PROTECTOR - Cover made with stainless steel, it’s function is to isolate the heating element from the

contents of the chamber (Fig. 8, page 11);

DISCHARGE RESERVOIR - Plastic container which must be acquired separately (it does not accompany the equipment).

Its function is to store the water discharged during the depressurization in case the depressurization hose is not

connected to the plumbing system (Fig. 1, page 9);

POWER CABLE - Used to connect the equipment to the power outlet (Fig. 1, page 9);

CLAMP - Used to fasten the discharge hose to the external steam exit (Fig. 12, page 11);

BUZZER - Internal device used is to emit the beeps produced by the autoclave (Fig. 1, page 9);

HOSES - It is provided 1 hose (1 m) for the autoclave water supply (Fig. 1, page 9) and 1 hose (1,5 m) to be connected to

the autoclave steam exit;

TEMPERATURE SENSOR CONNECTION - Connection used to measure the chamber internal temperature in case of cycle

validation essays in external certified laboratories;

CHAMBER - Produced in stainless steel, the sterilization chamber is where the instruments/articles to be sterilized are

placed (Fig. 9, page 11);

COVER - It is produced in carbon steel with textured electrostatic painting. The paint used (Nobak) has antimicrobial

properties (Fig. 9, page 11);

BASE - The base of the autoclave (metallic structure) is produced in carbon steel with textured electrostatic painting. The

paint used (Nobak) has antimicrobial properties (Fig. 9, page 11).

19

20

21

22

23

24

25

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

26

27

28

VOLTAJE

BREAKER

220 V 220 V (198 V - 242 V) 15 A (250 V)

AC VOLTAJE LINE

THERMOSTAT - Internal safety device of the equipment. Its function is to limit the excessive heating of the chamber

during the sterilization cycles or in case of a circuit board malfunction;

POWER CONTROL ELECTRONIC SYSTEM - Internal system of the equipment which monitors the temperature and the

pressure of the autoclave throughout the operation;

6

5

13

SAFETY VALVE - The safety valve is one of the devices responsible for relieving the pressure inside the chamber in

case it goes beyond the established limits;

MAINTENANCE MESSAGES - From time to time, the autoclave display will show some specific messages to warn the

user about the preventive maintenance of the equipment and the biological test. See “Preventive Maintenance”

(Item 10, page 20).

7

8

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

. The display represented below also shows We have listed below the various messages displayed by the autoclave

the initial information (brand, model and software version) when the autoclave is turned on. Note: The software version

may be updated at any time without prior notice.

CYCLES AND MESSAGES

WHEN TURNED ON

cristofoli

Quadra 54 v0.0

CYCLE OPTIONS

* By pressing Start while in additional info mode, there will be a submenu with further information/functions of the equipment.

Note: This autoclave allows the software update through a USB flash drive. This procedure must be performed by a Cristófoli Authorized

Technical Assistance Office.

1 - Cycles initiated by the user;

2 - Cycles completed by the autoclave;

3 - Shows the serial number of the autoclave;

4 - Shows how many days ago and how many times the user has been notified about performing the biological test;

5 - Shows how many days ago and how many times the user has been notified about performing the preventive maintenance;

6 - Shows date and time.

7 - Shows the available language of the display messages.

8 - Drains the remaining water from the sterilization chamber (e.g.: after the liquids cycle).

MESSAGES

SET

DATE/TIME?

INSERT DATE

01/JAN/2009

INSERT TIME

12:00 AM

SERIAL NUMBER

qd54-00000/00

DOOR OPEN

FILL UP

RESERVOIR

HEATING UP 00:00

T : 000°C

POWER OUTAGE

HEATING UP 00:00

T : 000°C p : 0.00

SubpressURE

detectED

DEPRESS. 00:00

p : 0.00 KGF/CM2

OVERpressURE

detectED

HEATING

TIME LIMIT

temp. x pressURE

incompatiBLE

CYCLE CONCLUDED

00:00

cYclE cancelLED

p : 0.00 KGF/CM2

selecT

program

DEPRESSURIZE?

ST: YES Can: no

PERFORM prevent.

MAINTENANCE

WATER FILLING

00:00

CLOSE THE DOOR! LACK OF WATER

IN THE reservOIR

PERFORM

BIOLOGICAL TEST

canceLLED BY

usER

STERILIZ. 00:00

T : 000°C p : 0.00

DRYING 00:00

T : 000°C

OPEN THE DOOR! COOLING 00:00

T : 000°C p : 0.00 T : 000°C

COOLING COOLING

00:00

1 4 5 6 7 8

BIOLOG INDICATOR

000 DAYS 000 EXP

01/JAN/2009

12:00 AM

SELECT LANGUAGE

ENGLISH

chamber

water draining

PREVENTIVE MAINT

000 DAYS000 EXP

ADDITIONAL info CYCLES initiated

00000

CYCLES COMPLETED

00000

SERIAL NUMBER

qd54000000

2 3

WRAPPED 10 min

INSTRUMENTS

plastics AND

COTTON 30 min

SURGICAL kit AND

FABRICS 30 min

liquids 30 min

TRANSFERRING ... transfer

CANCELLED

INSERt flash

DRIVE Or CANCEL

14

c

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

Check if the power cable is plugged in, switch on the circuit breaker in the back of the autoclave, the display will

show the following mesages: and , next, the display will go out. In order to turn the

display on again, press the START key for 2 seconds, the display will show the initial information (brand, model and

software version), the autoclave will beep twice and the display will show select program.

bootloader V000

aguarde . . .

bootloader V000

executando . . .

HOW TO USE THE AUTOCLAVE QUADRA 54

a

SAFETY NOTES

b

Open the door of the autoclave and load it with the materials to be sterilized, be careful not to lean them against

the chamber walls or internal steam exits, that will cause interference in the cycle and damages to the articles. Do

not overload the autoclave.

Warning! - During the autoclave operation, it is perfectly normal to hear some noises, some low, some loud. The

noises are generated by the valves opening and closing, deaeration and depressurization, they are part of the proper

functioning of the equipment. The door gasket and the VSPF valve, are safety mechanisms that when activated

discharge pressure automatically producing a loud noise. This autoclave must be installed in a proper and exclusive

sterilization room. Cristófoli is not responsible for accidents that might occur due to the starts caused by the noises

produced by the autoclave.

The symbol 14 appears in some places on the autoclave. This means those items require special attention and

that the user must observe their references in the Instruction Manual provided with the equipment regarding potential

hazards offered by them and any actions to be taken should an adverse situation occur.

Cristófoli Equipamentos de Biossegurança Ltda, does not take any responsibility for failures and/or accidents

caused by the non-observance of this warning.

ATTENTION! Before starting a new sterilization cycle, make sure the reservoir has enough water to supply the autoclave need

(at least 1,5 liters). Use only distilled water for the sterilization (in accordance with the EN 13060). Non-compliance with this

recommendation may cause obstructions of the autoclave hydraulic system (internal tubing and/or valves), stains on the

instruments and loss of warranty.

Close the door of the autoclave. To close it correctly, press it against the chamber, slide the handle downwards until

it reaches the end of the course (Fig. 6, page 11). To open the autoclave, slide the handle upwards and open the

door.

ATTENTION! In case the door of the autoclave is not properly closed, the program will not start. The autoclave will beep

and the display will show the message: close the door!

15

At the end of the depressurization, the drying stage will begin automatically, the display will show the message

drying and the temperature of the chamber. The autoclave Quadra 54 dries with the door closed. At the end of

the drying process, the autoclave will beep 3 times and the display will show the message cooling. At this moment,

the operator must open autoclave door and leave it ajar to accelerate the cooling process of the sterilized articles.

Within 5 minutes the autoclave will beep continuously and the display will show the message cycle concluded, only

then, remove the sterilized articles.

After cooling, if the flash drive memory unit is not connected, the equipment will beep and request it, by showing

the message on the display. insert DISk or cancel Note: In case the operator decide not to use the flash drive by

pressing Cancel, the display will show the message: transfer canceled, the data will not be transferred and there will

be no way to recover the information from that cycle later on.

f

g

While the data is being transferred, the display will show transferring... . In case the flash drive is full or there’s a

transfer error, the autoclave will alert the user about it. If the user needs to format the flash drive, it must be formatted as

a FAT file system, FAT32 system is not supported by the electronic circuit board of the equipment. When the data

transfer is finished, the display will show CYCLE concluded and it will beep until the CANCEL key is pressed. The autoclave

will then return to Standby mode and the display will show SELECT PROGRAM.

To transfer the data from the flash drive to your computer, simply insert it into the USB connection on your computer

and copy the reports to a local folder and print them.

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

e

Select the cycle desired by pressing the MODE key. Each cycle has a specific operation time and temperature. Each

time the MODE key is pressed, the display will show the preset programs in the following order:

Pressing once: wrapped Instruments 10 min.

Pressing twice: Plastics AND COTTON 30 min.

Pressing three times: SURGICAL Kit and fabrics 30 min.

Pressing four times: Liquids 30 min.

Pressing five times: additional info (see “Cycles and Messages”, page 13)

d

After choosing one of the preset cycles through the MODE key, press the START key;

In case this is not the first cycle of the day and the temperature of the autoclave is above 70 ºC, the display will

show cooling and the respective temperature. As soon as the ideal temperature for the new cycle is reached, the

autoclave will resume operation automatically by changing to and then heating UP;WATER filling

, the display will show the temperature and pressure rising gradually. When the solenoid valve shuts down When

the autoclave reaches the ideal sterilization temperature and pressure for the selected program, it will beep 3 times

and the display will show steriliz. (sterilizing) remaining like that for the preset time according to the program

chosen.

At the end of the sterilization, the solenoid valve will open, it will produce a low metallic noise, the autoclave will

beep 4 times and the display will show depress. (depressurizing).

During the heating and drying stages, the solenoid valve makes a humming noise, similar to the one produced

by electric motors, it may also open/close automatically during the drying stage.

16

hT . CANCEL key for 2 seconds. It’s not recommended to switch off urn the autoclave off after use To do that, press the

the circuit breaker in the back of the autoclave or disconnect the equipment from the outlet so that it is not

necessary to adjust the time and date again.

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

ATTENTION! Even after the beeps that indicate the conclusion of the cycle, the contents of the chamber will still be hot.

Never touch the internal parts of the autoclave directly chamber, trays, materials, etc. ait for them to be ( ) when hot, w

cool enough before handling. R gloves for thermal protectionemember to use safety .

Note: As a component of the equipment, the USB flash drive is provided along with the autoclave.

Fig. 13

ATTENTION!

When opening the autoclave for cooling, observe

the correct position of the door in the picture. The autoclave

Vitale Plus dries with the door closed, its opening is only

necessary to speed up the cooling process of the

instruments/articles sterilized.

Upper view

Note: Heating time values are expressed considering the technical data chart (Table 5, page 19) regarding the autoclave

proper working temperature range.

The table below provides information about the equipment heating time; sterilization temperature and pressure;

Sterilization time; drying time and maximum drying temperature.

Table 4

Sterilization

Temperature and Pressure Sterilization

Time

Mode

2

1- Wrapped Instruments 30 to 50 min. 134 ºC / 210 kPa (2.1 kgf/cm ) 10 min. 45 min.

2

2- Plastic and Cotton 30 to 50 min. 121 ºC / 118 kPa (1.2 kgf/cm ) 30 min. 45 min.

2

3- Surgical Kit and Fabrics 30 to 50 min. 121 ºC / 118 kPa (1.2 kgf/cm ) 30 min. 50 min.

2

4- Liquids 30 to 50 min. 121 ºC / 118 kPa (1.2 kgf/cm ) 30 min. - - - - -

Maximum Drying Temperature: 121 or 134 ºC (depending on the cycle chosen).

Drying

Time

Heating

Time

QUALITY CONTROL

Cristófoli equipment are tested and monitored individually, according to the parameters of the Table 4 (above). Besides

the physical parameters, all autoclaves are tested with chemical indicators (class 5). The tests with biological indicators are

performed on a batch basis.

d

c

2

17

Cancellation of the Cycle - If the cycle is cancelled, for any reason, the display will alternate between two

messages, the message indicating the cycle cancellation (CYCLE CANCELLED P:0.00 kgf/cm2) and the message

indicating the possible cause for that, which can be:

lack of water in the RESERVoir --- There’s no water in the reservoir or there was not water enough to fill the chamber

with the correct amount of water;

heating time limit -------------------- The heating time limit was reached and there was no sterilization;

incompatible Temp. x PRESSURE ---- The relation between the temperature and pressure of the chamber is ;incoherent

subPRESSure DETECTED During the sterilization, the pressure decreased below the acceptable level -------------- ;

OverPRESSure DETECTED During the sterilization, the pressure increased above the acceptable level ------------- ;

CANCELLED by user The operator pressed the CANCEL key ------------------- ;

door open ------------------------------ The operator opened the door during the heating or drying stage (before the valve

shut down);

power outage ------------------------ .There was a power outage at the workplace (during the sterilization stage only)

3

If it’s necessary to interrupt/cancel the heating, sterilization or drying cycle, just press the CANCEL key. In this case,

after the beep and the indication cycle cancelled on the display, the autoclave will beep continuously until the

2

pressure falls to 0,0 kgf/cm and the CANCEL key is pressed again to confirm the cancellation of the cycle, there will

be no effect in case the CANCEL key is pressed while there’s still pressure in the chamber;

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

DEPRESSURIZE?

ST : YES CAN : NO

Some situations may cause interruption and automatic cancellation of the cycle when:

the ideal pressure/temperature is not reached due to steam/pressure leak or overloaded chamber. In this case,

the cancellation will occur within 50 minutes at the most.

the sterilization cycle is initiated and the chamber is not supplied with water within 20 seconds, the cycle will be

canceled automatically. In case there’s a lack of water while filling up the chamber, the autoclave will show the

message and beep until the key is pressed to resume supply.FILL UP RESERVOIR Start

there’s a power outage or voltage fluctuations. The depressurization will occur when power returns. See note

below;

turning the autoclave on, there’s already some pressure in the chamber. When that happens, the autoclave

will beep continuously, the display will show cycle cancelled and the autoclave will depressurize. See note below;

Confirm the cancellation of the cycle manually by pressing the CANCEL key;

Check the possible causes, take the necessary measures to correct the problem and perform a new cycle

to reprocess the articles according to the instructions on “How to Use the Autoclave Quadra 54” (Page 14).

Before starting a new cycle, the operator must check if there is water left in the chamber, which must be

removed manually through the door with a clean and dry cloth that does not shed or through the function

“Chamber Water Draining” as described on topic 5 (Page 18). For your safety, remember to use Attention!

PPE (Personal Protective Equipment, like proper latex gloves);

Note: In the situations c and d above, if there’s pressure inside the chamber, the display will show the question:

By pressing the START key, the valve opens for depressurization; by pressing the CANCEL key,

the depressurization will happen , with the valve clo this will prevent the liquid gradually sed,

from boiling over inside the containers when the liquids sterilization cycle was selected;

ADVERSE SITUATIONS

a

b

1

4In case of activation of one of the safety devices (sudden steam escape), generally caused by obstruction of the

internal steam exit or by an obstruction of the solenoid valve, wait for complete depressurization before opening the

door. The display will show cycle cancelled - p : 0.00 KGF/CM2.

Chamber Water Draining - The “Chamber Water Draining” function must be used to eliminate any remaining water

in the chamber (e. g. after running the liquids cycle or canceling a cycle when there’s no pressure in the chamber)

before running a regular cycle. There will not be sterilization nor drying stages for this function. The chamber will be

2

heated up to 1 kg/cm of pressure, depressurizing in the sequence.

5

HOW TO IDENTIFY YOUR AUTOCLAVE

The purpose of the label located in the back of the

equipment is to identify the autoclave technical data.

ATTENTION! - The removal of the identification label and/or

any other labels/stickers affixed to the product will cause

automatic loss of warranty.

Note: The label presented here is just a sample model for

your reference.

LOT

SN

POWER

PRODUCT: CRISTÓFOLI STEAM STERILIZATION AUTOCLAVE.

MODEL FREQUENCY -

ANVISA REGISTER -

RESPONSIBLE TECHNICIAN -

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA

ROD BR 158 Nº 127 - CAMPO MOURÃO - PR

BRASIL - CEP 87309-650 - FONE: 55 44 3518-3401

CNPJ 01.177.248/0001-95 - INSCR. EST. 90.104.860-65

MADE IN BRAZIL

USE INSTRUCTIONS, PRECAUTIONS, CONSERVATION AND STORAGE:

SEE INSTRUCTION MANUAL.

MAXIMUM OPERATION PRESSURE -

CAPACITY -

CONFORMITY -

MODEL

Fig. 14

TIME X PRESSURE GRAPHS

Low Pressure Cycle (1. 2

2 kgf/cm )

Graph 2Graph 1

High Pressure Cycle (2.1 2

kgf/cm )

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1

1,1

1,2

1,3

05 10 15 20 25 30

Time (Min.)

2

Pressure (Kgf/cm )

Pressure x Time

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

1,8

2

2,2

2,4

2

Pressure (Kgf/cm )

0

0 5 10 15 20 25

Time (Min.)

Pressure x Time

18

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

TECHNICAL DATA

Table 5

* In case the altitude and/or temperature of your workplace is different from the values mentioned in this manual, contact

Cristófoli by the e-mail: [email protected].

Certifications ........................................................................

TECHNICAL DATA CHART QUADRA 54

The Autoclaves Quadra 54 are manufactured by Cristófoli

Biossegurança, company which Quality Management System is

certified and in accordance with the ISO 9001:2008, ISO

13485:2003, BPF- Boas Práticas de Fabricação - ANVISA, Brazilian

standard similar to GMP-FDA/US) and ISO 14001:2004 -

Environmental Management standards.

Capacity .............................................................................

Weight .................................................................................

Overall clearance ................................................................

Clearance required for the movement of the door .............

Chamber internal dimension (W x D) ...................................

Autoclave external dimension (W x H x D) ............................

Dimensions of the trays (W x H x D) .......................................

Clearance between the trays ..............................................

Voltage ................................................................................

Frequency ............................................................................

Power ...................................................................................

Power consumption .............................................................

Maximum operation pressure ..............................................

Temperature of drained water .............................................

Proper working temperature range ......................................

Proper working altitude .........................................................

54 liters

Stainless steel including components - 72,5 kg ( )

10 cm for each side of the autoclave

60 cm

34 x 61 cm

54 x 54 x 75 cm

28 X 2,5 X 47 cm

35 mm (approximately)

220 V AC

50 or 60 Hz

2800 Watts

750 Watts/hour

216 kPa (2.2 kgf/cm )

2

100ºC

15ºC to 40ºC

Up to 3.500 m

The manufacturer reserves the right to make changes and/or improvements to this product at any moment without prior notice.

19

CRISTÓFOLI

A U T O C L A V E S

I N S T R U C T I O N M A N U A L

Table of contents

Other Cristofoli Medical Equipment manuals

Popular Medical Equipment manuals by other brands

inhealth

inhealth Blom-Singer Instructions for use

Johnson & Johnson

Johnson & Johnson DePuy Synthes INSIGHT Lateral Access System manual

Allied Healthcare

Allied Healthcare L190 Operation & service manual

Ability dynamics

Ability dynamics RUSH FOOT EVAQ8 series Instructions for use

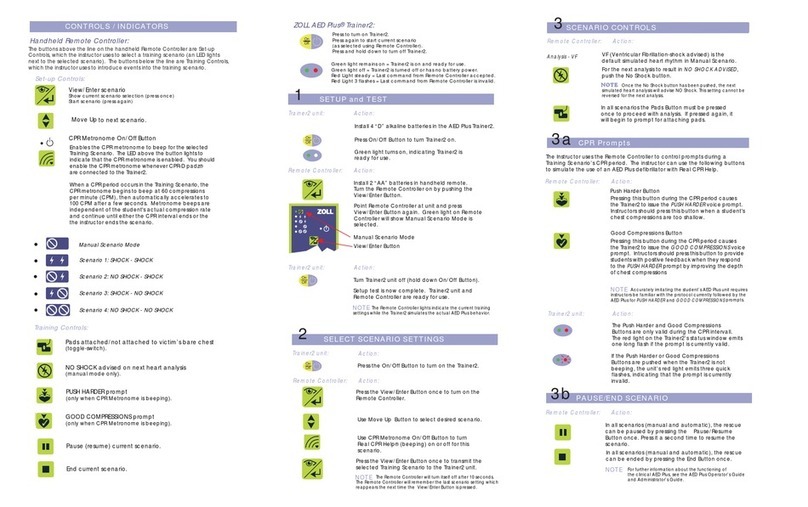

ZOLL

ZOLL AED Plus Trainer2 Operator's guide

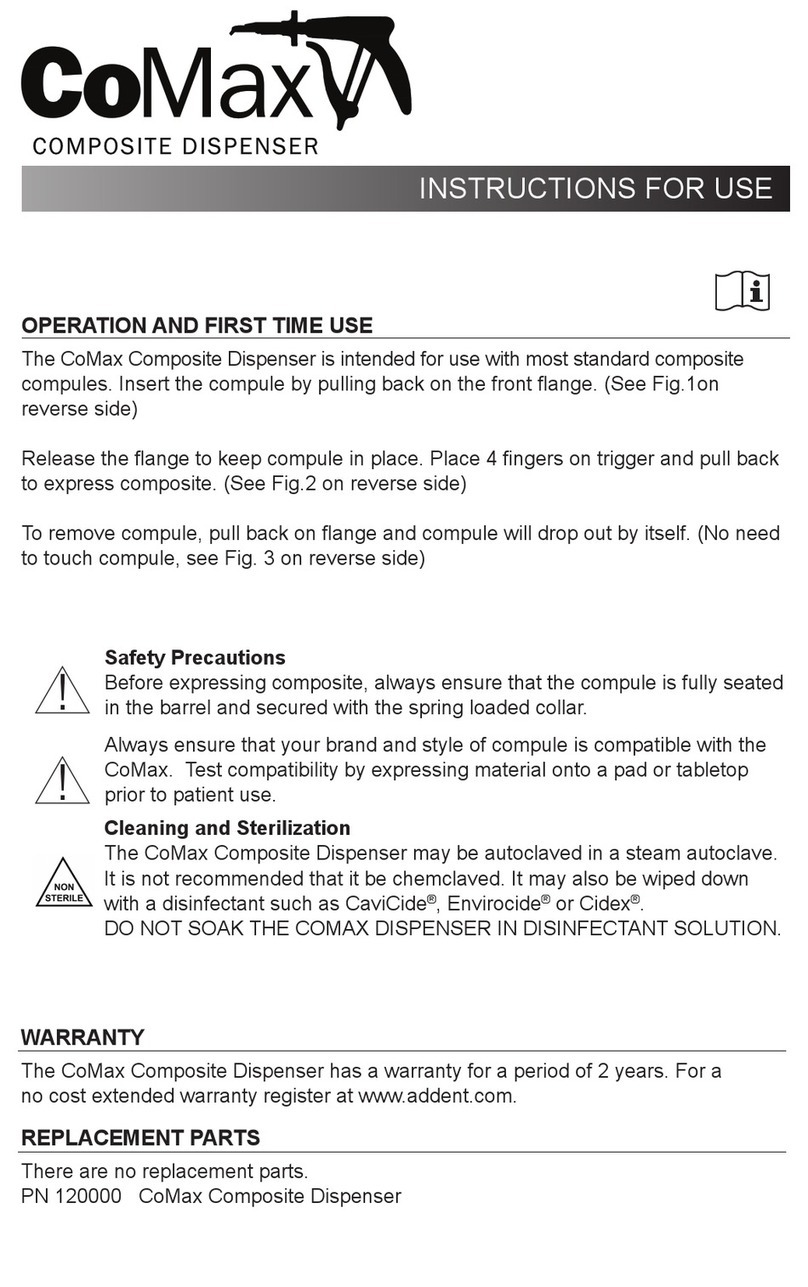

AdDent

AdDent CoMax Instructions for use