Cristofoli vitale 21 User manual

CRISTÓFOLI’S MISSION

CRISTÓFOLI QUALITY AND ENVIRONMENTAL POLICY

To develop innovative solutions to protect life and promote health.

Cristófoli Equipamentos de Biossegurança Ltda., established at Rodovia BR-158, nº 127, Jardim Bandeirantes in Campo

Mourão, Paraná, Brazil, manufactures biosafety equipment to assist the health care, having the following policy: "To develop

innovative solutions for health care by using agile, robust, and objective processes to better serve its customers. To fulfill all

the requirements of the applicable standards, promote the continuous improvement of its quality and environmental

standards, prevent pollution, reduce its environmental impact, and continuously train its staff, achieving, therefore, a

sustainable and profitable maximization of its value." Rev. 2.

*BPF: Brazilian standard similar to GMP - Good Manufacturing Practices (FDA / US)

Vitale Class 12/21 Autoclave

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

O

I

S

Cristófoli, Brazilian importing company and manufacturer of health products

certified by ISO 13485 - Health Products - Quality Management System -

Requirements for Regulatory Purposes and compliance with RDC 16/2013 - *BPF -

Boas Práticas de Fabricação - ANVISA requirements.

2

Meaning of Symbols ....................................................................................................................................

Introduction .................................................................................................................................................

Intended Use ...............................................................................................................................................

Recommendations and Warnings ...............................................................................................................

How to Identify your Autoclave ....................................................................................................................

Installation Instructions ..................................................................................................................................

Automatic Altitude Adjustment ......................................................................................................................

Safety Devices .............................................................................................................................................

How to Use the Vitale Class CD Autoclave ...................................................................................................

Failure Indications ..........................................................................................................................................

Performing a New Initial Cycle .....................................................................................................................

Technical Data ............................................................................................................................................

Quality Control .............................................................................................................................................

Preventive Maintenance / Monitoring .............................................................................................................

Troubleshooting ...........................................................................................................................................

How To Proceed When Service Is Needed .......................................................................................................

Guidance for Final Disposal of the Equipment ............................................................................................

Warranty Terms .............................................................................................................................................

Use Instructions - Quick Guide .....................................................................................................................

03

04

04

04

05

06

07

08

08

10

11

11

12

12

13

14

14

15

16

Manual Vitale Class Ingl. Rev.4-2018

INDEX

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

3

MEANING OF SYMBOLS

Tinta

com propriedade

antimicrobiana.

~

This side up

Maximum

Pile

Warning

Manufacturer

Alternating Current Gorunding

Protection Terminal

Fuse

Autoclavable

Date of

Manufacture

*Boas Práticas

de Fabricação

4

P

BF

LOT

SN

Fragile - handle

with care

Dangerous

Electrical Tension

Serial Number

Lot number

Keep out of

Sunlight

Recyclable

Keep Dry

ISO 13485

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

I

O

S

Antimicrobial

Painting

135 ºC

*BPF: Brazilian standard similar to GMP - Good Manufacturing Practices (FDA / US)

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

4

The complete reading of this manual is indispensable for safe use of the equipment and preventive maintenance

orientation.

Autoclaves work with high temperature and pressure, so must be handled by health care professionals, well aware of the

equipment operation.

Box content: 1 autoclave, 1 tray holder, 2 trays (Vitale Class 12) or 3 trays (Vitale Class 21), 1 measuring cup, 1 hose (1,5

m), 1 clamp, and 1 manual.

Read all instructions of this manual before using your autoclave. The incorrect use may result in sterilization failure and/or

accidents.

For your safety, when performing any kind of maintenance, remember to unplug the power cord and use PPE (Personal

Protective Equipment).

Do not allow patients, especially kids, to get close to your autoclave.

Before starting any sterilization program, make sure that the sterilization load is autoclavable (resistant to temperatures

up to 135° C under presence of steam and pressure).

When simultaneously sterilizing instruments with different autoclaving specifications, such as instruments that support

different pressures (1,2 or 2,2 kgf/cm²) or temperature levels(121 or 134°C), the operator must choose the program

which works with the lower temperature/pressure offered by the autoclave.

During the autoclave operation, it’s perfectly normal to hear noises, which are generated by the valve opening,

closing, deaerating, and depressurizing. These processes are part of the proper functioning of the equipment.

Cristófoli is not responsible for accidents that might occur due to the jolts caused by the noises produced by the

autoclave.

When the handle to open the door, the operator must do it easily. Never use too much force, pulling for it may

damage the equipment’s internal mechanisms.

It is necessary that the door is slightly open at the drying process. See “How To Use The Vitale Class Autoclave”(page

10, item f).

It is normal, when the operator opens the door at the end of the cycle to cool down the sterilized load, that some steam

comes out of the chamber.

The owner is responsible to perform, through a competent Laboratory, the thermometric validation of the autoclave.

Use totally perforated boxes and trays only, as it allows steam circulation and makes the drying process more

efficient.

It is recommended that the equipment be unplugged at the end of the workday.

Never sterilize or heat foods.

This equipment was developed for sterilization of heat-resistant articles/instruments using saturated steam under

pressure.

RECOMMENDATIONS AND WARNINGS

INTRODUCTION

INTENDED USE

MANUFACTURER

Cristófoli Equipamentos de Biossegurança Ltda.

Rod. BR 158, nº127 - Campo Mourão - PR - Brasil.

CEP 87309-650

CNPJ 01.177.248/0001 - 95 - Inscr. Est. 90104860-65

Website: www.cristofoli.com - e-mail: [email protected]

Responsible Technician

Eduardo Luiz Soppa

CREA-PR: 109201/D

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

5

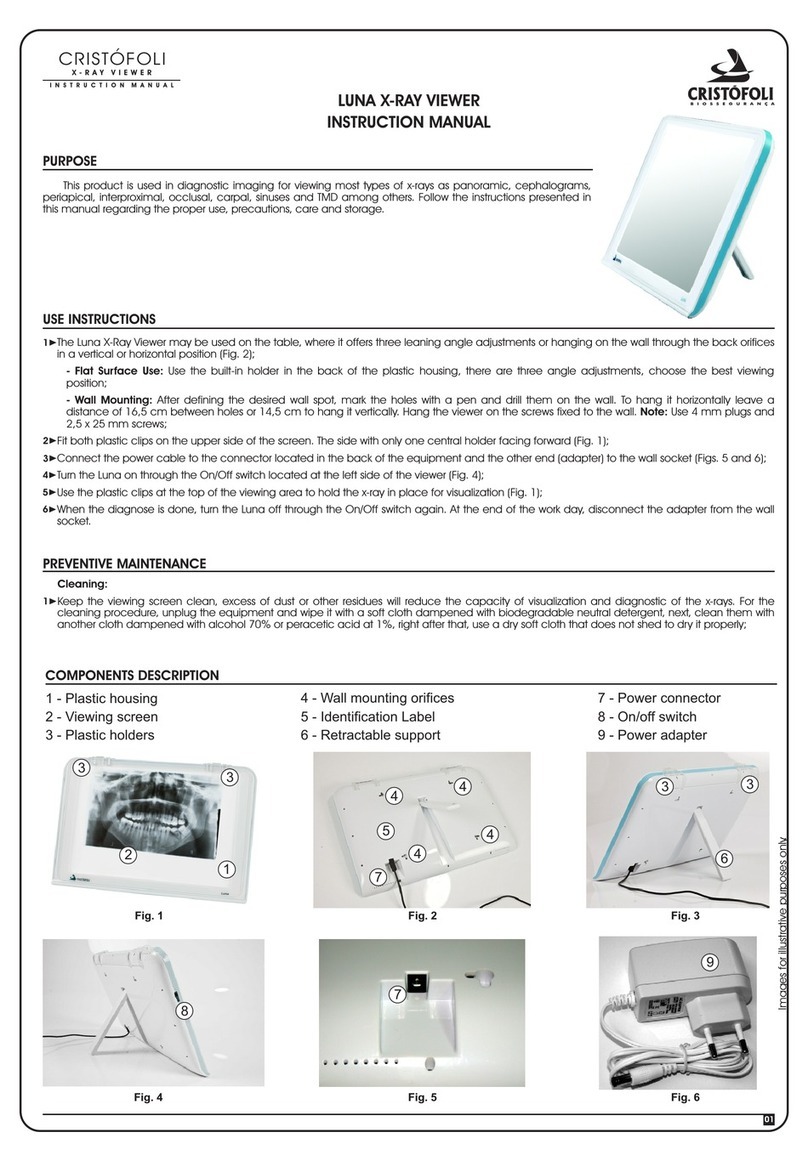

CANCELED LED HEATING/DRYING LED

STERILIZING / END

OF CYCLE LED

PRESSURE/TEMPERATURE LEDS

START CANCEL DRY

Fig. 4

Fig. 3

Fig. 2

Fig.5

LOT

SN

POTÊNCIA

PRODUTO: AUTOCLAVE CRISTÓFOLI PARA ESTERILIZAÇÃO A VAPOR.

MODELO

AUTOCLAVE VITALE CLASS CD

FREQUÊNCIA -

REGISTRO ANVISA -

RESPONSÁVEL TÉCNICO

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA

ROD BR 158 Nº 127 - CAMPO MOURÃO - PR

BRASIL - CEP 87309-650 - FONE: 55 44 3518-3432

CNPJ 01.177.248/0001-95 - INSCR. EST. 90.104.860-65

INDÚSTRIA BRASILEIRA

INSTRUÇÕES DE USO, PRECAUÇÕES, CONSERVAÇÃO E ARMAZENAMENTO:

CONSULTE O MANUAL DE INSTRUÇÕES

PRESSÃO MÁXIMA DE OPERAÇÃO -

CAPACIDADE -

CONFORMIDADE - NORMA NBR 11817

Fig.1

5 liters

FUSE HOLDER

HOW TO IDENTIFY YOUR AUTOCLAVE

The Identification label removal will cause automatic loss of warranty.

STERILIZATION CHAMBER

BASE

COVER

TEMPERATURE

SENSOR

INTERNAL

STEAM EXITS

DOOR

(Panel/Lid set)

LID

DOOR

GASKET

HANDLE

TRAY HOLDER

TRAYS

SAFETY VALVE/

ANTI-VACCUUM

PANEL

HANDLE

KEYBOARD

IDENTIFICATION

LABEL

CLAMP

EXTERNAL

STEAM EXIT

DEPRESSURIZATION

HOSE

POWER CABLE

“V” CUT

KEEP THE HOSE

ABOVE THE WATER LEVEL

CONDENSED WATER

DO NOT USE A LID

Images for ilustrative purposes only

The manufacturer reserves the right to make changes and/or improvements to this product at any moment without prior notice

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

ELECTRICAL INSTALLATION

. See “How to Proceed When Service is Needed” (Page 14) If the owner performs the installation with a non-

authorized electrician or technician, Cristófoli will not be responsible for services done in disagreement with the

orientations descibed in this manual.

The Vitale Class CD autoclave is an automatic dual voltage device (able to operate at 127 and 220 V), as shown in

the identification label, placed on the back of the equipment. See “How to Identify Your Autoclave” (Fig. 1, page 5).

For installation, use a grounded outlet (20 A), plugging phase/neutral or phase/phase at the side pins and grounding

at the middle pin: Never plug the grounding on neutral.

The Electrical Grounding is very important for the operator’s safety and for your equipment’s functionality. Therefore,

the center pin (grounding) must never be removed or cut. The failure to observe this procedure may damage your

autoclave. Install the equipment where the power cable can be easily disconnected.

Never use electric extensions, adapters or voltage transformers.

For the proper functioning of the autoclave, the electrical wire must be stable, in other words, without oscillations. It

is mandatory the use of an exclusive circuit breaker for the outlet where the autoclave will be installed. If after

following all the specifications, the electrical wire still oscillates, contact the local electricity company.

The electrical installation must follow the data from table below.

Table 1

AUTOCLAVE CIRCUIT BREAKER VOLTAGE

Vitale Class 12

Vitale Class 21

WIRING GAUGE

For distances up to 5 m (16 ft) from the circuit breaker to the outlet used to

connect the equipment, use 2,5 mm wiring. From 5 to 15 m (16 to 46 ft)

use 4 mm, and from 15 to 50 m (46 to 164 ft) use 6 mm. NOTE: For the 21

liters model (127V), for distances up to 15 to 35 m (49 to 114 ft) use 6 mm

wiring, and 8mm for 114 to 164ft distance.

8 A

127 / 220 V

12 A

NOMINAL CURRENT

15 A

20 A

6

1

2

4

3

INSTALLATION INSTRUCTIONS

The equipment must always be carried by two people to prevent it from falling down. The storage/installation must be

performed indoors, under room temperature, on a counter that can bear the weight of the autoclave.

Install the autoclave in a room that is exclusive for sterilization.

Install the autoclave on a flat, levelled and firm surface, and at a proper height for the operator to handle it

(approximately 80 cm / 2.6 feet from the floor). Leave enough room around the autoclave for proper handling of the

sterilization load.

DRAINAGE

Connect the provided hose to the external steam exit (Fig. 1, page 6), put the clamp and fasten it with a

screwdriver. The other side must be connected to the plumbing system (on a pipe that is able to tolerate at least 100°C)

or to an open and empty container, with a “V” cut at its end and placed about 40 cm above the autoclave level (Fig.

1, page 6). Keep the hose slightly stretched to avoid it from bending. Empty the container when the water reach the

hose and wash it with water and biodegradable neutral detergent.

If a hose change is needed, use only heat resistant rubber hose (5/16”, 300 psi as sample provided).

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

7

AUTOMATIC ALTITUDE ADJUSTMENT

During heating process, the heating/drying LED will light up and the 7 LEDs (Fig. 7) will blink. The whole process will be

performed automatically in at most 15 minutes. At the end, the LED will light up, announcing the end of the

adjustment.

Press to return. Open the door and wait the chamber cool down to use (15 minutes, approximately).

If there are any problems during the adjustment, press to repeat. See ”Failure Indications” (page 10) following

the recommendations related to the shown failure message.

Open the door of the autoclave and, using the measuring cup, put the correct amount of

distilled water directly inside the chamber (150 ml for the Vitale Class 12 or 250 ml for the

Vitale Class 21). Close the door and press to begin.

2

1

The performance of the autoclave is directly related to the atmospheric pressure, which varies according to the

altitude of where is it installed. The following instructions will guide you on how to perform the Initial Cycle of your

autoclave. This reinforces that your autoclave will efficiently work at the location where it is installed.

Fig.6

If the equipment is transferred to another place, see the topic “Performing a New Automatic Altitude Adjustment”

(page 11).

When turning the autoclave on for the first time, the 7 first LEDs of the temperature/pressure

LED bar will keep alight (Fig 6), showing the need to perform the altitude adjustment, that is the

first cycle of the autoclave. Perform the adjustment without any materials, (only water must be

inside the chamber) following the instructions below:

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

1/2

litro

ml

450

400

350

300

250

200

150

100

50

8

HOW TO USE THE VITALE CLASS CD AUTOCLAVE

a

b

Connect the power cable to an outlet and press , the Cristófoli logo will light up beeping 3 times, then the LED

that shows the voltaje the equipment is working will light up (1,7 kgf/cm² para 127 V and LED 1,8 kgf/cm² para 220 V).

Open the door of the autoclave, take out the trays and, using the measuring cup, put the correct amount of

distilled water directly inside the chamber berfore each cycle (Fig. 7), according to the table below:

Fig.7

Use only distilled water for sterilization. The non-compliance of this

recommendation may cause obstruction of the autoclave’s hydraulic system

(internal pipes e/or valves), stains on the instruments, and loss of warranty.

Table 3

AMOUNT OF DISTILLED WATER FOR EACH CYCLE

Vitale Class 21

250 ml

Vitale Class 12

150 ml

The Vitale Class CD autoclave has the following safety devices:

FUSE - This device protects the electrical installations and equipment against peaks of energy. The used fuse is the

glass 6,35x32 AGLF, fast acting. If substitution is needed, see “Troubleshooting” (page 13).

DOOR KEY - Internal device that prevents the functioning of the equipment if the door is not properly closed.

TEMPERATURE VS PRESSURE DATA CROSSING ELECTRONIC SYSTEM - Internal system that automatically cancels the

cycle if any problem is detected with pressure reading.

DOOR LOCKING - Internal device which prevents the handle from opening if there are high pressure levels inside the

chamber.

POWER CONTROL ELECTRONIC SYSTEM - Internal system that monitors the voltage fluctuation, keeping the

autoclave power constant.

THERMOSTAT - Internal device that limits the excessive heating of the chamber.

DOOR GASKET - If the pressure inside the chamber reaches 3 kgf/cm² (294 kPa), the door gasket will detach from

the edge of the door, having a loud noise (Fig. 4, page 5).

SAFETY VALVE/ANTI-VACCUUM - Device that, when needed, eases the vacuum inside the chamber. It also eases the

pressure if it exceeds the limits established (Fig. 4, page 5).

1

2

3

4

5

6

7

8

Tabla 2

AUTOCLAVE FUSEAC VOLTAGE

95 V - 254 V 10 A (250 V)

15 A (250 V)95 V - 254 V

Vitale Class 12

Vitale Class 21

SAFETY DEVICES

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

TIEMPO DE

SECADO

*For altitudes above 2.000 m, the sterilization time is 20 minutes. Maximum drying temperature: 129°C

Table 5

Default program

Extra drying

PROGRAMS STERILIZATION TEMPERATURE STERILIZATION PRESSURE STERILIZATION

TIME DRYING

TIME

HEATING TIME

10 a 60 min.

-------------

1,7 a 1,8 kgf/cm² ou 167 a 186 kPa

---------------------------------

129 a 132 °C ou 264 a 269 °F

--------------------------------

30 min.

20 min.

16 min.*

--------

Note: According to ABNT NBR 11816: 2003, the sterilization temperature i Interval must have the inferior limit defined by the sterilization temperature and superior limit of + 3°C.

If this is not the first cycle of the day and the temperature inside the autoclave is

above 70 °C, when pressing , 2 beeps will continuously sound, and the autoclave will

keep on standby mode, with the Cristófoli logo on. Wait some minutes until the

temperature of the chamber decreases and try again.

The table below shows the default values of the sterilization cycle:

9

Close the door of the autoclave pressing it against the chamber and move the handle

all the way down (Figures. 8 and 9).

Load the autoclave with the materials to be sterilized, be careful to not lean them against the chamber walls or

internal steam exits, the sterilization cycle. Do not overload the failure to follow these instructions may interrupt

autoclave. Do not exceed 75% of the chamber capacity Place the envelopes always with the paper (table 4).

side upturned, it the steam , resulting on a fast and efficient drying , and for th s eases penetration process e ame

reason, boxes and trays must be totally perforated, so that allows steam circulation and makes drying easier.

c

d

ePress to start, the autoclave will beep once, and the LED Aquecendo/Secando

(Heating/Drying) will be on, announcing the heating process, that may last between 10

and 60 minutes, depending on temperature, altitude, electrical wire, and amount of

instruments (table 5). During the functioning, the LEDs will show the increasing and

decreasing of pressure and temperature.

If when pressing the autoclave beeps continuously, it means the door is not

properly closed. Open and close the door correctly, as shown in the figures 8 and 9.

If the autoclave beeps 3 times, light on Aquecendo/Secando (Heating/Drying),

Cancelado (Canceled), and the 7 first temperature/pressure LEDs, it means the

operator needs to open and close the door again.

Fig. 8

Fig. 9

*Each envelope with 6 instruments at most. **The supports are sold separately.

Contact your local dealer. Table 4

Chamber’s Maximum Capacity

5 envelopes

(10 x 23 cm)*

13 envelopes

(10 x 23 cm)

N/A

12 envelopes

(10 x 23 cm)*

13 envelopes

(10 x 23 cm)

26 envelopes

(10 x 23 cm)

With 2 supports for

envelopes

Only trays

With 1 support for

envelopes**

VITALE CLASS 12 VITALE CLASS 21

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

Incompatible tension level, press to return.

The door was opened, press to return.

Canceled by user.

0/100

0,5/111

1,0/120

1,5/127

1,6/128

1,7/129

LED CAUSE

Heating time limit, press to return.

Low pressure, press to return.

Over pressure, press to return.

10

eWhen the autoclave reaches the sterilization temperature/pressure, it will beep once and the LED will blink

indicating the sterilization for 16 minutes (table 5).

Obs.: for altitudes higher than 2000 m, the sterilization will last 20 minutes. If the autoclave does not reach the

proper sterilization temperature in 40 minutes, by lack of water, excess of meterial or air leakage, the cycle will be

automatically canceled. Voltaje oscilations may cancel the cycle at any time.

If a cycle interruption/cancellation is needed, press . In this case, the LEDs Cancelado (Canceled) and 0,5

kgf/cm² will be on, the autoclave will beep twice and return to the standby mode.

At the end of the sterilization, the equipment will beep once, announcing depressurizing. The pressure LEDs will

indicate 0 pressure at the end of this process. After that, the heating/drying LED will blink with 2 beeps every 4

seconds, indicating the need to slightly open the door, for a proper drying (figures 10 and 11).

ATTENTION!

When opening the autoclave for drying, see the correct

position of the door (figures 10 and 11). Keep the handle

all the way down (fig. 11). Vitale Class performs drying

with open door. It is usual that in this moment, some

steam comes out through the door.

f

ATTENTION! Even after the cycle is finished, the chamber content will be still at high temperature Never directly

touch the chamber, trays or material, wait until the temperature is proper for handling. Remember to use glover for

security and thermal protection. Wait between 15 and 20 minutes for cooling before start a new cycle.

After drying, the autoclave will beep once and the LED will keep on. To return to the standby mode, press .

If a extra drying is needed, press to perform this process again.

After use, turn off the equipment pressing for 2 seconds.

g

h

FAILURE INDICATIONS

Table 6

When a cycle is canceled, the Vitale Class autoclave will light up a LED related to the possible cause of

canceling, together with the Cancelado (Canceled) LED, according to the table below:

Fig.10 Fig.11

Upper view

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

With the autoclave on, open the door and, using a measuring cup, pour the correct amount of

distilled water inside the chamber (150 ml for Vitale Class 12 or 250 ml for Vitale Class 21). Close

the door to start, press until the LEDs begin to blink (Fig. 12). If the autoclave beeps

continuously when pressing , it means the door was not correctly closed, open and close it

again.

During heating, the LED calentando/secando (heating/drying) will be on, and the 7 LEDs will blink. The entire process

is automatically performed in at most 15 minutes. At the end, the LED will indicate that the adjustment was

successfully performed.

2

1

If the equipment is transferred to another place (building, city, state) perform the Automatic

Altitude Adjustment again. To start this procedure again, follow the instructions below:

PERFORMING A NEW AUTOMATIC ALTITUDE ADJUSTMENT

Fig.12

11

TECHNICAL DATA CHART

Table 7

VITALE CLASS 12 VITALE CLASS 21

21 liters

23,3 kg

25,9 kg

Stainless Steel

25 x 43 cm

38 x 38 x 55 cm

19 x 1,2 x 38 cm (single size)

28,5 mm (approximate value)

127/220V AC (95 - 254 V)

50/60 Hz

1600 Watts

485 Watts/hour

2

216 kPa (2,2 kgf/cm )

100ºC

15ºC a 40ºC

Up to 3500 m

10363350017

12 liters

17,7 kg

19,4 kg

Stainless Steel

22 x 30 cm

35 x 34,5 x 48,5 cm

15,5 x 1,2 x 28 cm (small)

20 x 1,2 x 28 cm (large)

67 mm (approximate value)

127/220V AC (95 - 254 V)

50/60 Hz

1200 Watts

336 Watts/hour

2

216 kPa (2,2 kgf/cm )

100ºC

15ºC a 40ºC

Up to 3500 m

10363350017

Carbon steel with electrostatic painting wi antimicrobial properties (Nobac).

Capacity .............................................................

Net weight ...........................................................

Gross weight ........................................................

Material of the chamber / lid ...............................

Chamber internal dimensions (W x D) .................

Autoclave external dimensions (W x H x D) ..........

Dimensions of the trays (W x H x D) ......................

Free space between trays ..................................

Voltage (Automatic dual voltage) .......................

Frequency ...........................................................

Power ...................................................................

Power consumption .............................................

Maximum operation pressure ..............................

Temperature of drained water .............................

Proper room temperature ...................................

Proper working altitude ........................................

Base (metal structure) ..........................................

Certification .........................................................

ANVISA .................................................................

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

The Vitale Class Autoclaves are manufactured by Cristófoli Biossegurança,

company whose the Quality Management System is certified by ISO 13485, and in

accordance with RCD 16/2013 - BPF - Boas Práticas de Fabricação - ANVISA (Brazilian

standard similar to GMP - FDA/US).

12

For better functioning and durability of your autoclave, some procedures are needed. Monitoring and preventive

maintenance correspond to the accomplishment of all procedures below.

When performing any kind of maintenance, including cleaning, remember to unplug the power cord.

Tabla 8

External cleaning:

Must be performed with a soft cloth, water and biodegradable neutral detergent. After that, clean the

autoclave with a moistened with 70 % alcohol cloth or 1% peracetic acid. The handle must be cleaned the

same way before each material removal, after sterilization cycle.

Tray and chamber cleaning:

Use a soft nonabrasive sponge with biodegradable neutral detergent and distilled water. To remove the foam

use a cloth that does not shed. Finish the cleaning with 70% alcohol or 1% peracetic acid. It’s forbidden the

use of any descaler product for the cleaning, for the use of this products will damage the chamber, trays,

and internal pipes.

Sterilizing monitoring (chemical test):

Peform chemical test daily. To obtain more information about how to perform the chemical tests, consult

www.cristofoli.com at the session “Support” of your product or watch the video “Monitorizaçãp da

Esterilização emautoclaves – Parte 1 – Monitorização Física e Química” on www.youtube.com (CC

available).

Door gasket cleaning:

Remove the gasket by pulling it, after that, clean it with a cloth (which does not shed) moistened with water, and

place it on the lid again.

Sterilizing monitoring (biological test):

Peform biological test every 7 days. To obtain more information about how to perform the chemical tests,

consult www.cristofoli.com at the session “Support” of your product or watch the video “Monitorização da

Esterilização em Autoclaves – Parte II – Indicadores Biológicos” on www.youtube.com (CC available).

Replacement of the component “thermostat” (Item 6, page 8). See "How To Proceed When Service Is Needed"

(Page 14).

Replacement of the components “lid” (Fig. 4, page 5) and “chamber” (Fig. 5, page 5). See "How To Proceed

When Service Is Needed" (Page 14).

The Vitale Class CD autoclaves are individually monitored according to the physical parameters of the Table 5 (Page 9)

and tested with class 5 chemical indicators. The tests with biological indicators are done by lot sampling.

MAINTENANCE / MONITORINGPERIODICITY

DAILY

WEEKLY

Verification of the items: door gasket, safety valve/anti vacuum, thermal grease of the electrical resistence,

internal hoses, door locking, and external (drain hose). See "How To Proceed When Service Is Needed" (Page 14).

YEARLY

EVERY

3 YEARS

EVERY

10 YEARS

QUALITY CONTROL

PREVENTIVE MAINTENANCE / MONITORING

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

13

For any replacement of parts, contact your local dealer or authorized technical assistance office. It’s not

recommended the replacement by non-qualified people.

Listed below are the most frequent problems and possible solutions, which could be solved by the user.

POSSIBLE CAUSES SOLUTION

THE AUTOCLAVE SWITCHES ON, HEATS, BUT DO NOT BUILD UP PRESSURE

• Equipment installed in higher altitudes ------------------------------------- • Perform a new Automatic Altitude Adjustment, see “Performing a

New Automatic Altitude Adjustment” (Page 11).

POSSIBLE CAUSES SOLUTION

• The operator selected the program but there’s no actuation when

pressing ---------------------------------------------------------------------

• Incompatible Voltage -----------------------------------------------------------

• When pressing , all the LEDs blink 3 times ---------------------------

• The operator selected the program but didn’t press ------------- • Press .

• See “How To Use The Vitale Class Autoclave” (page 9, item e), if the

problem persists, see “How To Proceed When Service Is Needed”

(pág 14).

• See “How To Proceed When Service Is Needed” (pág 14).

• In this case, when turning the equipment on, the LEDs Cancelado

(Canceled), Aquecendo/Secando (Heating/Drying) and the LED

that indicates capacity will be alight (1,7 kgf/cm² for 127 V and 1,8

kgf/cm² for 220 V).

POSSIBLE CAUSES SOLUTION

• Lack of power ----------------------------------------------------------------------

•The autoclave is not connected to the outlet -----------------------------

• The key was not pressed to turn the autoclave on -----------------

• Blown fuse --------------------------------------------------------------------------

• Verify if there’s a power failure in your area.

• Connect the power cord to the outlet properly.

• Press .

• Replace the fuse, that is located near to the power chord: unplug the

autoclave, remove the cover of the fuse-holder, take out the

damaged fuse, put the new one, replace the cover and turn on the

equipment.

THE AUTOCLAVE PRESSURE GETS TOO HIGH, ACTIVATING THE SAFETY DEVICES

POSSIBLE CAUSES SOLUTION

• Obstruction of the hose connected to the external steam exit --------------- • Remove the hose that is connected to the external steam exit and

clear any obstruction. ATTENTION! Never use common plastic hose.

I, see “Installation Instructions” topic “Drainage” (pág 6). If the

problem persists, consult “How To Proceed When Service Is

Needed” (page 14).

POSSIBLE CAUSES SOLUTION

• There is voltage fluctuation ---------------------------------------------------

• Pressure/steam leak through the door gasket -----------------------------

• Overloaded chamber ---------------------------------------------------------

• Consult your local energy provider.

• “Preventive Maintenance” (page 12).Perform

• See “How to Use the Vitale Class CD Autoclave” (page 8 ).

THE AUTOCLAVE TAKES TOO LONG TO BUILD UP PRESSURE OR DOES NOT KEEP IT, SHOWING “CYCLE CANCELLED”

If the problem persists after the verification of all items, contact your local dealer.

TROUBLESHOOTING

THE AUTOCLAVE DOES NOT SWITCH ON

THE AUTOCLAVE SWITCHES ON BUT DOES NOT HEAT UP

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

14

Cualquier eventual problema con su equipamiento, consulte el primer tópico “Resolviendo Pequeños

Problemas”(page 13), si el problema persiste, please have in hands the model of your autoclave, voltage, serial number,

and the date of manufacture, found in the identification label located in the back of the autoclave (Fig. 1, page 6) , and a

description of the problem. Next, contact your local dealer for an evaluation and possible repair your equipment. It will be

also necessary to have the original invoice from your dealer to confirm the date of purchase.

Always contact your local dealer. If you have problems contacting your dealer, contact us through our website:

www.cristofoli.com.

The environment belongs to everyone, therefore, it is up to each one of us to make decisions that will help in its

preservation and reduction of the damages resulting from human activities.

All products have a useful life span, but it is not possible to determine how long is it, as it varies according to the

intensity and how the equipment is used or handled. Exception made for the component “lid” which must be replaced

every 10 years.

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA makes clear its concern, already demonstrated by the

implementation of the Environmental Management System, according to standard NBR ISO 14001:2004, and strongly

recommends users of their products to seek the best destination when disposing their equipment or components,

taking into account the materials recycling legislation effective in each country.

We advise you to take your equipment to specialized recycling companies that, due to the continuous and fast

paced development of new recycling technologies and materials reuse, provide the best way of disposing the

equipment. Cristófoli contributes this way to reduce the consumption of non-renewable raw materials.

On behalf of all users, we thank you for your comprehension and cooperation.

HOW TO PROCEED WHEN SERVICE IS NEEDED

GUIDANCE FOR FINAL DISPOSAL OF THE EQUIPMENT

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

5

15

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA. warranties the Cristófoli Autoclaves for 01 (one) year against any

manufacturing defect from the date of the purchase receipt (provided it contains the serial and lot numbers of the

equipment), of which 03 (three) months refer to the legal warranty (established by section II, art. 26, CDC, Brasil) and nine (09)

months to the contractual warranty (arranged in art. 50, CDC, Brazil). Visit our website www.cristofoli.com and register your

product online.

Traveling costs (based on the distance traveled in km) and the stay of the authorized technician for installation, repair or

maintenance before or after the warranty period will be responsibility of the buyer/owner as well as the costs related to the

autoclave sterilization monitoring (tests with biological indicators) and freight charges for shipping the equipment to the

authorized technical assistance office for repairs or, if necessary, to the factory itself

If any item from preventive maintenance needs to be replaced, the cost will be responsibility of the owner, for those are

parts/products susceptible to wear and tear.

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA. is not liable for damages / accidents caused by improper use,

operation or installation of its products, in this case the equipment will lose its warranty and the repair will be paid by the buyer

/ owner.

The warranty will be voided in cases of:

• Problems arising from natural causes (such as floods, lightning, etc.);

• Use of non-distilled water for the operation of the autoclave;

• Damage caused by accidents, such as: dents, drops, short circuits, fire, etc.;

• Damage caused by humidity, excessive exposure to sun light and salinity;

• Sinister (theft or robbery);

• Improper use / installation of the equipment and/or plugging it into an incorrect voltage outlet;

• Problems due to failure of the power supply and/or building wiring;

• Removal and/or tempering of the serial number shown in the identification label of the product;

• Signs of tampering and/or blotted out data on the purchase or service receipt of the equipment;

• Tampering and/or modification of the equipment;

• Signs of external violation of the product or broken factory seal;

• Lack of annual preventive maintenance of the equipment, which must be proved by the service receipt or neglect, or

problems caused by absence of preventive maintenance, when it is indispensable.

• Use of non-original or not acquired at the CRISTÓFOLI Authorized Service Network parts;

• Repairs performed by technicians who are not part of the CRISTÓFOLI Authorized Service Network;

• Noncompliance with any measure or caution recommended in the instruction manual of the product.

ATTENTION!

In order to validate the contractual warranty of the product it is necessary to send a copy of the purchase receipt to the

following e-mail address: [email protected].

WARRANTY TERMS

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

1. Connect the power cable to an outlet and press to turn the autoclave on.

2. Open the door and use the measuring cup to pour the correct amount of distilled water directly inside the chamber

150 ml for Vitale Class 12 and 250 ml for Vitale Class 21.

3. and close the door correctly.Load the autoclave with the materials to be sterilized

4. Press to start, The autoclave will automatically perform heating, sterilization, depressurization, and drying, according

to the table below data. At the end of the drying process, the autoclave will beep until the operator open the door.

5. After depressurizing, the autoclave will beep twice every 4 seconds. Slightly open the door for drying. Note: if a extra

drying is necessary, see the instruction manual.

6. At the end of the process, the LED will be on. Wait until the temperature of the material decreases to handle it.

16

USE INSTRUCTIONS - QUICK GUIDE

Read carefully the Instruction Manual

TIEMPO DE

SECADO

*For altitudes above 2.000 m, the sterilization time is 20 minutes. Maximum drying temperature: 129°C

Default Program

Extra Drying

PROGRAMS STERILIZATION TEMPERATURE STERILIZATION PRESSURE STERILIZATION

TIME DRYING

TIME

HEATING TIME

10 a 60 min.

-------------

1,7 a 1,8 kgf/cm² ou 167 a 186 kPa

---------------------------------

129 a 132 °C ou 264 a 269 °F

--------------------------------

30 min.

20 min.

16 min.*

--------

The Autoclave is an equipment for steam sterilization, it works with high temperature and pressure. The

autoclave must be handled by trained professional and kept at a location with controlled access.

Attention! Perform preventive maintenance on the autoclave according to the instruction manual specifications.

Test your autoclave with biological indicators every 7 days.

CRISTÓFOLI

A U T O C L A V E S

U S E R M A N U A L

This manual suits for next models

3

Table of contents

Other Cristofoli Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Dräger

Dräger PAS Colt Series Instructions for use

GE

GE Vivid 4 BT03 RFI Service manual

DENTSPLY

DENTSPLY SmartLite Max L.E.D. Curing Light Directions for use

Otto Bock

Otto Bock 8S9 Series Instructions for use

bort medical

bort medical 114 150 manual

Verily Life Sciences

Verily Life Sciences Study Watch user manual

CME Medical

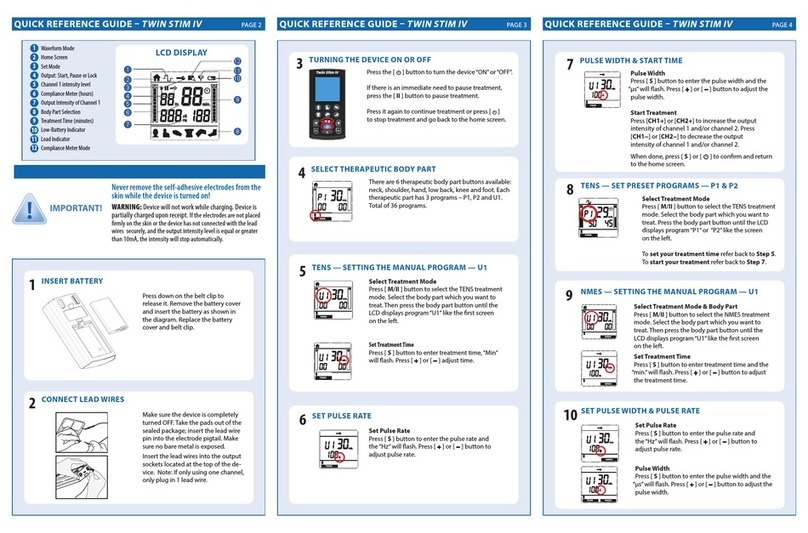

CME Medical BODY GUARD 545 quick start guide

Roscoe Medical

Roscoe Medical TWIN STIM IV Quick reference guide

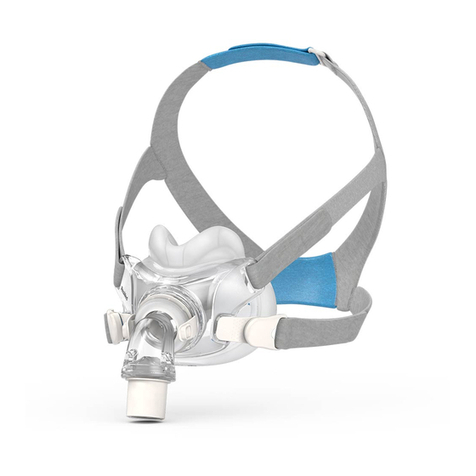

ResMed

ResMed AirFit F30 user guide

InMode

InMode InMode System with BodyFX Handpiece Operator's manual

Nidek Medical

Nidek Medical ARK-530 Operator's manual

Creative

Creative PC-68A Instructions to user