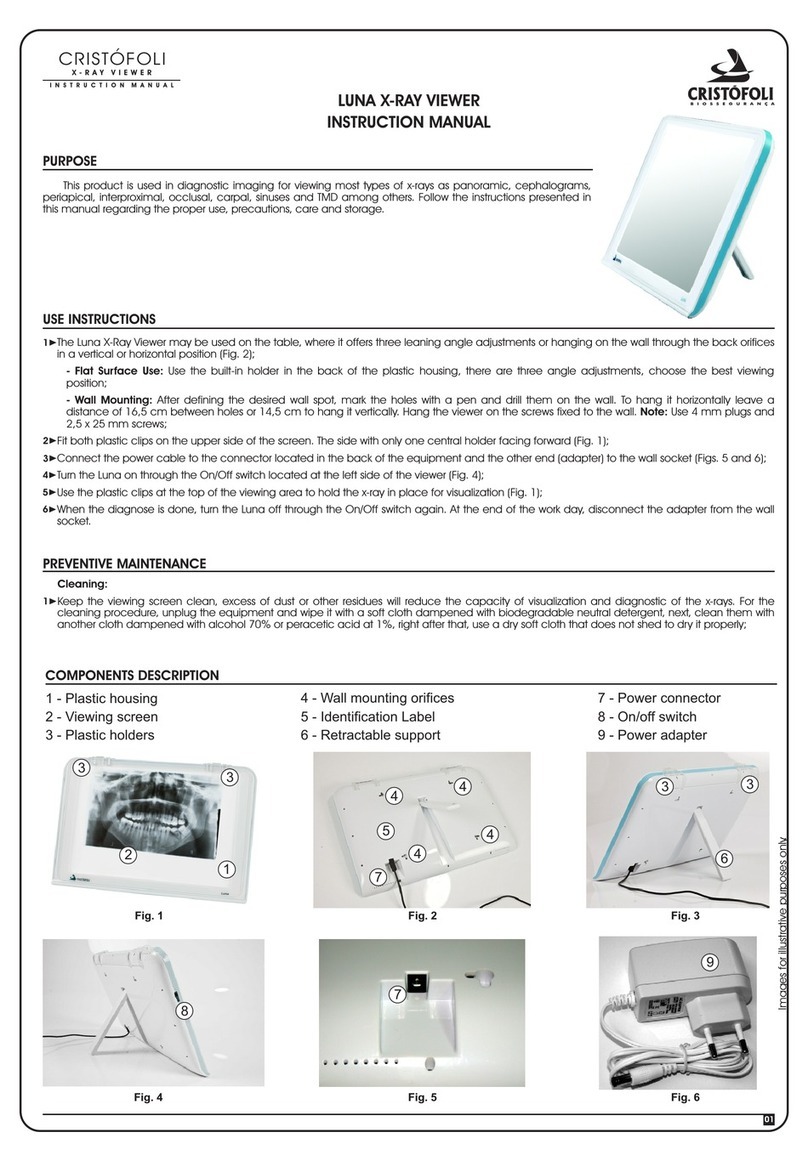

Cristofoli SuperGap Evolution 2 User manual

SuperGap Evolution 2

Vacuum Pump

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

O

I

S

To develop innovative solutions to protect life and promote health.

Cristófoli Equipamentos de Biossegurança Ltda., established at Rodovia BR-158, nº 127,

Jardim Bandeirantes in Campo Mourão, Paraná, Brazil, manufactures biosafety equipment to

assist the health care, having the following policy: "To develop innovative solutions for health

care by using agile, robust, and objective processes to better serve its customers. To fulfill all the

requirements of the applicable standards, promote the continuous improvement of its quality

and environmental standards, prevent pollution, reduce its environmental impact, and

continuously train its staff, achieving, therefore, a sustainable and profitable maximization of its

value." Rev. 2.

CRISTÓFOLI’S MISSION

CRISTÓFOLI QUALITY AND ENVIRONMENTAL POLICY

Cristófoli, Brazilian importing company and manufacturer of

health products certified by ISO 13485 - Health Products -

Quality Management System - Requirements for Regulatory

Purposes and compliance with RDC 16/2013 - *BPF - Boas

Práticas de Fabricação - ANVISA requirements.

Manual Bomba de Vácuo Supergap 3 Ingl. Rev.2-2018

2

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

INDEX

Meaning of Symbols .........................................................................................................

Introduction ......................................................................................................................

Intended Use ....................................................................................................................

Recommendations and Warnings ....................................................................................

Installation Instructions ......................................................................................................

Safety Devices ..................................................................................................................

Component Description ...................................................................................................

How To Use the SuperGap Evolution Vacuum Pump ........................................................

How To Identify Your Autoclave .........................................................................................

Technical Data .................................................................................................................

Preventive Maintenance ...................................................................................................

Troubleshooting ................................................................................................................

Quality Control ..................................................................................................................

How To Proceed When Service Is Needed ........................................................................

Guidance For Final Disposal Of The Equipment ................................................................

Warranty Terms ..................................................................................................................

03

04

04

04

05

09

09

09

10

10

11

12

13

13

14

15

3

MEANING OF SYMBOLS

Maximum Pile

Warning

Manufacturer

Grounding

Protection Terminal

Date of

Manufacture

3

Keep Dry

Recyclable

Keep out of sunlight

This side up

Fragile - handle

with care

LOT

SN

Serial Number

Lot number

ISO 13485

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

I

O

S

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

Responsible Technician

Eduardo Luiz Soppa

CREA-PR: 109201/D

MANUFACTURER

Cristófoli Equipamentos de Biossegurança Ltda.

Rod. BR 158, nº127 - Campo Mourão - PR - Brasil

CEP 87303-650

CNPJ 01.177.248/0001-95 - Inscr. Est. 90104860-65

Website: www.cristofoli.com - e-mail: [email protected]

4

The complete reading of this manual is indispensable for safe use of the equipment and

preventive maintenance orientation. The owner is responsible to perform the adequacy of the

electrical, hydraulic, suction and drainage systems.

The SuperGap Evolution vacuum pump must be handled by professionals, well aware of

the equipment operation.

Box content:

- 1 Supergap Evolution 2 Vacuum Pump. - 1 noise reducer.

- 1 residue filter. - 4 leveler glides with nuts and washers.

- 2 corrugated hoses (1,5 m). - 3 clamps.

- 2 R/L adapters. - 1 hose for water inlet.

- 1 manual.

INTRODUCTION

This equipment was developed for suction of fluids and residues from odontological

treatments or surgeries.

INTENDED USE

RECOMMENDATIONS AND WARNINGS

Read all instructions of this manual before using your SuperGap Evolution. The incorrect use

may result in malfunction and/or accidents.

For your safety, when performing any kind of maintenance, remember to unplug the power

cord and use PPE (Personal Protective Equipment).

Do not allow patients, especially kids, to get close to the equipment.

Never use your vacuum pump without water.

During the vacuum pump operation, it’s perfectly normal to hear noises, which are part of

the proper functioning of the equipment. Cristófoli is not responsible for accidents that might

occur due to jolts caused by the noises produced by SuperGap Evolution.

Do not use the vacuum pump as a water pump.

Do not place any kind of fabric under the vacuum pump, for it makes difficult the

ventilation, causing overheating and damage to the equipment.

Never move or drag the vacuum pump by the power cord or hoses, keep those parts away

from heat or sharp corners.

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

5

INSTALLATION INSTRUCTIONS

Instal vacuum pump on a flat, levelled and firm surface, at the same level or below the

dental unit, never above.

The installation place must be ventilated, dry, clean, free of dust, corrosive gases, and

direct sunlight. Keep SuperGap 2 away from the customer service area and from places

where there’s movement of people. Leave enough room around the equipment (at least 50

cm) for ventilation and preventive maintenance accomplishment.

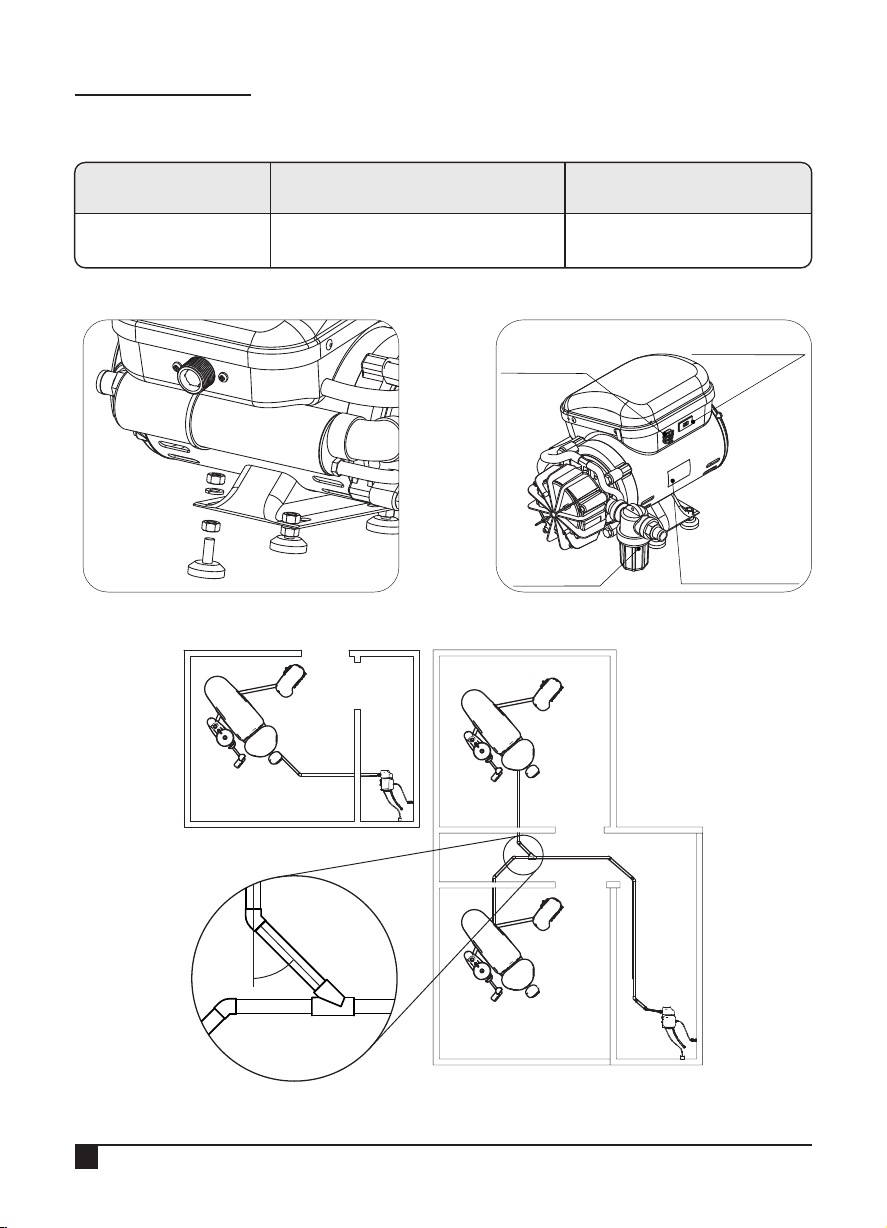

Open the package, remove the equipment and put the leveler glides, for it, use a 5/16" fork

wrench. Put the lock washers and fasten the nuts for all the glides (Fig. 5, page 8).

1

2

3

ELECTRICAL INSTALLATION (Vacuum Pump)

See “How To Proceed When Service Is Needed” (Page 13). If the owner performs the

installation with a non- authorized electrician or technician, Cristófoli will not be responsible

for services done in disagreement with the orientations descibed in this manual.

4

As shown in the identification label, the SuperGap 2 is a dual voltage device, and it

leaves the factory adjusted for 220 V. For 127 V operation, reposition the selector switch,

placed at the back of the equipment (Fig. 9, page 9). See “How To Identify Your

Vacuum Pump” (Fig. 11, page 10).

For installation, use a grounded outlet (2 Pins + Grounding, 20 A), plugging phase/neutral or

phase/phase at the side pins and grounding at the middle pin: Never plug the grounding

on neutral.

Electrical Grounding is very important for the operator’s safety and for your equipment’s

functionality. Therefore, the center pin (grounding) must never be removed or cut. The

failure to observe this procedure may damage your autoclave. Install the equipment

where the power cord can be easily disconnected.

Never use electric extensions, adapters or voltage transformers.

For the proper functioning of the autoclave, the electrical wire must be stable, in other

words, without oscillations. It is mandatory the use of an exclusive circuit breaker for

the outlet where the autoclave will be installed. If after following all the specifications,

the electrical wire still oscillates, contact the local electricity company.

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

6

Note: In 127 V regions, use “one-pole” circuit breaker.

In 220 V regions, use “two-pole” for phase-phase and “one pole” for phase-neutral.

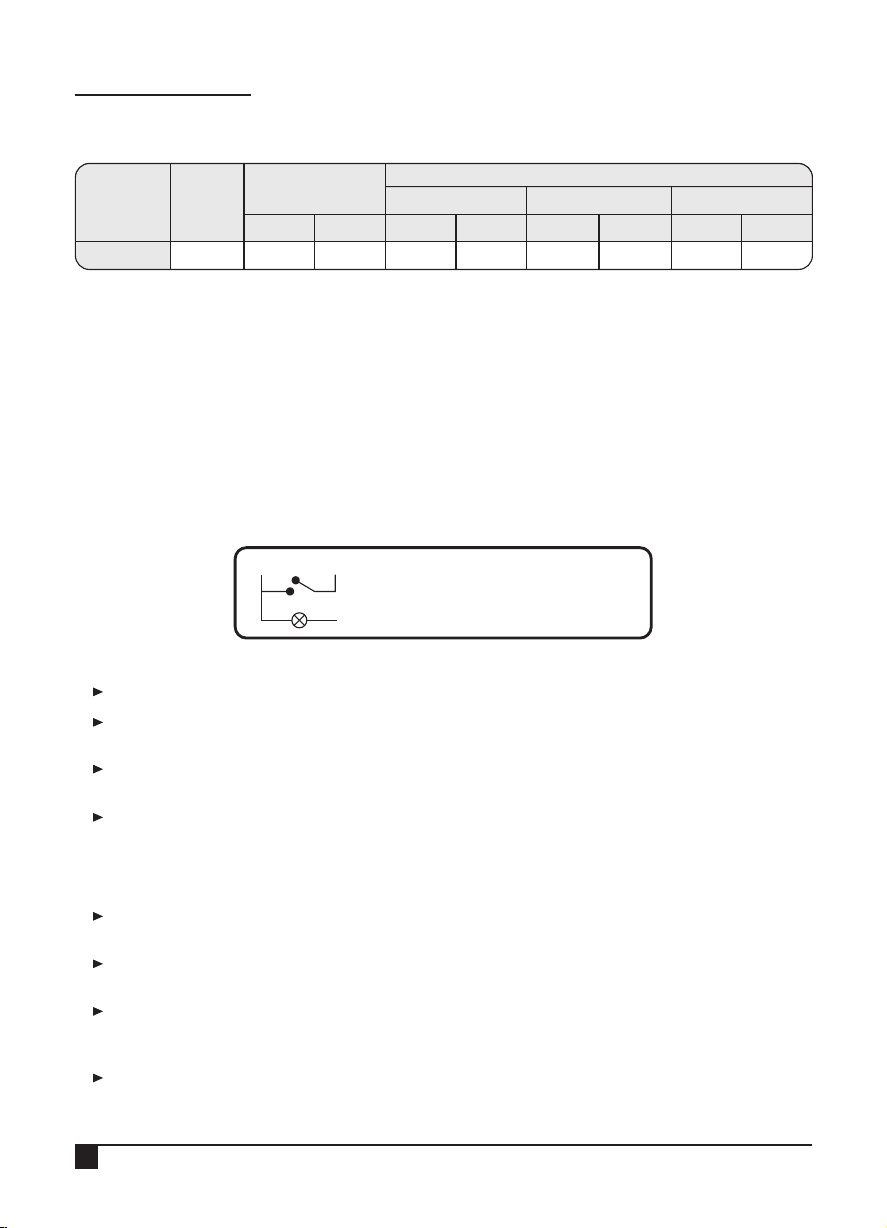

Table 1

3/4

SUPERGAP 2

Up to15 m from 15 to 30 m above 30 m

127 V AC 127 V AC 127 V AC 220 V AC220 V AC220 V AC127 V AC 220 V AC

MODEL POWER

(HP)

CIRCUIT BREAKER

(C Curve)

WIRING GAUGE FROM THE CIRCUIT BREAKER UP TO THE VACUUM PUMP (mm²)

15 2,5 2,5 42,5 64

25

ELECTRICAL INSTALLATION (suction instruments activation)

See the dental unit or vacuum pump kit manual to find the activation wiring for the

microswitches and instal it to the strip connector of the vacuum pump (Fig. 9, page 9).

White: Micro switch.

Red: 12 V DC (LED). Note: For dental units or vacuum pump kits which has indicating LED at

the sution instruments.

Black: Ground (GND).

HYDRAULIC INSTALLATION

Provide, close to the vacuum pump, a water supply with a 3/4" external thread water valve.

The water inlet pressure must be around 3 to 40 wcm (water column meters), above 20 wcm,

it could be possible to hear an acute sound from the flow regulator.

Connect the hose with a 90° angle to the water inlet at the front of the vacuum pump (Fig. 8,

page 9) and the other side to the water valve.

The water flow regulation is automatically done by an internal device (Fig. 8, page 9).

SUCTION

The pipe that connects the dental unit to the vacuum pump must have an inclination level

between 0 and 10 %.

It is recommended that right angle connections at the pipes be avoided, prefer 45°

connections and/or soft curves to optimize vacuum (Fig. 7, page 8).

Connect the residue filter to the suction inlet (Fig. 6, page 8), after that, connect the

corrugated hose to the filter. Remember to put the clamp before fitting the hose, fasten it

firmly.

Fasten the R/L adapter at the dental unit suction inlet, after that, fit the other side of the hose

to the R/L adapter (fit the clamp before, as described above).

Fig. 1

Red

Negro

White

White - Red = micro switch

Red - Black = LED

+

-

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

7

DRAINAGE

The one-way noise reducer minimizes the noise produced by the airflow inside the pipe.

The vacuum pump induces air to the plumbing system, so open drains or siphons near will

release air, noise and probably bad smell, therefore, every drain at the establishment must

have a siphon.

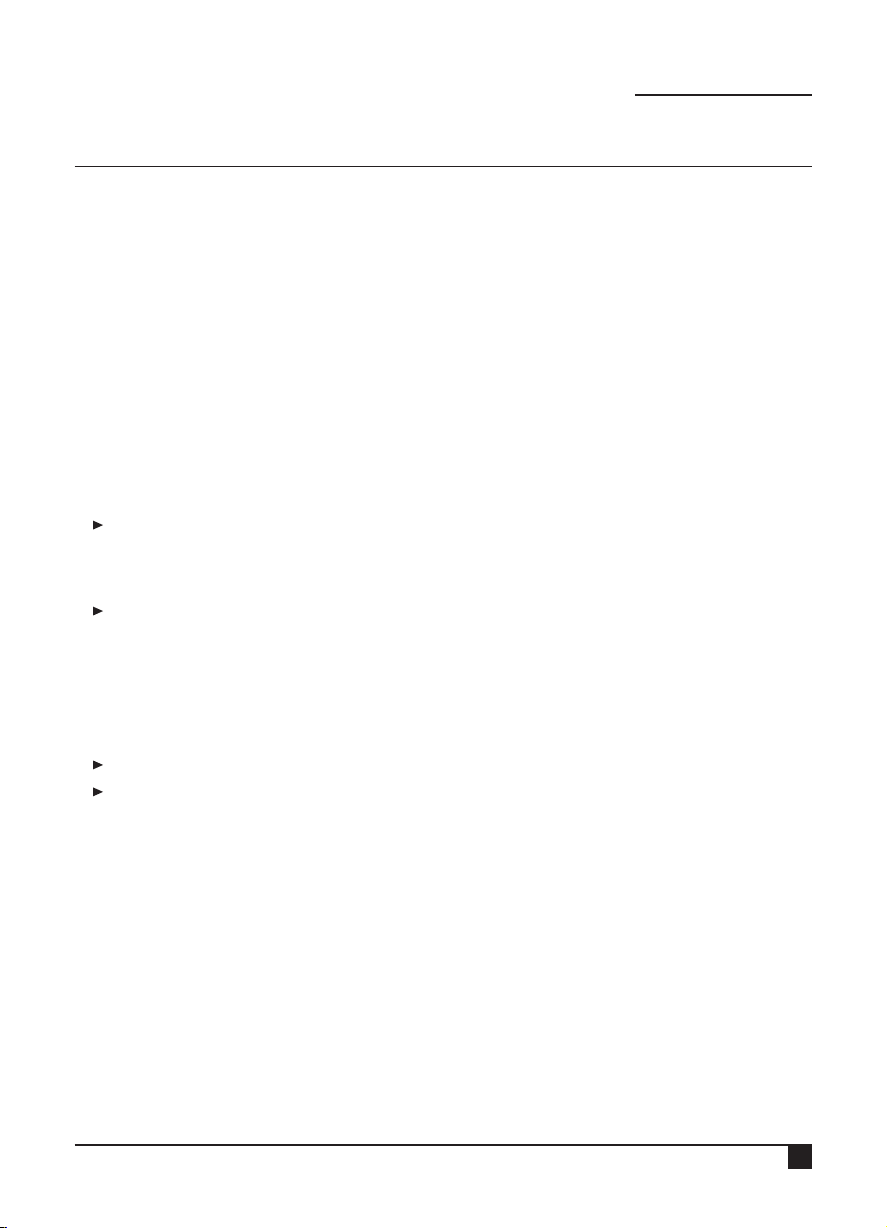

Connect the corrugated hose to the drain exit and fasten it with the clamp (Fig. 2).

Cut the hose at the most convenient place (Fig. 2) and install the noise reducer (Fig. 3)

observing the arrow that indicates flow direction (Figs. 3 and 4). Attention!

The incorrect installation of the noise reducer (backwards) will cause damage to the vacuum

pump.

Connect the R/L adapter to the drain exit of the dental unit, after it, connect the hose to the

adapter and fasten it with the clamp. Note: The vacuum pump and the cuspidor may be

connected to the same drain, since that there’s an exclusive siphon for the cuspidor, to avoid

excessive noise.

3

1

2

Fig. 4

Detailed image of the flow indication arrow

Fig. 2

Fig. 3

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

8

Table of dimmensions for pipes from the vacuum pump to the dental unit.

*Consider the most distant from the dental unit vacuum pump.

SuperGap 2 10 m max. 32 mm

Model Pipes length* Pipes diameter

Table 2

Fig. 5 Fig. 6

Strip

Connector

Residue

Filter

Voltage

Selector Switch

Identification

Label

Fig. 7

45 °

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

9

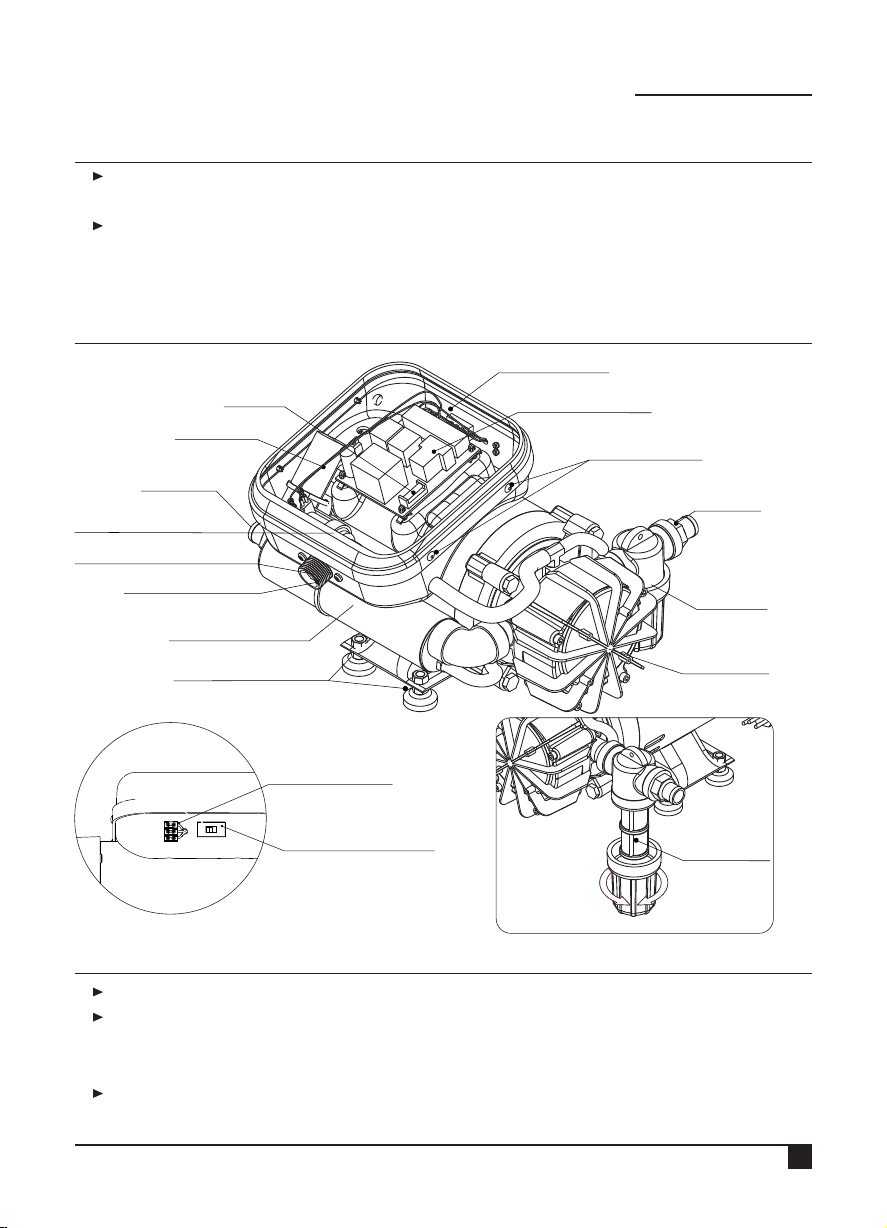

Strip connector

Voltage Selector

Switch

Fig. 9

(detail)

Fig. 8

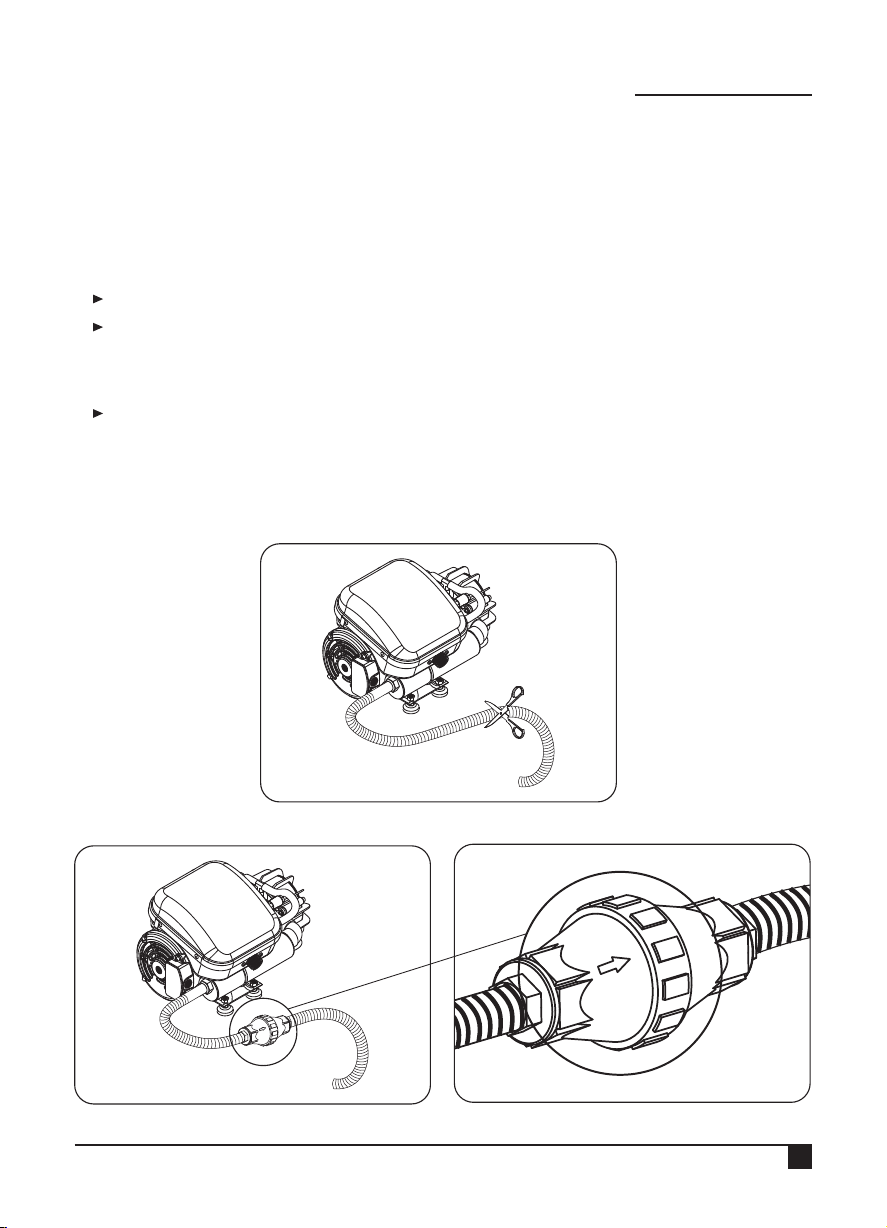

COMPONENT DESCRIPTION

FUSE - Internal device, located at the electronic circuit (glass model - fast acting - 300mA),

that protects the electrical installations and equipment against peaks of energy (Fig. 8).

THERMAL FUSE - Internal device that, in case of overheating, automatically disconnects the

motor. The motor will work again as the temperature gets back to normal levels.

SAFETY DEVICES

1

2

Before turning on the vacuum pump, make sure the water supply valve is open.

At the first use, it is necessary to wait for 2 minutes until the vacuum system is filled with water.

To turn on the vacuum pump, just take the suction instrument out from it’s support, and to

turn it off, get the instrument into the support again, so the vacuum pump will be

automatically deactivated.

At the end of the workday, clean the residue filter (Fig. 10). See “Preventive Maintenance”

(Page 11).

HOW TO USE THE SUPERGAP EVOLUTION VACUUM PUMP

1

2

3

Fig. 10

Filtering

element

Solenoid valve

Electronic circuit

Capacitor

Fuse

Water inlet

Drain exit

Flow limiter

Water feedback

system

Leveler glides

Comand box

Residue

filter

Vacuum

system

Suction

(inlet)

Plastic rivets

OPEN

CLOSE

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

10

Fig. 11

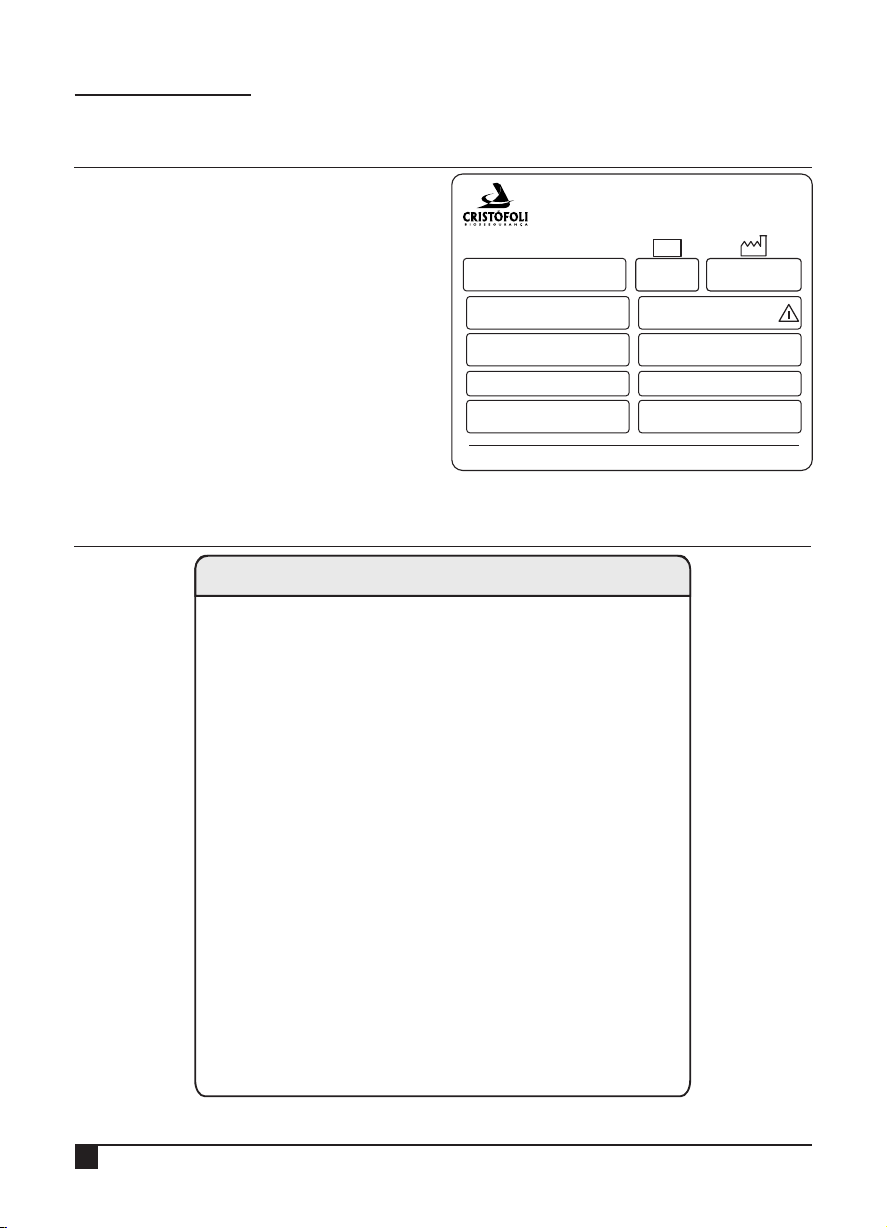

The identification label, located at the

back of the equipment, identifies the

technical data of the vacuum pump.

ATTENTION! - The removal of the identification

label or any sticker glued on the equimpent will

cause automatic loss of warranty.

HOW TO IDENTIFY YOUR AUTOCLAVE

TECHNICAL DATA

Table 3

Class ......................................................................

Capacity ................................................................

Gross weight (wrapped) .........................................

Net Weight .............................................................

External dimensions (W x H x D) ..............................

Box dimensions (W x H x D) .....................................

Voltage ..................................................................

Frequency ..............................................................

Water consumption ...............................................

Power .....................................................................

Power Consumption ...............................................

Maximum flow (air) .................................................

RPM ........................................................................

Maximum Vacuum ................................................

Noise level .............................................................

Appropriate relative humidity (operation) ...............

Appropriate relative humidity (transportation and

storing) ...................................................................

Appropriate atmospheric pressure .........................

Room temperature (operation) ..............................

Room temperature (transportation and storing) .....

Certification ........................................................... This equipment is manufactured by

Cristófoli Biossegurança, company

whose the Quality Management System

is certified by and in accordance with ISO

13485:2003.

I

Suitable for up to 4 dental units

14,6 kg

13,5 kg

23,2 cm x 23,5 cm x 35 cm

27 cm x 27 cm x 39 cm

127/220V AC - single-phase

60 Hz

0,16 l/min.

560 W - 3/4 HP

0,56 /hkW

300 liters / min.

3450

620 mm Hg

78 dB

70 %

0 a 75 %

70 - 106 kPa

5 ºC a 40 ºC

-5 ºC a 55 ºC

LOT

S N

PRODUCT: VACUUM PUMP

USE INSTRUCTIONS, PRECAUTIONS, CONSERVATION AND STORING:

SEE THE USER MANUAL.

POWER

MODEL

DIMENSIONS (W x H x D)

MAXIMUM FLOW (AIR)

FREQUENCY

ANVISA RESPONSIBLE TECHNICIAN

VACUUM MAX. PRESSURE

MODEL

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

TECHNICAL DATA CHART

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA

ROD BR 158 Nº 127 - CAMPO MOURÃO - PR - BRASIL

CEP 87309-650 - TEL.: 55 44 3518-3449

CNPJ 01.177.248/0001-95 - INSCR. EST. 90.104.860-65

INDUSTRIA BRASILEÑA

11

PREVENTIVE MAINTENANCE

For better functioning and durability of your vacuum pump, some procedures are needed.

Preventive maintenance correspond to the accomplishment of all procedures below.

PERIODICITY

MAINTENANCE

DAILY

Vacuum pump internal cleaning:

It is recommended that a specific product for this purpose be used, for example, a

detergent which is suitable to disinfect and dissolve residues inside the vacuum

system, for it will reduce the need of cleaning and keep the suction capacity

through duct clearance. To perform this kind of cleaning, proceed according to the

cleaning product manufacturer’s instructions.

Residue filter cleaning:

Open the filter cover by turning it counterclockwise (Fig. 10, page 9), remove-it and

discard the residue in appropriate place. Wash the cover of the residue filter and

filtering element, verify if the gasket inside the cover is properly placed, and

reposition the residue filter. If the gasket is damaged, replace-it. To buy extra filtering

elements, consult your local Cristófoli authorized dealer. ATTENTION! Never forget to

reposition the filtering element of the residue filter. Small fragments are enough

to damage the internal components of the vacuum pump.

MONTHLY

External cleaning:

Unplug the power cord and perform cleaning with a feather duster or a soft cloth,

slightly moistened with water and biodegradable neutral detergent, after it, clean

with a cloth, moistened with 70% alcohol and 1% peracetic acid. Never use

solvents or petroleum derivatives. Verify the openings at the bottom of the motor, if

there’s dirtiness accumulation on it, perform cleaning.

YEARLY

General revision and flow limiter regulation (we recommend that this procedure

be performed by an authorized technical assistance):

Unplug the power cord and close the water supply valve. Remove the hose

connected to the water supply valve. Remove the filtering screen and take the flow

limiter out of the water inlet with a needle nose plier. Rotate the tip of the flow limiter

counterclockwise, taking care not to damage the internal rubber disc. After

removing, wash the parts below running water. When mounting it, take care not to

press the rubber disc. Reposition the set back to the valve. Reconnect the hose to

the water inlet. Turn on the vacuum pump and make the measuring test again.

Measuring test (water consumption): Disconnect the hose from the drain exit of the

vacuum pump. Use a measuring cup with ml (millilitre) scale and a stopwatch.

Activate the vacuum pump, wait for 3 to 5 minutes, until the flow of expelled water

stay constant. Place the measuring cup at the vacuum pump water exit and collect

the expelled water for 1 minute. After this time, observe if the amount of expelled

water is 160 ml. If the result taken is different from the indicated value, perform the

procedure again.

Table 4

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

12

TROUBLESHOOTING

ATTENTION! For any replacement of parts, contact yout local dealer. It’s not

recommended the replacement by non-qualified people.

Listed below are the most frequent problems and possible solutions, which could be solved

by the user.

THE VACUUM PUMP DOES NOT SWITCH ON

•Lack of power -------------------------------------------------

•Disarmed circuit breaker ----------------------------------

•The power cord is not plugged in ----------------------

•When taking out the suction instrument out of the

support , the vacuum pump does not activate -------

•Fuse burn ------------------------------------------------------

POSIBLE CAUSES SOLUTION

•Verify if there’s a power failure in your area.

•Rearm the circuit breaker.

•Connect the power cord to the outlet properly.

•Consult “How to proceed when service is needed”

(Page. 13).

•Change the fuse, which is located at the electronic

circuit, inside the command box. To replace the

fuse, unplug the equipment from the outlet, push

the pins of the plastic rivets (Fig. 8, page 9) inside

the command box, with a slim tip, remove de rivets

and the cover, locate the fuse and replace it by a

new one. Take out the the pushed plastic pins,

place the lid again and the plastic rivets. Note: To

place the rivets, insert the plastic pins at the center

of the rivets, about 2 mm, put the rivets inside the

holes and push the pins until they get alined with

the rivets to lock it. See “Safety Devices” (Item 1,

page 9).

If the problem persists after the verification of all items, contact your local dealer.

THE VACUUM PUMP SWITCHES ON BUT PRODUCES INSUFICIENT OR DOES NOT

PRODUCE VACUUM

•Lack of water in the vacuum pump --------------------

•The residue filter is full ----------------------------------------

•The redisue filter cover isn’t properly closed -----------

•Air entrance through the pipes ---------------------------

•Verify if the water valve is closed or if there’s lack of

water ar your area.

•Clean the residue filter. See “Preventive

Maintenance” (Page. 11).

•Remove the residue filter cover, verify the gasket

fitting and mount it again.

•Verify if there’s weak connections or leaks at the

dental unit vacuum pipes.

POSIBLE CAUSES SOLUTION

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

13

Cristófoli Vacuum Pumps are individually monitored according to internal test and

manufacturing patterns approved by Cristófoli’s quality control.

QUALITY CONTROL

If there’s any problem with your equipment, at first, see the topic “Troubleshooting” (Page.

12), if the problem persists, contact your local dealer for an evaluation and possible repair of

your equipment. It will be also necessary to have the original invoice from your dealer to

confirm the date of purchase.

Before contact, have in hands the model of your autoclave, voltage, serial number, and

the date of manufacture, found in the identification label located in the back of the

equipment (Fig. 6, page. 8) and a description of the problem.

Always contact your local dealer. If you have problems contacting your dealer, contact

us through our website: www.cristofoli.com.

HOW TO PROCEED WHEN SERVICE IS NEEDED

THE VACUUM PUMP STOPS AND DOES NOT SWITCH ON

•The motor is overheated and the thermal fuse was

activated -------------------------------------------------------- •Wait until the motor gets cold, if it doesn’t get back

to work, see “How To Proceed When Service Is

Needed” (Page 13).

•Verify voltage and electrical wire conditions;

POSIBLE CAUSES SOLUTION

If the problem persists after the verification of all items, contact your local dealer.

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

14

GUIDANCE FOR FINAL DISPOSAL OF THE EQUIPMENT

The environment belongs to everyone, therefore, it is up to each one of us to make

decisions that will help in its preservation and reduction of the damages resulting from

human activities.

All products have a useful life span, but it is not possible to determine how long is it, as it

varies according to the intensity and how the equipment is used or handled. Exception

made for the component “lid” which must be replaced every 10 years.

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA strongly recommends users of

their products to seek the best destination when disposing equipment or components,

taking into account the materials recycling legislation effective in each country.

We advise you to take your equipment to specialized recycling companies that, due to

the continuous and fast paced development of new recycling technologies and materials

reuse, provide the best way of disposing the equipment. Cristófoli contributes this way to

reduce the consumption of non-renewable raw materials.

On behalf of all users, we thank you for your comprehension and cooperation.

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

15

WARRANTY TERMS

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA warranties the Cristófoli Vacuum Pumps

for 01 (one) year against any manufacturing defect from the date of the purchase receipt

(provided it contains the serial and lot numbers of the equipment), of which 03 (three) months

refer to the legal warranty (established by section II, art. 26, CDC, Brasil) and nine (09) months to

the contractual warranty (arranged in art. 50, CDC, Brazil). Visit our website www.cristofoli.com

and register your product online.

Traveling costs (based on the distance traveled in km) and the stay of the authorized

technician for installation, repair or maintenance before or after the warranty period will be

responsibility of the buyer/owner as well as the costs related to the autoclave sterilization

monitoring (tests with biological indicators) and freight charges for shipping the equipment to

the authorized technical assistance office for repairs or, if necessary, to the factory itself.

The warranty will be voided in cases of:

• Problems arising from natural causes (such as floods, lightning, etc.);

• Sinister (theft or robbery);

• Damage caused by accidents, such as: dents, drops, short circuits, fire, etc.;

• Problems due to failure of the power supply and/or building wiring;

• Improper use / installation of the equipment and/or plugging it into an incorrect voltage

outlet;

• Removal and/or tampering of the serial number shown in the identification label of the

product;

• Signs of tampering and/or blotted out data on the purchase or service receipt of the

equipment;

• Signs of external violation of the product or broken factory seal;

• Use of non-original or not acquired at the CRISTÓFOLI Authorized Service Network parts;

• Alteration in the equipment performed by the client.

• Repairs performed by technicians who are not part of the CRISTÓFOLI Authorized Service

Network;

• Noncompliance with any measure or caution recommended in the instruction manual of

the product.

Fuse and filtering element are not covered by warranty.

ATTENTION!

In order to validate the contractual warranty of the product it is necessary to send a copy of

the purchase receipt to the following e-mail address: [email protected].

C R I S T Ó F O L I

V A C U U M P U M P S

I N S T R U C T I O N M A N U A L

Table of contents

Other Cristofoli Medical Equipment manuals

Popular Medical Equipment manuals by other brands

PLUSOPTIX

PLUSOPTIX S12R Software update

orfit

orfit HP PRO 25000/33 Instructions for use

Nambison's softroniX

Nambison's softroniX Hi-Power Digi-Scope user manual

SELVAS Healthcare

SELVAS Healthcare Accuniq BC310 user manual

Blatchford

Blatchford ElanIC quick start guide

Humanscale

Humanscale TouchPoint T7 user manual