CROWN INDUSTRIAL AUT-O-DOR 1510 User manual

G-993-R3

Crown Industrial Operators

(Formerly manufactured by Richards-Wilcox)

213 Michelle Court

So. San Francisco, CA 94080

Phone (650) 952-5150

Fax (650) 873-1495

website: www.crown-industrial.com

Copyright © Crown Industrial Operators 2011

GENERAL

INSTALLATION,

OPERATION,

MAINTENANCE,

and PARTS MANUAL

for your

1510 SWING-GATE

OPERATOR MODEL "F"

HEAVY DUTY & EXTRA HEAVY DUTY

CROWN

NDUSTRAI IL

OPERATORS

CONTENTS

PARAGRAPH PAGE

1 INTRODUCTION............................................................................... 1

A Purpose......................................................................................... 1

B Models Covered............................................................................ 1

C Application..................................................................................... 1

D Description.................................................................................... 1

2 INSTALLATION AND OPERATION................................................... 1

A General ......................................................................................... 1

B Preparing The Mounting Channel................................................. 2

C Mounting the Operator.................................................................. 2

D Mounting the Arms........................................................................ 2

E Wiring the Operator....................................................................... 6

F Phasing Out Motor........................................................................ 6

G Adapting Controls.......................................................................... 7

H Preliminary Limit Switch Adjustment ............................................. 7

I Setting the Clutch.......................................................................... 7

J Final Limit Switch Adjustment ....................................................... 7

3 MAINTENANCE ................................................................................ 8

A General ......................................................................................... 8

B Lubrication..................................................................................... 8

C Preventative maintenance............................................................. 8

4 PARTS............................................................................................... 9

A To Order Replacement Parts......................................................... 9

B Parts List....................................................................................... 9

Parts List-Heavy Duty 1/2, 3/4, 1 HP Operator............................. 10

Parts List-Extra Heavy Duty 1 HP Operator.................................. 12

WARRANTY...................................................................................... 14

Note: We reserve the right to modify or change, without prior notice,

any statements or information contained herein. If exact dimensions

or specifications are required by the customer certified prints will

be furnished without charge upon request to Crown Industrial. This

manual covers standard catalogued operators only and does not cover

special non-standard equipment.

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

1. GENERAL INTRODUCTION

A. PURPOSE: This Crown Installation, Operation,

Maintenance and Parts Manual has been developed to

assist you in the installation, operation and maintenance

of your electric operator and thus enable you to utilize it

to its maximum efficiency.

B. MODELS COVERED: The manual covers the

Model 1510 Operator in production and contains the

latest information available. The parts pages have been

prepared so that you can easily determine the parts

contained in your Electric Operator.

C. DESCRIPTION:

(1) GENERAL: The Heavy Duty Operator is built into a

compact unit consisting of an instantly reversing motor, a

precision made speed reduction mechanism with V-belt

and pulleys, a safety friction disc clutch, an emergency

release, a fully automatic double acting limit switch, a

heavy duty crank and connecting arm assembly, and

a weather resistant cover (Figure 1). The Extra Heavy

Duty Operator is similar but without the V-belt and

pulleys.

(2) MOTORS: The motor has ample reserve power to

take occasional overloads, and is furnished in 1/2, 3/4,

or 1 HP sizes for standard gates, and a 1 HP (gearhead

motor) for extra large and heavy gates. Motors are

available in single phase, however three phase current is

highly recommended for best all around performance.

(3) SHAFTS AND GEARS: Shafts and gears in the

heavy unit are mounted in long life bearings enclosed

in an oil tight housing and operate at all times in a bath

of grease (extra heavy duty units are oil filled). The

automatic limit switch is built on the reduction unit and

stops the gate in the desired open or closed position.

(4) CRANK AND CONNECTING ARMS: The operating

levers consist of a heavy duty crank and connecting

arms. The crank arm is driven by a safety friction disc

clutch which protects equipment in case the gate comes

in contact with an obstruction. A disconnecting device is

provided to allow manual operation.

2. INSTALLATION AND OPERATION

A. GENERAL

The Crown Industrial 1510 Electric Gate Operator is

rugged, well designed, dependable, and field proven

to be trouble free for swing gates. To ensure correct

installation and proper operation, observe the following

instructions:

(1) CHECK THE SHIPMENT: Included with the

installation packet is a copy of the material specification

sheet for the components supplied with the order.

Compare the components received with the material

specification sheets to insure that all equipment is

complete.

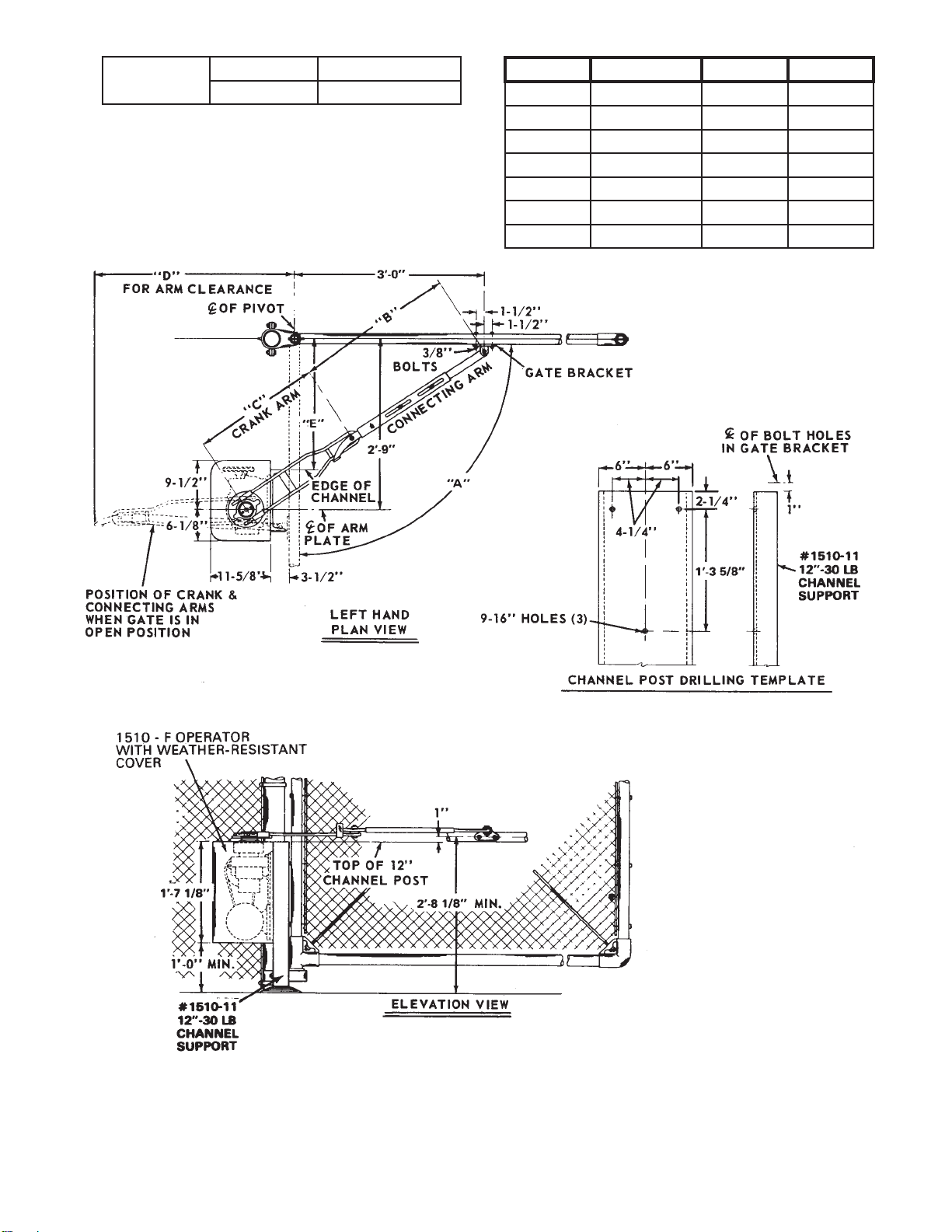

Figure 1.

1510 Heavy Duty Swing Gate Operator.

(Shown with weather-resistant cover removed)

Figure 2. Swing Gate

RIGHT HAND SWING

LEFT HAND SWING

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

(3) CHECK THE GATES: Before starting Operator

installation, inspect to ensure that the gates are in good

working condition, are rigidly supported, and have no

obstructions to block or retard their swing. Electric Gate

Operators cannot be expected to power operate gates

where conditions prevent or resist manual operation.

Latches, foot bolts, or other devices should be removed

from the gate to prevent their accidental engagement.

When standing in a position facing the closed gate and

the gate swings toward you to open, the gate has its

pivot pin to the left, this is considered a left hand. When

the gate has its pivot pin on the right and opens toward

you, it is considered right hand. Refer to Figure 2 Swing

Gate for gate handing.

(4) REVIEW THE INSTALLATION DRAWINGS: The

installation drawings show the layout of the gate,

template drilling for the gate bracket and channel post,

and general terms used to describe components.

Review of the installation drawings will familiarize you

with the equipment.

(5) PREPARING THE GATE: The Electric Gate

Operator powers the gate through a gate bracket

attached to an intermediate cross rail of the gate. If the

gate is not provided with a cross rail, a 2-1/2"x 2-1/2"

x 3/8" or larger structural angle can be installed, leg

up, across the gate to receive the gate bracket. The

cross rail is prepared for the gate bracket by drilling two

mounting holes on the horizontal center line of the cross

rail. These holes are located from the center line of the

gate pivot or hinge pin - see Figure 3, 4, 5, or 6.

B. PREPARING THE MOUNTING CHANNEL

(1) CONCRETE EMBEDDED TYPE:

(a) The channel post for support of the Operator is

an optional extra cost item. When furnished as an

optional part of the operator equipment, they will be pre-

drilled for the mounting of the Operator and hot dipped

galvanized. When the channel posts are not provided,

posts of the size indicated on Figure 3 or 4 are required.

These posts should be drilled in accordance with the

channel post drilling template on Figure 3 or 4. It is

recommended that the posts be hot dipped galvanized

or specially treated to avoid corrosion. The channel post

should be set to dimensions shown on Figure 3 or 4 in

concrete piers, considering the angle of the gate in the

full open position. The size and depth of the piers may

vary with soil and fill types.

NOTE: The customer and/or contractor is

responsible for the proper installation of the

mounting posts. The posts must be installed plumb

and in exact position as shown on Figure 3 or 4.

(b) The top of the channel post should be positioned

vertically one inch below the horizontal center line of the

gate bracket mounting holes drilled in the gate cross rail.

The back of the channel post web should be located

parallel to, and three and one-half inches away from the

gate frame in the gate’s fully opened position (regardless

of degree of opening).

(c) Locate the inside edge of the channel post flange

(Dim. "E") from the center line of the gate pivot and

along the line of the opened gate as indicated on Figure

3 or 4.

(2) PAD MOUNTED TYPE: The type mounted channel

for support of the Operator is available as an optional

extra cost item. When furnished, they will be pre-drilled

for mounting of the Operator and to the concrete pad.

NOTE: A suitable mounting pad with (4 ea.) 3/4"

diameter studs is the responsibility of the customer

and/or contractor. The pad must be level and the

studs in the exact position as shown on Figure 5.

C. MOUNTING THE OPERATOR

(1) Remove the Electric Gate Operator from the crate.

The Gate Operators are universal and therefore can be

used on either hand gate. (Heavy Duty Units Only).

NOTE: The extra heavy duty operators are handed.

(2) Remove the front cover of the Operator by removing

the self-tapping screws from the edges of the cover and

sliding the front cover down, then away.

(3) Remove the nuts, lock washers, and flat washers

from the bolts on the back of the Operator. Raise the

Operator into position on the channel post, inserting

the mounting bolts. Secure the Operator with the flat

washers, lock washers, and nuts.

D. MOUNTING THE ARMS

(1) Release the arm plate by pulling down on the clutch

release chain located on the side of the Operator. To

keep the arm plate disengaged, insert a wedge of some

sort between the clutch yoke the chain is connected to

and the bottom of the clutch. Check to see if the arm

plate is free to rotate. (See Figure 7).

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

Figure 3. Installation of Operator - Heavy Duty 1/2, 3/4, and 1 H.P.

(Using Concrete Embedded Mounting Channel)

E2’ - 1-1/4" LEFT HAND

2’ - 4-3/4" RIGHT HAND ABCD

90° 2’ - 6-1/4" 2’ - 0" 3’ - 2"

95° 2’ - 7 1/4" 2’ - 1" 3’ - 6"

100° 2’ - 8" 2’ - 2" 3’ - 10"

105° 2’ - 8-3/4" 2’ - 2-3/4" 4’ - 1"

110° 2’ - 9-3/4" 2’ - 3-1/2" 4’ - 4"

115° 2’ - 10 1/4" 2’ - 4 1/4" 4’ - 8"

120° 2’ - 11" 2’ - 4-3/4" 4’ - 11"

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

G-993-R3 3

Figure 4. Installation of Operator - Extra Heavy Duty 1 H.P.

ABCD

90° 2’ - 10-1/2" 2’ - 2-1/4" 3’ - 6"

95° 2’ - 11-5/8" 2’ - 3-7/8" 3’ - 7-1/8"

100° 3’ - 0-1/4" 2’ - 4-1/4" 3’ - 7-3/4"

105° 3’ - 1-3/8" 2’ - 5-1/8" 3’ - 8-7/8"

110° 3’ - 2-1/4" 2’ - 6-1/8" 3’ - 9-3/4"

115° 3’ - 3" 2’ - 6 7/8" 3’ - 10-1/2"

120° 3’ - 3-5/8" 2’ - 7-1/2" 3’ - 11-1/8"

1' - 8"

2' - 3"

8 1/2"

1'-10"

1'- 5"

1'- 3"

14"

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

Figure 5. Installation of Operator - Heavy Duty 1/2, 3/4, and 1 H.P.

(Using Pad Mounted Column)

ABCD

90° 2’ - 6-1/4" 2’ - 0" 3’ - 2"

95° 2’ - 7-1/4" 2’ - 1" 3’ - 6"

100° 2’ - 8" 2’ - 2" 3’ - 10"

105° 2’ - 8-3/4" 2’ - 2-3/4" 4’ - 1"

110° 2’ - 9-3/4" 2’ - 3-1/2" 4’ - 4"

115° 2’ - 10-1/4" 2’ - 4-1/4" 4’ - 8"

120° 2’ - 11" 2’ - 4 3/4" 4’ - 11"

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

(2) Mount the crank arm in place by inserting the rod

ends into the two holes at the edge of the arm plate on

top of the Operator. Be sure the pivot stud at the end of

the arm is pointing up. By sliding the arm into or out of

the arm plate holes, you can adjust the distance between

the center point of the arm plate to the pivot stud to

dimension "C" shown on Figure 3, 4, or 5. Tighten the

two set screws securely on each side of the arm plate to

secure the crank arm into the arm plate.

(3) Loosen the adjusting bolts on the connecting arm.

Remove the nut and washer from the crank arm pivot

stud and install the hooked end of the connecting arm

to the crank arm. Note that the extended hooked end

over-travel stop on the connecting arm should fall on

the side of the crank arm away from the gate pivot. The

gate bracket on the far end of the connecting arm should

then be attached to the gate cross rail with the 3/8" bolts

provided. (See Figure 3, 4, or 5).

(4) With the gate closed, the arms should then be

placed in a position so that the center point of the crank

arm pivot stud falls on a direct line between the center

point of the arm plate and the center point of the gate

bracket. With this accomplished, the adjustment bolts on

the connecting arm should be tightened.

(5) The gate should then be opened, with the clutch

disengaged, by manually breaking the dead center

condition of the crank arm and connecting arm away

from the gate pivot and then manually swinging the gate

open.

WARNING: After breaking the dead center position

of the arms, do not attempt to open the gate with

operator arms. Hands can be pinched between the

crank and connecting arms as the gate reaches the

open position.

(6) When the gate is fully open, the arms should

assume the position shown by the dotted lines in Figure

3, 4, or 5. If the arms reach a locking position before

the gate is fully open, a re-adjustment of the arms is

required.

E. WIRING THE OPERATOR

(1) Wire the Operator and control circuit as shown

onokay the wiring diagram enclosed, "General Operator

Wiring and Control Information Manual". BE SURE ALL

POWER IS OFF.

F. PHASING OUT MOTOR

(1) Remove the weather plate, gasket, and retaining

ring from the arm plate and lift the arm plate from the

operator. Remove the wedge from the clutch.

(2) THREE PHASE: Turn power on. Using the left side

reversing contactor for counter-clockwise rotation, and

the right side contactor for clockwise rotation, press

one of the control buttons. Note the direction the top of

the operator is rotating. For a pair operation, operators

should be tested separately. If the top is rotating counter-

clockwise, then the left side contactor coil should be

energized. If the wrong coil happens to be energized, for

the counter-clockwise direction, exchange any to power

leads.

(3) SINGLE PHASE: The operator and reversing starter

are factory prepared for proper rotation.

(4) Check both directions several times to ensure proper

phasing of motors. In case the motor continues to run at

end of travel and the limit switch does not stop rotation,

check the limit switch function and review the proper

control circuit wiring.

SNAP ACTION

SWITCHES

PINION

SWITCH CAM

PULL OUTWARD,

AWAY FROM CENTER

AND ROTATE TO

ADJUST TIMING Figure 6. Adjusting Limit Switch

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

G. ADAPTING CONTROLS

(1) Using the left side contactor for counter-clockwise

rotation of the top of the operator, determine if this

rotation sends an open or close signal to the left side

contactor. On pair operated gates, one operator is to

be wired as described, and the second operator is

wired using the opposite reversing starter coils. I.E. If

less contactor coil opens the right-hand gate, the right

contactor coil will open the left-hand gate.

H. PRELIMINARY LIMIT SWITCH ADJUSTMENT

(1) Loosen the four clutch tension bolts and then set the

arm plate back into place on the clutch. Do not replace

any other items at this time.

(2) To adjust the limit switch, (Figure 6), manually open

the gate to within 6 inches of its fully open position, at

the same time allowing the clutch to slip. At this point,

determine which snap action switch would shut the

operator off. Pull outward on the cam in line with that

switch and rotate it toward the switch and over it just

far enough to shut the operator off. The cam must be

rotated in the same direction as the crank arm is rotated

to open the gate. The cam should also be reengaged

with the center pinion at this point.

(3) Manually close the gate to within 6 inches of its

fully closed position. Pull outward on the other cam and

rotated toward an slightly over the other snap action

switch. The cam must be rotated in the same direction

as the crank arm is rotated to close the gate and must

be reengaged with the center pinion.

I. SETTING THE CLUTCH (Figure 7)

(1) Remove the arm plate and tighten down the four

clutch tension bolts evenly (see Figure 7) until the friction

is sufficient to operate the gate. Never tighten the bolts

so that the clutch cannot be slipped by forcing the end

of the crank arm, and never I just bolts consecutively,

but always directly across from each other so as to

provide even tension. An equal turn of each bolt is a very

important adjustment procedure.

WARNING!! Some electrical gate operator control

circuits can cause immediate gate operation upon

applying power. Ensure that the path of the gate

and operating arm is free from obstructions and

personnel.

(2) Replace on plate being certain the clutch pins are

engaged and electrically start the gate moving until it is

halfway between the open and closed position. Cut the

power at this point.

(3) If the gate can be manually moved from this halfway

point, readjust the clutch accordingly.

(4) After the clutch is adjusted to suit, replaced the

retaining ring, gasket, and weather plate in that order.

J. FINAL LIMIT SWITCH ADJUSTMENT

(1) With Power on, opened the gate until it stops under

its own power. If it stops short, electrically start gate

closing and cut the power. Pull outward on the opening

cycle switch camp and rotate away from the opening

cycle snap action switch one tooth on pinion gear and

reengage with center pinion. Turn power on.

(2) Close the gate until it stops under its own power. If

it stops short, electrically start gate open and cut power.

Pull outward on the closing cycle switch camp and

rotates away from the closing cycle snap action switch

one tooth on pinion gear and reengage with center

pinion. Turn power on.

(3) Continue cycling the gate and make cam

adjustments until the gate stops in the proper location.

(4) Replace the front weather resistant cover.

ARM PLATE CLUTCH TENSION

ADJUSTMENT

(FRONTAND BACK)

TOP VIEW

CLUTCH TENSION

ADJUSTMENT

(FRONTAND BACK)

Figure 7. Adjusting Clutch

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

3. MAINTENANCE

A. GENERAL:

To ensure that the electric operator is ready for operation

at all times, it must be inspected systematically each will

preclude serious damage or failure. Proper adjustment

and lubrication must be maintained and checked as

recommended in the following.

B. LUBRICATION

(1) Lubrication Intervals:

EVERY 6 MONTHS

1. Lubricate Pivot Points with SAE 10 Oil.

2. Check Oil Seals for Leakage.

EVERY 12 MONTHS

1. Clean Limit Switch Cam and Pinion Gear and

lubricate with SAE 10 oil.

2. Check oil level. If low, fill with lithium

complex extreme pressure grease, NLGI No. 2.

3. For Extra Heavy Duty Units (1 H.P.), check

green colored tag attached to the gearmotor.

CAUTION: Do Not Overfill. Do Not Use Machine Oil.

C. PREVENTATIVE MAINTENANCE

To prevent damage or improper operation, the following

inspections should be made at least EVERY SIX

MONTHS.

1. Check pivot points for wear.

2. Inspect drive belt for wear.

(Does not apply to Extra Heavy Duty 1 H.P. Units)

3. Inspect clutch discs for wear.

4. Check clutch for correct tension.

5. Check limit switch cams and pinion for wear.

6. Check that all bolts are tight.

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

3. PARTS

A. TO ORDER REPLACEMENT PARTS:

Order all replacement parts using the numbers shown on

the following parts list pages.

(1) Send in Serial Number of Electric Operator.

(2) SPECIFY the number of pieces needed.

(3) Order by part number and the name of the part.

(4) Indicate how the material should ship.

(5) State whether transportation charges are to be

prepaid or collect.

(6) Name and address of person or company to whom

invoice is to be sent.

B. PARTS LIST

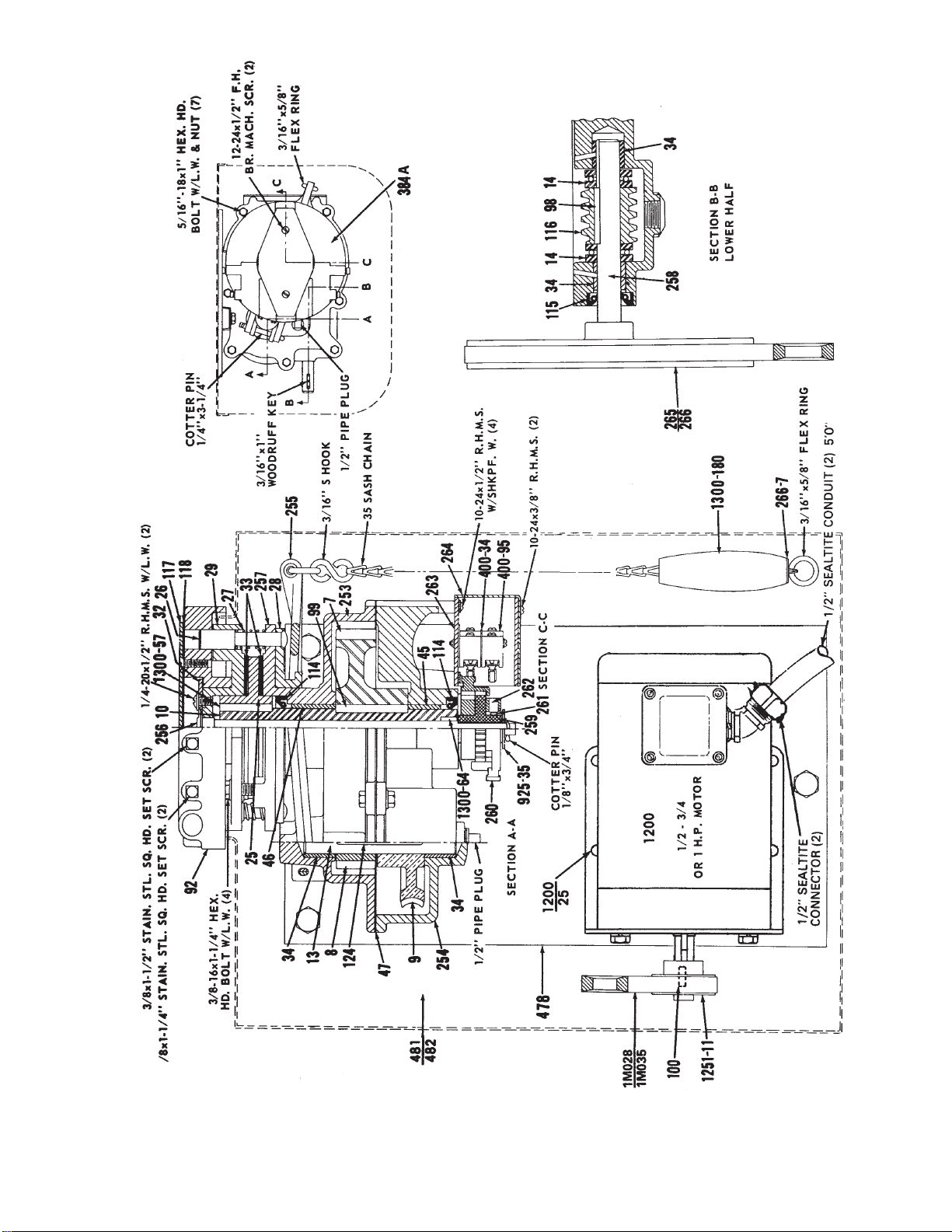

The following pages list the replacement parts illustrated

in Figure 8 and 9.

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

G-993-R3 9

FIGURE NO. PART NUMBER DESCRIPTION

8 266-7 Washer

8 400-34 Switch Insulator (2 per operator)

8 400-95 Snap Action Switch (2 per operator)

8 1200 Motor Per Specifications

8 1200-25 Motor Mounting Bracket

8 1251-11 Motor Pulley

8 1300-57 Clutch Collar Key

8 1300-64 Clutch Shaft Bushing

8 1300-180 Handle

8 1500-7 Gear

8 1500-8 Pinion Gear

8 1500-9 Worm Gear

8 1500-10 Clutch Shaft

8 1500-13 Pinion Shaft

8 1500-14 Thrust Bearing (2 per operator)

8 1500-25 Clutch Shaft Collar

8 1500-26 Clutch Pin (2 per operator)

8 1500-27 Compression Spring (2 per operator)

8 1500-28 Pin Shift Collar

8 1500-29 Top Clutch Plate

8 1500-32 Retaining Disc

8 1500-33 Clutch Disc (2 per operator)

8 1500-34 Bearing (4 per operator)

8 1500-45 Bearing

8 1500-46 Bearing

8 1500-47 Gasket

8 1500-92 Arm Plate

8 1500-98 Worm Shaft Key

8 1500-99 Clutch Shaft Key

8 1500-100 Key

8 1500-114 Clutch Shaft Oil Seal (2 per operator)

8 1500-115 Worm Shaft Oil Seal

8 1500-116 Worm

8 1500-117 Arm Plate Cap

8 1500-118 Arm Plate Cap Gasket

8 1500-124 Pinion Shaft Key

8 1500-253 Upper Gear Housing (Incl. 1500-34 & 1500-46 Bearing)

8 1500-254 Lower Gear Housing (Incl. 1500-34 & 1500-45 Bearing)

8 1500-255 Release Yoke

8 1500-256 Clutch Bolt

8 1500-257 Bottom Clutch Plate

8 1500-258 Worm Shaft

8 1500-259 Switch Throw Pinion

8 1500-260 Switch Cam (2 per operator)

8 1500-261 Switch Cam Spring (2 per operator)

8 1500-262 Closed Eye Eyelet (2 per operator)

8 1500-263 Switch Frame

8 1500-264 Switch Cover

8 1500-265 5" P.D. Pulley (Std. Speed)

8 1500-266 8.7" P.D. Pulley (Low Speed)

8 1500-384A Clutch Assembly (Consisting of Parts: 25, 26, 27, 28, 29, 32, 33, 92, & 257)

8 1500-428 Weather Resistant Cover Front

8 1500-478 Base Plate

8 1500-481 Weather Resistant Cover Back

8 1MO28 28" 4L V Belt (used with 5" P.D. Pulley)

8 1MO35 35" 4L V Belt (used with 8.7" P.D. Pulley)

PARTS LIST -- HEAVY DUTY 1/2 3/4 - 1 HP OPERATOR

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

Figure 8. Illustration of Parts - Heavy Duty 1/2 - 3/4 - 1 HP Operator

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

FIGURE NO. PART NUMBER DESCRIPTION

9 400-34 Switch Insulator (2 per operator)

9 400-95 Snap Action Switch (2 per operator)

9 405-226 Spring (2 per operator)

9 405-2120-1 1/4" x 1-1/2" Ring

9 925-35 Washer

9 1300-64 Clutch Shaft Bushing

9 1300-180 Handle

9 1500-64 Arm Plate

9 1500-65 Top Clutch Plate

9 1500-66 Bottom Clutch Plate

9 1500-69 Shift Collar

9 1500-73 Clutch Disc (2 per operator)

9 1500-75 Pivot Pin (2 per operator)

9 1500-77 Pivot Pin (2 per operator)

9 1500-148 Arm Plate Cap

9 1500-149 Arm Plate Cap Gasket

9 1500-206A Base Assembly L.H.

9 1500-207A Base Assembly R.H.

9 1500-213 Arm Plate

9 1500-214 Clutch Spacer

8 1500-215A Clutch Assembly (Consisting of Parts: 64, 65, 66, 69, 73, 75, 77, 213, and 405-226)

8 1500-227A Top CoverAssembly L.H.

8 1500-228A Top CoverAssembly R.H.

8 1500-229A Front Cover L.H.

8 1500-230A Front Cover R.H.

8 1500-231 Motor Shim

8 1500-237A Clutch Lever Assembly

8 1500-238 Release Pivot Pin

8 1500-240 Gearmotor 230/460-60-3 R.H.

8 1500-241 Gearmotor 230/460-60-3 L.H.

8 1500-259 Switch Throw Pinion

8 1500-260 Switch Cam (2 per operator)

8 1500-261 Spring (2 per operator)

8 1500-262 Closed End Eyelet (2 per operator)

8 1500-264 Switch Cover

8 1500-385 Clutch Bolt

8 1500-389 Support Stud (4 per operator)

8 1500-390A Limit Switch Housing Assembly

PARTS LIST -- EXTRA HEAVY DUTY 1 HP OPERATOR

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

Figure 9. Illustration of Parts - Extra Heavy Duty 1 HP

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

Crown Industrial Operators

213 Michelle Court

So. San Francisco, CA 94080

Phone (650) 952-5150

Fax (650) 873-1495

website: www.crown-industrial.com

GUARANTEE

If, within a period of one year from date of shipment, any part of a CIO

Electric "Aut-o-doR" Operator is found defective due to poor materials

or workmanship, new parts will be furnished free of charge F.O.B.

manufacturer’s plant, providing the equipment has been given normal

and proper usage, lubrication, and maintenance and is still the property

of the original purchaser and/or part of the original installation. THIS

WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, AND THE MANUFACTURER MAKES

NO IMPLIED WARRANTY OF MERCHANTABILITY BEYOND THE

EXPRESSED TERMS HEREOF. MANUFACTURER’S LIABILITY FOR

DAMAGES, INCLUDING CONSEQUENTIAL DAMAGES RESULTING

FROM ANY SUCH DEFECTIVE PRODUCT IS STRICTLY LIMITED TO

THE DELIVERY OF NEW PARTS, AS SET FORTH ABOVE.

Operator Serial Number _______________________________ H.P. ____________________________________

Supplied on Crown Industrial Operators Order Number __________________________________________________

Power Supply ____________ Volts ___________ Hz _______________ Phase __________________________

Installed At _______________________________ Date _______________________________________________

Notes ________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

MAINTENANCE INFORMATION

(To Be Filled Out By User)

G-993-R3

Table of contents

Other CROWN INDUSTRIAL Gate Opener manuals