Smartdoor TURN T100 User manual

301057 2021-03-26

Operating Instructions

Swing Door Operator

smartdoor TURN T100

Language: English

smartdoor TURN T100 | Operating Instructions

2

Table of contents

1GENERAL INFORMATION......................................................................................... 5

1.1 PRODUCT IDENTIFICATION ................................................................................... 5

1.2 PRODUCT OVERVIEW............................................................................................ 6

1.2.1 THE BASIC MODULE ............................................................................................. 6

1.2.2 THE LINKAGE..................................................................................................... 7

1.2.3 THE OPERATING ELEMENTS..................................................................................... 7

1.2.4 THE SAFETY ELEMENTS ......................................................................................... 7

1.2.5 THE DRIVE MODULE ............................................................................................. 7

1.2.6 THE CONTROL MODULE ......................................................................................... 8

1.2.7 THE COMMUNICATION MODULE ................................................................................ 8

1.2.8 THE SMARTDOOR SERVICE TOOL.............................................................................. 9

1.2.9 THE SMARTDOOR APP .......................................................................................... 9

2SAFETY ................................................................................................................. 10

2.1 SYMBOLS AND DISPLAY OF WARNINGS ................................................................ 10

2.2 STATE-OF-THE-ART AND APPLIED STANDARDS...................................................... 10

2.3 INTENDED USE .................................................................................................. 13

2.4 LIMITATION OF LIABILITY ................................................................................... 13

2.5 USER GROUP ..................................................................................................... 13

2.6 RISK................................................................................................................. 13

2.7 MISUSE............................................................................................................. 13

3PRODUCT DESCRIPTION ....................................................................................... 15

3.1 TERMS .............................................................................................................. 15

3.2 SWING DOOR TERMS.......................................................................................... 16

3.3 LINKAGE TYPES ................................................................................................. 17

3.4 HOLDING VARIANTS ........................................................................................... 20

3.4.1 DOOR HANDLE WITH LATCH (WITH AND WITHOUT LOCK) ................................................ 20

3.4.2 DOOR HANDLE WITH BLOCKED LATCH (WITH AND WITHOUT LOCK)..................................... 20

3.4.3 DOOR HANDLE WITH LATCH AND ELECTRIC DOOR OPENER ............................................... 21

4ASSEMBLY............................................................................................................. 22

4.1 SAFETY DURING ASSEMBLY: ............................................................................... 22

4.2 MECHANICAL INSTALLATION ............................................................................... 22

4.2.1 MOUNTING PLATE ............................................................................................. 23

4.2.2 ADAPTER PLATE................................................................................................ 24

4.2.3 ASSEMBLY LINKAGE ........................................................................................... 24

4.2.4 LINKAGE DISASSEMBLY ....................................................................................... 25

4.3 ELECTRIC INSTALLATION .................................................................................... 26

4.3.1 CONNECTION .................................................................................................. 26

4.4 COMMISSIONING VIA AUTO-LEARNING FUNCTION................................................. 26

4.4.1 FUNCTIONAL TEST (COMMISSIONING PUSH&GO)......................................................... 27

4.4.2 FUNCTIONAL TEST (AFTER INSTALLATION)................................................................. 27

4.4.3 HOLDING FORCE FUNCTIONAL TEST IN THE CASE OF CURRENT INTERRUPTION ........................ 27

4.4.4 FUNCTION TEST (START AFTER CURRENT INTERRUPTION)................................................ 27

4.5 COMMISSIONING OPERATING ELEMENTS.............................................................. 28

4.5.1 BLUETOOTH OPERATING ELEMENTS ......................................................................... 28

4.5.1.1 ADDITION OF BLUETOOTH OPERATING ELEMENTS ...................................................... 28

4.5.1.2 DELETING BLUETOOTH OPERATING ELEMENTS .......................................................... 29

4.5.1.3 COMMISSIONING OF SMARTDOOR BLUETOOTH PUSH BUTTON ........................................ 29

4.5.1.4 COMMISSIONING OF SMARTDOOR BLUETOOTH MODULE (WITH PUSH BUTTON) .................... 30

4.5.1.5 ADDITION OF SMARTPHONE ............................................................................... 31

4.5.2 WIRED OPERATING ELEMENTS ............................................................................... 31

smartdoor TURN T100 | Operating Instructions

3

4.5.2.1 CONNECTION OF EXTERNAL CONTACTS .................................................................. 31

4.5.2.2 WIRED OPENING PULSES .................................................................................. 31

4.5.2.3 COMMISSIONING WIRED PUSH BUTTON.................................................................. 31

4.5.2.4 COMMISSIONING WIRED RADAR .......................................................................... 32

4.6 COMMISSIONING SAFETY ELEMENTS.................................................................... 32

4.6.1 COMMISSIONING SIO AND SIS PRESENCE SENSORS .................................................... 33

4.6.1.1 CONNECTION SIO /SIS.................................................................................. 33

4.6.1.2 TEST SIGNAL TEST ........................................................................................ 33

4.6.2 COMMISSIONING ELECTRIC DOOR OPENER (COM, NO AND NC)....................................... 34

4.6.3 COMMISSIONING MOTOR LOCK (COM, NO AND NC AND MORE)....................................... 35

4.6.4 COMMISSIONING DAY/NIGHT SWITCH-OVER.............................................................. 36

5FUNCTIONS........................................................................................................... 37

5.1 AUTOMATIC SWITCH-ON FUNCTION AFTER POWER FAILURE ................................... 37

5.2 AUTOMATIC TROUBLESHOOTING FUNCTION.......................................................... 37

5.3 AUTO-LEARNING FUNCTION ................................................................................ 38

5.3.1 PREREQUISITES ............................................................................................... 38

5.3.2 IMPLEMENTATION OF THE AUTO-LEARNING FUNCTION (WITH PROG KEY) ............................ 39

5.4 LOW-ENERGY MODE ........................................................................................... 40

5.5 FUNCTIONS OF INPUTS AND OUTPUTS ................................................................. 41

5.5.1 SIO: SAFETY SENSOR OPENING ............................................................................ 41

5.5.2 SIS: SAFETY SENSOR CLOSING............................................................................. 41

5.5.3 OPENING PULSE (DAY+NIGHT) ............................................................................. 41

5.5.4 OPENING PULSE (DAY+NIGHT)+LOCK FEEDBACK ...................................................... 41

5.5.5 OPENING PULSE (DAY) ....................................................................................... 41

5.5.6 DAY/NIGHT SWITCH-OVER................................................................................... 42

5.5.7 LOCK FEEDBACK ............................................................................................... 42

5.5.8 MODE SWITCH-OVER ........................................................................................ 42

6OPERATING MODE ................................................................................................ 43

6.1 AUTOMATIC OPERATING MODE (LED: GREEN) ....................................................... 43

6.2 OPERATING MODE - CONTINUOUSLY OPEN (LED: FLASHING GREEN) ....................... 44

6.3 OPERATING STATUS INITIALISATION (LED: FLASHING ORANGE)............................. 44

6.4 AUTO-LEARNING OPERATING STATUS (LED: FLASHING RED/ORANGE)..................... 45

6.5 SYSTEM ERROR OPERATING STATUS (LED: FLASHING RED).................................... 45

7OPERATION .......................................................................................................... 46

7.1 MAIN SWITCH.................................................................................................... 46

7.2 SETTING THE HOLD-OPEN TIME ........................................................................... 46

7.2.1 PROCESS ....................................................................................................... 46

7.3 MANUAL RESET OF AN ERROR ............................................................................. 47

7.3.1 PROCESS ....................................................................................................... 47

7.4 SWITCHING OVER THE OPERATING MODE............................................................. 47

7.4.1 SWITCH-OVER OF THE OPERATING MODE .................................................................. 47

7.5 SMARTDOOR APP ............................................................................................... 48

7.5.1 SYMBOLS ....................................................................................................... 48

7.5.2 MAIN MENU -MY DOORS..................................................................................... 49

7.5.3 CONNECT NEW DOOR OPERATOR IN THE APP.............................................................. 49

7.5.4 PASSWORD FOR RELEASE OF A SMARTPHONE .............................................................. 49

7.5.5 DOOR CONTROL ............................................................................................... 50

7.5.6 USER MANUAL /FAQ ......................................................................................... 51

8SERVICE................................................................................................................ 52

8.1 CARE / OPERATOR CHECKS ................................................................................. 52

8.1.1 SWITCH OFF ................................................................................................... 52

8.1.2 CHECKS ........................................................................................................ 52

8.1.3 CARE............................................................................................................ 52

8.2 MAINTENANCE / INSPECTION BY TRAINED SPECIALIST PERSONNEL ........................ 52

smartdoor TURN T100 | Operating Instructions

4

9TROUBLESHOOTING.............................................................................................. 53

9.1 RESET............................................................................................................... 53

9.1.1 PROCESS ....................................................................................................... 53

10 TECHNICAL DATA ............................................................................................... 54

10.1 AREA OF USE AND OPENING TIMES IN LOW-ENERGY OPERATION ............................ 54

11 APPENDIX .......................................................................................................... 55

11.1 CONNECTING TERMINALS ................................................................................... 55

11.2 ASSIGNMENT OF FUNCTION TO INPUTS AND OUTPUTS .......................................... 56

11.3 DISPLAY LED AND SYSTEM ERROR ....................................................................... 57

11.3.1 COMMUNICATION MODULE ................................................................................... 57

11.3.2 CONTROL MODULE ............................................................................................ 57

11.4 CONSTRUCTION PLANNER TEMPLATE –OBJECT OVERVIEW..................................... 59

11.5 CONSTRUCTION PLANNER TEMPLATE –ELECTRICAL DIAGRAM ................................ 60

11.6 ELECTRICAL DIAGRAMS ...................................................................................... 61

11.6.1 EXAMPLE ELECTRIC DOOR OPENER (MASTER).............................................................. 61

11.6.2 EXAMPLE ELECTRIC DOOR OPENER (MASTER WITH RELEASE)V1 ........................................ 62

11.6.3 EXAMPLE ELECTRIC DOOR OPENER (MASTER WITH RELEASE)V2 ........................................ 63

11.6.4 EXAMPLE ELECTRIC DOOR OPENER (SLAVE)................................................................ 64

11.6.5 EXAMPLE CONVERSION OF ELECTRIC DOOR OPENER WITH INTERCOM SYSTEM (DC) ................. 65

11.6.6 EXAMPLE MOTOR LOCK (MASTER-MASTER)................................................................. 66

11.6.7 EXAMPLE MOTOR LOCK (MASTER-SLAVE)................................................................... 67

11.7 PUSH BUTTON TEMPLATE .................................................................................... 68

11.8 AUTO-LEARNING FUNCTION ................................................................................ 69

smartdoor TURN T100 | Operating Instructions

5

1General information

1.1 Product identification

For precise identification the type plate attached to the control module is marked with the

following details:

Company name: Gotthard 3 Mechatronic Solutions AG

Gotthardstrasse 3

CH –5630 Muri (AG)

Type: smartdoor TURN T100

Serial number: e.g. 0100-01-01-01-20-0000-0535

Reference number: 301010a

Year of manufacture: e.g. 2020

Mains connection: e.g. 100-240 V, 50/60 Hz

Power consumption: 41 W

Rated load: 30 Nm

Admissible temperature range: -15 °C to +50 °C

Classified according to DIN 18650-1:

Installation firm: (place holder for installation firm sticker)

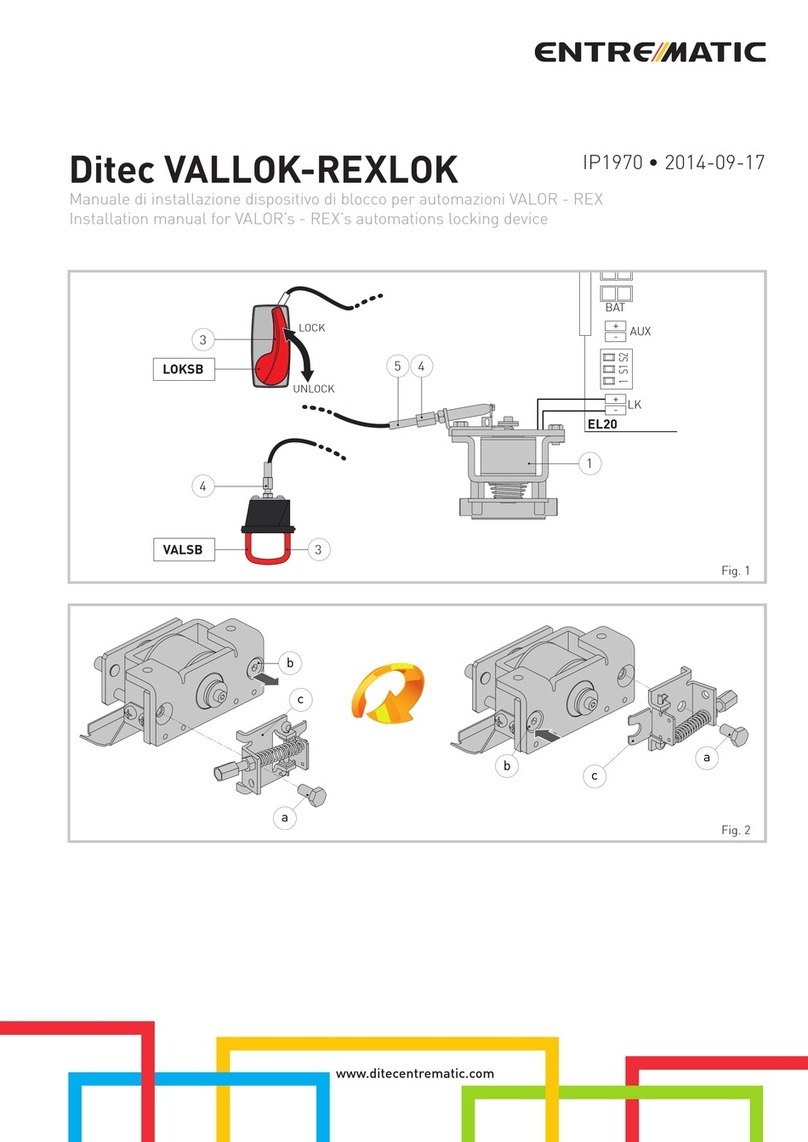

Photographic example:

Figure 1: Product identification

1

2

3

4

5

6

7

8

1

2

1

2.3

0

2

smartdoor TURN T100 | Operating Instructions

6

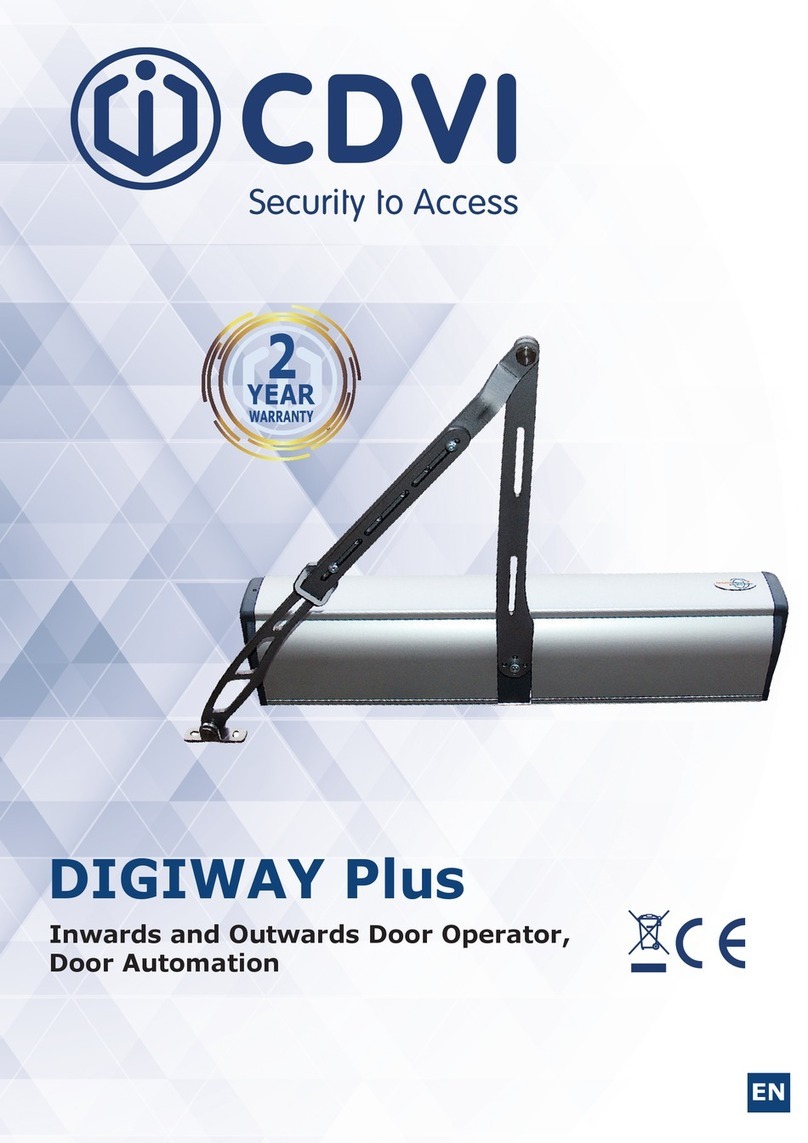

1.2 Product overview

Figure 2: Product overview

1.2.1 The basic module

The new EN 16005 standard defines the LOW-ENERGY operating mode and allows a door

operator to operate without safety elements without danger of injury. The smartdoor TURN

targets precisely this application. With its Auto-Learning function it automatically calculates the

necessary door parameters and makes easy work of commissioning. No safety elements are

required.

Figure 3: smartdoor TURN T100 basic module

smartdoor TURN T100 | Operating Instructions

7

1.2.2 The linkage

The smartdoor TURN can be fitted with the following linkage types:

•Sliding linkage

•Scissor linkage

The linkage types and their uses are described in chapter 3.3 Linkage types.

1.2.3 The operating elements

The smartdoor TURN can be fitted with the following elements:

•smartdoor Bluetooth button which opens the smartdoor TURN and can switch between the

operating modes

•Standard switch, which opens the smartdoor TURN or can switch between the operating

modes with the smartdoor Bluetooth module

•smartdoor APP which can open the smartdoor TURN, switch between the operating modes

and change parameters

•Wired standard switch which can open the smartdoor TURN

•Wired radar which can open the smartdoor TURN

A separate function can be assigned to each button e.g. as opening contact (Day + Night),

opening contact (Day), or mode switch

Figure 4: Operating element examples

If there is an additional switch for disabled persons to activate the drive, a pictogram needs to

be applied to the button in accordance with EN 16005 Appendix D - picture D.1.

1.2.4 The safety elements

If you want to connect safety elements then the smartdoor TURN offers as standard a

connection strip for all standard safety elements.

The smartdoor TURN can be fitted with the following safety elements:

•Presence sensors which control the swing range of the door in the opening direction (SIO)

•Presence sensors which control the swing range of the door in the closing direction (SIS)

•All standard motor locks and electric door openers (working current, static current)

•Key switches, rotary switches or timers, to switch between day and night mode

Figure 5: Examples of safety elements

1.2.5 The drive module

This 1.7 kg, extremely compact power pack can supply a drive-side torque of over 30 Nm and is

practically silent. So that a driven door can also be actuated easily by hand (even without

electricity), its internal efficiency on both sides has been corresponding optimised. The sensor

system, integrated into the gearbox, allows a rapid and optimum reaction of the control system

to external influences. (detection of obstacles, wind pressure etc.)

smartdoor TURN T100 | Operating Instructions

8

Figure 6: Drive module

In the +/-15° range a mechanical reset torque is generated internally such that the door can be

held in the closed position without motor power. Thus, in the currentless state the door behaves

like a self-closing drawer.

The closing torque is symmetrically present in both directions of rotation. For this reason, a

swing door is held mechanically in the middle position, even in the currentless state.

1.2.6 The control module

The control module incorporates the control system, the connecting terminals and the power

supply.

Figure 7: Control module

The control module automatically learns (Auto-Learning) the correct direction of rotation and the

closing characteristic and saves this with system-related standard and limit values.

All possible connection options and the entire kinematic (lever systems, mass of the door leaf,

limit positions etc.) are detected and tested by the control module before each door opening.

1.2.7 The communication module

The smartdoor TURN has a communication module, which permits a switch-over of the

operating mode and communication with other devices. The communication module allows rapid

switching from Automatic mode to Continuously Open and back. An existing error can also be

manually acknowledged and the hold-open time set.

Figure 8: Communication module

More operating modes can be activated as required with the Service Tool.

The communication module is responsible for the communication with the smartdoor Bluetooth

button, Bluetooth modules, smartdoor APP and the Service Tool.

smartdoor TURN T100 | Operating Instructions

9

1.2.8 The smartdoor Service Tool

The smartdoor Service Tool can be used by the service technician on a Windows Notebook to

carry out a wide range of adjustments after mechanical installation. This includes the following:

•Setting the parameters

•Activation of Bluetooth devices

•Saving and loading of parameter recipes

•Auto-Learning

•Managing and loading firmware

•Status overview for controlled commissioning of external equipment

The Service Tool is only for trained specialist personnel. A detailed description of the smartdoor

Service Tool is provided in a separate handbook.

Figure 9: smartdoor Service Tool

1.2.9 The smartdoor APP

The smartdoor TURN can be operated and adjusted using the smartdoor APP.

A detailed description of the smartdoor APP can be found in chapter 7.5 smartdoor APP .

Figure 10:smartdoor APP

smartdoor TURN T100 | Operating Instructions

10

2Safety

2.1 Symbols and display of warnings

Various symbols are used in these operating instructions for easier understanding:

NOTICE

Tips and information, which help you work correctly and efficiently.

CAUTION

Important note, when materials are damaged or the function can be affected.

WARNING

Important note, when materials are damaged or the function can be affected.

2.2 State-of-the-art and applied standards

The system complies with the state-of-the-art and accredited safety technology rules. It has

been developed, constructed and produced in compliance with the following standards:

•Machinery Directive 2006/42/EC

•Household and similar electrical appliances. Safety. EN 60335-1

•Particular requirements for drives for gates, doors and windows EN 60335-2-103 (where

applicable)

•Power operated pedestrian doorsets. Safety in use. Requirements and test methods. EN

16005.

•Safety-related parts of control systems EN ISO 13849

13849-1:2016 (General design principles), category 2 PL c

13849-2:2016 (Validation)

•Electromagnetic compatibility (EMC) EN61000

Part 6-2: Generic standards –Immunity for industrial environments

Part 6-3: Generic standards –Emission standard for residential, commercial and light-

industrial environments

NOTICE

Partly completed machinery in the sense of the EC directive 2006/42/EC is only

designed to be installed in or combined with other machinery or in other partly

completed machinery or systems to form a machine in the sense of the above

directive.

smartdoor TURN T100 | Operating Instructions

11

WARNING

This product may not be operated until it has been determined that the whole

machine / system in which it has been installed, corresponds to the provisions of the

above EC directive.

In the event of any alteration of the product without the manufacturer's approval,

this declaration loses its validity.

NOTICE

The installer and operator must jointly carry out a risk assessment during the

planning of the system.

smartdoor TURN T100 | Operating Instructions

12

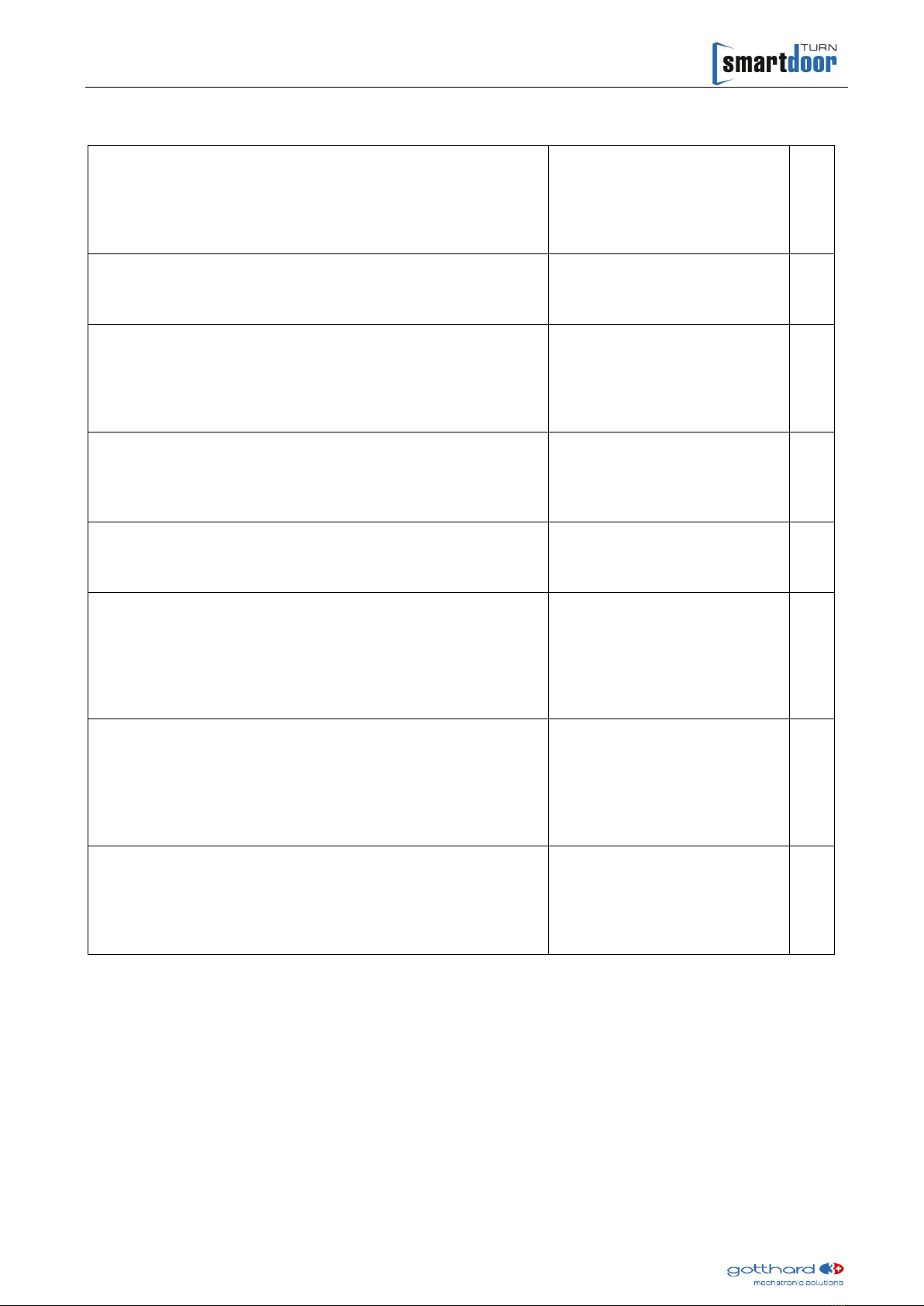

Encoding systems for automatic doors (DIN 18650)

1 –swing door operator

2 –Sliding door operator

3 –Swing/sliding door operator

4 –Folding door operator

5 –Revolving door drive

Drive type

1

1 –200,000 test cycles at min. 1200 cycles/24 h

2 –500,000 test cycles at min. 2400 cycles/24 h

3 –1,000,000 test cycles at min. 4000 cycles/24 h

Durability of the drive

2

1 –Swing door

2 –Sliding door

3 –Swing/sliding door

4 –Folding door

5 –Revolving door

Door leaf type

3

0 –Not suitable as fire door

1 –Suitable as smoke-protection door

2 –Suitable as fire door

3 –Suitable as fire door & smoke-protection door

Suitability as fire door

4

1 –Force limit

2 –Connection for external safety systems

3 –Low energy

Safety devices on the drive

5

0 –No particular requirements

1 –In escape routes with a break-out fitting

2 –In escape routes without a break-out fitting

3 –For self-closing fire doors with break-out fitting

4 –For self-closing fire doors without a break-out

fitting

Special requirements of

drive/functions and

installation

6

0 –No safety devices

1 –With adequately dimensioned safety distances

2 –With protection against crushing, shearing and

trapping of fingers

3 –With built-in break-out fitting unit

4 –With presence sensor

Safety on the automatic

door system

7

1 –No specifications

2 –from -15 °C to +50 °C

3 –from -15 °C to +75 °C

4 –Temperature range in accordance with the

manufacturer's details

Ambient temperatures

8

Table 1: Encoding systems for automatic doors

Nos. 1, 2, 5, 6, 8 relate to the drives.

Nos. 3, 4, 7 relate to the complete door systems

smartdoor TURN T100 | Operating Instructions

13

2.3 Intended use

The smartdoor TURN T100 is an electromechanical swing door operator and is designed

exclusively for opening and closing swing doors for standard use in public and private dry

interiors and standard door heights.

Any other use is considered as improper use. The manufacturer is not liable for damage

resulting from improper use; the risk in this case lies entirely with the operator.

The smartdoor TURN T100 may not be used for escape routes.

Intended use of equipment also includes compliance with the manufacturer's operating

instructions and regular care and maintenance.

2.4 Limitation of liability

Manipulation or modification of the parameters of the automatic door, unless performed by an

authorised service technician, exempts the manufacturer from liability for any resulting damage.

Modifications of the parameters may only be carried out by qualified personnel.

Installation is at one's own risk and must take place in accordance with operating instructions.

The manufacturer accepts no responsibility for non-compliance.

Assembly, commissioning, inspection, maintenance and repair work on the system must be

conducted according to the check lists. The chapter on commissioning (See chapter 5.3 Auto-

Learning function) and the maintenance checklist (see inspection book) may be helpful here.

Children may not clean, play with or use the product.

2.5 User group

The swing door operator can be used by children from 8 years and above, elderly and frail users

and persons with disabilities or with lack of experience and knowledge when these are

supervised or have been instructed in relation to the safe use of the appliances and understand

the resulting dangers.

Otherwise, the swing door operator should only be used when the risk assessment for the user

indicates a low risk.

2.6 Risk

There are risks of shearing and crushing from the various closing edges and the linkage on

automatic doors. To avoid this danger there should be no items in the opening area of the swing

door. The securing of crushing and shearing points on secondary closing edges must be

guaranteed by the door manufacturer.

The danger point on the secondary closing edge on each swing door (including manually

operated) is generally recognised by all users of a door. It cannot be influenced by the

manufacturer.

2.7 Misuse

Foreseeable misuse is any use other than as described in these operating instructions. This

includes:

•mechanical or electrical bypassing

•The use of other than original parts

•Conversions, modifications and manipulations

•Non-compliance with the instructions

NOTICE

The manufacturer stated in this report is only the manufacturer of a drive and not

the manufacturer of the final machinery.

smartdoor TURN T100 | Operating Instructions

14

The operator is responsible for the operation of automatic door systems and for

regular maintenance and safety inspections.

The "Operator checks" checklist can be helpful for this (see inspection book).

smartdoor TURN T100 | Operating Instructions

15

3Product description

3.1 Terms

Term

Explanation

Hinge side

The side of the door on which the hinges are located, to which the

door leaf is attached. Usually, the side of the door facing the opening

direction.

Opposite hinge side

The other side of the door to the hinge side. Usually, the side of the

door facing the closing direction.

Contactor

Buttons, switches or motion detectors for actuation of the door

operator. Actuation function in "automatic" operating mode and

sometimes in other operating statuses.

Indoor opening

contact

(day + night)

Door opening button which is active in day and night mode and

which is usually mounted on the inside of the door.

The actuation function is activated in the "automatic" operating

mode and opens the door automatically at the press of a button.

Outdoor opening

contact

(day only)

Door opening button which is only active when day mode is actuated

and which is usually mounted on the outside of the door.

The actuation function is activated in the "automatic" operating

mode and opens the door automatically at the press of a button.

Push&Go

If the door is pushed manually out of the closed position in

"automatic" operating mode, the door opens automatically. The

sensitivity of this function can be set.

Safety sensor

Opening

(SIO)

Presence sensor (e.g., active infrared-light sensor or scanner) for

securing the door swing range in the opening direction. The sensor is

usually attached on the hinge side of the door to the door leaf and

triggers a STOP pulse.

Safety sensor Closing

(SIS)

Presence sensor (e.g. active infrared-light sensor or scanner) for

securing the door swing range in the closing direction. The sensor is

usually attached to the opposite hinge side of the door onto the door

leaf and triggers a REOPEN pulse.

Emergency stop

button

(EMERGENCY)

Self-latching emergency stop button, which can stop the door

operator immediately in an emergency. The EMERGENCY situation is

ended by releasing the emergency stop button.

Electric door opener

(LOCK)

Working and static current door opener (NC / NO) designed as AC or

DC door opener.

The delay time of the door opener is detected automatically by the

control system.

Lock feedback

(RR)

The lock feedback is an integrated contact in the door latch which is

actuated by the mechanical locking of the door with the door lock

bolt. It notifies the control system that the door is mechanically

locked and cannot therefore be opened by the door operator.

Key switch

(KEY)

Any standard commercial key switch can be used as a KEY.

The key switch makes safe door opening possible from the interior

and exterior. There are however many other functions available,

e.g., day/night switch-over, which can be triggered with the key

switch.

Airlock system

(SLS)

Two consecutive doors, each with a door operator, which are

connected together and ensure that only one door is open.

smartdoor TURN T100 | Operating Instructions

16

Closing sequence

control

(SFR)

System with two door leaves, each with a door operator. The two

door leaves can be opened and closed in a mutually coordinated

sequence.

Table 2: Terms

3.2 Swing door terms

Figure 11: Swing door terms

Key:

A Main closing edge

B Secondary closing edge

C Opposite closing edge

smartdoor TURN T100 | Operating Instructions

17

3.3 Linkage types

Sliding linkage

Scissor linkage

Lintel assembly

Opposite hinge

3D:

3D:

Front:

Front:

Closed (lintel depth -20…+80 mm)

Closed (lintel depth -20…+150 mm)

Lintel depth >150 mm with long insert

profile

smartdoor TURN T100 | Operating Instructions

18

Sliding linkage

Scissor linkage

Open (lintel depth -20… +80 mm):

Open (lintel depth -20… +150 mm):

Lintel assembly

Hinge side

3D:

3D: Assembly not possible

Front:

Closed (overfold -80...+80 mm)

Opening angle max. 100°

Opening angle max. 110°

Opening angle max. 110°

smartdoor TURN T100 | Operating Instructions

19

Sliding linkage

Scissor linkage

Open (overfold -80…+80 mm)

Door leaf assembly

Opposite hinge

3D: Assembly not recommended

3D: Assembly not possible

Door leaf assembly

Hinge side

3D:

3D:

Front:

Front:

Opening angle max. 110°

Opening angle max. 80°

smartdoor TURN T100 | Operating Instructions

20

Sliding linkage

Scissor linkage

Closed (overfold 0...+60 mm)

Closed (overfold -20...+100 mm)

Open (overfold 0…+60 mm)

Open (overfold -20…+100 mm)

Table 3: Linkage types (DIN left)

3.4 Holding variants

There are generally three holding variants:

1Door handle with latch (with and without lock)

2Door handle with blocked latch (with and without lock)

3Door handle with latch and electric door opener

3.4.1 Door handle with latch (with and without lock)

Holding variants:

This is a normal door with a door handle and possibly a lock.

Open:

The door handle must be actuated by a person to open the door. Remote actuation is not

possible. After actuating the door handle, a Push&Go is detected inside and outside and the door

opens.

Close:

When closing, the door operator checks that the door closes fully and the latch engages.

Locking:

The door is mechanically locked and cannot now be opened.

If remote actuation is required, the latch clip can used (see chapter 3.4.2 Door handle with

blocked latch (with and without lock) or an electric door opener mounted (see chapter 3.4.3

Door handle with latch and electric door opener).

3.4.2 Door handle with blocked latch (with and without lock)

Holding variants:

In this variant the latch is mechanically disabled with the latch clip and the door is held with the

patented closing function.

Open:

All opening pulses (wired and via Bluetooth) and Push&Go are possible.

Close:

When closing, the door operator checks that the door closes fully. The holding force is applied

by the patented closing function and can be adjusted with the Auto-Learning function (see

chapter 5.3 Auto-Learning function).

Locking:

Opening angle max. 100°

Opening angle max. 100°

From overfold >50 mm: 90°

Overfold >100 mm with long insert

profile

This manual suits for next models

1

Table of contents

Popular Door Opening System manuals by other brands

raumplus

raumplus AIR-B S34 Installation instruction

SECO-LARM

SECO-LARM SD-7104SGEX1Q manual

Dorex

Dorex 8500 Series installation instructions

Assa Abloy

Assa Abloy Besam SW200i user manual

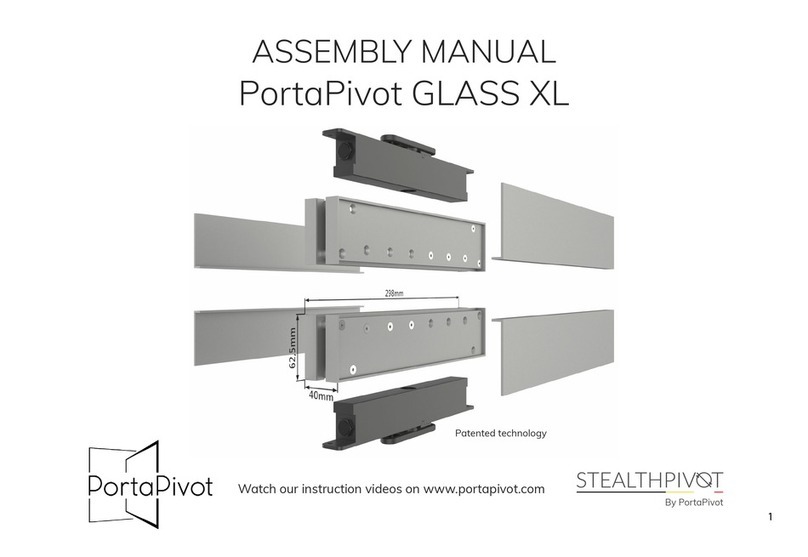

PortaPivot

PortaPivot StealthPivot XL Assembly manual

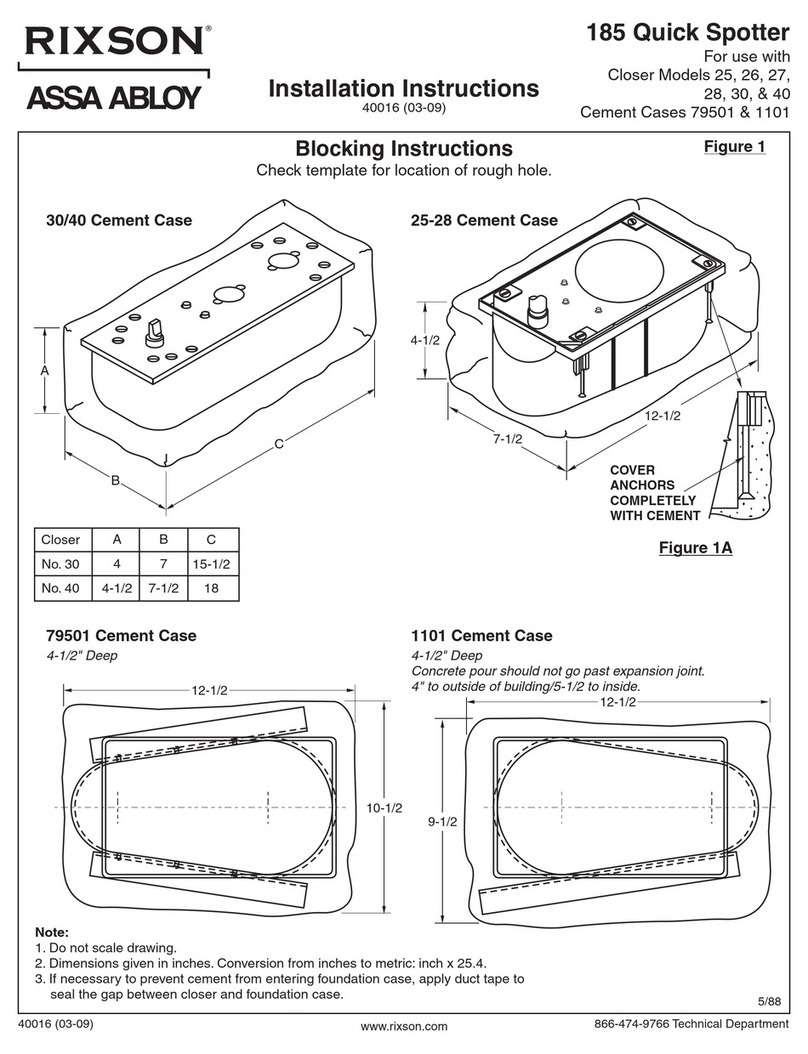

Assa Abloy

Assa Abloy RIXSON 185 Quick Spotter installation instructions