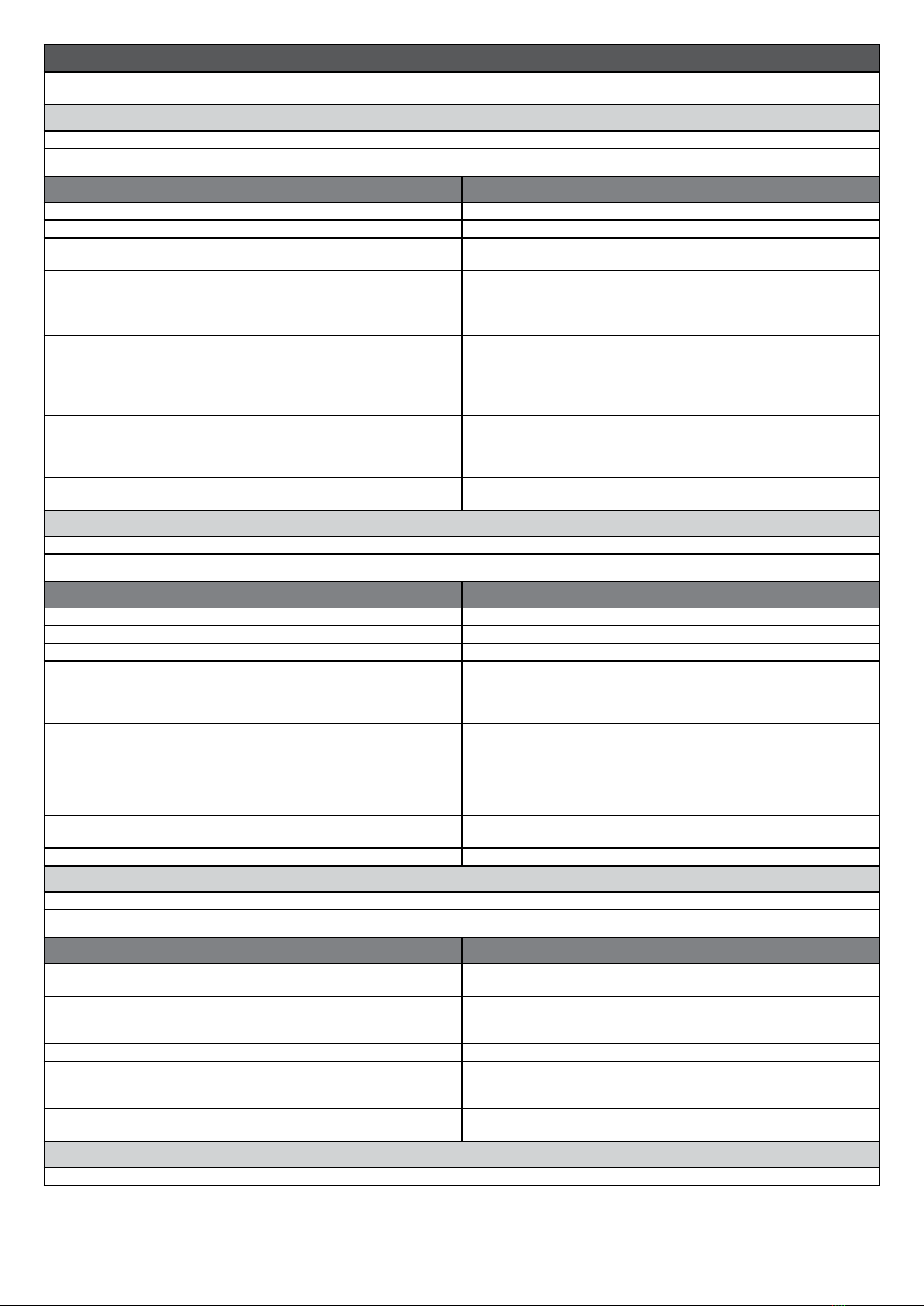

Courtesy light: on/off This command enables activation and deactivation

of the courtesy light on the control unit and that

programmable on Output 1. For the courtesy light

connected to Output 1, the command is only ena-

bled when this output is programmed in “courtesy

light” mode (Control unit functions > advanced pa-

rameters > output conguration > output 1 (ash)

> courtesy light). CAUTION! – The courtesy light is

switched off automatically if the relative time interval

elapses, as programmed in the function “courtesy

light time” (Control unit functions > advanced pa-

rameters > output conguration > courtesy light

time). Input congured as normally open.

Apartment block Step-by-step Program the required operating

mode, ss apartment block 1 (“command congura-

tion” > “step-by-step” > operating mode: ss apart-

ment block 1)

This command is factory set to Input 1, with oper-

ating mode “ss apartment block 1” and operating

sequence “open- stop - close - open”. When the

command is sent, the control unit makes the auto-

mation run the manoeuvre following that previously

(or still) in execution, according to the order of ma-

noeuvres given in the programmed sequence. Note

– This apartment block step-by-step command is

used for apartment blocks and in general envisag-

es programming of all apartment block transmitters

with a single “apartment block step-by-step” key.

Input congured as normally open.

Stop Stop in closure Program the desired mode from

those listed in Table 1-L (“command conguration”

> “Stop in closure” > mode ...)

When this command is sent, the control unit stops

the manoeuvre in progress and activates the ap-

plication to execute the set operating mode. Input

congured as normally closed.

Emergency stop (0x28) When this command is sent, the door opens re-

gardless of its position. The input must remain

active. The safety equipment is ignored and all

close commands are also ignored (button press,

automatic closure, etc.). Only the hardware safe-

ties remain active. The door's operation is restored

when the input is deactivated. Input congured as

normally closed.

Interlocking (0x29) When this command is sent, the control unit stops

the manoeuvre in progress. Input congured as

normally closed. It is used together with an output

congured as Interlocking (see Interlocking output)

Apartment block open Opening Program the required operating mode,

apartment block 1 open (“command conguration”

> “opening” > operating mode apartment block 1

open)

When this command is sent, the control unit acti-

vates the application to perform the opening ma-

noeuvre only until the limit switch is reached. Note

– This command is useful when using control pho-

tocells or a magnetic detector loop. Input cong-

ured as normally open.

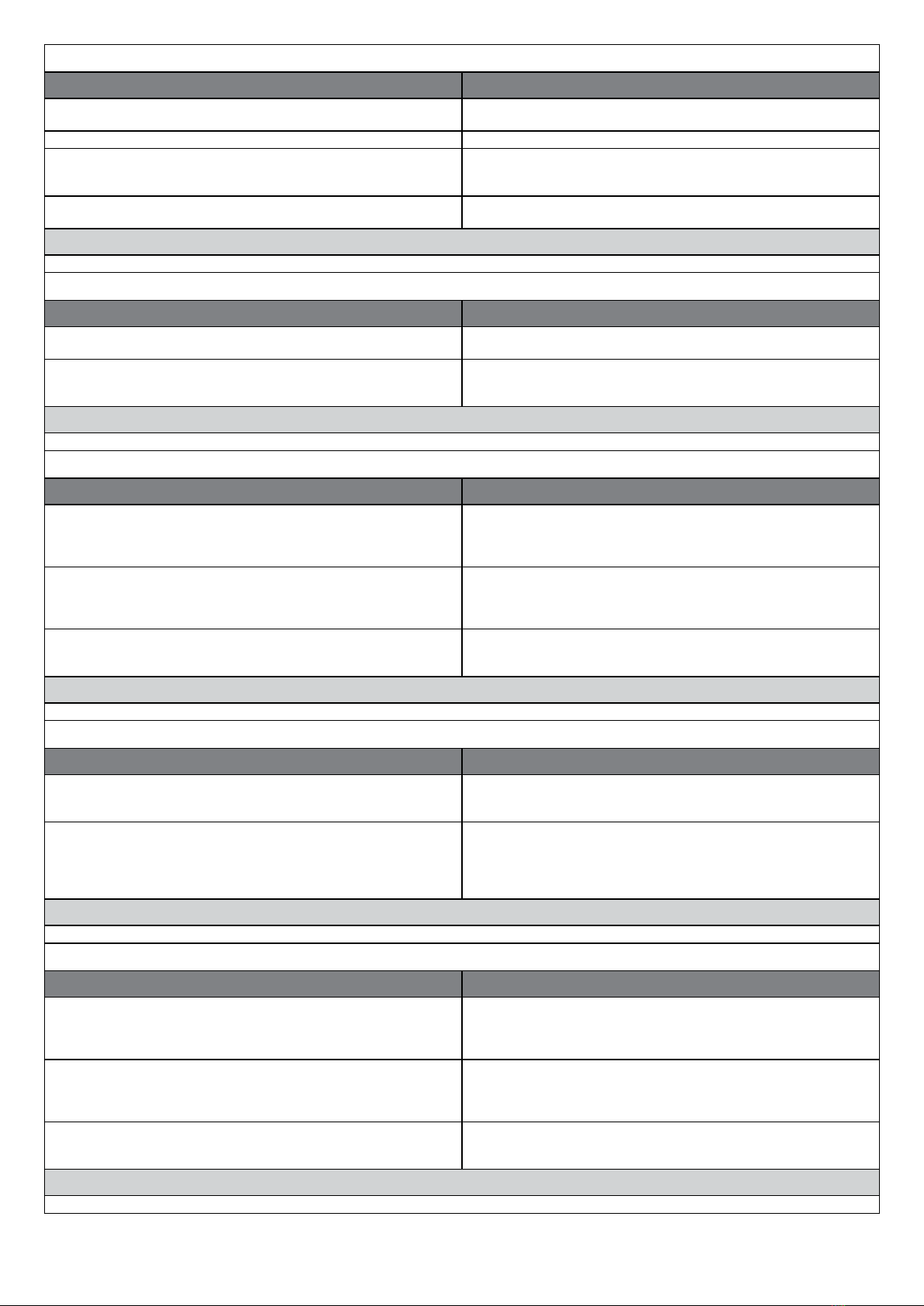

Photo

Safety function

Photo Program the desired mode from those listed

in Table 1-F (“command conguration” > “photo”

> mode ...)

When this command is sent, the control unit acti-

vates the application according to the selected ma-

noeuvre type. Input congured as normally closed.

Photo 1

Safety function

Photo 1 Program the desired mode from those list-

ed in table 1-G (“command conguration” > “photo

1” > mode ...)

When this command is sent, the control unit acti-

vates the application according to the selected ma-

noeuvre type. Input congured as normally closed.

Photo 2

Safety function

Photo 2 Program the desired mode from those list-

ed in table 1-H (“command conguration” > “photo

2” > mode ...)

When this command is sent, the control unit acti-

vates the application according to the selected ma-

noeuvre type. Input congured as normally closed.

Photo 3

Safety function

Photo 3 Program the desired mode from those list-

ed in table 1-I (“command conguration” > “photo

3” > mode ...)

When this command is sent, the control unit acti-

vates the application according to the selected ma-

noeuvre type. Input congured as normally closed.

Release and open When this command is sent, the control unit is re-

leased (restoring normal operating status) and ac-

tivates the application to execute an Opening ma-

noeuvre. Input congured as normally open.

Release and close When this command is sent, the control unit is re-

leased (restoring normal operating status) and acti-

vates the application to execute a Closing manoeu-

vre. Input congured as normally open.

Automatic opening active This command enables the activation or deactiva-

tion of the function for bluebus control photocells

and inputs congured in “apartment block open”

mode. Note – the factory setting of this function is

“active”. For example, if this function is active, when

the control photocells are engaged, the control unit

activates the application to execute an Opening

manoeuvre. Input congured as normally open.

Deactivate automatic opening This command enables deactivation of the “auto-

matic opening active” mode described above. In-

put congured as normally open.