Installation Instructions for Surface Wall Mount Electromagnetic Door

Holders Catalog Series EM 508 24120

P/N 3101128 ISSUE 1 © 2006

501-1012DE-1-01

Description

The EM 508 Series are surface wall mount door holders for use

with single doors. All are ULand cULListed and FM approved.

Installation

Install and wire in accordance with applicable codes, standards,

suchas NFPApublications70 (National ElectricalCode), 72 (Na-

tionalFireAlarm Code), and80 (Standardfor Fire Doors and Fire

Windows), and/or other regulations applicable to the country

and locality of installation and in accordance with authorities

having jurisdiction.

Table 1. Specifications

Cat.No. Volts Amps

EM 508 24120 24V AC 60 Hz 0.015

24V DC 0.015

120V AC 60 Hz 0.015

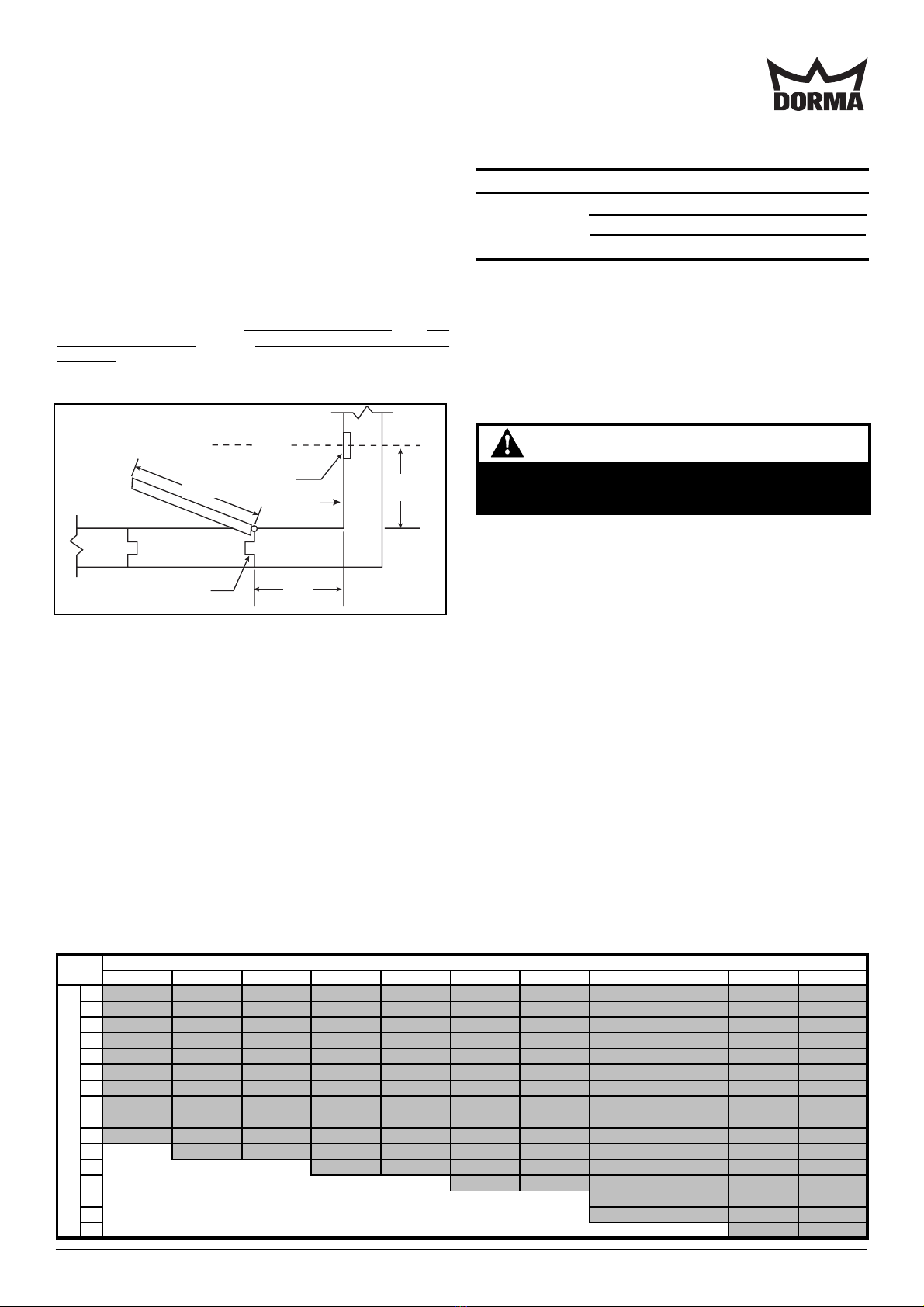

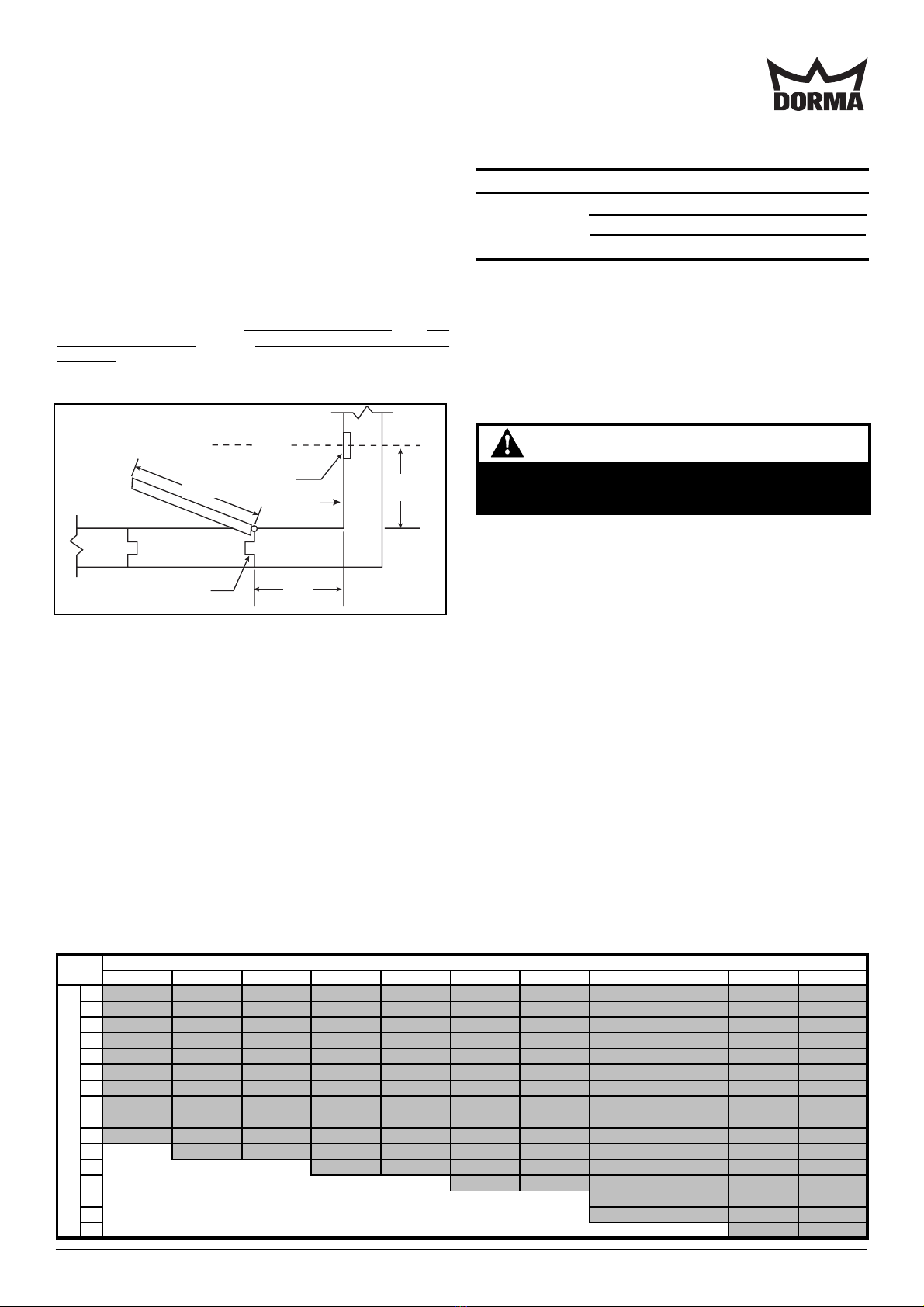

1. Using Figure 1 and Table 2, locate the intersection of

DimensionX and DimensionY. DimensionZ is shownat the

intersection in the gray area.

NOTE: If dimension X or Y is not shown on the chart,

extrapolate Dimension Z. (i.e., if X=7, and Y=30, Z

= (27-5/8 - ((27-5/8 - 27-1/4)/2)) => Z = 27-9/16" )

2. Mount the surface housing (supplied) vertically on the

horizontal center line and 5" from the top of the door with

two 1/4-20 x 1" screws (provided).

NOTE: The outlet box must be able to withstand a maximum

holding force of 50 pounds.

If X and Y intersect in the blank area in Table 2, DO NOT

install the outlet box. The contact plate and electromagnet

cannot be aligned with these dimensions.

Door

Door jamb

Wall line

Outlet box

center

line

X

Z

Y

Figure 1. Locating the Door Holder

Table 2. Dimension chart (in inches (mm))

Electromagnet Assembly Mounting

1. Refer to Figure 4. If not using surface metal raceway (not

supplied), secure the acrylic insulating sleeve (provided) to

the hole in the surface housing with the #8-32 x 3/16" screw

provided.

WARNING

To prevent electrical shock, ensure power is discon-

nected.

2. Pull field wiring through conduit into the surface housing. If

surface metal raceway (not supplied) is being used, the

required size is 1/2" wide x 11/32" high. The raceway will

seat 1/4" into the surface housing. Wiring should be run

through the acrylic insulating sleeve where applicable.

3. Establish earth-ground continuity in accordance with

applicable codes, standards and authorities having

jurisdiction.

4. Refer to Figure 2 and connect as instructed below:

a. 120V AC operation. Connect power field wiring to

terminalsmarked "120VAC"and "COM."

b. 24VAC/DCoperation. Connect power field wiring to

terminalsmarked "24VAC/DC"and "COM."

5. Mount the connected assembly onto the surface housing

and secure it with (2) #10-32 x 7/8" screws (supplied).

NOTE: The combined projection of the surface housing,

electromagnet assembly, and the armature assembly

is 4 1/16".

DORMA Architectural Hardware * Dorma Drive - Drawer AC, Reamstown, PA 17567

28 30 32 34 36 38 40 42 44 46 48

226 (660) 28 (711) 29 7/8 (759) 32 (813) 34 (864) 36 (914) 38 (965) 40 (1016) 42 (1067) 43 7/8 (1114) 45 5/8 (1159)

426 (660) 28 (711) 29 7/8 (759) 32 (813) 34 (864) 36 (914) 38 (965) 40 (1016) 42 (1067) 43 7/8 (1114) 45 5/8 (1159)

625 5/8 (651) 27 5/8 (702) 29 5/8 (752) 31 3/4 (806) 33 3/4 (857) 35 3/4 (908) 37 3/4 (959) 39 3/4 (1010) 41 3/4 (1060) 43 5/8 (1108) 45 3/8 (1153)

825 1/4 (641) 27 1/4 (692) 29 1/4 (743) 31 3/8 (797) 33 1/2 (851) 35 1/2 (902) 37 3/8 (949) 39 1/2 (1003) 41 1/2 (1054) 43 3/8 (1102) 45 1/4 (1149)

10 24 5/8 (625) 26 3/4 (679) 28 3/4 (730) 30 7/8 (784) 33 (838) 35 (889) 37 (940) 39 1/8 (994) 41 1/8 (1045) 43 (1092) 44 7/8 (1140)

12 23 3/4 (603) 25 7/8 (657) 28 (711) 30 1/8 (765) 32 1/4 (819) 34 3/8 (873) 36 3/8 (924) 38 1/2 (978) 40 5/8 (1032) 42 1/2 (1080) 44 3/8 (1127)

14 23 3/4 (603) 25 (635) 27 1/4 (692) 29 3/8 (746) 31 1/2 (800) 33 3/4 (857) 35 7/8 (911) 38 (965) 40 (1016) 42 (1067) 43 7/8 (1114)

16 21 3/4 (552) 24 (610) 26 1/4 (667) 28 1/2 (724) 30 3/4 (781) 33 (838) 35 1/8 (892) 37 1/4 (946) 39 3/8 (1000) 41 3/8 (1051) 43 3/8 (1102)

18 20 (508) 22 1/2 (572) 25 (635) 27 3/8 (695) 29 3/4 (756) 32 (813) 34 1/4 (870) 36 1/2 (927) 38 5/8 (981) 40 5/8 (1032) 42 1/2 (1080)

20 18 1/4 (463) 21 (533) 23 1/2 (597) 26 (660) 28 1/2 (724) 30 7/8 (784) 33 1/8 (841) 35 3/8 (899) 37 5/8 (956) 39 5/8 (1006) 41 5/8 (1057)

22 18 3/4 (476) 21 5/8 (549) 24 3/8 (619) 27 (686) 29 3/8 (746) 31 3/4 (806) 34 1/8 (867) 36 1/2 (927) 38 5/8 (981) 40 3/4 (1035)

24 22 1/2 (572) 25 1/2 (648) 28 1/8 (714) 30 5/8 (778) 33 1/8 (841) 35 5/8 (905) 37 7/8 (962) 40 (1016)

26 Do not install outlet box if 26 1/4 (667) 29 (737) 31 5/8 (803) 34 1/4 (870) 36 1/2 (927) 38 5/8 (981)

28 Dimensions X and Y intersect in this blank area. 29 3/4 (756) 32 1/2 (826) 34 7/8 (886) 37 1/8 (943)

30 The armature and electromagnet cannot be aligned. 27 3/4 (705) 30 5/8 (778) 33 (838) 35 3/8 (899)

32 31 3/8 (797) 33 7/8 (860)

X = Dimension of door jamb to wall

Y = Dimension of door width