DORM CS

• The door opens at creep speed .

Once the door reaches the desired opening width, set

1I1eprogramme switch to 'PARTIAL OPENING".

• The door stops and the newly-established partial opening

width

is

saved .

Funktlonal test

Ugh barriers

Interrupt the light barriers individually during the dosing cycle

• The LED on the interface PCB goes out and the door

changes direction.

With the door open, Interrupt the light barriers for several

seconds

• The door remains open for as long as the light barriers are

interrupted.

• Once the light barrters are uninterrupted, the door doses

aMer elapse of the preset hofd-open time.

An automatic test of the light barriers also takes place before

every dosing operation.

Activators

Check all activators connected to the various programme

switch posmons. The correct setting may be found in the

relevant assembly instructions.

Emergency stop

Set 1110programme switcl1 to 1110'AUTOMATIC' position;

• During the closing sequence, actuate the -Emergency

stop. switch: the door stops and changes drection.

Briefing

Following successful commissioning and functional testing of

the door unit the operating instructions are to be handed over

to the Operator and a briefing given.

Optional unctions

If the following optional functions are installed, they must be

tested as Iollows.

Airlock

Two successive doors forming an airlock:

Irrespective of the side from which the openIng pulse Is

initiated, the first door opens and then doses.

Only then should 1I1esecond door open aOOdose.

Signal 01 passage (bell contact)

The acoustic signal must be checked by interrupting the light

barriers.

Door status signalling

Check acoustic or optical door status signalling system.

.•.

Commissioning

I

Adjustment

I

Functional testing

Preparationfor commissioning Adjustment01thepartialopeningwidth

The partial opening width can be separately adjusted using

ttle programme S\Vilch. Set the programme switdl to

"PERMANENT OPEN";

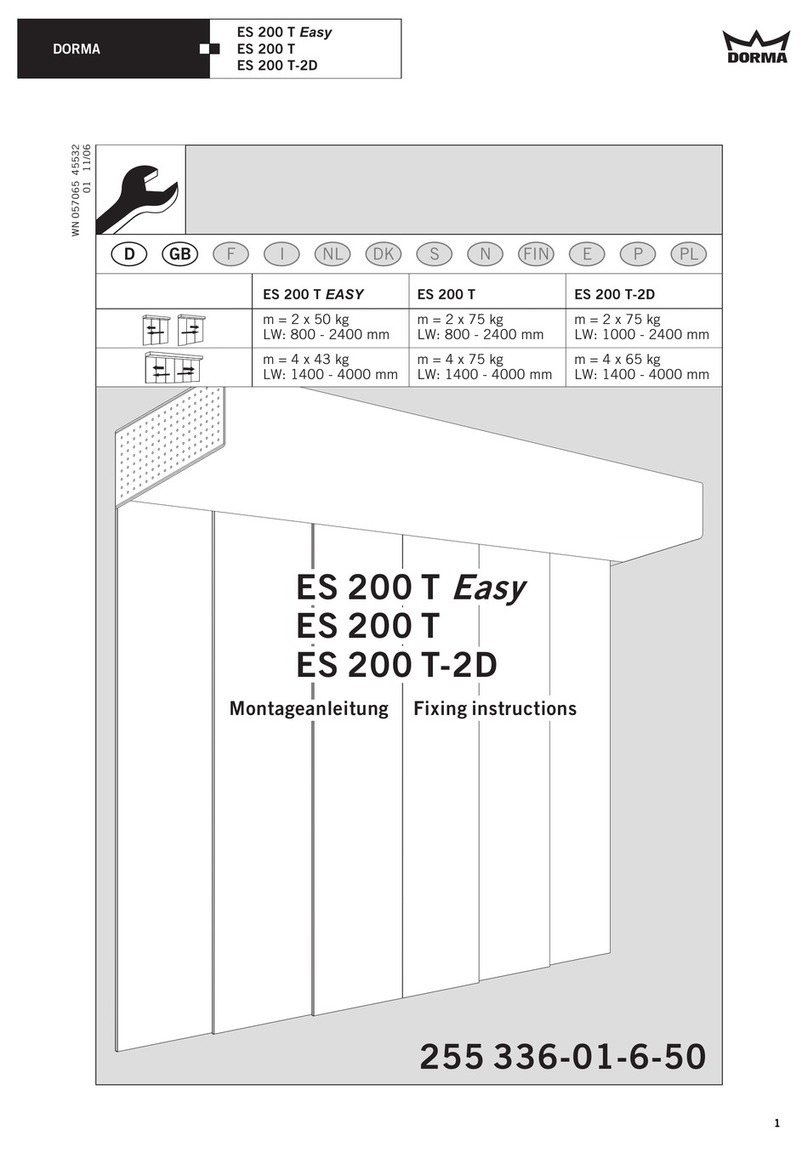

Basic prerequlsttes

• The drive unit is fully assembled.

• The protective earth is connected.

• The light barriers are connected.

• Components supplied separately, such as programme

switch, activator and k>cking mechanism, are installed and

connected.

• The end stops are adjusted so that at maximum opening

width both moving leaves are in contact with the stops;

when door is dosed, neither moving leaves nor Inactive

leaves

toud"l

the sealing profile.

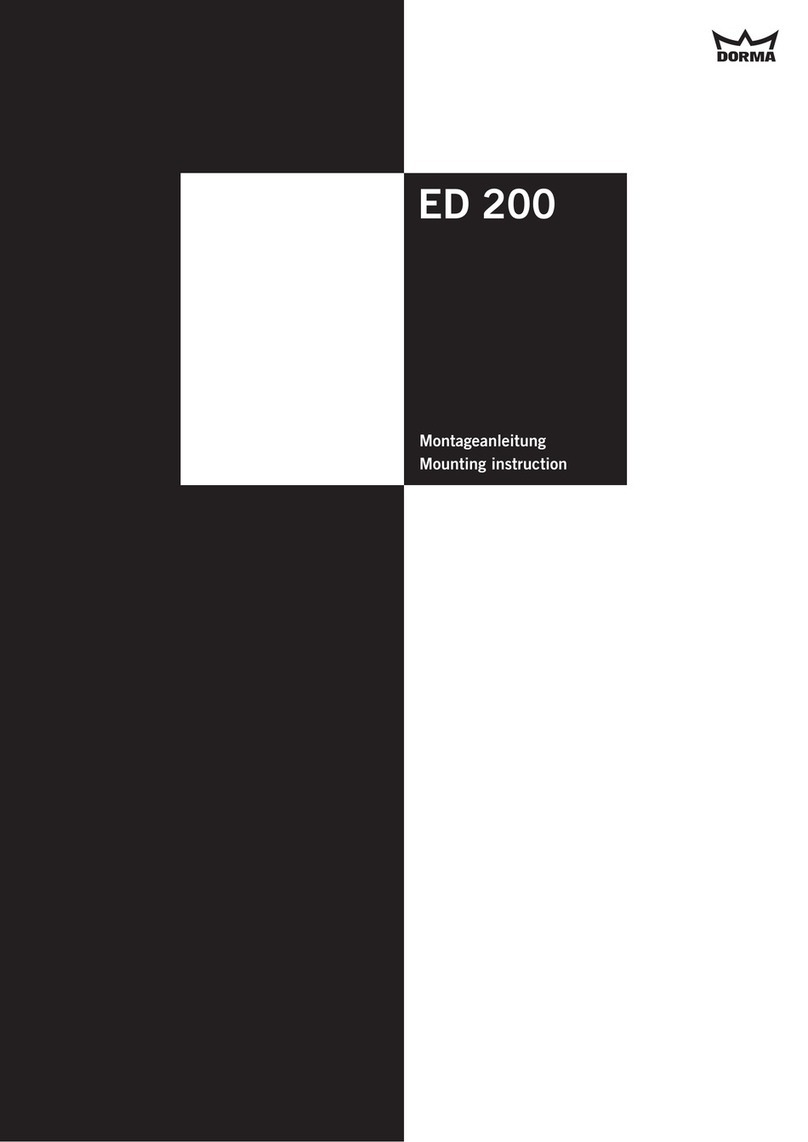

Commissioning

Move the door leaf to half--open position.

Move the programme switd1 to the -Automatic. position.

Press the Service pushbutton.

Programme loading

Conned to the mains. Wait for the start-up phase of approx. 25

sees. (dicking noise in relay).

Keep service pushbutton pressed until the door initiates a

dosing sequence, which initiates the programme loading

operation.

This means that the basic factory settings for the control

system are automatically aligned with the basic sliding door

parameters.

The basic values for opening width, motor type and door

weight are loaded but not Slored in 1I1ememory yet.

At.

If the door opens, the motor connection poles must

LU be reversed and the

commissioning

procedure

repeated.

The change In the counting direction of the

Incremental encoder Is only detected during the Inftlal

program/data upload operation.

Starting learning cycle

1. Set programme switcl1 to 1I1e"AUTOMATIC" posi1ion.

2. Close the door.

3. Press service pushbutton for approx. 3 sec.

• The door opens at creep speed, and during this opening

seCJJenco determines the opening width, motor type and

door weight.

• The door then closes again.

• Finally, the unit tests for a locking mechanism; if oneis

connected, what type.

Then the door opens a short way and doses again up to

three times.

4. Finally, brieflypress service pushbutton

• The door opens quickly and whilst in the open position

saves the parameters it has determined.

Adjustments

The control system has been preset so ttlat it is optimised to

suit the most froquent1y-occurring situations.

Should you wish to adjust the settings, this can be done using

the hand terminal

(Hl).

Instructions on how to do so will be

found in the hand terminal operating instructions.

To return to the basic settings

Connect to the mains. Wait for the start-up phase of approx. 25

sees. Keep service pushbutton pressed until the door initiates

a closing sequence.