Croydex Beaulieu Series User manual

1

Beaulieu Vanity Unit, Mirror and Light

Thank you for purchasing this Croydex product. Please follow the xing and care instructions to

ensure that your product is tted safely and that it retains its high quality nish. Please retain this

leaet for future reference.

This instruction leaet applies to the following products:

WC410122E BEAULIEU WHITE VANITY UNIT AND MIRROR SET

WC410176E BEAULIEU LIGHT OAK VANITY UNIT AND MIRROR SET

IMPORTANT INSTALLATION INFORMATION

THIS IS A CLASS 2 APPLIANCE AND MUST NOT BE CONNECTED TO EARTH

INPUT: 220-240V ~ 200mA 4.8W IP 44

HAZARDOUS VOLTAGES INSIDE – DO NOT OPEN SEALED UNITS

THIS PRODUCT MUST BE CONNECTED TO A SWITCHED LIVE LIGHTING CIRCUIT

THERE ARE NO USER REPLACEABLE PARTS IN THE LIGHT UNIT

In accordance with Statutory Instrument 2004 No. 3210 - The Building (Amendment) (No.3)

Regulations 2004, any work, other than repair/replacements, in a room where there is water (e.g.

kitchen, bathroom, etc.) must be either:

• carried out by an electrician who is a member of a competent person self-certication

scheme who will certify the work complies with the Building Regulations and you do not need to

notify your local authority, or,

• carried out after prior notication to the Local Authority Building Control Department, which

has responsibility for ensuring that the work is inspected and tested.

IMPORTANT WARRANTY INFORMATION

In accordance with Statutory Instrument 2004 No. 3210 - The Building (Amendment) (No.3)

Regulations 2004, the installer must give the occupier of the premises in which this product has

been installed a certicate to conrm that the requirements of regulations 4 and 7 have been

satised, or the installation of this product must be inspected and tested by the Local Authority

Building Control Department who will issue a compliance certicate.

A copy of this certicate may be required for certain warranty claims. Failure to provide a copy of

the certicate may invalidate the warranty.

This does not affect your statutory rights.

We recommend that you make yourself aware of the Regulations before you undertake any

work and if you require clarication you should contact your Local Authority Building Control

Department.

CAB 100 R01

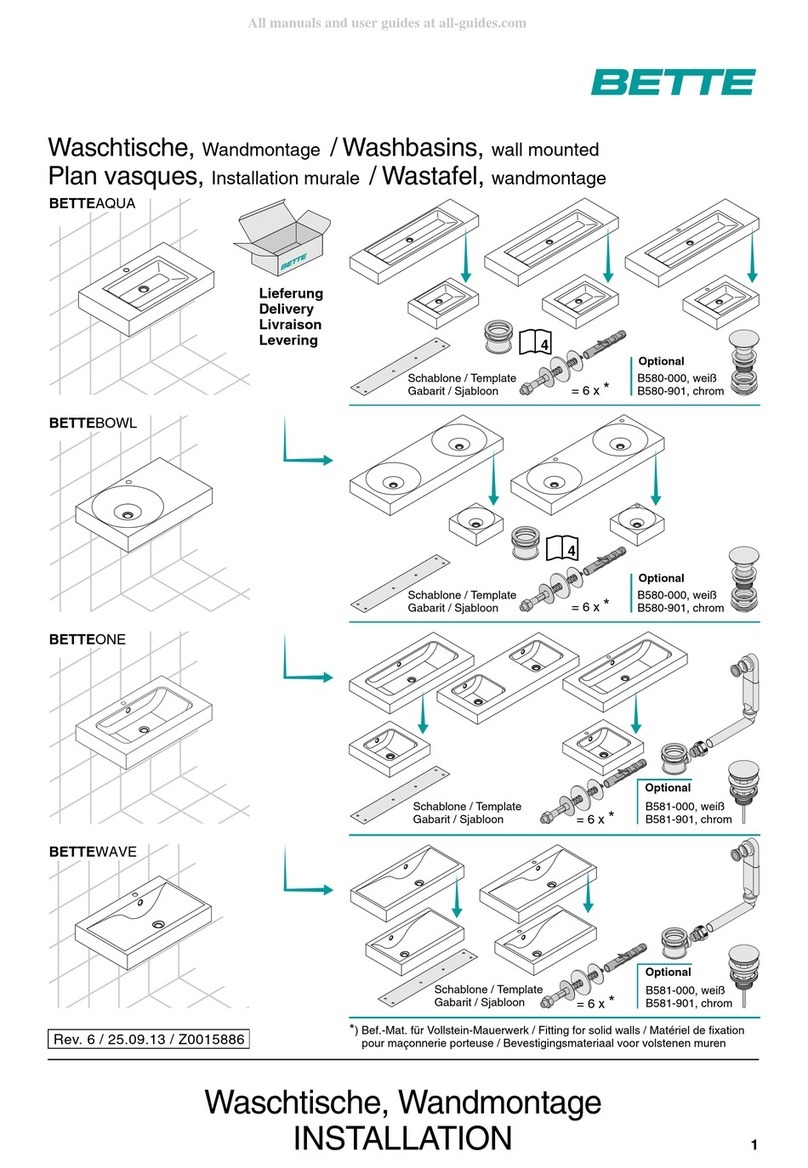

Fixing Pack Contents and Tools Required

Drill; 8mm Masonry Drill Bit; 8mm Ceramic Drill Bit (optional); Cross Head Screwdriver; Hacksaw;

Bradawl; Pencil.

KEEP DIY TOOLS OUT OF THE REACH OF CHILDREN

Home Safety Advice

It is recommended that two people t the cabinet to ensure that it is tted safely.

Always take care when using an electric drill, particularly in the bathroom. Always check for hidden

cables and pipe work before drilling and take extreme care if there is any water in the working area.

It is advisable to use a residual current circuit breaker (RCCB).

Always wear suitable eye protection when drilling.

If the product is to be tted on a ceramic tiled wall, a ceramic drill bit should be used. Always

ensure that the drill hole passes through the central tiled area rather than through the grouted area.

To prevent unnecessary damage to the tile, mask the area around the hole with tape before drilling.

Do not strike the product with hard or sharp objects.

Do not overload the cabinet. Maximum safe working load is 15kg evenly distributed if mounted on

to a solid wall. If mounted on to a cavity wall reduce the load to 10kg evenly distributed.

Fixing Instructions

Positioning the Mirror

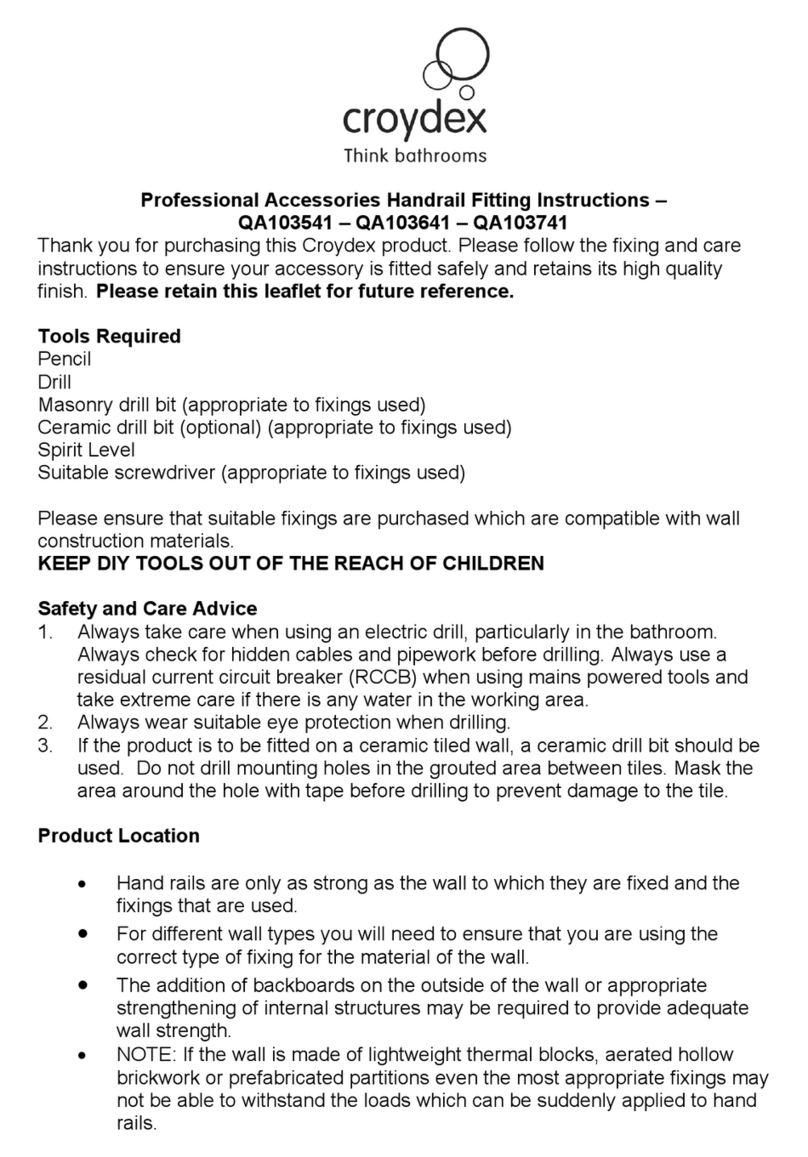

1. The light unit is rated IP44 and must only be

installed in the Outside Zones, as shown in Figure 1.

2. Ensure that the access to the switched

electrical supply is located behind the intended

mounting position for the mirror.

Product Care

To retain the best quality nish, clean product regularly with a soft damp cloth.

Do not use abrasive or chemical cleaners as these will damage the product.

Do not position glass components in close contact with a heat source.

Do not strike glass with hard or sharp objects.

Product Location

Vanity units are only as strong as the wall to which they are xed and the xings that are used.

For different wall types you will need to ensure that you are using the correct type of xing for the material

of the wall.

The addition of backboards on the outside of the wall or appropriate strengthening of internal structures

may be required to provide adequate wall strength.

NOTE: If the wall is made of lightweight thermal blocks, aerated hollow brickwork or prefabricated

partitions even the most appropriate xings may not be able to withstand the loads which can be

suddenly applied to the vanity unit.

CAB 100 R01

2

Figure 1.

CAB 100 R01

3

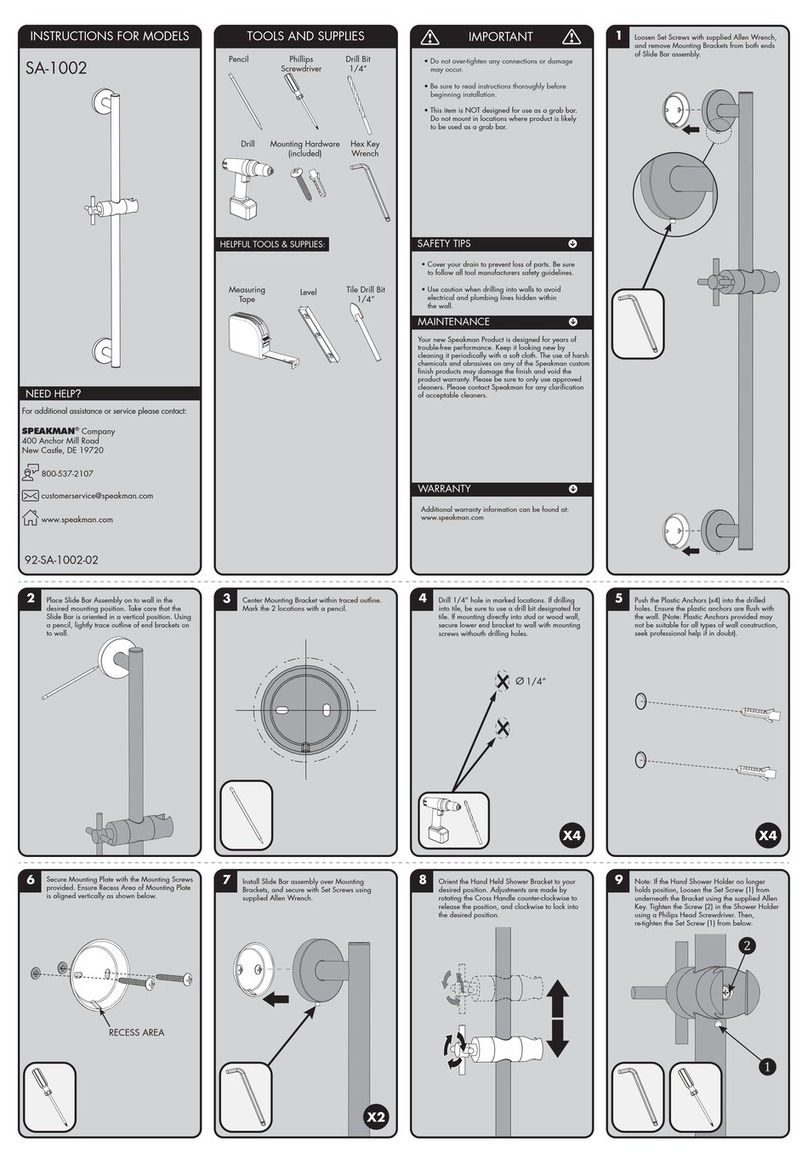

Assemble the Hang ‘N’ Lock bracket sections

making sure all parts are slotted together tightly.

Place the Hang ‘N’ Lock bracket onto the

hanging baton at the back of the Vanity Unit and

measure the dimension ‘A’ – See g.1.

Determine the desired location of the Vanity Unit

and mark a point at the top edge of the cabinet

on the wall surface. Using dimension ‘A’ draw a

horizontal reference line below the top mark to

determine the position of the bottom edge of the

Hang ‘N’ Lock bracket.

Place the bottom edge of the

Hang ‘N’ Lock bracket onto the

reference line and using a pencil,

mark the screw hole positions in each

cam recess. Remove the Hang ‘N’ Lock

bracket from the wall surface prior to

drilling.

Marked Screw Position

2

Drill the marked holes to a depth of 45mm.

Insert the wall plugs level with the surface

of the wall. (Note: if you are tting the

product to a tiled surface, insert the wall

plugs below the surface of the tile to avoid

cracking, the tile) Insert 2 x screws (Either

countersink or standard screws can be

used) through the Hang ‘N’ Lock cams and

loosely secure the Hang ‘N’ Lock bracket

to the wall.

With the Hang ‘N’ Lock bracket loosely

attached to the wall, adjust for height

and level by rotating the cams with

a at head screwdriver aligning the

bottom edge of the HNL bracket with

the reference line, then fully tighten the

mounting screws using a philips

screwdriver, to securely x the bracket

into position. Adjust for level if required.

34

1

Bottom edge of Hang ‘N’ Lock bracket

Top edge of Vanity Unit

‘A’

Vanity Unit Installation

Hang ‘N’ Lock xing components - Vanity Unit

Hang ‘N’ Lock xing components - Mirror

A. Hang ‘N’ Lock

Bracket x 1

D. Hang ‘N’ Lock

Cam x 2

H. Wall Plugs x 2

F. Countersink Fixing

Screws x 2 (Optional)

G. Fixing Screws x 2

(Optional)

E. Hang ‘N’ Lock

Locking Stud x 2

B. Hang ‘N’ Lock

Bracket x 1

4 screws are supplied within this

xing pack.

Only 2 x screws are required to

install the Hang ‘N’ Lock bracket.

Please use either the countesink or

dome head xing screws supplied.

C. Hang ‘N’ Lock Spacer

(Small)

A. Hang ‘N’ Lock

Bracket x 1

C. Hang ‘N’ Lock

Cam x 2

G. Wall Plugs x 2

E. Countersink Fixing

Screws x 2 (Optional)

F. Fixing Screws x 2

(Optional)

D. Hang ‘N’ Lock

Locking Stud x 2

B. Hang ‘N’ Lock

Bracket x 1

4 screws are supplied within this

xing pack.

Only 2 x screws are required to

install the Hang ‘N’ Lock bracket.

Please use either the countesink or

dome head xing screws supplied.

CAB 100 R01

4

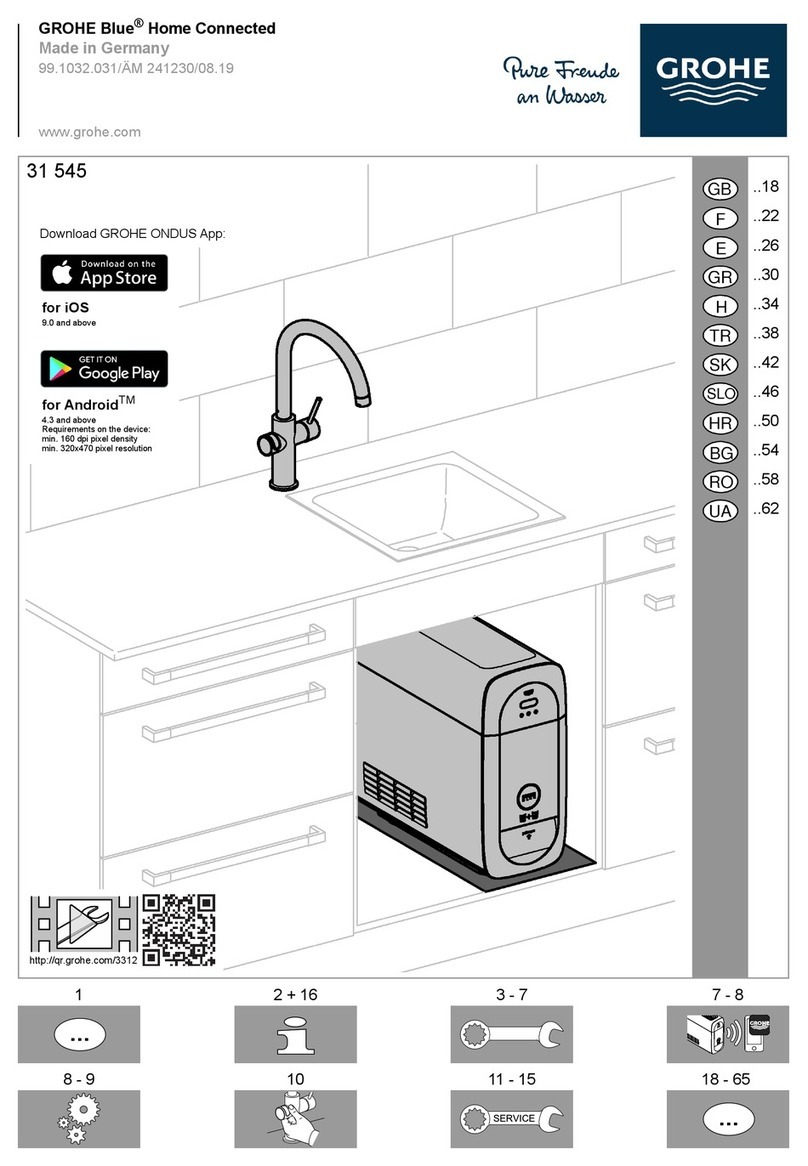

Mirror Installation

Light Module Installation (optional)

1. Align the two pilot holes at the top of the mirror with the corresponding holes located on the light

module.

2. Thread the lighting cable through the channel on the rear of the mirror prior to securing the light module

in position.

3. IMPORTANT: The lighting cable must be threaded through the channel on the rear of mirror and

located into the recess at the rear of the mirror.

4. Using the screws provided, secure the light modules onto the mirror using the a philips screwdriver.

DO NOT OVERTIGHTEN.

Assemble the Hang ‘N’ Lock bracket sections

making sure all parts are slotted together tightly.

Place the Hang ‘N’ Lock bracket onto the

hanging baton at the back of the mirror and

measure the dimension ‘A’ – See g.1.

Determine the desired location above the Vanity

Unit and mark a point at the top edge of the

mirror on the wall surface. Using dimension ‘A’

draw a horizontal reference line below the top

mark to determine the position of the bottom

edge of the Hang ‘N’ Lock bracket.

Place the bottom edge of the

Hang ‘N’ Lock bracket onto the

reference line and using a pencil,

mark the screw hole positions in each

cam recess. Remove the Hang ‘N’ Lock

bracket from the wall surface prior to

drilling.

Marked Screw Position

2

Drill the marked holes to a depth of 45mm.

Insert the wall plugs level with the surface

of the wall. (Note: if you are tting the

product to a tiled surface, insert the wall

plugs below the surface of the tile to avoid

cracking, the tile) Insert 2 x screws (Either

countersink or standard screws can be

used) through the Hang ‘N’ Lock cams and

loosely secure the Hang ‘N’ Lock bracket

to the wall.

With the Hang ‘N’ Lock bracket loosely

attached to the wall, adjust for height

and level by rotating the cams with

a at head screwdriver aligning the

bottom edge of the HNL bracket with

the reference line, then fully tighten the

mounting screws using a philips

screwdriver, to securely x the bracket

into position. Adjust for level if required.

Hang the mirror onto the Hang ‘N’ Lock

bracket, to complete the installation.

34

1

Bottom edge of Hang ‘N’ Lock bracket

Top edge of Mirror

‘A’

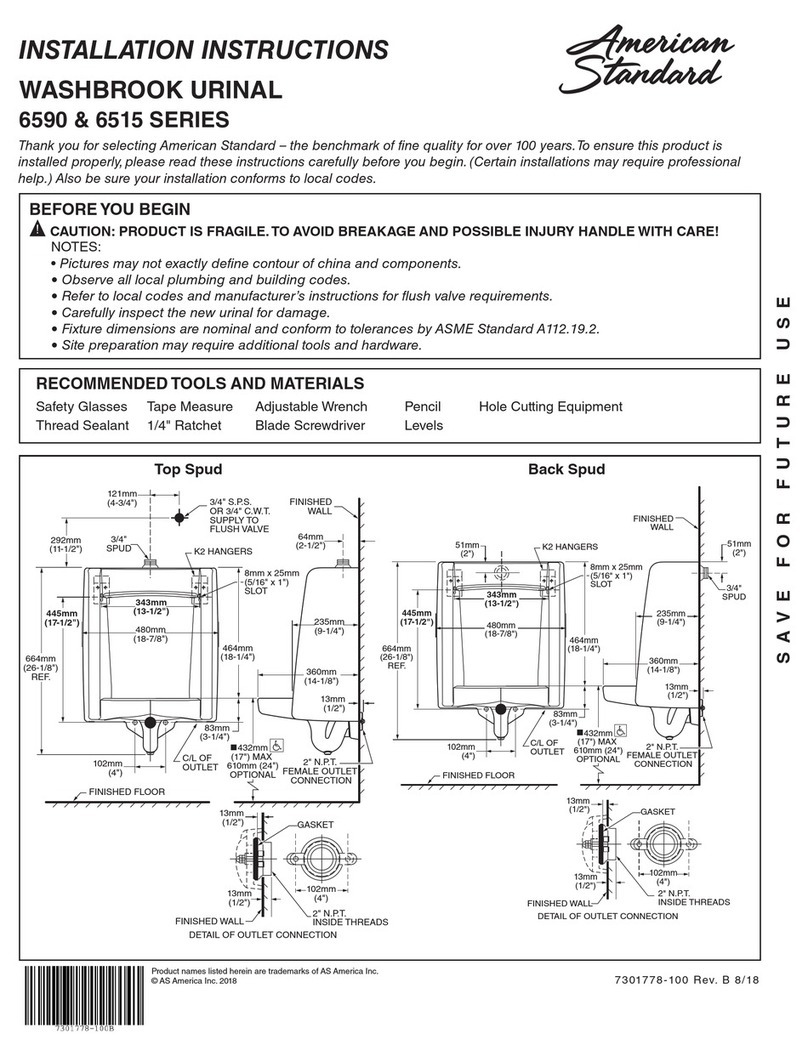

CONNECTING TO THE MAINS SUPPLY

1. Ensure that the switched electrical mains supply to which the light unit is to be connected is

turned off.

2. Connect the exible mains supply cable on the light unit to the switched lighting circuit

ensuring that the Live (Brown) conductor is connected to the switched Live on and the Neutral

(Blue) conductor is connected to the Neutral on the domestic electrical mains supply. Note:

Connection of the product to the domestic electrical mains supply must only be carried out by

a Building Regulations Part P certied electrician or must be checked by your Local Authority

Building Control Department.

This product complies with the requirements of

• European Parliament/Council Directive 2006/95/EC the Low Voltage Directive with current

amendments

• European Parliament/Council Directive 2004/108/EC on electromagnetic compatibility

(EMC Directive) with current amendments.

Applicable Standards with amendments:

• BS EN 55-015

• BS EN 61547

• BS EN 60355-1

• BS EN 60598-1

• BS EN 61558-2-5

For details of the other items in the Croydex range please visit our website: www.croydex.com

Croydex, Central Way, Andover, Hants, SP10 5AW, UK

Tel: +44 (0) 1264 365881

Fax: +44 (0) 1264 356437

Email: [email protected]

CAB 100 R01

5

910 10

9. Peel off the protective cover strip from the back of the hook and loop

fasteners and place on the back of the mirror frame.

(The adhesive tape is ideal for use on tiled and laminate surfaces but

may cause damage to painted and papered walls.)

10. Carefully lower the mirror to a vertical position and press the

adhesive pads against the wall to secure the bottom of the mirror.

The mirror can be removed by separating the hook and loop fastener

between the mirror and wall.

Operating Instructions

Cabinet Lights

To turn the LED lights on or off, operate the switch for the lighting circuit.

Product Care

To retain the best quality nish, clean product regularly with a soft cloth and mild detergents. Do not

use abrasive or chemical cleaners, as these will damage the product.

Operating Instructions

Cabinet Lights

To turn the LED lights on or off, operate the switch for the lighting circuit.

Product Care

To retain the best quality nish, clean product regularly with a soft cloth and mild detergents. Do not

use abrasive or chemical cleaners, as these will damage the product.

Do not place hot objects onto the surface of the wooden shelves.

Do not position glass components in close contact with a heat source.

CAB 100 R01

6

EU DECLARATION OF CONFORMITY

To the Restriction of Hazardous Substances (RoHS)

Directive 2011/65/EU

1. Description of product:-

Name: Vanity Unit and Illuminated Mirror Set

Part No. WC4101XXE

2. Directives complied with:-

European Council Directive 2011/65/EU of 8 June 2011 on the restriction of the use

of certain hazardous substances in electrical and electronic equipment (recast).

3. Declaration

It is hereby certified that the concentration by weight of the restricted substances in

the homogenous materials in the products described above at section 1 do not

exceed the maximum allowed concentrations listed in European Council Directive

2011/65/EU Annex II Restricted substances referred to in Article 4(1) and maximum

concentration values tolerated by weight in homogeneous materials, as detailed

below:

Substance

Concentration

Lead

0.1%

Mercury

0.1%

Cadmium

0.01%

Hexavalent Chromium

0.1%

PBB (Polybrominated Biphenyls)

0.1%

PBDE ( Polybrominated Diphenyl Ethers)

0.1%

For and on behalf of CROYDEX

P.Pegden

Product and Procurement Director

Date: 04-01-2016

CAB 100 R01

7

EU DECLARATION OF CONFORMITY

To the Low Voltage Directive (LVD) 2014/35/EU and

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

1. Description of product:-

Name: Vanity Unit and Illuminated Mirror Set

Part No. WC4101XXE

2. Directives complied with:-

European Parliament/Council Directive 2014/35/EU on the harmonisation of the laws

of the Member States relating to the making available on the market of electrical

equipment designed for use within certain voltage limits (LVD) Directive (recast).

European Parliament/Council Directive 2014/30/EU on the harmonisation of the laws

of the Member States relating to electromagnetic compatibility (EMC) Directive

(recast).

3. Declaration

The products listed above in section 1 conform to the following harmonised

standards:

LVD

BS EN 60598-1:2015

BS EN 60598-2-1:1989

BS EN 62493:2015

BS EN 62471:2008

EMC

Emissions: BS EN 55015:2013

Immunity: BS EN 61547:2009

For and on behalf of CROYDEX

P.Pegden

Product and Procurement Director

Date: 04-01-2016

This manual suits for next models

2

Table of contents

Other Croydex Plumbing Product manuals

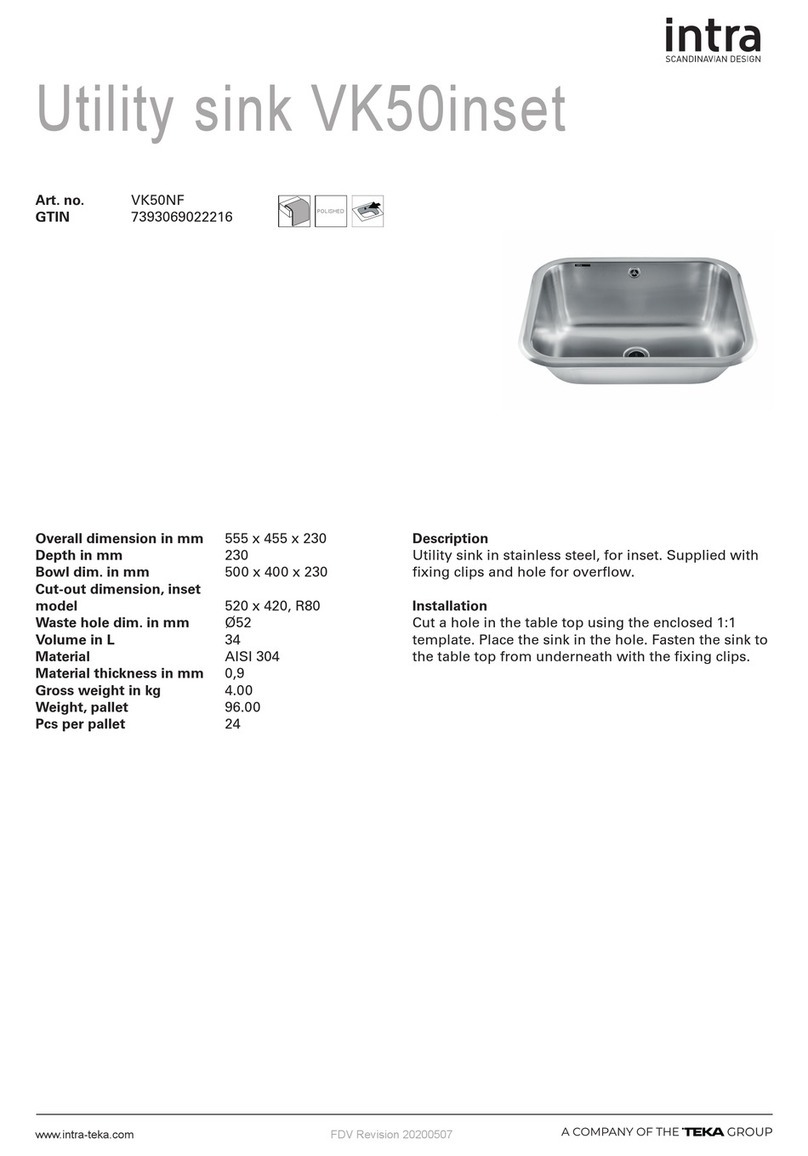

Popular Plumbing Product manuals by other brands

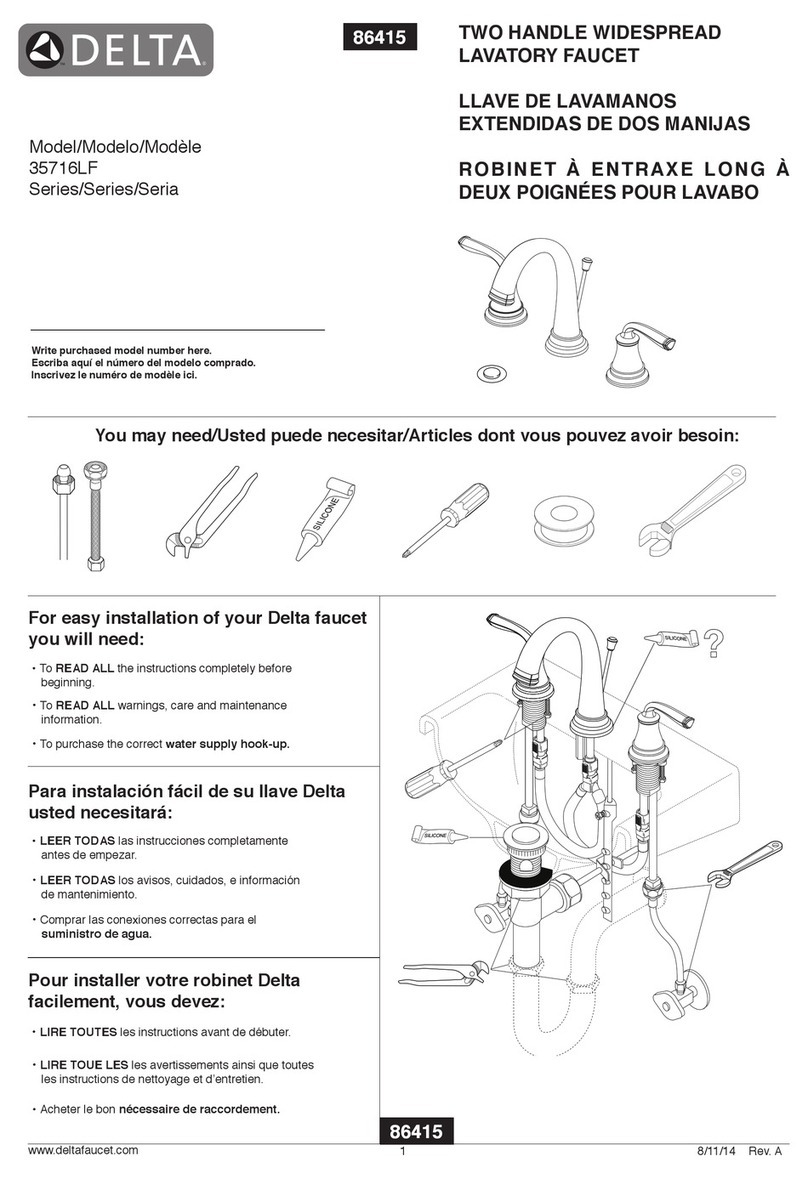

Delta

Delta 35716LF Series manual

KWC

KWC ONO touch light PRO 12.652.011.000 Installation and service instructions

Moen

Moen ioDIGITAL 3384 Installation

Tres

Tres TOUCH-TRES 1.61.445 Technical manual

Viega

Viega 6168.5 Instructions for use

American Standard

American Standard One 2064.461 installation instructions

Hans Grohe

Hans Grohe AXOR Citterio 39136 1 Series Installation/User Instructions/Warranty

Viega

Viega Multiplex Trio Visign MT3 Instructions for use

Hans Grohe

Hans Grohe Talis S 32841010 Instructions for use/assembly instructions

Toto

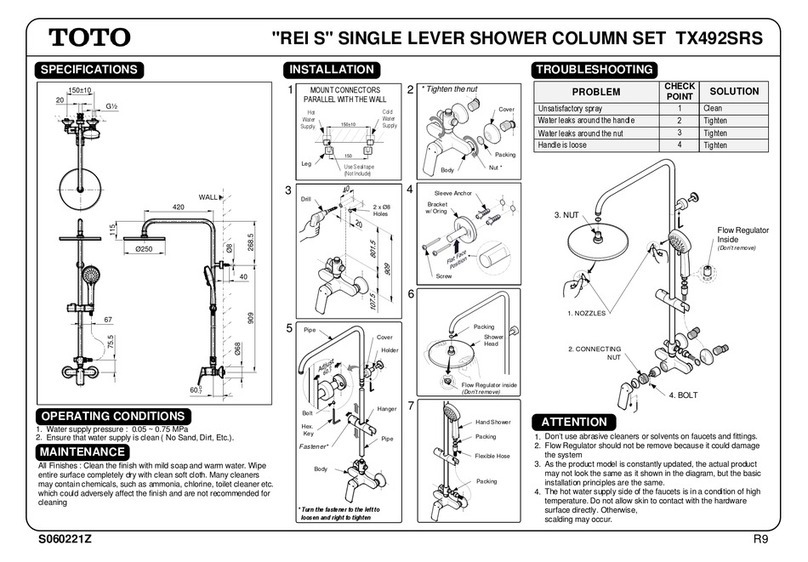

Toto REI S TX492SRS quick start guide

Clou

Clou Wash Me CL/02.13030 installation instructions

Brizo

Brizo R60700 quick start guide