CRRC MS-JY111-L User manual

眉山中车紧固件科技有限公司

MEISHAN CRRC FASTENING SYSTEM CO.,LTD.

Hydraulic Unit(MS-JY111-L)

Instruction Manual

Notice

1. Please read and understand the warning/caution label.

2. Only the personnel who have trained by Meishan CRRC Fastening System Company as well as

learned this manual are allowed to operate this pump.

3. If any other information is required, please contact Meishan.

Warning

1. Please wear eye protection.

2. Only the approved part or components can be used for maintenance or repair.

3. This pump cannot be used in flammable environment.

Safety Instruction

1. A half hour long hands-on training session with qualified personnel is recommended before

using Meishan equipment.

2. Meishan equipment must be maintained in a safe working condition at all times. Tools and

hoses should be inspected at the beginning of each shift/day for damage or wear. Any repair should be

done by a qualified repairman trained on Meishan procedures.

3. Repairman and Operator must read manual prior to using equipment. Warning and Caution

stickers/labels supplied with equipment must be understood before connecting equipment to any

primary power supply. As applicable, each of the sections in this manual have specific safety and other

information.

4. Read MSDS Specifications before servicing the tool. MSDS Specifications are available

from the product manufacturer or your Meishan representative.

5. When repairing or operating Meishan installation equipment, always wear approved eye

protection.

6. Only genuine Meishan parts shall be used for replacements or spares. Use of any other parts

can result in tooling damage or personal injury.

7. If a part affixed with warning labels is replaced, or labels are missing or damaged, the end

user is responsible for replacement. Refer to assembly drawing and parts list for replacement part

number and proper placement.

8. Disconnect primary power source before performing maintenance on Meishan equipment or

changing Nose Assembly.

9. Tools and hoses should be inspected for leaks at the beginning of each shift/day. If any

equipment shows signs of damage, wear, or leakage, do not connect it to the primary power supply.

10. Mounting hardware should be checked at the beginning of each shift/day.

11. Make sure proper power source is used at all times.

Contents

1. Structure...................................................................................................................................................4

1.1 Technical Data............................................................................................................................... 4

1.2 Structure of Pump & Valve........................................................................................................... 4

1.3 Hydraulic Tube.............................................................................................................................. 5

2. Principle of Operation............................................................................................................................. 6

3. Pressure Setting of PULL & RETURN...................................................................................................7

3.1 Recommended PULL and RETURN pressure:.............................................................................7

3.2 Adjusting the Pressure Setting...................................................................................................... 8

4. Preparation for Operation........................................................................................................................9

5. Maintenance & Cautions......................................................................................................................... 9

1. Structure

1.1 Technical Data

Motor

1.5kw

Flow

piston

pump

1.11L/min

gear

pump

4.0L/min

Max. Pressure

piston

pump

700bar

gear

pump

170bar

Gross

Weight

28kg

Unloading

Valve

10-150bar

Regulating

Valve

10-700bar

Pressure

Limiting

Valve

of

B

Way

10-340bar

Dimension 540mm×400mm×700m

m

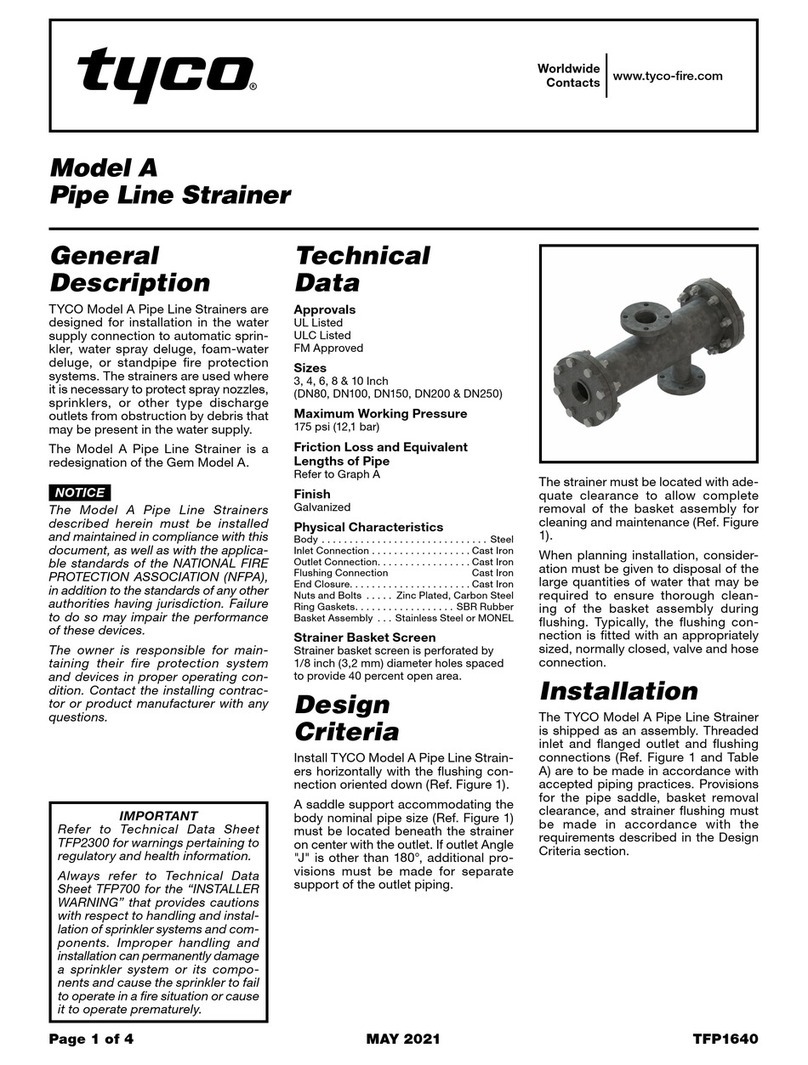

1.2 Structure of Pump & Valve

Fig.1 Structure of Pump

The pump contains motor, pump head, tank, liquid level switch, cooling system, etc..

The viscosity of hydraulic fluid shall be 4~1500

s

mm 2in which the best practise is

Ⅱ

10~500

s

mm 2. The temperature shall be -25℃—+80℃. Depress the rivet tool in air for

several circles before use to make sure the hydraulic fluid fully fills the hydraulic system.

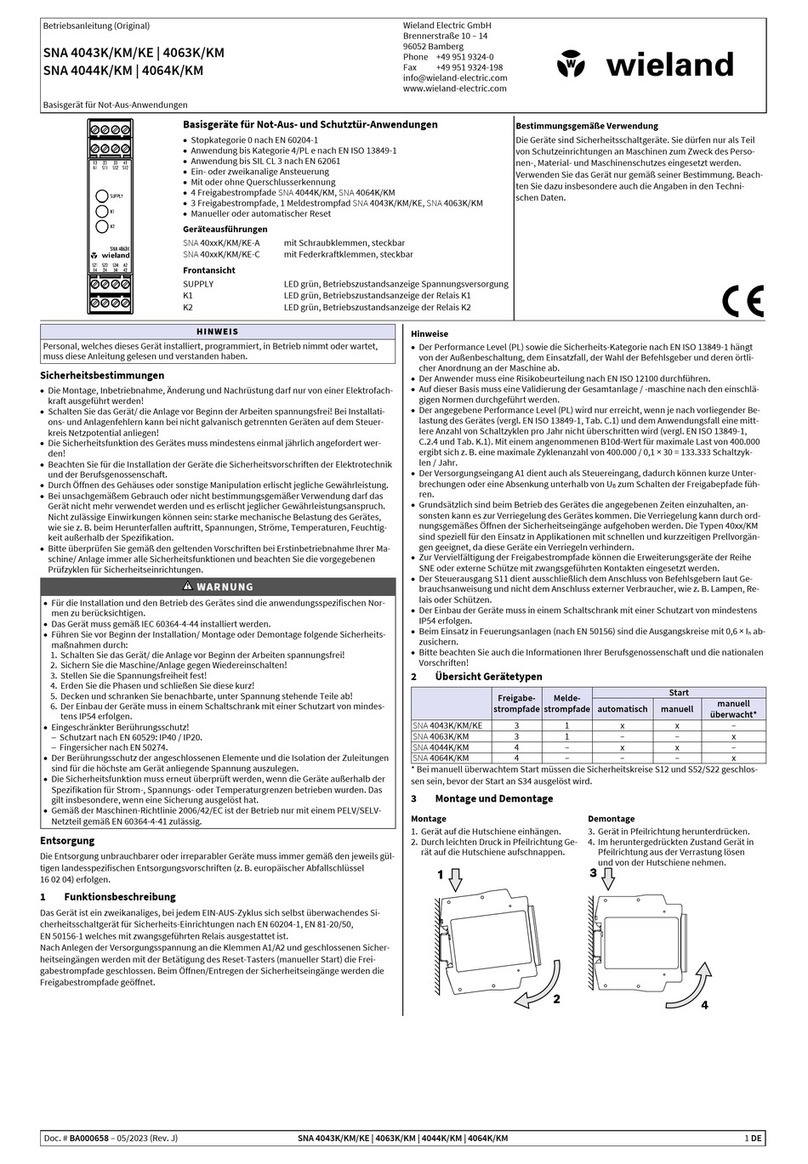

Fig. 2 Structure of Valves

The valves contains master limiting valve, unloading valve, pressure limiting valve of

B way, unloading changeover valve, magnetic directional valve, filter system, manifold

block.

1.3 Hydraulic Tube

The hydraulic tube is equipped with high-pressure tube sourcing from CEJN, and

quick disconnect couplers from Paker(paker371、paker372).

Recommended Hydraulic Fluid: 32# Anti-wear Hydraulic Fluid (temperature at

-12℃~20℃) & 46# Anti-wear Hydraulic Fluid (temperature at 20℃~50℃).

2. Principle of Operation

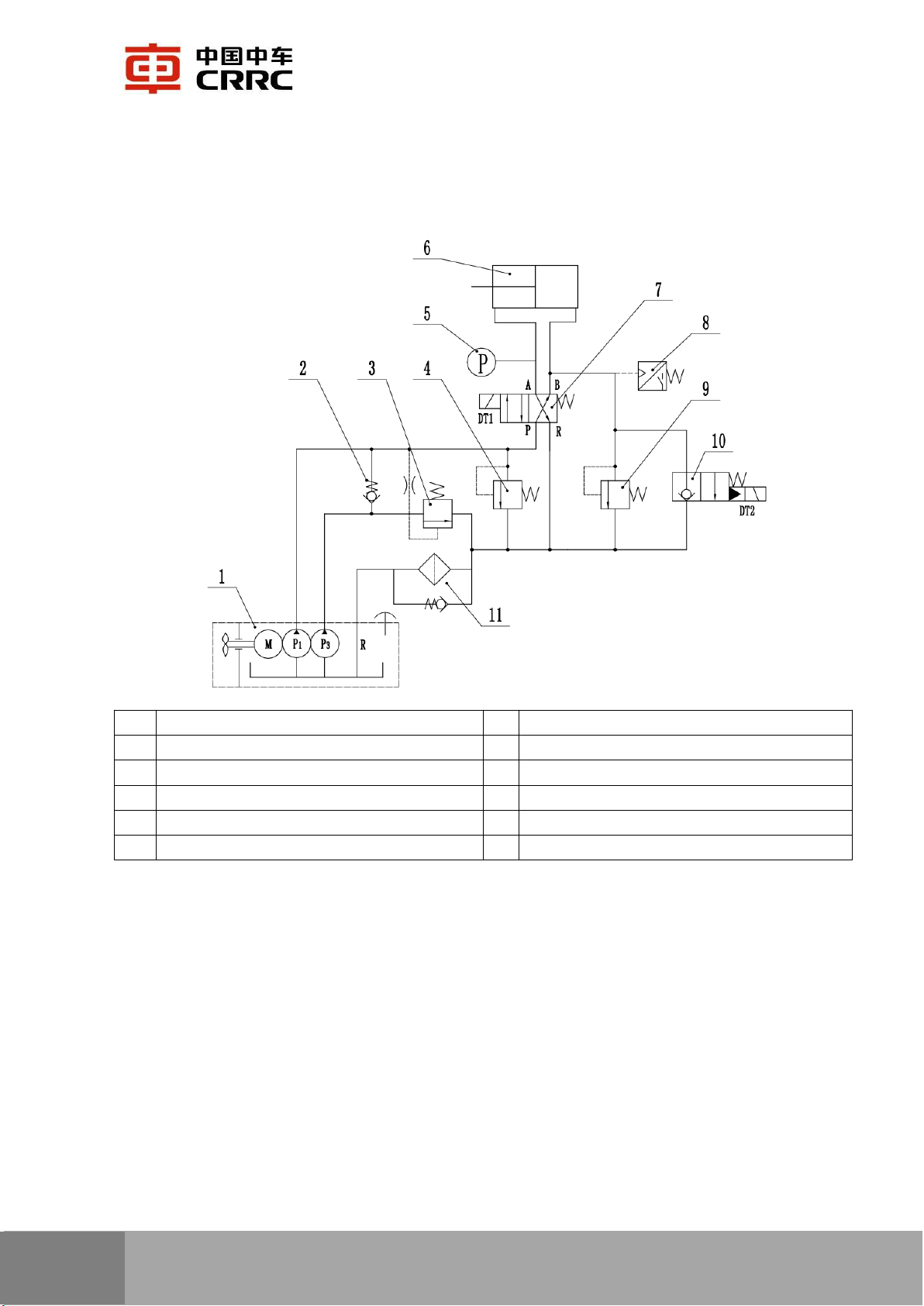

1 Hydraulic pump aggregate 7 Solenoid valve

2 Directional valve 8 Pressure relay

3 Unloading valve 9 Pressure-limiting valve

4 Overflow valve 10 Two-way solenoid valve

5 Pressure transmitter 11 Strainer

6 Installation tool

Fig. 3 Principle Diagram

When the tool trigger is depressed, motor runs, DT1 is powered on, and the left

contact of four-way solenoid closed, then the hydraulic unit start PULL circle. When

PULL pressure reaches to a pre-set value, the DT1 is shut down, and the right contact of

four-way solenoid closed, then the hydraulic unit start RETURN circle. When PUSH

pressure reaches a pre-set value, the motor shut down, and DT2 is powered on for 1s, the

pressure is released. See below for the action of solenoid valve.

3. Pressure Setting of PULL & RETURN

3.1 Recommended PULL and RETURN pressure:

Tool Model Nosepiece PULL Pressure RETURN Pressure

MS-2624PT MS-5106 4900-5800psi 2650psi-3200psi

MS-BT20 MS-7880L (Installation) 4050psi-4350psi 2650psi-3200psi

MS-7880CC (Cutting) 4650psi-5100psi 2650psi-3200psi

Status

Item

Trigger

Electrom

agnet

DT1

Electro

magnet

DT2

Motor

Status

Pressure

Relay

Start Pull + + - On Off

Pull Finished + + - On Off

Start Return - - - On On

Return Finished - - - On On

Unloading - - + Off Off

2

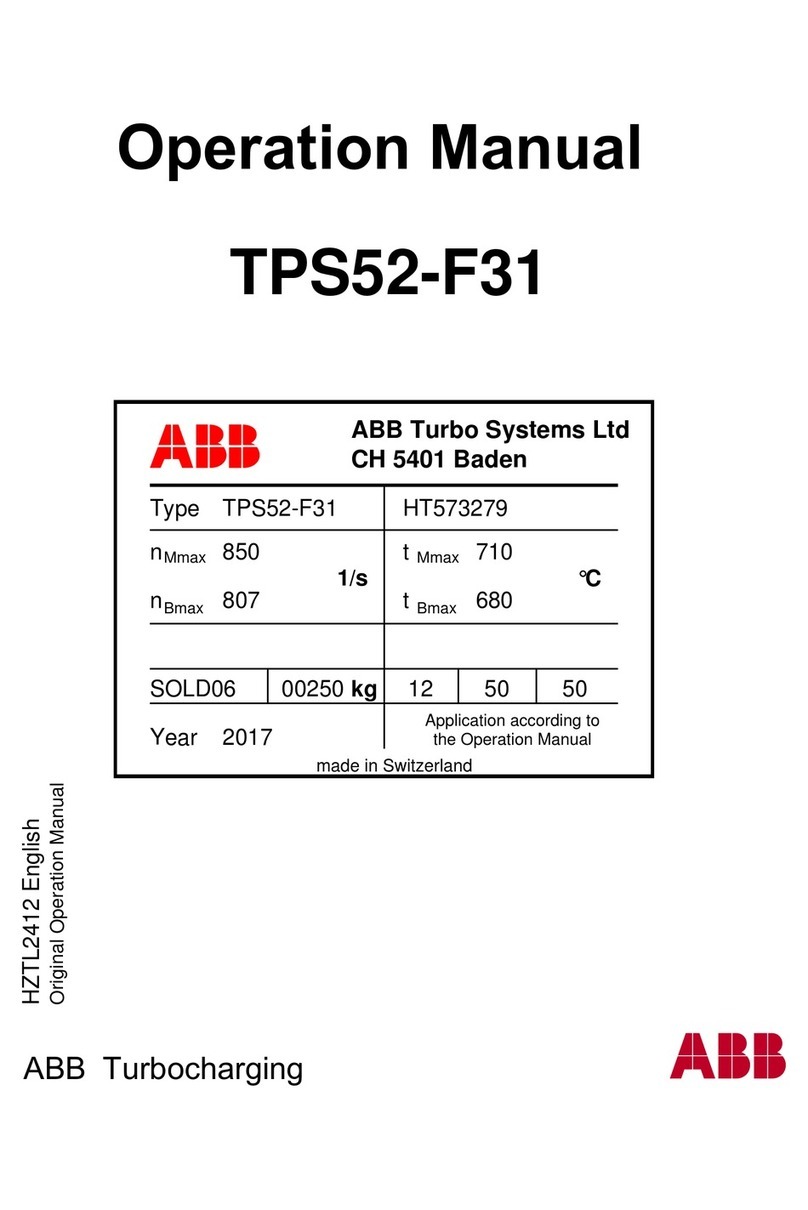

3.2 Adjusting the Pressure Setting

Fig. 4 Adjusting the Pressure

3.2.1 Master Regulating Valve for regulating the PULL pressure of installation and

cutting tool:

a. Turn the valve clockwise to rise the pull pressure;

b. Turn the valve counterclockwise to decrease the pull pressure.

3.2.2 Return Regulating Valve for regulating the RETURN pressure:

a. Loosen the locknut (white nut) on the valve;

b. Start pumping;

c. With a screwdriver, slowly turn the adjusting screw(black screw);

d. Turn the adjusting screw clockwise to rise the pressure, turn the adjusting screw

counterclockwise to decrease the pressure;

e. When the desired pressure is reached, lock the adjusting screw in position by

tightening the locknut while hold the position of the adjusting screw.

Master Regulating

Valve

Return Regulating

Valve

4. Preparation for Operation

a. Repairman and Operator must read manual prior to using equipment. A training

session with qualified personnel is recommended before using this equipment.

b. Check all hoses and tools for damage and leaks. The leaks of hydraulic fluid

leads to severe personal injury.

c. Keep the coupler of pipe away from dirt. Any dirt or fiber leads to defect and

must be cleaned up prior to using this equipment.

d. The thread sealant tape is recommended to seal the thread of pipe to avoid

leakage. DO NOT use plastic tape to enwind the thread of pipe, the chippings of plastic

tape leads to damage to valve.

e. Before connecting the tool trigger to hydraulic unit, the hydraulic pipe must be

connected to the hydraulic unit first.

5. Maintenance & Cautions

a. Keep the hydraulic unit clean.

b. Replace the hydraulic fluid once running for every 250 hours.

c. Disconnect the power supply of hydraulic unit while it is not supposed to be

used.

d. Inspect the level of hydraulic fluid regularly, add fluid as needed.

e. Do not move the hydraulic unit by hauling the pipes; protect the structure shell

from damage; protect the hydraulic unit from falling when moving it.

f. Inspect all pipes and hoses for signs of damage and leaks, replace the hoses and

accessories as needed.

g. Inspect all connection of tools everyday before work.

h. Regularly inspect the screws of tool and hydraulic unit for loosening.

i. Take care of all connections from break, scrap and joint failure when using this

hydraulic unit.

眉山中车紧固件科技有限公司

地址:中国·四川眉山市东坡区科工园二路

电话:182 2815 1235 0086 28 38283773

传真:0086 28 38164262

MEISHAN CRRC FASTENING SYSTEM CO.,LTD.

Add:Road No.2,Hi-tech Zone,Dongpo district,Meishan,Sichuan,

province,China

Tel:182 2815 1235 0086 28 38283773

Fax:0086 28 38164262

眉山中车紧固件科技有限公司

地址:中国·四川眉山市东坡区科工园二路

电话:182 2815 1235 0086 28 38283773

传真:0086 28 38164262

MEISHAN CRRC FASTENING SYSTEM CO.,LTD.

Add:Road No.2,Hi-tech Zone,Dongpo district,Meishan,Sichuan,

province,China

Tel:182 2815 1235 0086 28 38283773

Fax:0086 28 38164262

Table of contents