CIP 2.0 IOM | 7

WARNING

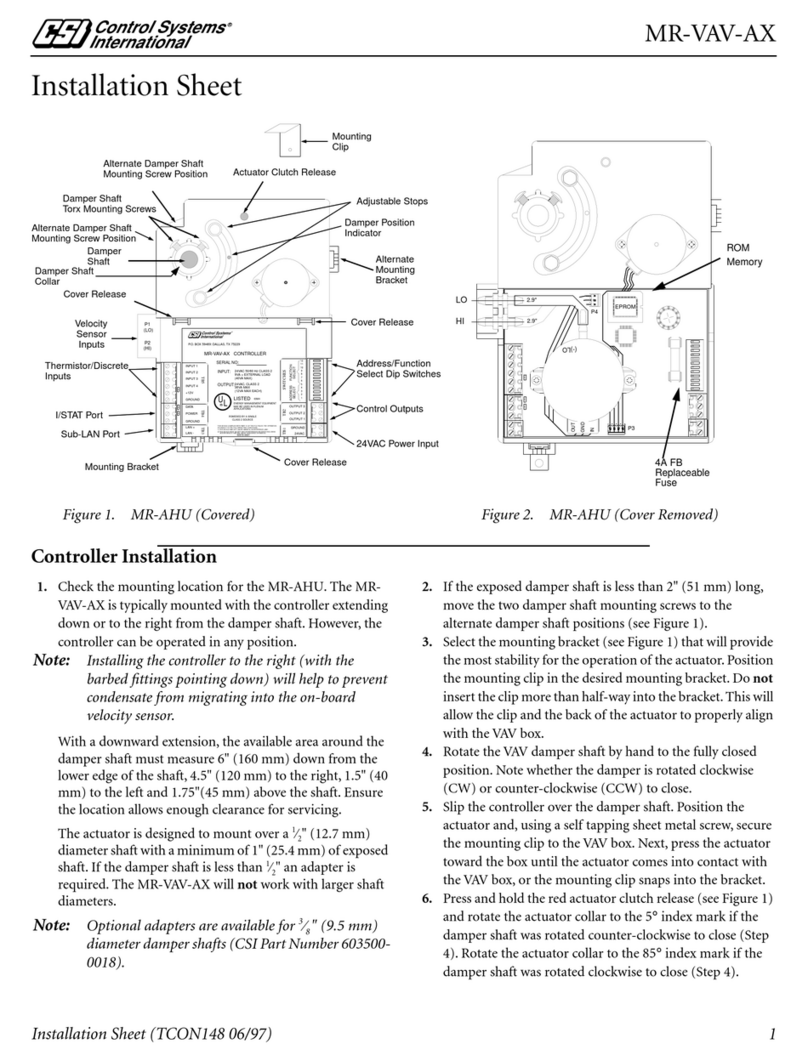

INSTALLATION The CIP 2.0 control cabinet arrives mounted to the skid and pre-wired to in-

struments installed on the skid. Typical installation requires a dedicated 480V

3-Phase with Branch Circuit Protection with enough amperage for the configu-

ration. Electrical schematics provided with the control panel indicate location,

voltage, and amperage requirement for the panel.

To avoid electrocution, ALL electrical work should be done by a registered elec-

trician, following industrial safety standards and local codes. All power must be

OFF and safely locked out during installation.

The CIP 2.0 system is designed to work as a standalone system or configured

to connect to the plant network via Ethernet for permissions, data logging, and

E-Stop connectivity. If the system is intended to communicate with the plant net-

work, an Ethernet drop must be provided to the CIP 2.0 control system and the

system uses 4-5 unique IP addresses depending on configuration.

DISCLAIMER OF LIABILITY

CSI does not assume responsibility and expressly disclaims liability for loss,

damage, or expenses that arise in any way from the installation, operation, use,

or maintenance performed in accordance with this manual. CSI assumes no

responsibility for any infringement of patents or other rights of third parties that

may result from use of the module. No license is granted by implication or other-

wise under any patent or patent rights.

CSI reserves the right to make changes to the product, specifications, or this

manual without prior notice.

Note: CSI recommends that the cabinet be supplied with clean process air at

the minimum pressure and flow rate for your application.

AIR CONNECTIONS

Note: CSI recommends that the control cabinet be supplied with clean instru-

ment air at the minimum pressure and flow rate for your application.

AIR INPUT TO CABINET

Air connection 1/2” NPT Female