4/CULLIGAN ESTATE®2/2MWATERCONDITIONER

Preparation

COMPONENTDESCRIPTION

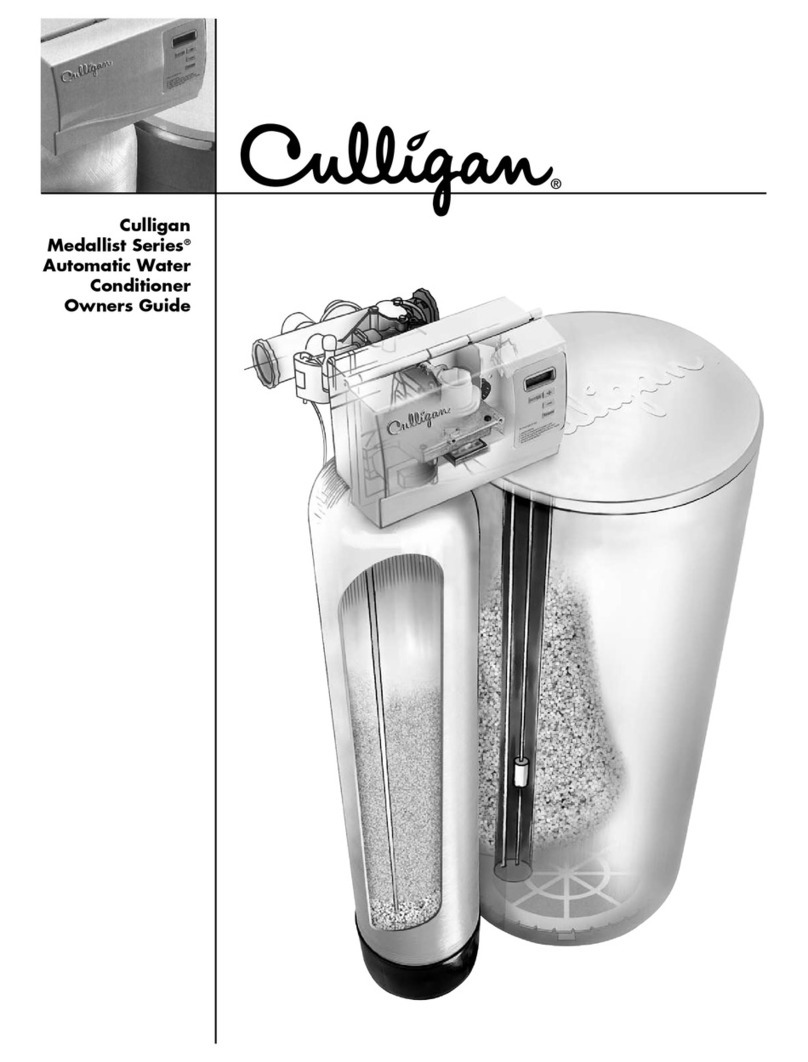

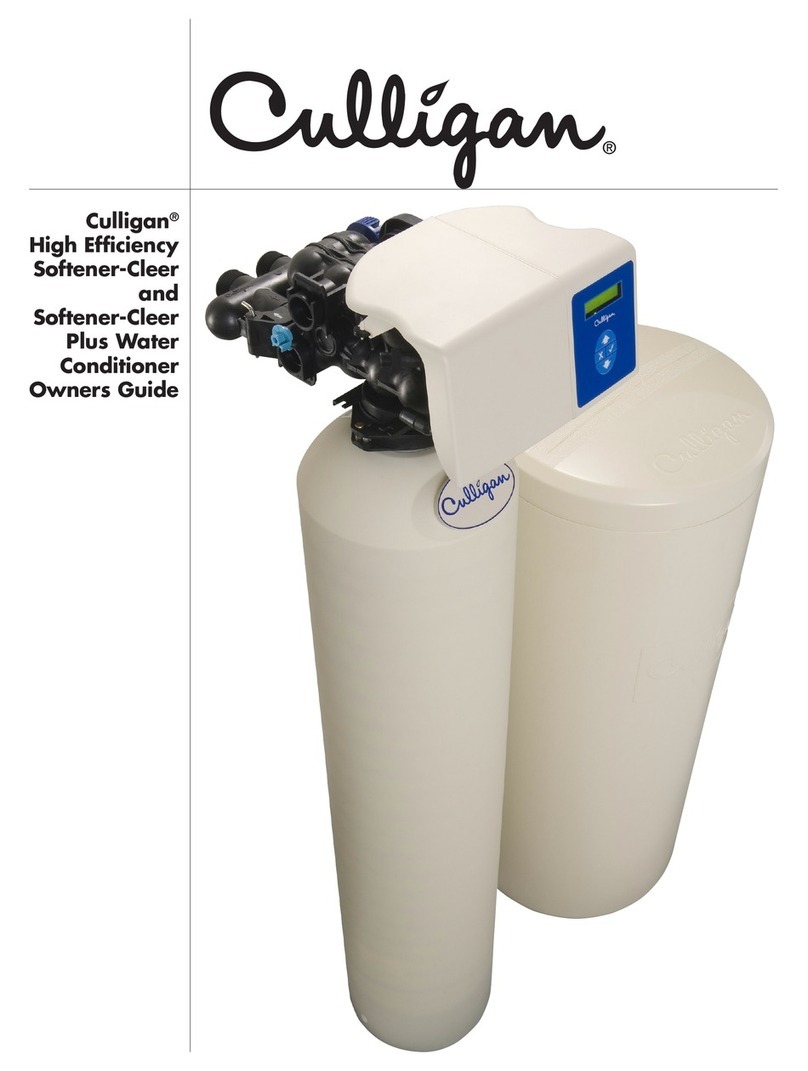

The water conditioner is shipped from the factory in three

cartons. Remove all components from their cartons and

inspect them before starting installation.

Control Valve Assembly — Includes the 5-cycle regenera-

tioncontrolvalve andelectronic timer assembly.Asmall parts

package contains installation hardware and consumer

literature, including an Owner's Guide and warranty policy.

MediaTank—Containsthemediatankcomplete withCullex®

ion exchange resin, underbedding and outlet manifold.

Salt Storage Tank Assembly — Includes salt storage

container with support plate and Dubl-Safe™brine refillvalve

and chamber.

TOOLSAND MATERIALS

The following tools and supplies will be needed, depending

on installation method. Observe all applicable codes.

All Installations

• Safety glasses

• Phillipsscrewdrivers,small and mediumtip

• Gaugeassembly (PN 00-3044-50or equivalent)

• Silicone lubricant (PN 00-4715-07 or equivalent) - DO

NOTUSEPETROLEUM-BASEDLUBRICANTS

• A bucket, preferably light-colored

• Towels

Special Tools

• Torch, solder and flux for sweat copper connections

• Threading tools, pipe wrenches and thread sealer for

threaded connections.

• Saw, solvent and cement for plastic pipe connections.

Materials

• Brineline, 5/16"(PN 00-3031-28or equivalent)

• Drain line, 1/2" (PN 00-3030-82, gray, semi-flexible; or

PN00-3319-46, black,semi-rigid; orequivalent)

• Thread sealing tape

• Pressurereducingvalve (ifpressure exceeds 125psi [860

kPa],PN 00-4909-00or equivalent)

• Pipe and fittings suited to the type of installation

• Water softener salt (rock, solar or pellet salt formulated

specifically for water softeners)

BYPASS

A bypass valve is included with the control valve assembly.

APPLICATION

Waterquality— Verify that raw water hardness and iron are

within limits. Note the hardness for setting the salt dosage

and recharge frequency.

Pressure — If pressure exceeds 125 psi (860 kPa), install a

pressure reducing valve (see materials checklist). On private

water systems, make sure the minimum pressure (the pres-

sureatwhich thepumpstarts) isgreater than 20psi (140 kPa).

Adjust the pressure switch if necessary.

CAUTION:The use of a pressure reducing valve

may limit the flow of water in the household.

Temperature— Do not install the unit where it might freeze,

or next to a water heater or furnace or in direct sunlight.

LOCATION

Spacerequirements —Allow6-12inches(15-30cm)behind

the unit for plumbing and drain lines and 4 feet (1.3 metres)

above for service access and filling the salt container.

Floorsurface— Choosean areawithsolid, levelfloor freeof

bumps or irregularities. Bumps, cracks, stones and other

irregularities can cause the salt storage tank bottom to crack

when filled with salt and water.

Drainfacilities— Choose a nearby drain that can handle the

rated drain flow (floor drain, sink or stand pipe). Refer to the

Drain Line Chart, Table 1 (page 7), for maximum drain line

length.

NOTICE:Most codesrequireananti-siphondevice orairgap.

Electrical facilities — A 6-foot grounded cord is provided.

The customer should provide a 3-prong grounded receptacle,

preferably one not controlled by a switch that can be turned

off accidentally. Observe local electrical codes.

WARNING: ELECTRICAL SHOCK HAZARD! DO

NOT REMOVE THE GROUNDING PRONG! IF THE

RECEPTACLE IS DESIGNED ONLY FOR 2-PRONG

PLUGS,OBTAINA3-PRONGADAPTERANDGROUND

IT SECURELY TO THE RECEPTACLE. DO NOT USE

EXTENSIONCORDS.