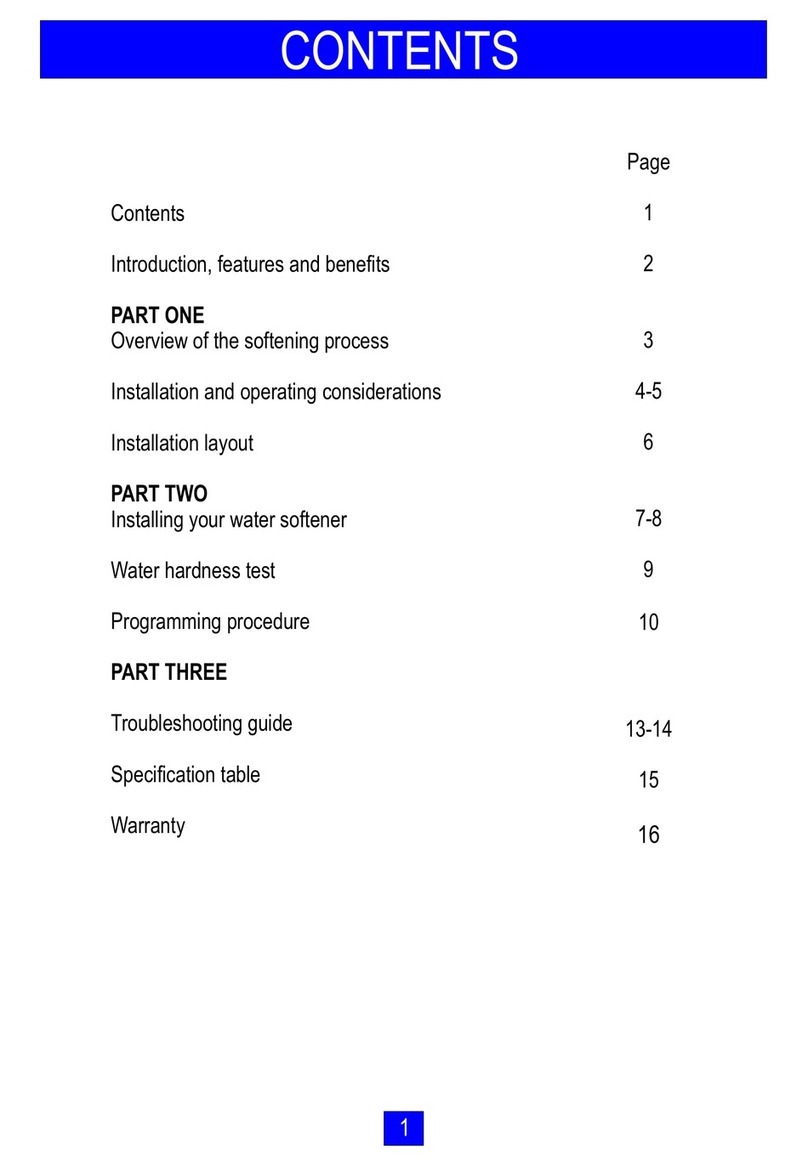

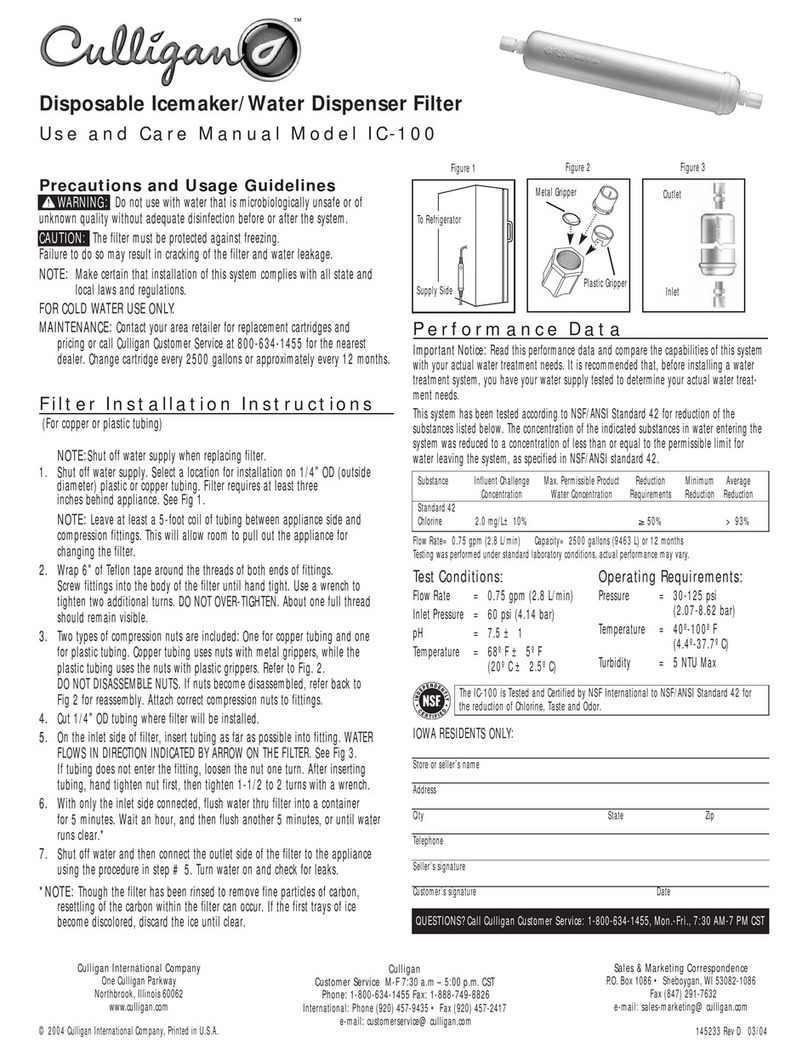

Softener Capacity

Compensated Hardness

CAPACITY AND SALT SETTINGS

As mentioned previously, the softener will regenerate once the amount of water equal to

the treated water volume set point has passed through the turbine for meter models or

after a fixed time interval for timeclock models. Regeneration is either delayed until the

selected regeneration time or immediate depending on how the microprocessor is

programmed. Before completing the programming, the following information must be

determined:

1. Compensated Water Hardness.

If your water supply contains iron, compensate for it by the following procedure.

1. Multiply the iron by 0.1 and add the result to the hardness.

Example: (3 ppm of iron x 0.1) + 25 gpg of hardness = 25.3 gpg of total hardness

2. Choose the % capacity you want and refer to the table below for the appropriate

multiplier.

Example: 67% capacity gives a multiplier of 1.5.

TABLE 2

% capacity 50% 67% 75%

Multiplier 2 1.5 1.33

3. Multiply the result from Step 1 by the multiplier chosen in Step 2. This is the

compensated hardness.

Example: 25.3 gpg total hardness x 1.5 = 38 gpg compensated hardness.

4. Use the effective hardness for sizing and to determine salt dosage and regeneration

frequency.

5. The forced regeneration feature should be used for Soft-Minder meter operation to

ensure the resin bed does not become iron fouled due to lack of water flow. See

"Programming the Option Settings" for the forced regeneration feature.

2. Salt Dosage

From Table 3, select the salt dosage at which the softener will be operated.

• Low Setting — Maximum salt efficiency, more frequent regeneration, reduced

overall softening capacity.

• Medium Setting — Good combination of efficiency and overall softening capacity.

• High Setting — Maximum softening capacity, less frequent regeneration, and

reduced salt efficiency.

Recommended whenever iron is present and for hardness levels above 30 Grains

Per Gallon, or high volume water usage.

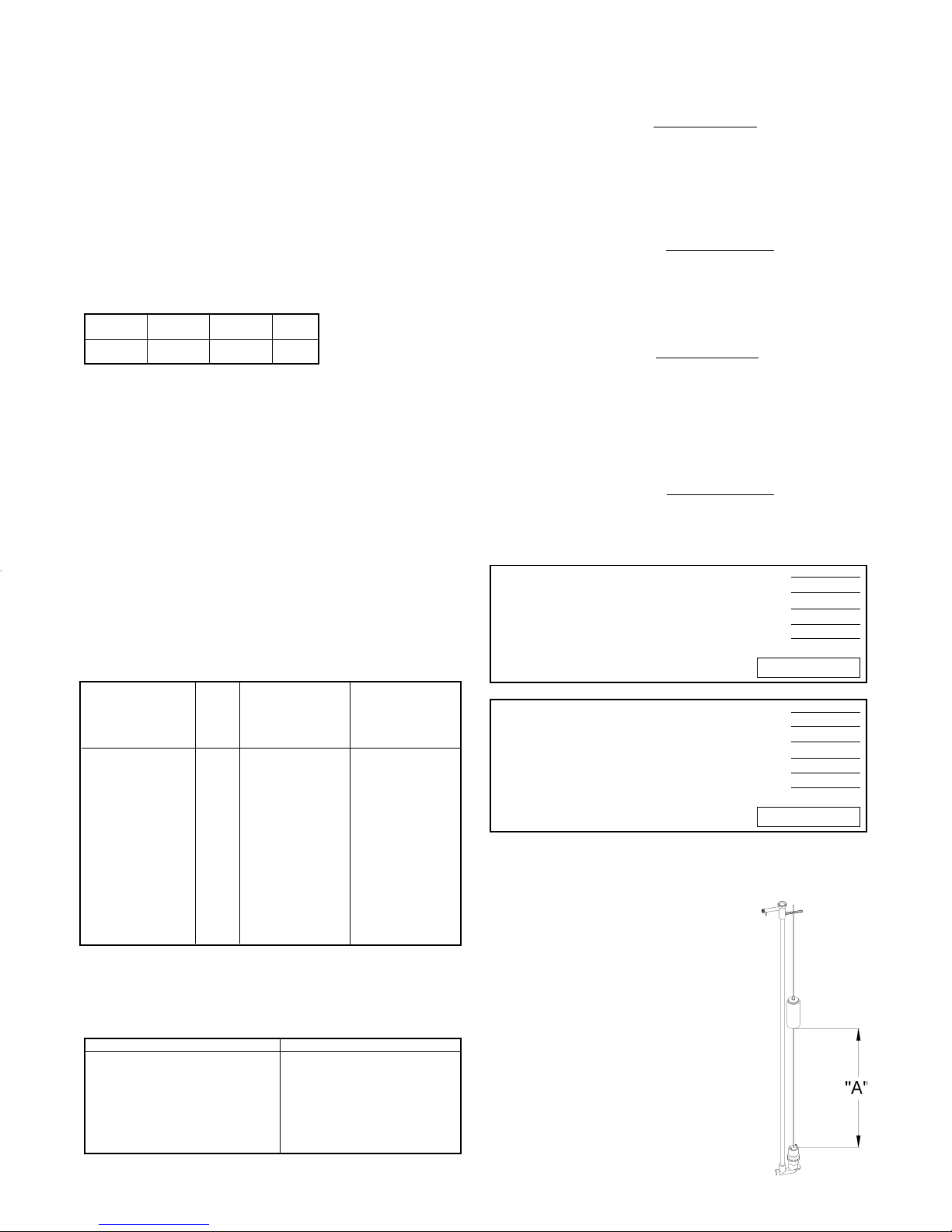

TABLE 3 - SALT DOSAGE

160 lb.

Capacity Brine Tank 250 lb. Brine Tank 375 lb. Brine Tank

"A" Dimen. "A" Dimension "A" Dimension

Secondary

Salt Capacity (Only) Secondary Primary Secondary Primary

Dosage

0.7 ft31 ft31.5 ft3in. (cm) in. (cm) in. (cm) in. (cm) in. (cm)

4 18,300 X X 7-3/4 19.7 6-5/8 16.8 4-5/8 11.7 5-1/2 14.0 3-1/2 8.9

5 20,000 20,200 20,000 9-1/2 24.1 8 20.3 6 15.2 6-1/2 16.5 4-1/2 11.4

6 22,000 22,500 23,50011-1/4 28.6 9-3/8 23.8 7-3/8 18.7 7-1/2 19 5-1/2 14

7 23,200 24,400 26,500 13 33 10-7/8 27.6 8-7/8 22.5 8-1/2 21.6 6-1/2 16.5

8 24,100 25,700 29,00014-3/4 37.512-1/4 31.1 10-1/4 26 9-1/2 24.1 7-1/2 19

9 25,100 27,000 31,30016-1/2 42 13-5/8 34.6 11-5/8 29.5 10-1/2 26.7 8-1/2 21.6

10 26,100 28,300 33,30018-1/4 46.3 15 38.1 13 33 11-1/2 29.2 9-1/2 24.1

11 26,800 29,400 35,000 20 51 16-3/8 41.6 14-3/8 36.5 12-1/2 31.7 10-1/2 26.7

12 27,500 30,500 36,50021-3/4 55.217-3/4 45.1 15-3/4 40 13-1/2 34.3 11-1/2 29.2

13 X 31,500 38,40021-1/2 59.719-1/8 48.6 17-1/8 43.5 14-1/2 36.8 12-1/2 31.7

14 X 32,500 39,20025-1/4 64.120-1/2 52.1 18-1/2 47 15-1/2 39.4 13-1/2 34.3

15 X 33,300 40,400 — — 21-7/8 55.5 19-7/8 50.5 16-1/2 42 14-1/2 36.8

16 X 34,100 41,200 — — 23-1/4 59 21-1/4 54 17-1/2 44.5 15-1/2 39.4

17 X 35,000 41,800 — — 24-5/8 62.5 22-5/8 57.5 18-1/2 47 16-1/2 42

18 X X 42,400 — — 26 66 24 61 19-1/2 49.5 17-1/2 44.5

19 X X 42,900 — — 27-3/8 69.5 25-3/8 64.5 20-1/2 52.1 18-1/2 47

20 X X 43,500 — — 28-3/4 73 26-3/4 68 21-1/2 54.6 19-1/2 49.5

3. Treated Water Volume Set Point

Calculate the treated water volume set point using the following information:

• Softening capacity — Grains (based upon salt dosage setting).

• Compensated hardness of water supply — Grains Per Gallon

• Estimated daily water usage — Gallons Per Day (refer to Table 4)

TABLE 4 - Daily Water Usage

Persons in Household Gallons Per Day

2 150

3 225

4 300

5 375

6 450

7 525

8 600

9 675

10 750

Example - Meter: Softener Model Medallist 2M

Capacity @ 9 lb. Salt Dosage: 25,100 Grains

Compensated Water Hardness: 19 Grains Per Gallon

Estimated Daily Water Usage: 300 Gallons Per Day

Treated Water Volume Set Point = — Water Usage

Softening Capacity 25,100 Grains

Divide by Compensated Hardness ÷ 19 Grains per Gallon

Result is total number of gallons 1,321 Gallons

of soft water per regeneration

Subtract daily Water Usage (needed — 300 Daily Water Usage (One Day Supply)

as a reserve to ensure continuous 1,021 Gallons

soft water until regeneration occurs).

Round down to nearest ten for Treated

Water Volume Set Point 1,020 Gallon Setting

Set "CAPG" to 102

Example - Timeclock: Softener Model Medallist 2

Capacity @ 9 lb. Salt Dosage: 25,100 Grains

Compensated Water Hardness: 19 Grains Per Gallon

Estimated Daily Water Usage: 300 Gallons Per Day

Treated Water Volume Set Point = — Water Usage

Softening Capacity 25,100 Grains

Divide by Compensated Hardness ÷ 19 Grains per Gallon

Result is total number of gallons 1,321 Gallons

of soft water per regeneration

Subtract daily Water Usage (needed — 300 Daily Water Usage (One Day Supply)

as a reserve to ensure continuous 1,021 Gallons

soft water until regeneration occurs).

Divide by daily water usage ÷ 300

3.4 Days

Round down to nearest day 3.0 Days

Set "CAP" to 3

Use the following worksheets to calculate and record the proper settings.

Treated Water Volume Set Point Work Sheet - Meter Models

1. Enter Softening Capacity

2. Divide by Compensation Hardness ÷

Result is Total Gallons of Soft Water Per Regeneration =

3. Subtract Daily Water Usage (Reserve —

Result =

Round down to nearest ten for Treated Water Volume Set Point Gallons

Treated Water Volume Set Point Work Sheet - Timeclock Models

1. Enter Softening Capacity

2. Divide by Compensation Hardness ÷

Result is Total Gallons of Soft Water Per Regeneration =

3. Subtract Daily Water Usage (Reserve —

4. Divide by Daily Water Usage ÷

Result =

Round down to nearest ten for days between regeneration set point Days

Note: All Softening capacity is based on using sodium chloride as the regenerate: If

potassium chloride is used reduce the rated softening capacity by 20%.

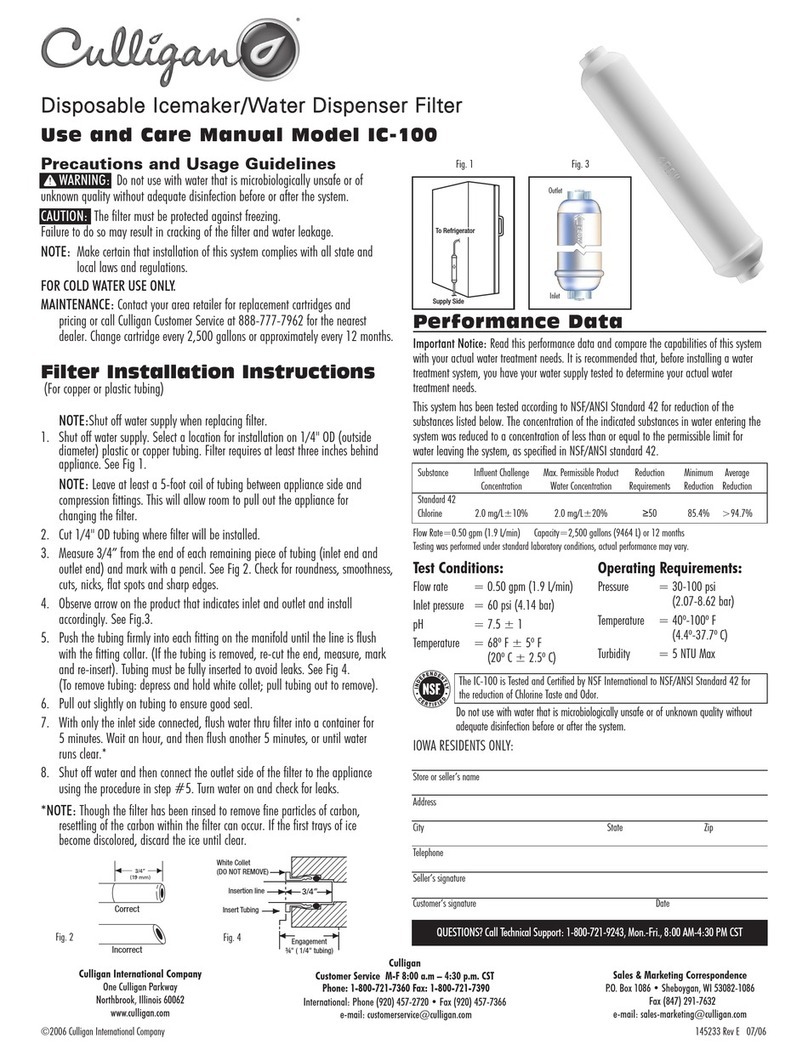

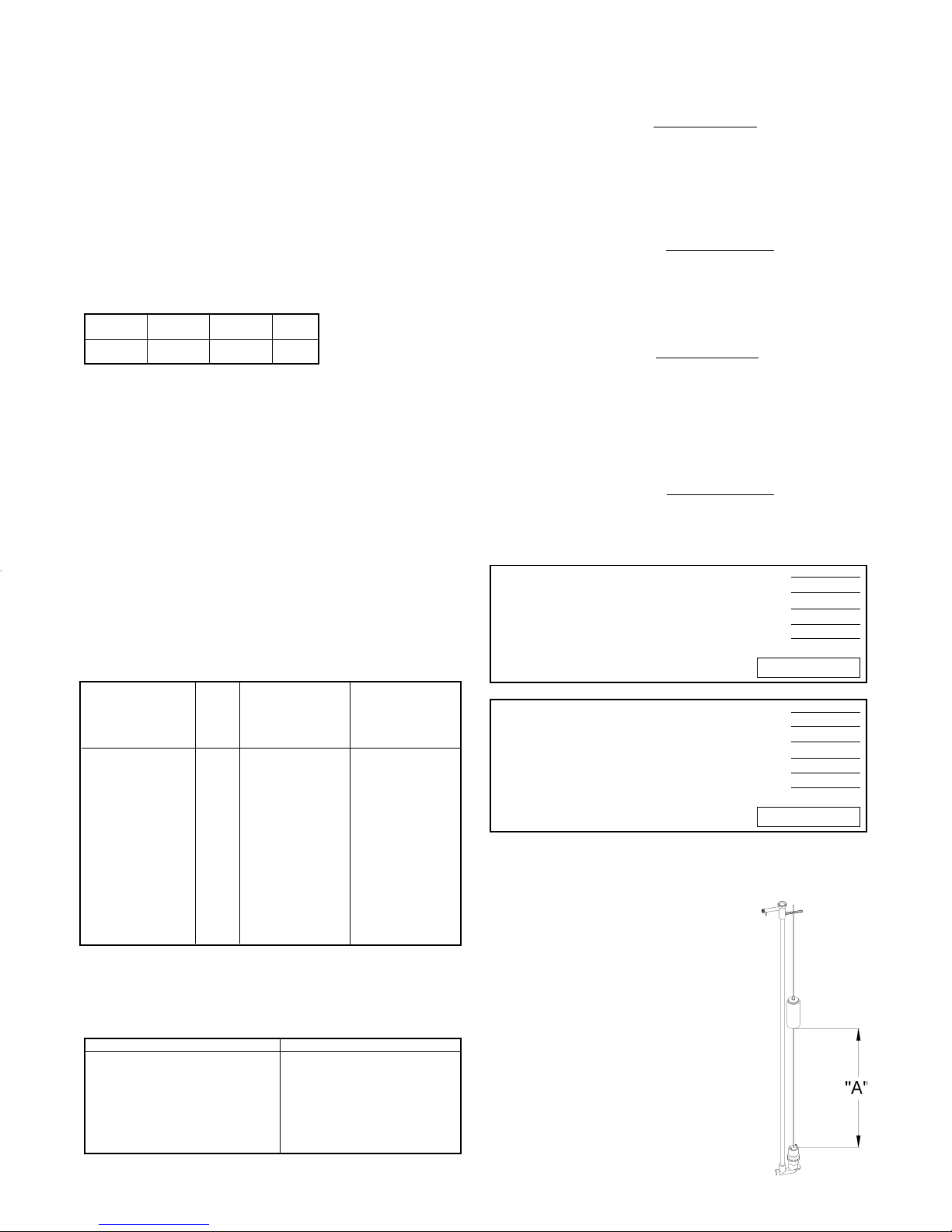

BRINE VALVE "A" DIMENSION

The brine valve contains a float-actuated safety shut-off

device to prevent overflow of the brine tank in the unlikely

case of an electrical or mechanical failure during the brine tank

refill cycle.

It is recommended that the brine valve float be used as in-

tended, that is, as a secondary, safety shut-off. Remember, the

timer mechanism provides the primary refill shut-off. To use

the float as a safety shut-off, refer to Table 4 for the salt dosage

and brine tank size being used. The "A" dimension is the

distance between the filter screen and the bottom of the float

(Figure 11) when the float stem is in its fully raised position;

adjust the float and rubber grommets accordingly.

Softener Capacity

Compensated Hardness

FIG. 11

01882362 (Rev. A - DCO 2461) 05/01