Contents

Chapter 1 Safety Precautions ....................................................................................................................5

Safety Guidelines........................................................................................................................5

Cautionary Symbol Definitions......................................................................................................6

Safety Precautions ......................................................................................................................7

Safety Decals ...........................................................................................................................12

Safety Sign-off Sheet.................................................................................................................14

Chapter 2 Specifications .........................................................................................................................15

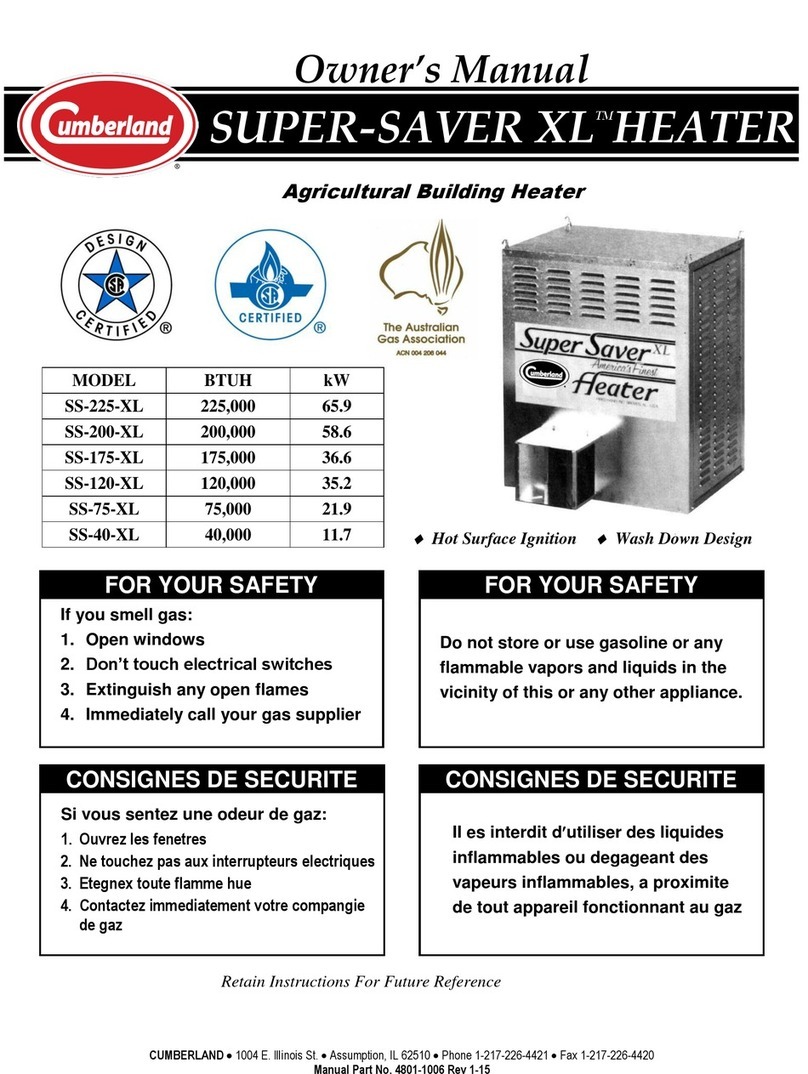

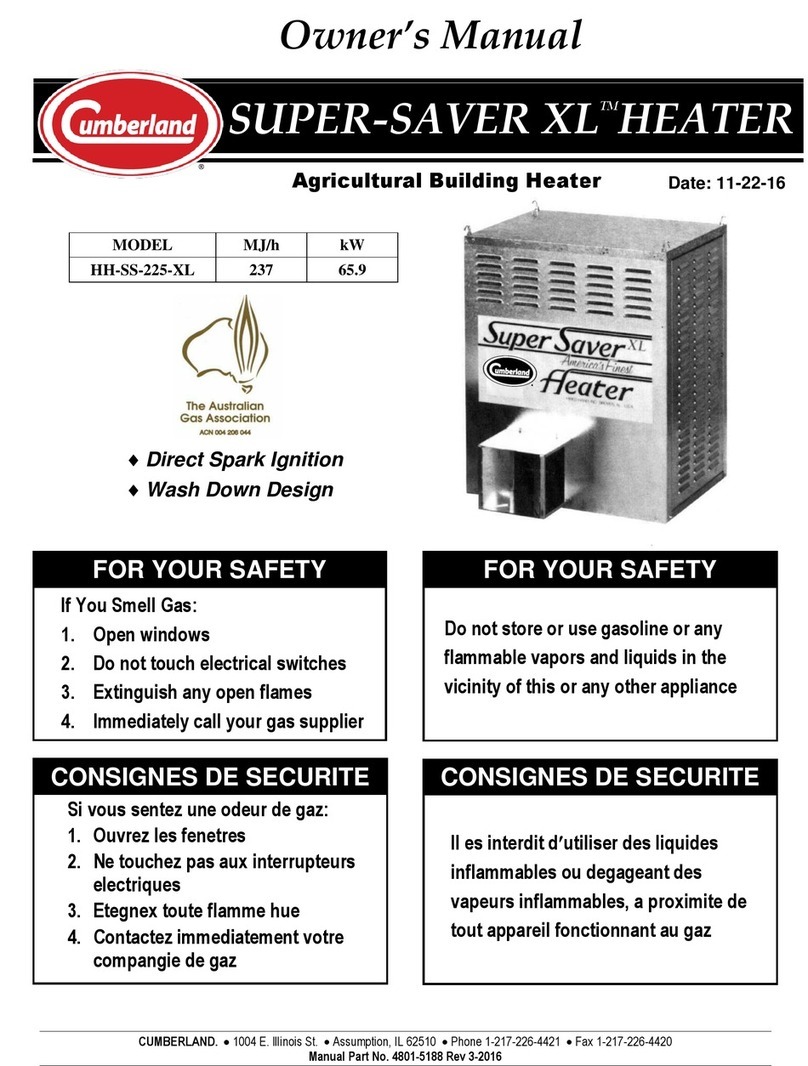

VariFlame vapor propane specifications ......................................................................................15

VariFlame natural gas specifications...........................................................................................16

Electrical and environmental specifications .................................................................................16

Timing specifications .................................................................................................................17

Chapter 3 System Overview ....................................................................................................................19

Heater component functions ......................................................................................................19

Burner control module and sequence of operation .......................................................................21

Chapter 4 Installation ..............................................................................................................................23

Installing the air diverter.............................................................................................................23

Installing for recirculating operation (indoor) ................................................................................24

Wiring Diagrams and Schematics ...............................................................................................27

Pipe sizing guidelines ................................................................................................................32

Chapter 5 Startup and Operation .............................................................................................................35

Pre-startup inspections ..............................................................................................................35

Emergency heater shutdown......................................................................................................35

Normal heater shutdown............................................................................................................35

Starting the heater.....................................................................................................................36

Operating the burner .................................................................................................................36

Adjusting the heater output ........................................................................................................37

Chapter 6 Service and Maintenance ........................................................................................................39

Cleaning the heater ...................................................................................................................39

Guidelines for checking gas pressure .........................................................................................39

Checking the valve inlet pressure ...............................................................................................40

Checking the valve output pressure ............................................................................................41

Replacing the motor and fan wheel.............................................................................................42

Replacing the air proving switch .................................................................................................44

Replacing the Temperature High Limit Switch..............................................................................46

Replacing the Flame Probe........................................................................................................47

Replacing the Ignitor..................................................................................................................49

Replacing the control board .......................................................................................................50

Replacing the gas valve.............................................................................................................52

Chapter 7 Troubleshooting......................................................................................................................55

Troubleshooting ........................................................................................................................55

Chapter 8 Parts........................................................................................................................................59

VariFlame Controller Parts .........................................................................................................59

Switch and Probe Parts .............................................................................................................60

Gas Parts .................................................................................................................................61

Motor and Blower Wheel Parts ...................................................................................................62

GSI Group, LLC Limited Warranty ...........................................................................................63

PNEG-2091 VariFlame™ Heater 3