4

• Read this guide carefully before using and main-

taining the appliance, and keep it with care in an

accessible place for any future consultation by

the various operators.

• Moreover, the manual must always accompany

the product through its life, even in case of trans-

fer.

• Before performing any maintenance, disconnect

the electricity supply.

• Unauthorised actions, tampering or modifica-

tions that do not follow the information provid-

ed in this manual can cause damages, injuries or

fatal accidents and null and void the warranty.

• Use or maintenance that fail to comply with the

instructions in this manual may cause damage,

injury or fatal accidents.

• The rating plate provides important technical

information that is vital in case of a request for

maintenance or repair of the appliance: please

do not remove, damage or modify it.

• Some parts of the appliance may reach high

temperatures. We recommend you avoid touch-

ing surfaces and do not get materials either flam-

mable or sensitive to heat near the appliance.

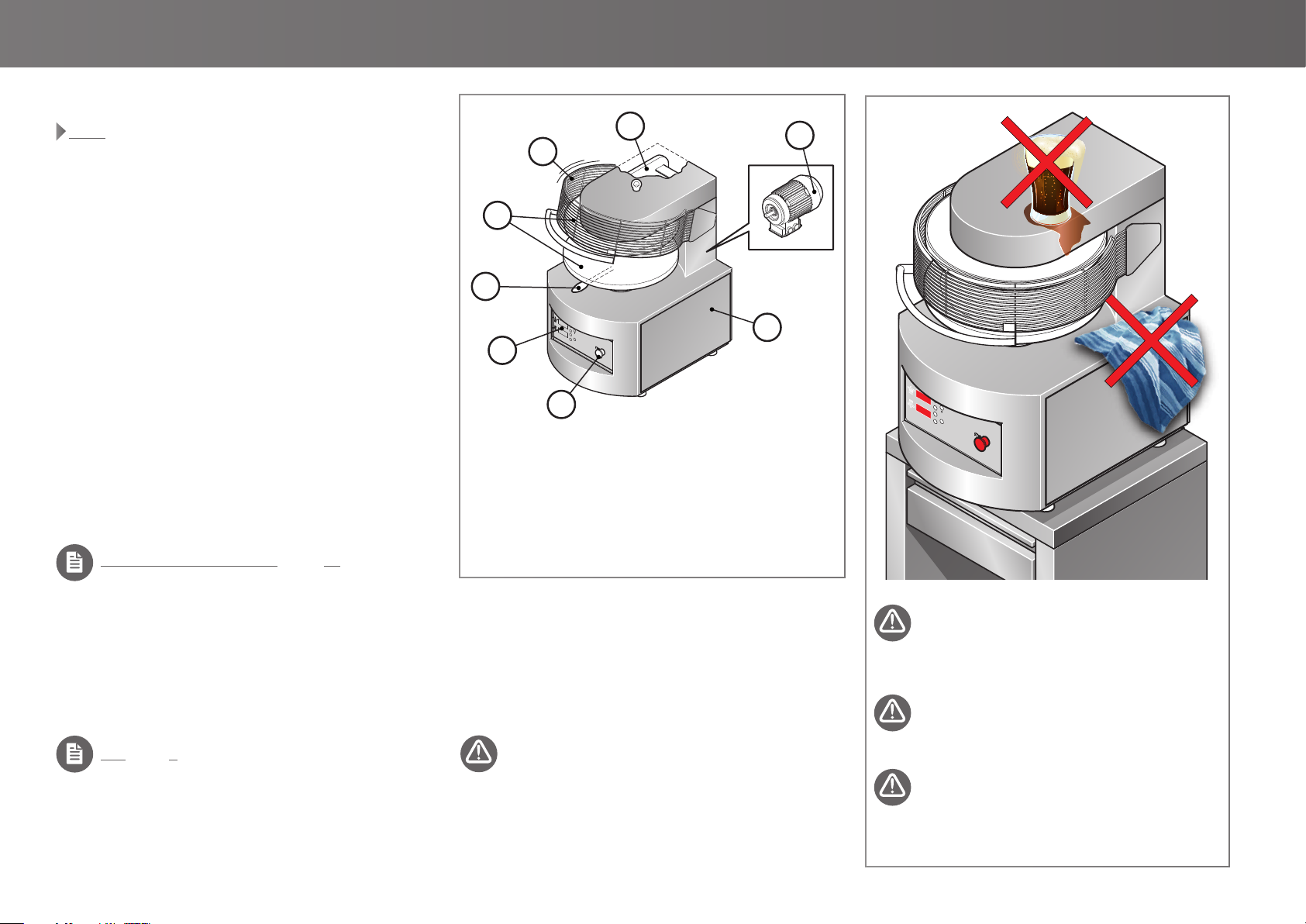

• Do not rest objects on the product, above all if

built in material sensitive to heat.

• These appliances are intended for use in com-

mercial applications, for example in kitchens,

restaurants, canteens, hospitals and commercial

companies such as bakeries, butcher shops, etc.,

but not for the continuous or mass production

of food.

Any use other than that indicated is con-

sidered improper, potentially dangerous for peo-

ple and animals and might irreparably damage

the equipment. Improper use of the equipment

voids the warranty.

• The device can be used by children aged 8 and

under and by persons with reduced physical,

sensory or mental abilities, or lacking in expe-

rience or the necessary knowledge, provided

they are under surveillance or after they have re-

ceived instructions relating to the safe use of the

appliance and understand the dangers inherent

in it. Children must not play with the appliance.

Cleaning and maintenance designed to be car-

ried out by the user must not be carried out by

unsupervised children.

• The staff using the appliance must be profes-

sionally prepared and periodically trained on its

use, as well as the safety and accident preven-

tion regulations.

• Children must be supervised to make sure they

do not play with the appliance or parts of it.

• FIRE HAZARD: leave the area around the equip-

ment free and clean of fuels. Do not keep flam-

mable materials near this appliance.

• WARNING: EXPLOSION HAZARD! It is forbidden

to use the product in potentially explosive envi-

ronments.

• WARNING: always switch off the main switch

when you finish using the appliance, above all

during cleaning or in cases of prolonged down-

time.

• If you notice any anomaly (e.g. damaged power

cable, etc.), malfunction or fault, do not use the

appliance and contact a Service Centre author-

Safety instructions

ized by the Manufacturer. Ask for original spare

parts or the Warranty will be forfeited.

• To avoid risks, if the power cable is damaged, it

must be replaced by the manufacturer, its ser-

vice agent or qualified personnel.

• Place the emergency phone numbers in a visible

location.

• Monitor the appliance during its entire oper-

ation, do not leave dishes in the product unat-

tended!

• Failure to follow these regulations may cause

damage or even fatal injury, subsequently inval-

idating the guarantee and relieving the Manu-

facturer of all liability.

• We recommend you have the appliance checked

by an Authorized Service Centre at least once a

year.