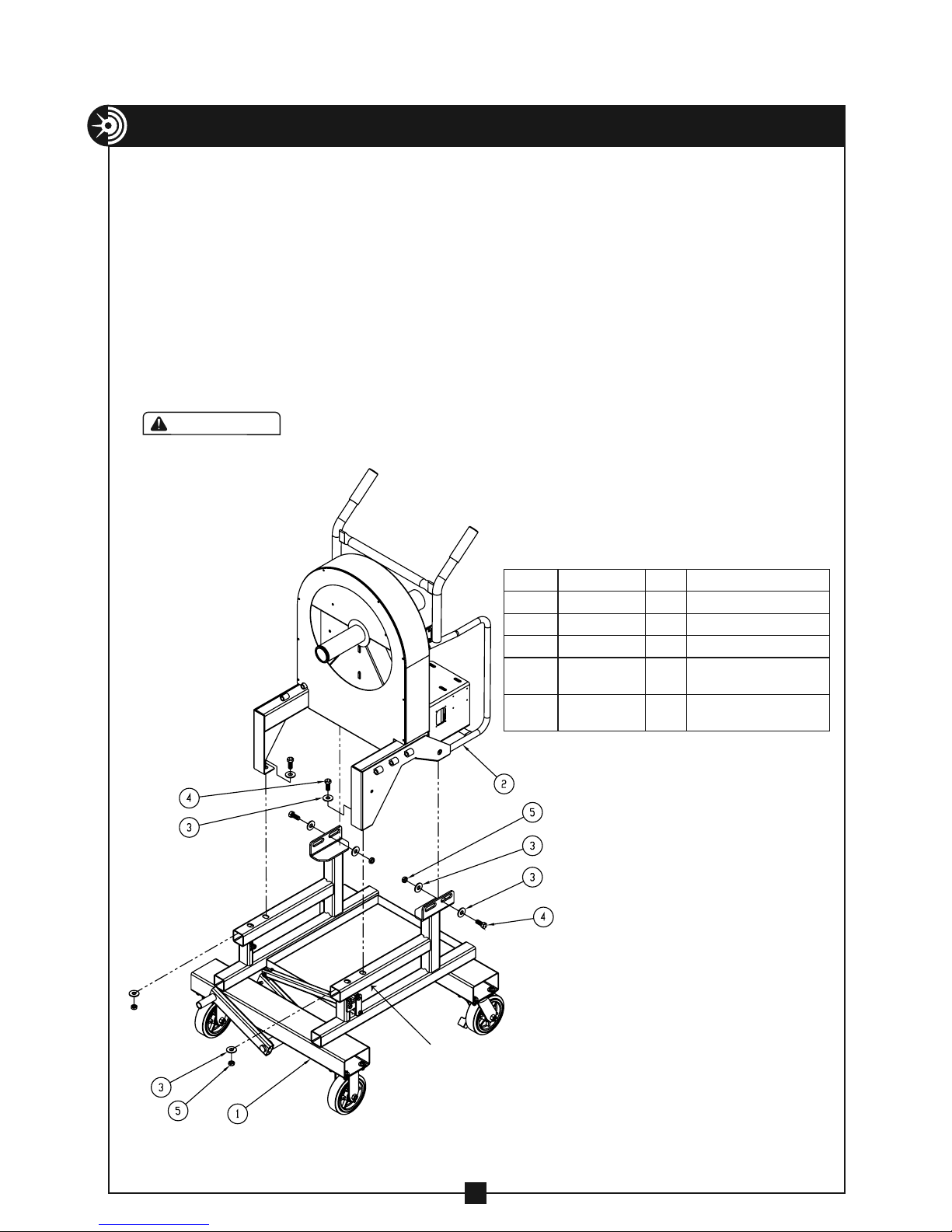

EXPLODED VIEW & PARTS LIST

6

ITEM# PART# QTY DESCRIPTION

1........ 2-1301-4...........1 ........ LOCKNUT, NYLON INSERT – 5/16-18

2........ 2-1501-4...........3 ........ LOCKNUT, NYLON INSERT – 3/8-16

3...........33-29 .............1........ SCREW, SKT. SHOULDER – 3/8" ×2"

4....... 77-002D1..........3........ SCREW, HX. HD. CAP – 5/16-18 ×3/4"

5...... 77HRB-001 ........1........ SCREW, SKT. SHOULDER – 3/8" ×3/4"

6...... 77HRB-002 ........1........ SCREW, SKT. SHOULDER – 3/8" ×1"

7...... 77HRB-005 ........3........ SCREW, HX. HD. CAP – 3/8-16 ×2 3/4"

8...... 77HRB-006 ........1........ SCREW, SKT. SHOULDER – 3/8-16 ×1/2"

9...... 77HRB-101 ........1........ BASE

10..... 77HRB-104 ........1........ LEVER – FOOT

11..... 77HRB-112 ........1........ CONNECTOR – LINKAGE

12..... 77HRB-119 ........1........ CLAMP – CONNECTOR

13..... 77HRB-126 ........1........ ARM – LINKAGE

14..... 77HRB-129 ........1........ ARM – LEVER

15..... 77HRB-130 ........1........ MOUNT – BRACKET

16.........452-27 ...........16 ....... WASHER, LOCK – 3/8"

17.........452-28 ...........16 ....... NUT, HEX – 3/8-16

18..........506-3 ............16 ....... WASHER, FLAT – 3/8"

19........513-001 ...........2........ CASTER – SWIVEL

20........513-002 ...........2........ CASTER – FIXED

21.........524-11 ...........16 ....... SCREW, HX. HD. CAP – 3/8"-16 ×1"

22.........610-25 ............2........ LOCKNUT, THIN NYLON INSERT – 3/8-16

23.........747-37 ............1........ SPRING

24.........812-14 ............2........ BUSHING

LINKAGE ARM STORAGE

When the roller support linkage arm

is not required, a storage bracket is

provided. See Figure 6 for linkage

arm storage illustration.

Figure 6

Linkage

Arm

Connector

Clamp