RETAIN SAFETY INFORMATION

4

4

IMPORTANT SAFETY INFORMATION

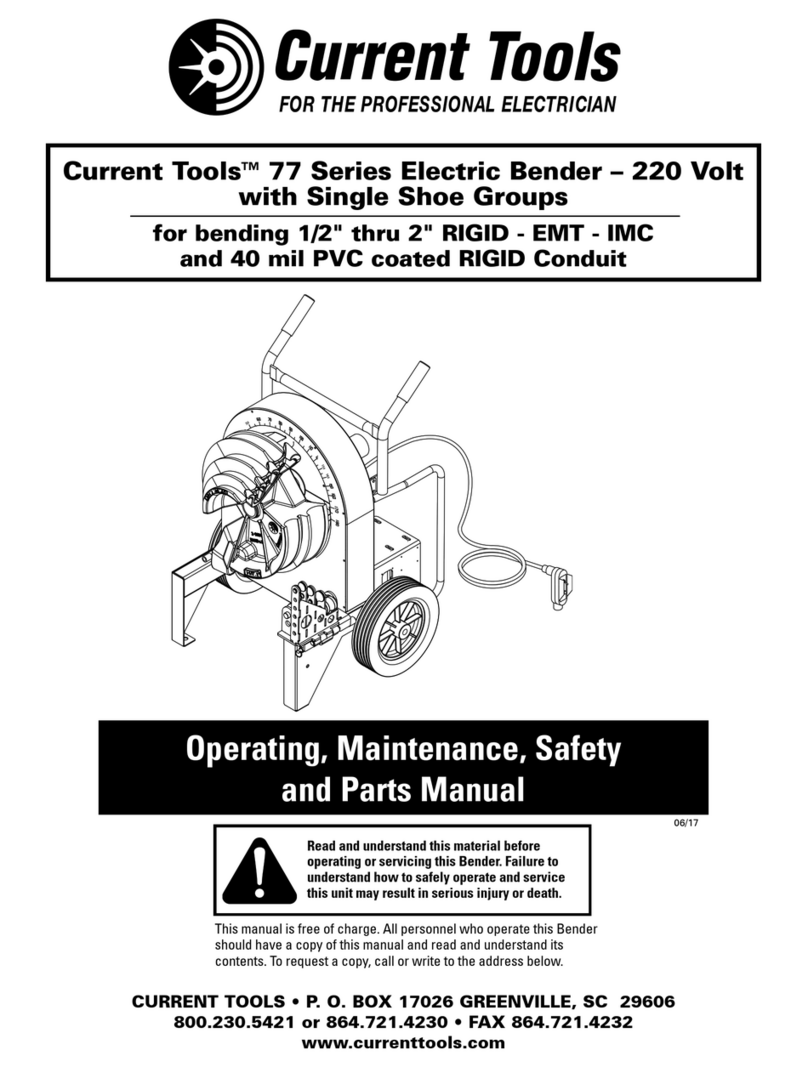

This manual should be read and understood by all personnel who operate

or service this Bender. Failure to understand how to safely operate and

service this unit could result in serious injury or death. This unit should

only be operated and serviced by qualified personnel.

NEVER operate the bender in an explosive atmosphere.

NEVER operate the bender in wet or damp locations.

DO NOT expose the bender to rain.

ALWAYS use 120 VAC, 20 amp ground fault protected

receptacle for power supply that is properly installed and meets

all applicable electrical codes. See grounding instructions on

page 8.

ALWAYS inspect power cord before using bender.

Replace damaged or worn cords. DO NOT modify the plug

provided with the bender.

ALWAYS make sure the circuit breaker switch is in the “off”

position before plugging in. This will reduce the risk of

unintentional starting.

ALWAYS use 12-gauge extension cords that have three prong

grounding type plugs and three-hole receptacles that accept

the bender’s plug. DO NOT use an adapter.

NEVER use an extension cord longer than 100 feet. NEVER

use a damaged extension cord.

ALWAYS disconnect power to the bender before servicing or

changing shoes, attachments or supports, and when not in

use.

NEVER alter this equipment. Doing so will void the warranty

and could cause serious injury or death.

NEVER remove guards, they are installed for your protection.

ALWAYS check for damaged or worn parts. Check for alignment

of moving parts, binding of moving parts, breakage of parts,

mounting and any other conditions that may affect its

operation. A guard or other part that is damaged should be

properly repaired or replaced.

WARNING

WARNING

WARNING

WARNING