FIXTURE INSTALLATION

FIXTURE INSTALLATION

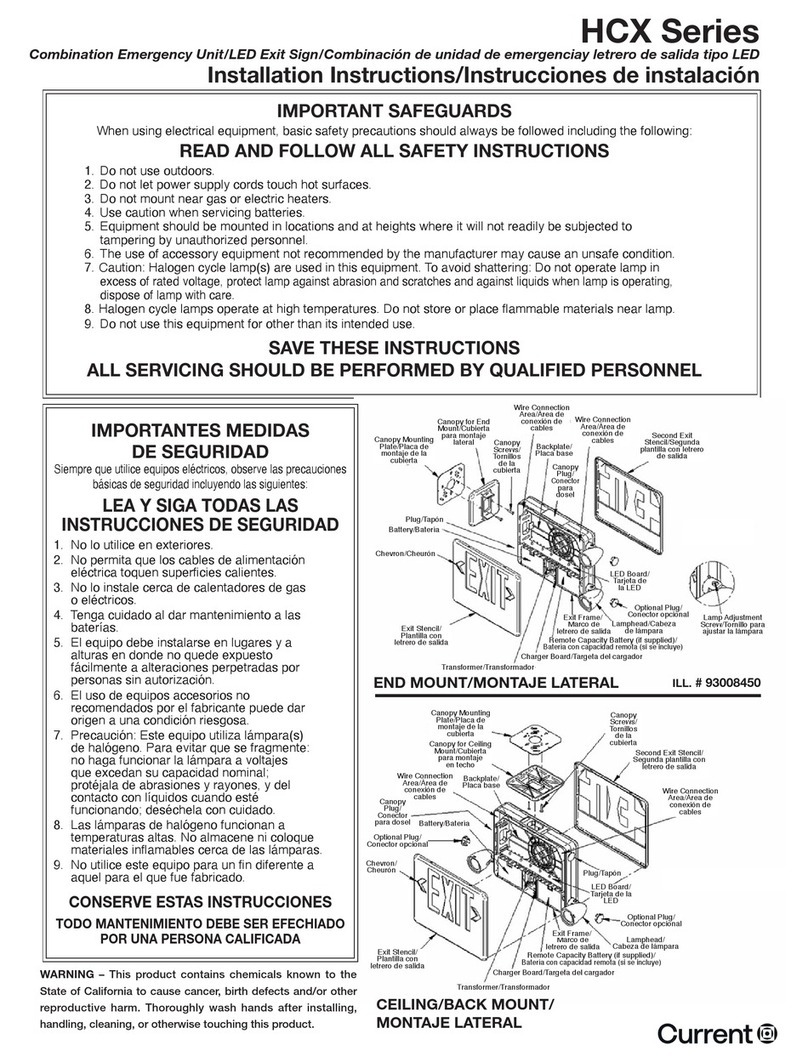

Wall, Ceiling or Pole Mounting

1. The DYNHL mounting plate can be mounted directly to a wall, ceiling

or

pole (using appropriate hardware). If “J-box” mounted and the plastic

housing back K.O. is removed the unit is not considered water proof.

2. Once mounting plate is secured, you can hang the DYNHL Industrial

Unit

and add security screws (qty 4).

3. If the DYNHL unit is mounted to the ceiling the 4 security screws are to

be added to keep the unit secure to the mounting plate.

4. If “J-box” mounted & wired thru box, ground DYNHL mounting plate

with

green ground wire & green hex head screw (provided).

5. For all units wired using conduit, use 1 of the 3 conduit (K.O.)

mounting locations.

6. Only use UL Listed water tight conduit fittings that meet the

requirements of the UL 514B Standard for Conduit Tubing and Cable

Fittings when using (K.O.’s see note 5).

7. Connect wire from the unit to the building leads and secure with

wire nuts.

8. For remote capable DYNHL models, cut ORANGE wire connector from

orange remote leads and strip ½ inch for both lead ends. Observe

proper polarity when connecting remote leads to remote fixtures.

Pos. (+) to red remote fixture lead and Neg. (-) to black remote

fixture lead.

9. Connect battery pack harness to PCB charger harness.

10. For pole mounting used additional #8-32 x ¼ long screws (qty 2) and

both toothed mounting brackets as shown. Banding straps are not

provided due to varying pole and column dimensions.

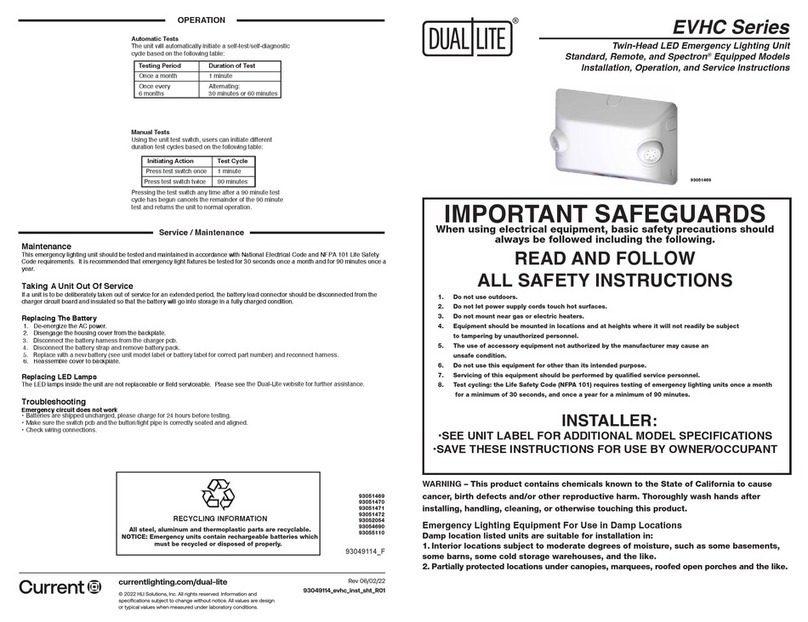

OPERATION

Lamp Head Adjustment

1. Loosen the three captive screws on the Food Processing clear cover.

2. Remove cover (all models without clear cover skip step 1 & 2).

3. Loosen set screws 2 per head and adjust axially on stem.

4.

Rotate lamp heads to desired position.

5. Lock set screws once desired position is set (hex wrench provided).

6. Reverse steps 2&1 (if required).

OPERATION

***Once remote capacity basemodels DYNHL12I-4X or DYNHL12I-4X-FP have been installed press and

hold the test button for more than 5 seconds to initiate the “LOAD LEARN” process.***

DYNHL Wiring Diagram

“AC ON” LED is illuminated green when AC power is present.

NOTE: All models are supplied with an AC Lockout circuit, which prevents the emergency lights from

illuminating when the battery is connected and no AC power is present.

NOTE: All models are supplied with Low Voltage Disconnect circuit, which prevents damage to the battery

from deep discharge during prolonged emergency operation.

NOTE: Batteries are often shipped in a discharged state – this is normal. The battery will require charging.

Allow 24 hours of charging before testing the unit.

Models are equipped with SPECTRON®

Self-Testing/Self-Diagnostic Circuitry and provide:

• Visual indication of AC power status

• Visual indication on self-diagnostic status and results

Visual indication of any unit malfunctions include –

• Battery Disconnected

• Battery Fault

• Charger Fault

• LED Driver Fault

• Lamp Fault

• Load Learn Failure

SPECTRON® also includes:

Browout protection: Unit will automatically transfer to emergency

operation upon detection of low AC power

(approximately 80% of nominal line.)

Time Delay Retransfer: upon return of normal AC power, unit will

remain in emergency mode for an additional

15 minutes to allow AC power to stabilize.

Unit can be hung by threaded rod (3/8" rod is

recommended).

Use appropiate hardware to support this unit when

threaded rod mounted. Lock tight glue is

recommended for all mounting hardware.

DRILL "W" (.397

O

)

MTG PLATE HOLES

8X 5/16 DIA.

8X BANDING

STRAP SLOT

1" X 1/4"

TYPICAL BANDING

STRAPS (NOT PROVIDED)

Pole Mounting

4

2

3

1

5

1

10

7

6

5

6

7

8

9

BLK (NEG -) RED (POS +)

RED (POS +)

BLK (NEG -)

RIBBON

CABLE

J6 J10 J5

J9 AC2 AC1

AC INPUT

BLK (HOT)

WHT (COM)

ORG (NEG -)

ORG (POS +)

ORG

WIRE

CONN.

REMOTE

LEAD (+) REMOTE

LEAD (-)

93055896

93061887

93159164

93055897

93055812

NOTE: IF UNIT IS IN A WET LOCATION

ENVIORNMENT, ALL COVER SCREWS

ARE TO BE TORQUED TO 5-6 IN-LBS

OR UNTIL COVER SEATS WITH

HOUSING

DO NOT OVER TIGHTEN SCREWS (7

PLCS)

2

1

2

Units are equipped with a laser activated testing feature which allows test initiation with a laser pointer (sold separately).

- For a 1 minute test, aim laser beam onto area shown until the unit’s lamp heads turn on and the green LED Status

Indicator starts blinking twice every second. The unit will stay in this mode for the complete duration of the test.

- To change from a 1 minute test to a 90 minute test, aim laser onto area shown again until the green LED Status

Indicator starts blinking at a slower pace, once every second. The unit will stay in this mode for the complete duration of

the test.

- To cancel test cycle, aim laser onto area shown while the 90 minute test is in progress until the unit’s lamp heads turn

off and LED Status Indicator stops blinking and comes back to a solid green.

NOTE:

Maintain a steady beam onto area shown.

TEST BUTTON

93159180

93159181

Laser Activated Testing

93159182

LASER TEST

SENSOR