CAB INSTALLATION

9 of 25

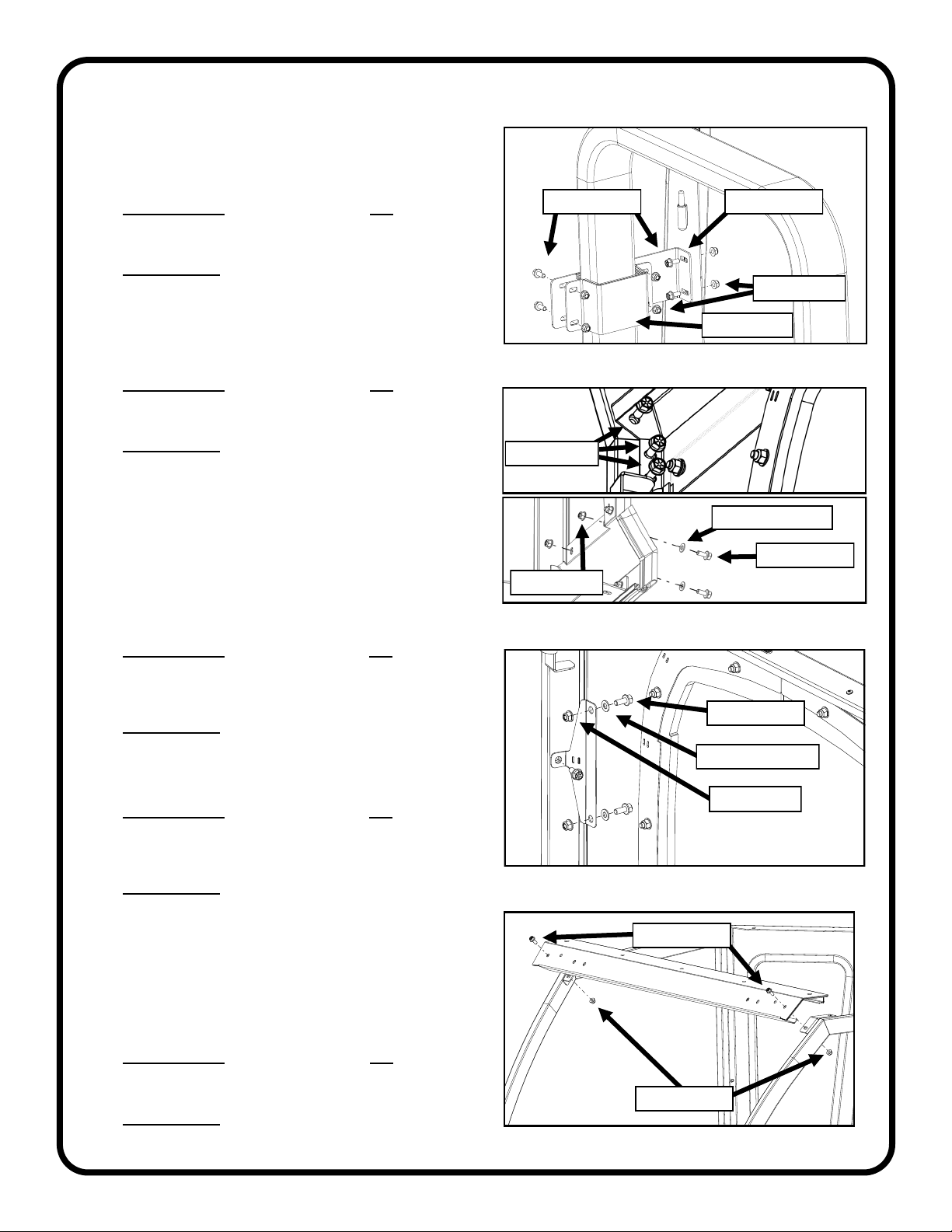

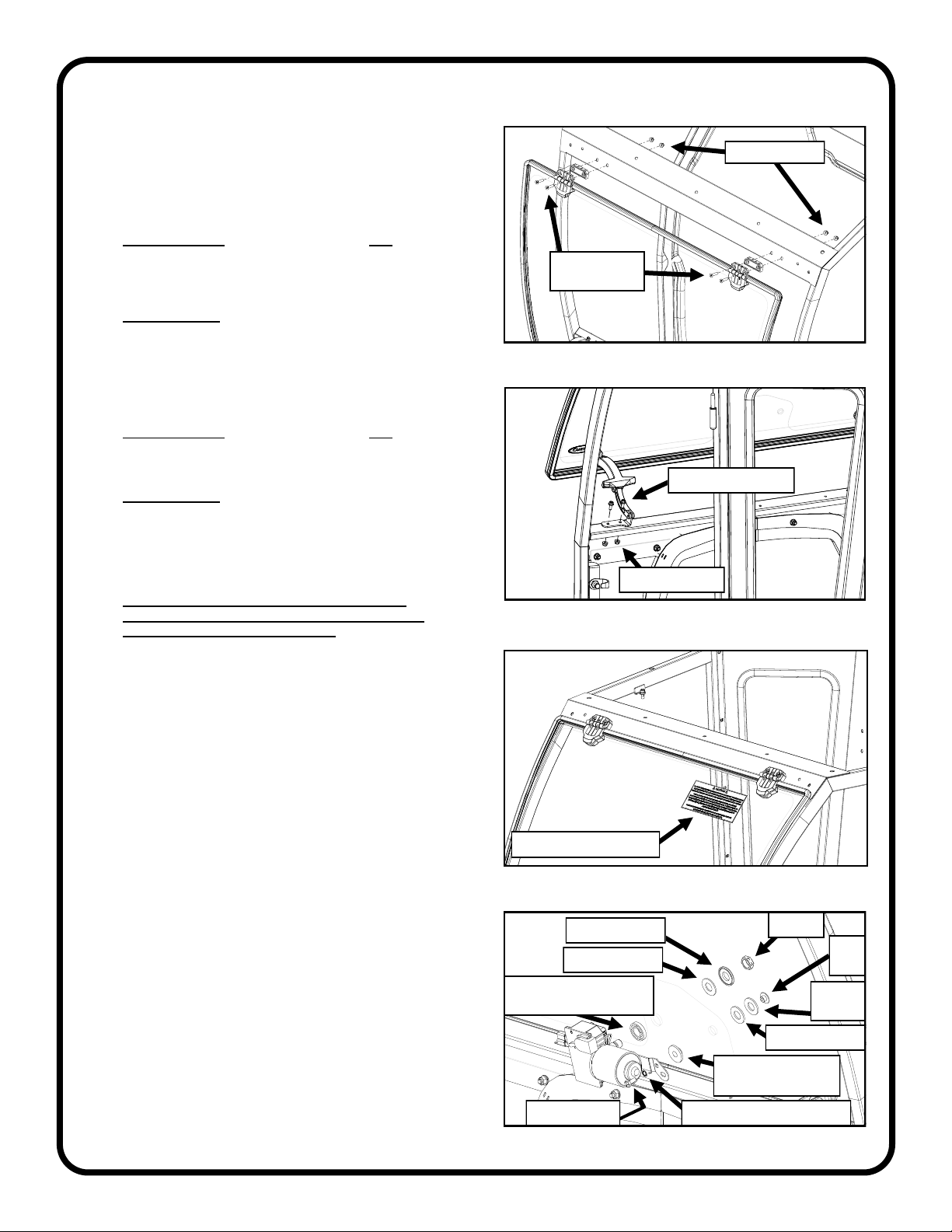

Fig. 11.1 (Attach Main Harness To Cowl)

Fig. 11.4 (Bottom shown, top similar)

STEP 11: (CAB WIRING)

11.1 Attach the main power wire harness to the top of the cowl

cross brace, about 6” from the end of the windshield

wiper motor connector, using a P-clip and hardware. The

connector end should be outside the cab with the rest of

the harness on the inside. See Figure 11.1.

Hardware Used Qty

#10-32 x 1/2” Pan Head Screw 1

#10-32 Hex lock Nut 1

Tools required

#2 Phillips Screw Driver

3/8” Wrench or Socket.

11.2 Snap in the heater switch and connect the wire harness.

11.3 Attach the harness to the under side of the cowl with the

supplied P-clamp & hardware listed below. See Figure

11.1.

Hardware Used Qty

#10-32 x 1/2” Pan Head Screw 1

#10-32 Hex lock Nut 1

Tools required

#2 Phillips Screw Driver

3/8” Wrench or Socket.

11.4 Run the wire harness down along the right side trim ring,

fastening with the (3) factory installed wire ties and

through the 11/16” hole in the right side cowl window.

See Figure 11.4.

11.5 Locate the supplied 7/16” I.D. rubber grommet. Slice the

grommet in order to wrap it over the wire harness and

then install into the 11/16” cowl hole.

11.6 Run the harness to the battery compartment on the right

side of vehicle under the floorboard. Make sure that

wires will not be cut or pinched routing to battery.

11.7 Locate the fuse harness (WH-GF). Make certain the fuse

is installed in the fuse holder. Connect the fuse harness

to the main power harness via the bullet connectors.

Install the ring terminal found on the fuse harness to the

positive battery terminal stud and secure using the nut

which was removed in step 1.1. See Figure 11.7.

11.8 Install the ring terminal of the main power wire harness to

the negative battery terminal stud. Do not reinstall the

negative battery terminal at this time. Coil the slack in

the power harness and secure with a wire tie. See Figure

11.7. Double check that the wires are not pinched or

near sharp or hot surfaces.

NOTE: At the installer’s discretion, wiring for accessories

may also be installed at this time.

Fig. 11.7 (Power Supply Connections)

P-Clamp

P-Clamps on Underside of

Cross Brace

Wire Tie