TFP1321

Page 8 of 18

• If the Diaphragm Gauge (K) indicates

no drop in pressure, re-open the Dia-

phragm Supply Valve (P) and pro-

ceed to the next step.

Step 10. Partially open the System

Main Control Valve (B). Slowly close the

Main Drain Valve (D) as soon as water

discharges from the Main Drain Valve

(D). Observe the Automatic Drain Valve

(F) for leaks. If there are leaks, deter-

mine/correct the cause of the leakage

problem before proceeding.

NOTICE

When the System Main Control Valve

(B) is partially opened, the pressure on

the DV-5aDiaphragm Chamber may

increase. This increase in pressure is

normal, and if the pressure is greater

than the valve trim maximum pressure

rating provided in the Technical Data

section, the pressure is to be relieved

to at least the valve trim pressure rating

by partially and temporarily opening the

Manual Control Station (M); however,

do not allow the pressure as indicated

on the Diaphragm Gauge (K) to drop

below the supply pressure shown on

the Water Supply Gauge (J), since this

action may result in tripping of the

DV-5aValve.

Step 11. Close the hinged cover of the

Manual Control Station (M), and insert a

new break rod in the small hole through

the top of the enclosing box.

Step 12. Fully open the System Main

Control Valve (B).

Step 13. After setting a fire protec-

tion system, notify the proper authori-

ties and advise those responsible for

monitoring proprietary and/or central

station alarms.

NOTICE

In order to prevent the possibility of a

subsequent operation of an overheated

solder type pilot sprinkler, any solder

type pilot sprinklers that were possibly

exposed to a temperature greater than

their maximum rated ambient must be

replaced.

Step 7. Operate (open) the Manual

Control Station (M) and then open

the Diaphragm Supply Valve (P). After

unaerated water ceases to discharge

from the Manual Control Station (M)

drain tube, slowly close the operating

lever by pushing it up. Do not close the

hinged cover at this time.

Step 8. After allowing water to flow out

of the Manual Reset Actuator (N) drain

tube until aerated water ceases to dis-

charge, reset the Manual Reset Actua-

tor (N) by pressing the Reset Knob and

hold until water stops flowing from its

drain tube and the pressure builds and

reaches approximately 15 psi (1,0 bar)

on the Diaphragm Gauge (K). Pressure

will then build up in the DV-5aDia-

phragm Chamber.

Note: After relieving trapped air, check the

Manual Reset Actuator (N) to make sure

there is no water draining from its drain tube.

If water is draining, reset the Manual Reset

Actuator (N) as previously instructed.

Step 9. Verify the ability for the DV-5a

Diaphragm to hold pressure as follows:

• With the diaphragm chamber pres-

surized per Step 8, temporarily close

the Diaphragm Supply Valve (P), and

then observe the Diaphragm Gauge

(K) for a drop in pressure.

• If a drop in pressure is noted, the

DV-5aDiaphragm is to be replaced

and/or any leaks must be corrected

before proceeding to the next step.

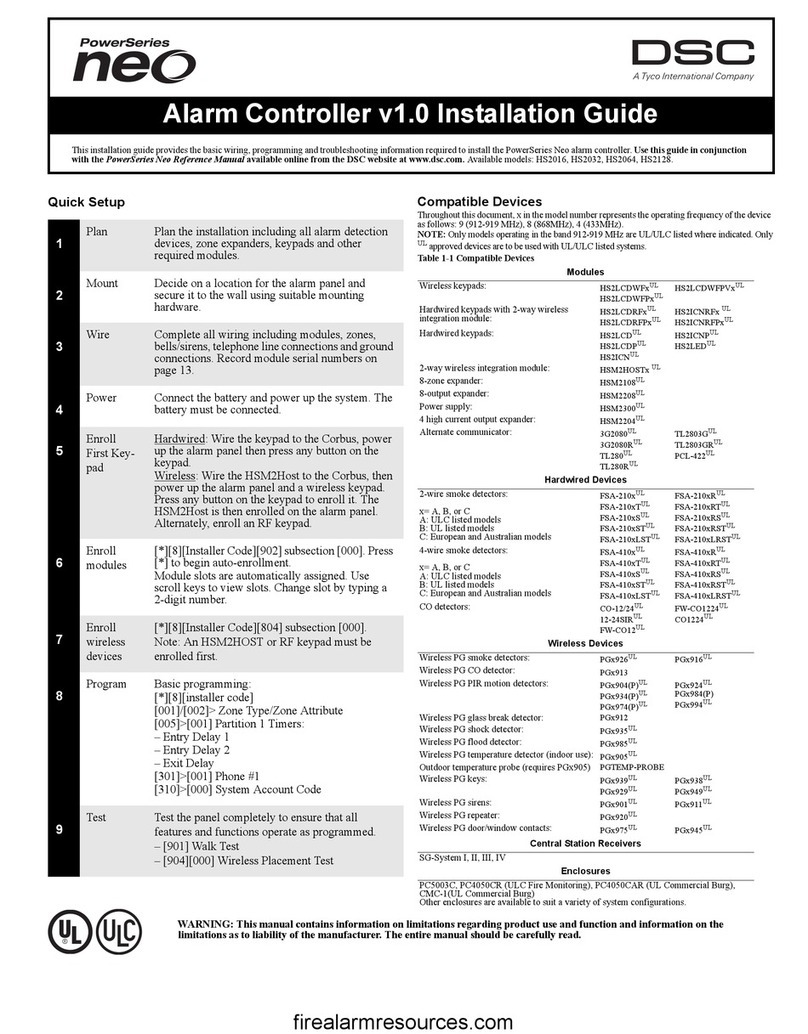

Valve Setting

Procedure

Perform Steps 1 through 13 when ini-

tially setting the TYCO DV-5aValve,

after an operational test of the fire pro-

tection system, or after system opera-

tion due to a fire. Refer to Figures 16,

17, or 18, as applicable.

Step 1. Close the System Main Control

Valve (B).

Step 2. Close the Diaphragm Supply

Valve (P).

Step 3. Open the Main Drain Valve (D),

System Drain Valve (E), and all auxil-

iary drains in the system. Close the

auxiliary drain valves and the System

Drain Valve (E) after water ceases to

discharge. Leave the Main Drain Valve

(D) open.

At this time make certain that the

Pressure Gauge Valves and the Alarm

Control Valve (H), as applicable, are

open.

Step 4. Depress the plunger of the

Automatic Drain Valve (F) to verify that

it is open.

Step 5. Clean the Diaphragm Supply

Strainer (Q) by removing the clean-

out plug and strainer basket. The Dia-

phragm Supply Strainer (Q) may be

flushed out by momentarily opening

the Diaphragm Supply Valve (P).

Step 6. Reset the automatic Elec-

tric Actuation by resetting the electric

detection system in accordance with

the manufacturer’s instructions to de-

energize the solenoid valve.