Custom Audio Electronics DPT 282 PLM User manual

Other Custom Audio Electronics Printer manuals

Custom Audio Electronics

Custom Audio Electronics Kube Scanner 120 User manual

Custom Audio Electronics

Custom Audio Electronics PD190 User manual

Custom Audio Electronics

Custom Audio Electronics MODUS3 User manual

Custom Audio Electronics

Custom Audio Electronics s'print DPT100-B User manual

Custom Audio Electronics

Custom Audio Electronics F 190 User manual

Custom Audio Electronics

Custom Audio Electronics MT002 User manual

Custom Audio Electronics

Custom Audio Electronics Mini PLUS User manual

Custom Audio Electronics

Custom Audio Electronics STIMARE STIMA-SML User manual

Custom Audio Electronics

Custom Audio Electronics DP24-40 H User manual

Custom Audio Electronics

Custom Audio Electronics Q3X User manual

Custom Audio Electronics

Custom Audio Electronics P190 User manual

Custom Audio Electronics

Custom Audio Electronics P3 User manual

Custom Audio Electronics

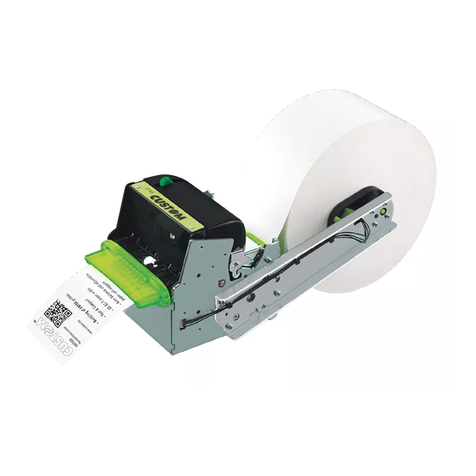

Custom Audio Electronics VKP80III User manual

Custom Audio Electronics

Custom Audio Electronics TK300II User manual

Custom Audio Electronics

Custom Audio Electronics KPM302III User manual

Custom Audio Electronics

Custom Audio Electronics s'print DPT100-B User manual

Custom Audio Electronics

Custom Audio Electronics TPTCM60III User manual

Custom Audio Electronics

Custom Audio Electronics KPM150H User manual

Custom Audio Electronics

Custom Audio Electronics Neo User manual

Custom Audio Electronics

Custom Audio Electronics FT190 User manual