Effective 2/2/2001

Page 1I.L. 70C1037H03

1.0 General Description of Digitrip Trip Units ................. 2

1.1 Protection ............................................................... 4

1.2 Mode of Trip and Status Information ........................ 4

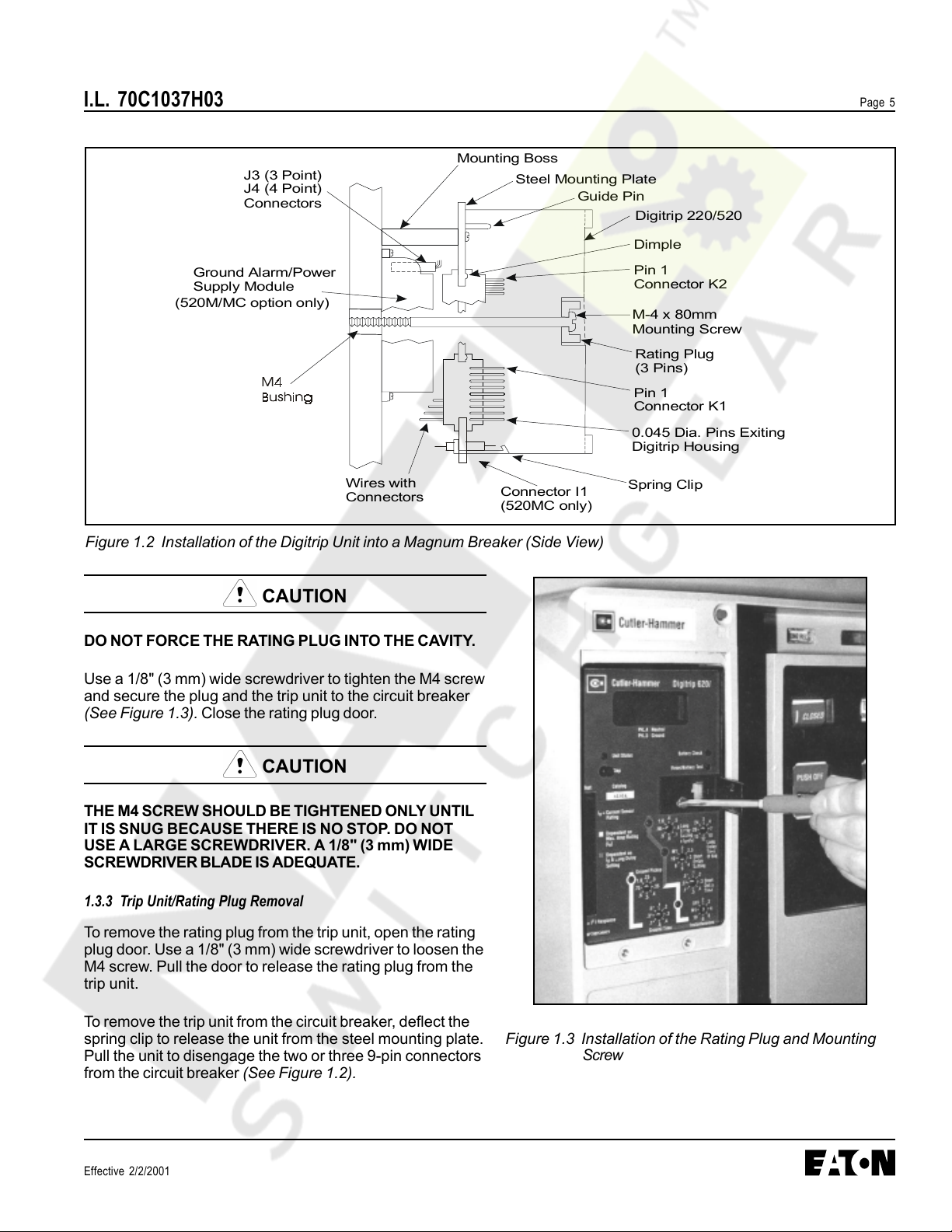

1.3 Installation and Removal .......................................... 4

1.3.1 Installation of the Trip Unit ............................ 4

1.3.2 Rating Plug Installation ................................ 4

1.3.3 Trip Unit/Rating Plug Removal ...................... 5

1.4 Wiring ..................................................................... 6

1.5 Plexiglass Cover ..................................................... 6

1.6 Ground Alarm/Power Supply Module

(520M & 520MC Models only) ................................. 6

1.6.1 Auxiliary Power ............................................ 6

1.6.2 Ground Alarm .............................................. 6

1.6.3 Ground Fault Trip ......................................... 6

1.6.4 Ground Fault Alarm ...................................... 6

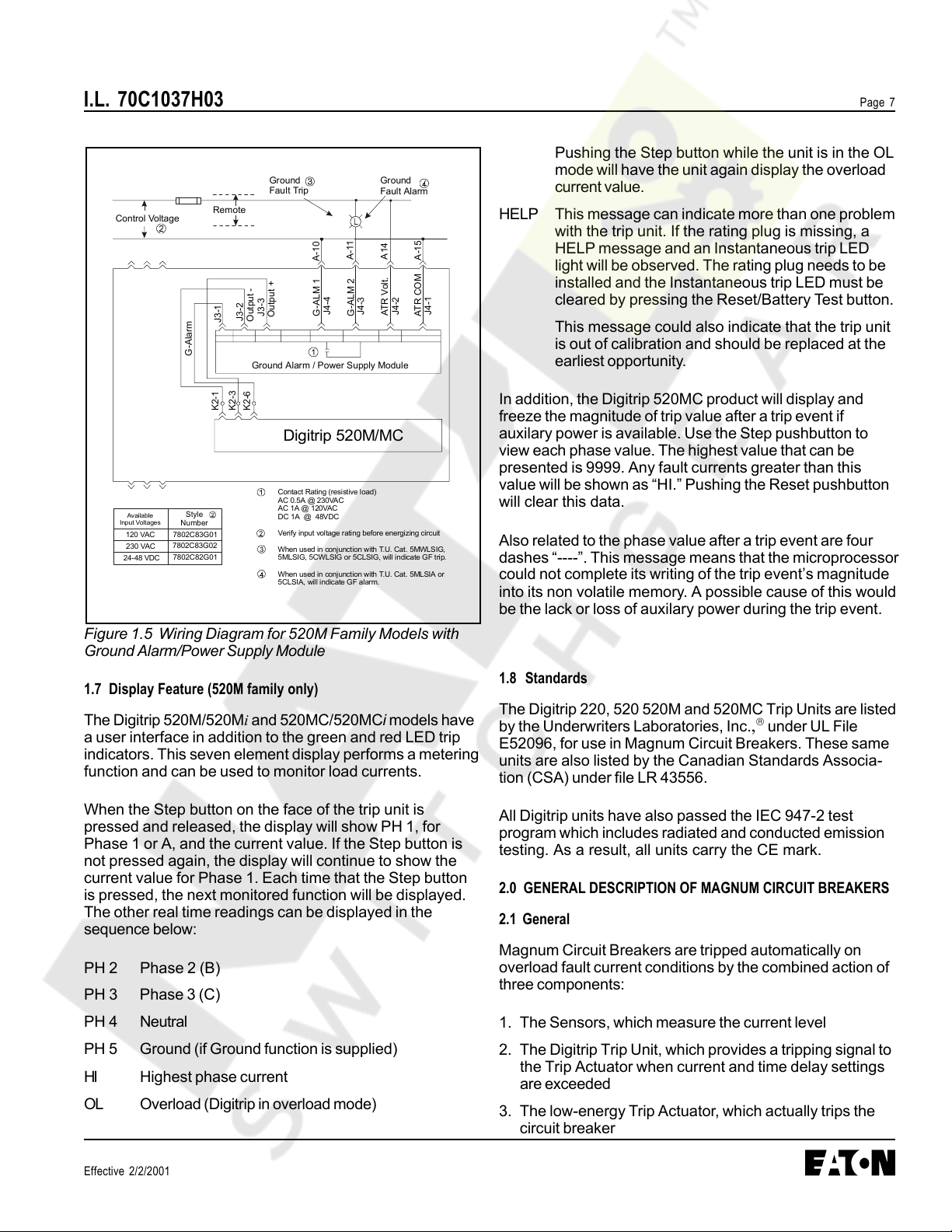

1.7 Display Feature (520M family only) ......................... 7

1.8 Standards ............................................................... 7

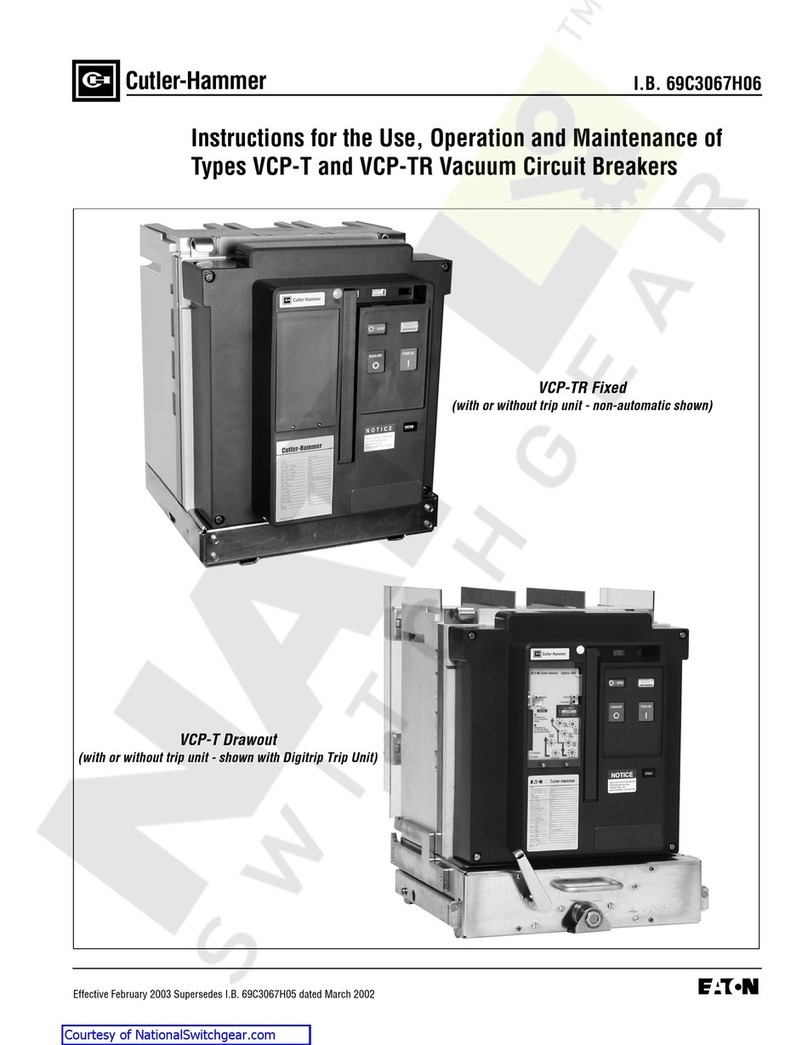

2.0 General Description of

Magnum Circuit Breakers ........................................ 7

2.1 General ................................................................... 7

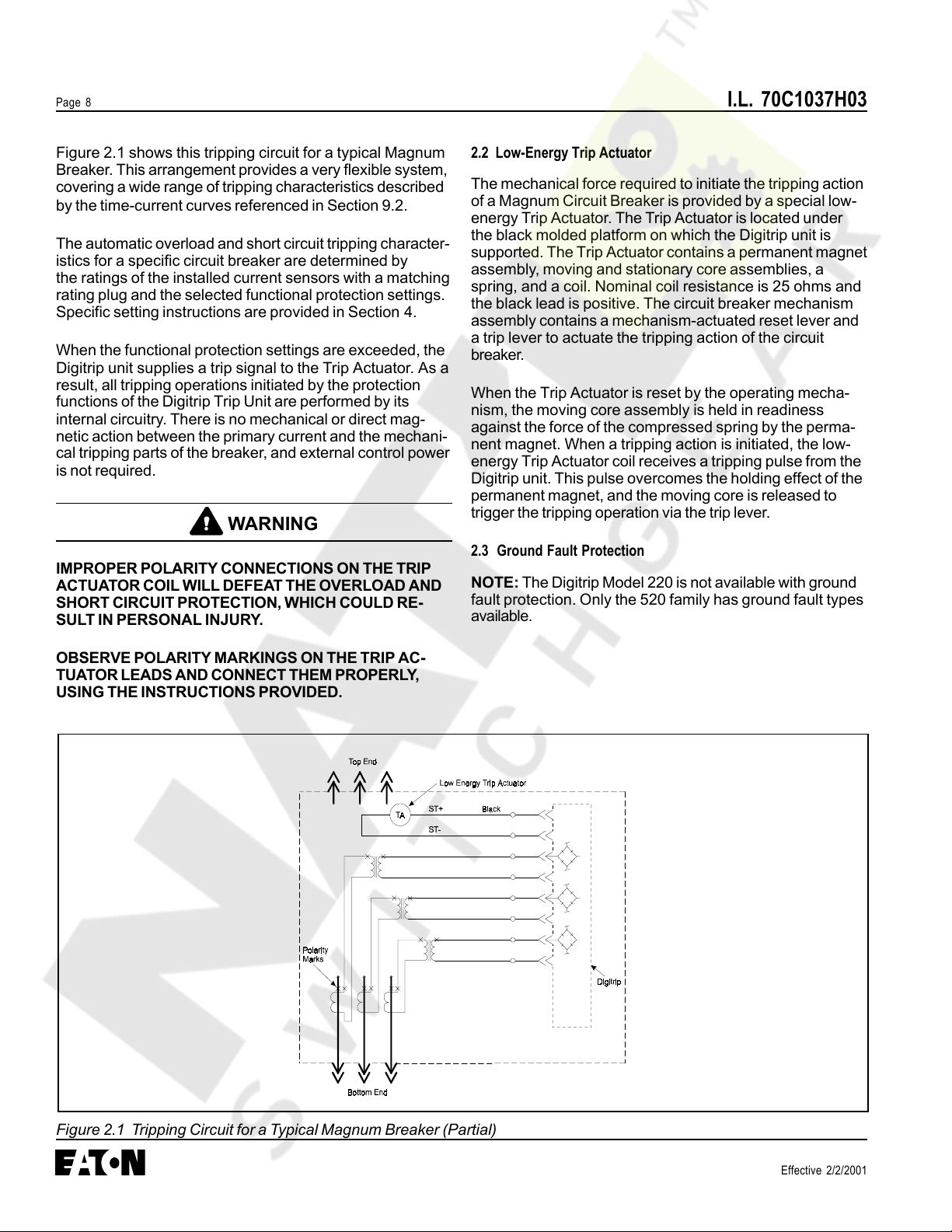

2.2 Low Energy Trip Actuator ........................................ 8

2.3 Ground Fault Protection .......................................... 8

2.3.1 General ........................................................ 9

2.3.2 Residual Sensing ......................................... 9

2.3.3 Source Ground Sensing ............................... 9

2.3.4 Zero Sequence Sensing ............................... 9

2.3.5 Multiple Source/Multiple Ground .................. 9

2.3.6 Ground Fault Settings .................................. 9

2.4 Current Sensors (Magnum Frames less than

or equal to 3200A) ................................................. 10

2.5 Current Sensors (Magnum Frames greater

than 3200A) .......................................................... 10

3.0 Principles of Operation .......................................... 10

3.1 General ................................................................. 10

3.2 Trip and Operation Indicators ................................. 15

3.3 Making Current Release ........................................ 15

3.4 Zone Interlocking (520 family only) ........................ 15

4.0 Protection Settings ............................................... 20

4.1 General ................................................................. 20

4.2 Long Delay Current Setting ................................... 20

4.3 Long Delay Time Setting ....................................... 20

4.4 Short Delay Current Setting................................... 21

4.5 Short Delay Time Setting ...................................... 21

4.6 Instantaneous Current Setting ............................... 21

4.7 Ground Fault Current Setting ................................. 22

4.8 Ground Fault Time Delay Setting .......................... 22

4.9 INCOM Communications (520MC model only) ....... 22

4.9.1 Breaker Interface Module (BIM) .................. 22

4.9.2 Remote Master Computer .......................... 23

4.9.3 INCOM Network Interconnections ............... 23

5.0 Test Procedures .................................................... 24

5.1 General ................................................................. 24

5.2 When to Test ........................................................ 24

5.3 Functional Field Testing ........................................ 24

5.3.1 Field Test Kit ............................................... 24

5.3.2 Handheld Functional Test Kit ...................... 25

5.3.2.1 Description of Handheld Test Kit ...... 25

5.3.2.2 Test Procedure ................................ 25

5.3.2.3 Currents .......................................... 25

5.3.2.4 Batteries ......................................... 25

5.4 Performance Testing for Ground Fault

Trip Units - Primary Injection ................................. 25

5.4.1 Code Requirements ................................... 25

5.4.2 Standards Requirements ............................ 25

5.4.3 General Test Instructions ........................... 25

6.0 Battery ................................................................. 26

6.1 General ................................................................. 26

6.2 Battery Check ....................................................... 26

6.3 Battery Installation and Removal ........................... 27

7.0 Frame Ratings

(Sensor Ratings and Rating Plugs) ................. 10, 27

8.0 Record Keeping .................................................... 28

9.0 References ............................................................ 28

9.1 Magnum and Magnum DS Circuit Breakers ........... 28

9.2 Time-Current Curves .............................................. 28

Appendix A Zone Interlocking Examples ....................... 32

Appendix B Troubleshooting Guide ................................ 34

Appendix C Typical Breaker Master

Connection Diagram .............................................. 36

WARNING

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS

ENERGIZED. DEATH OR SEVERE PERSONAL INJURY

CAN RESULT FROM CONTACT WITH ENERGIZED

EQUIPMENT. ALWAYS VERIFY THAT NO VOLTAGE IS

PRESENT BEFORE PROCEEDING. ALWAYS FOLLOW

SAFETY PROCEDURES. CUTLER-HAMMER IS NOT

LIABLE FOR THE MISAPPLICATION OR

MISINSTALLATION OF ITS PRODUCTS.

WARNING

OBSERVE ALL RECOMMENDATIONS, NOTES, CAU-

TIONS, AND WARNINGS RELATING TO THE SAFETY

OF PERSONNEL AND EQUIPMENT. OBSERVE AND

COMPLY WITH ALL GENERAL AND LOCAL HEALTH

AND SAFETY LAWS, CODES, AND PROCEDURES.

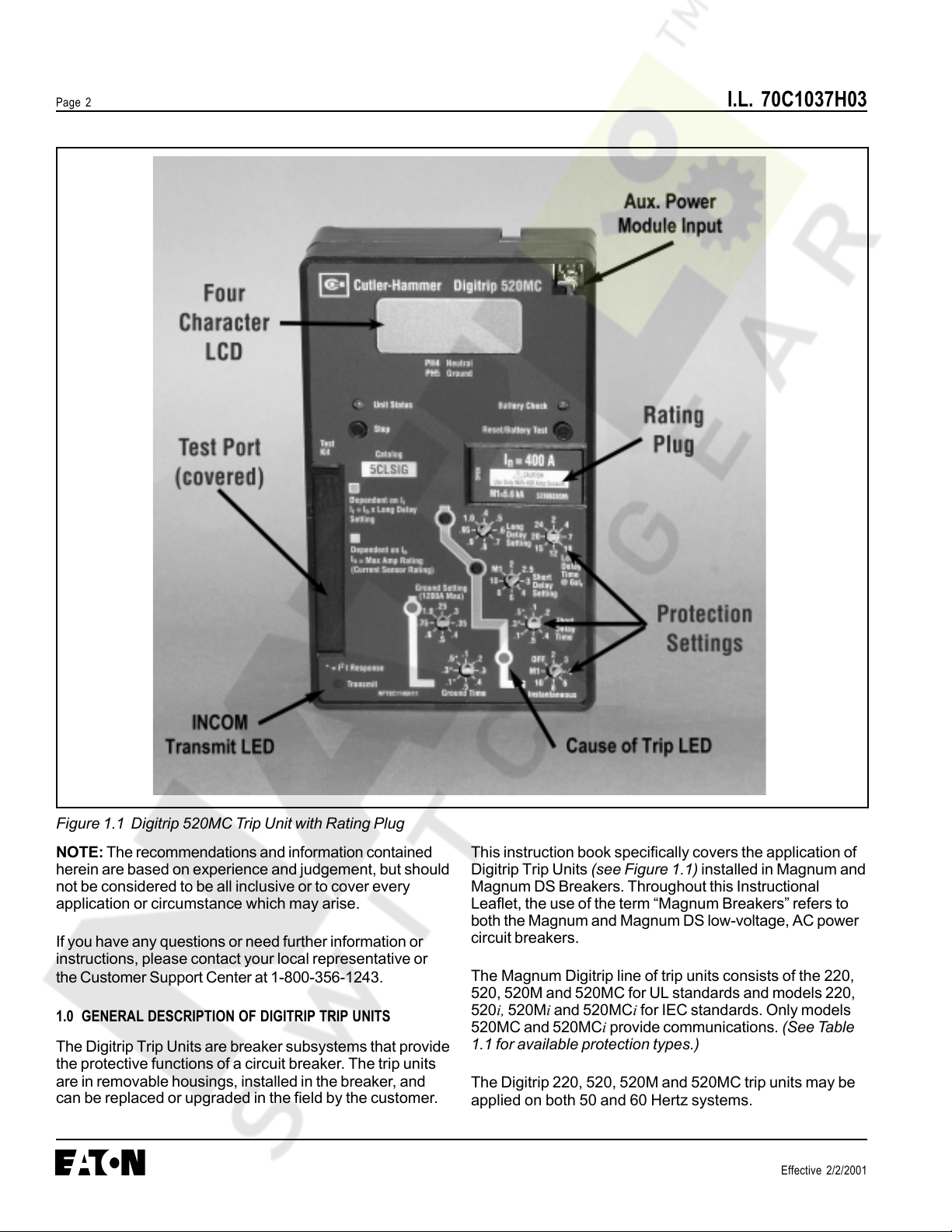

I.L. 70C1037H03

Instructions for Digitrip Models 220, 520, 520i, 520M,

520Mi, 520MC and 520MCiTrip Units for use only in

Cutler-Hammer Magnum and Magnum DS Circuit Breakers

Table of Contents

G

*

Cutler

-

Hammer

F

;

T

*

N

Courtesy of NationalSwitchgear.com