CUTLER-HAMMER 24kV Type W-VAC Circuit Breaker

Effective 12/98 Page 1of 47

SECTION 1: INTRODUCTION

1-1 PRELIMINARY COMMENTS AND SAFETY

PRECAUTIONS

This technical document is intended to cover most

aspects associated with the installation, application,

operation and maintenance of the W-VAC Vacuum

Circuit Breakers. It is provided as a guide for

authorized and qualified personnel only. Please refer

to the specific WARNING and CAUTION in Section 1-

1.2 before proceeding. If further information is

required by the purchaser regarding a particular

installation, application or maintenance activity, a

Cutler-Hammer representative should be contacted.

1-1.1 WARRANTY AND LIABILITY INFORMATION

NO WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OF MERCHANTABILITY,

OR WARRANTIES ARISING FROM COURSE OF

DEALING OR USAGE OF TRADE, ARE MADE

REGARDING THE INFORMATION,

RECOMMENDATIONS AND DESCRIPTIONS

CONTAINED HEREIN. In no event will Cutler-

Hammer be responsible to the purchaser or user in

contract, in tort (including negligence), strict liability or

otherwise for any special, indirect, incidental or

consequential damage or loss of use of equipment,

plant or power system, cost of capital, loss of power,

additional expenses in the use of existing power

facilities, or claims against the purchaser or user by

its customers resulting from the use of information

and descriptions contained herein.

1-1.2 SAFETY PRECAUTIONS

All safety codes, safety standards and/or regulations

must be strictly observed in the installation, operation

and maintenance of this device.

WARNING

THE WARNINGS AND CAUTIONS INCLUDED AS

PART OF THE PROCEDURAL STEPS IN THIS

DOCUMENT ARE FOR PERSONEL SAFETY AND

PROTECTION OF EQUIPMENT FROM DAMAGE.

AN EXAMPLE OF A TYPICAL WARNING LABEL

HEADING IS SHOWN ABOVE IN REVERSE TYPE

TO FAMILIARIZE PERSONNEL WITH THE STYLE

OF PRESENTATION. THIS WILL HELP TO

ENSURE THAT PERSONNEL ARE ALERT TO

WARNINGS, WHICH MAY APPEAR THROUGHOUT

THE DOCUMENT. IN ADDITION, CAUTIONS ARE

ALL UPPERCASE AND BOLDFACE AS SHOWN

BELOW.

CAUTION

COMPLETELY READ AND UNDERSTAND THE

MATERIAL PRESENTED IN THIS DOCUMENT

BEFORE ATTEMPTING INSTALLATION,

OPERATION OR APPLICATION OF THE

EQUIPMENT. IN ADDITION, ONLY QUALIFIED

PERSONS SHOULD BE PERMITTED TO

PERFORM ANY WORK ASSOCIATED WITH THE

EQUIPMENT. ANY WIRING INSTRUCTIONS

PRESENTED IN THIS DOCUMENT MUST BE

FOLLOWED PRECISELY. FAILURE TO DO SO

COULD CAUSE PERMANENT EQUIPMENT

DAMAGE.

1-2 GENERAL INFORMATION

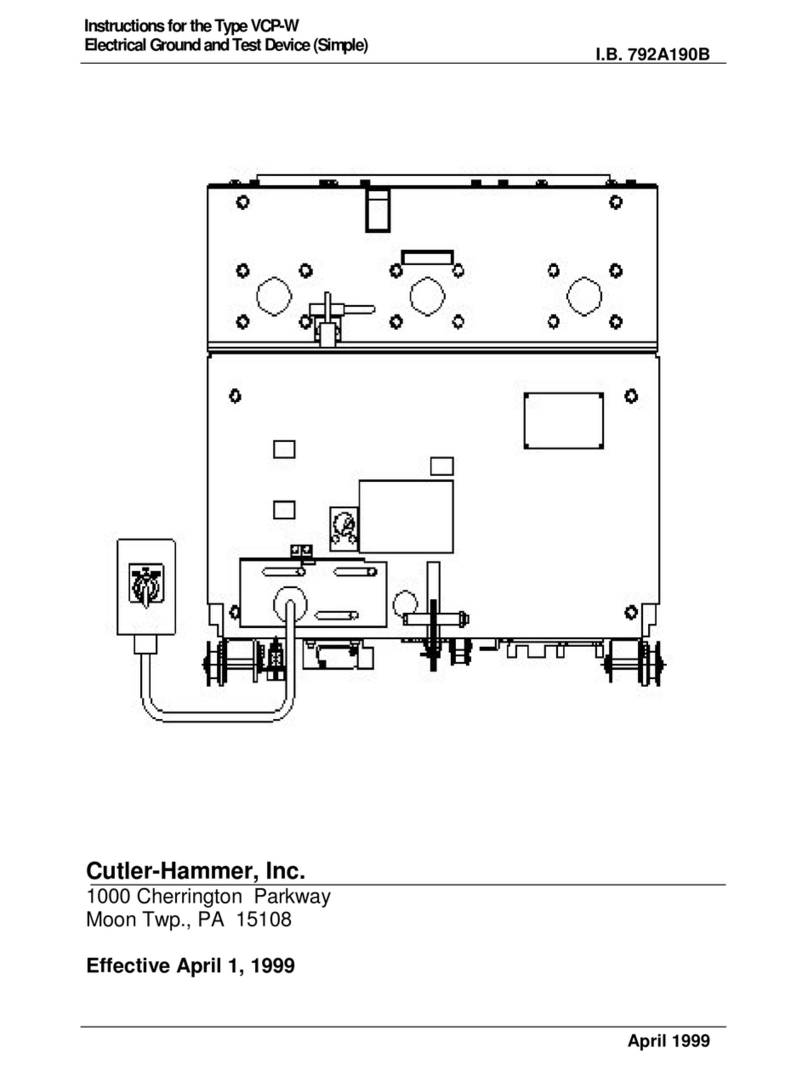

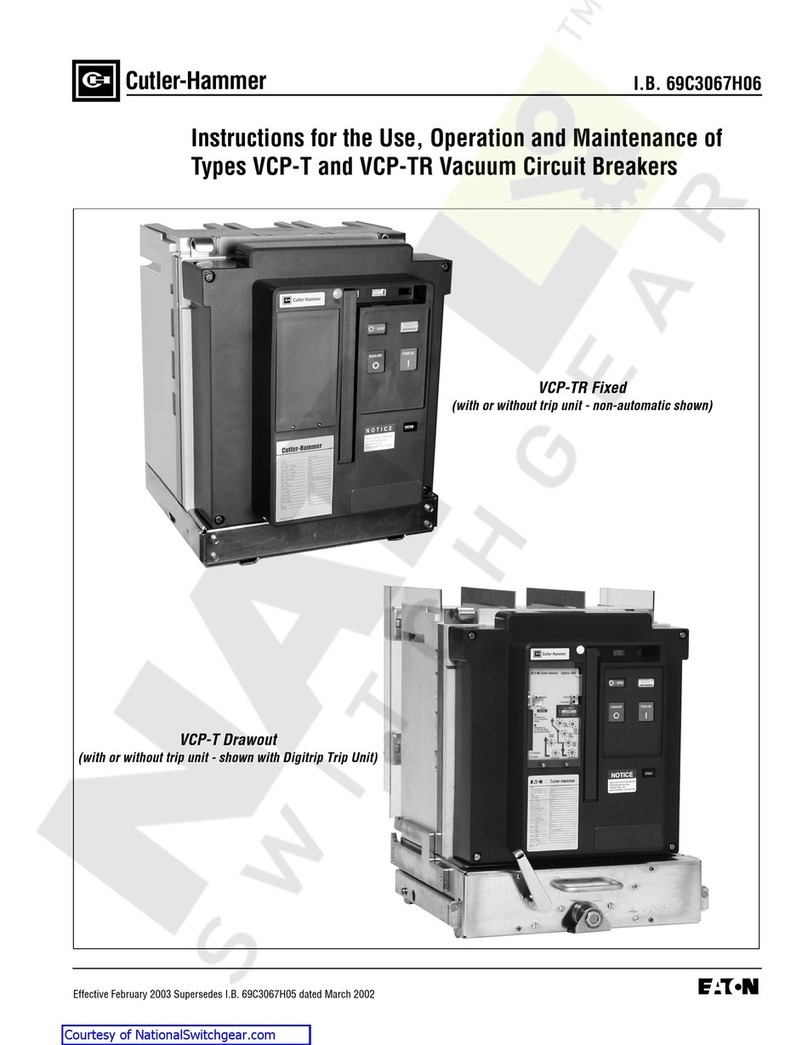

The purpose of this book is to provide instructions for

unpacking, storage, use, operation and maintenance

of 24kVType W-VAC Vacuum Circuit Breakers. They

are horizontal draw-out, mid-mount removable

interrupting elements ideal for use in new metal-clad

switchgear, as well as for modernization and life

extension of existing switchgear. Designed to IEC

Standards for reliable performance, ease of handling,

and simplified maintenance, 24kVType W-VAC

Vacuum Circuit Breakers provide reliable control and

protection for electrical equipment and circuits. In

addition, these technologically advanced circuit

breakers provide higher insulation levels in less

space, thus reducing the overall switchgear size.

WARNING

SATISFACTORY PERFORMANCE OF THESE

CIRCUIT BREAKERS IS CONTINGENT UPON

PROPER APPLICATION, CORRECT

INSTALLATION AND ADEQUATE MAINTENANCE.

THIS INSTRUCTION BOOK MUST BE CAREFULLY

READ AND FOLLOWED IN ORDER TO OBTAIN

OPTIMUM PERFORMANCE FOR LONG USEFUL

LIFE OF THE CIRCUIT BREAKERS.

!

!