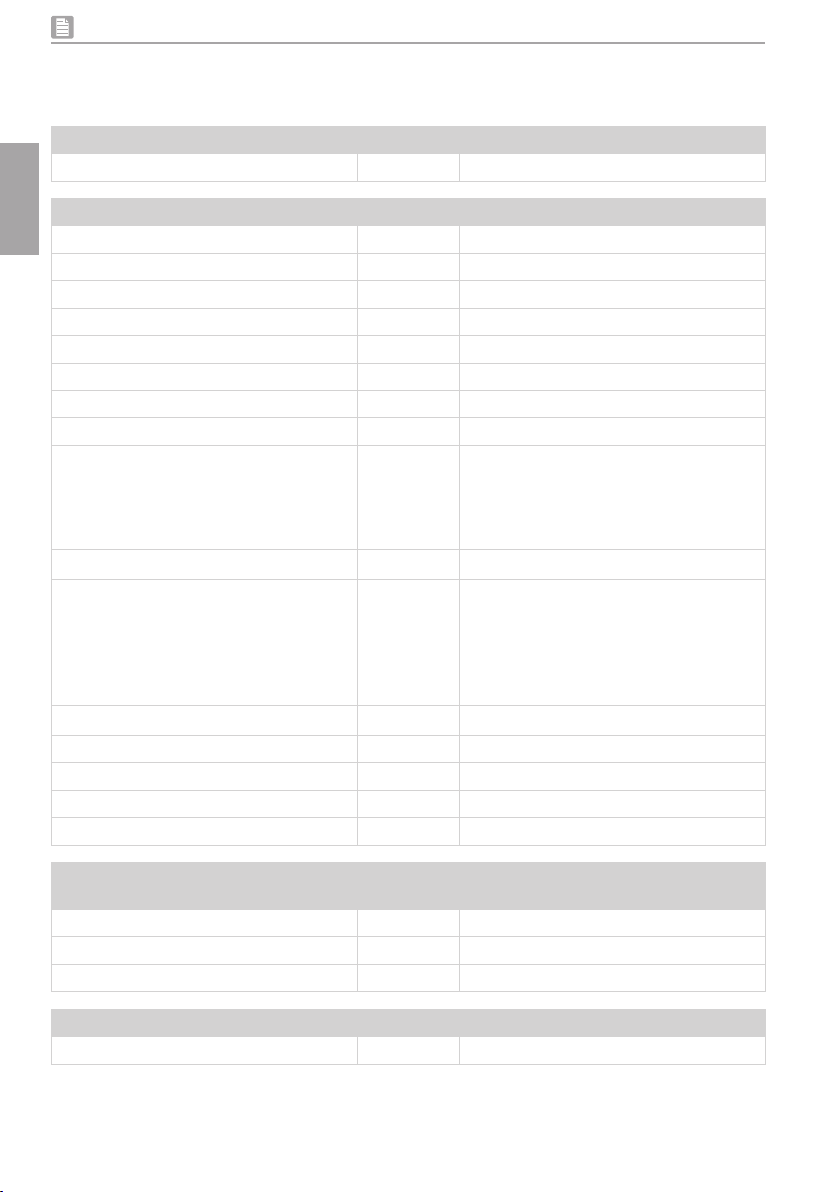

1018100100L02 1907V005 1

8.2 Information regarding the pres-

sure vessel . . . . . . . . . . . . . . . . . . 18

8.3 Pressure tank . . . . . . . . . . . . . . . . 18

8.4 Instructions for use for the pres-

sure vessel (explanation by Be-

hälter-Werk Burgau GmbH) . . . . . . 19

9 Commissioning. . . . . . . . . . . . . . . . . . . 20

9.1 Remove the packaging . . . . . . . . . 20

9.2 Unit with castors . . . . . . . . . . . . . . 20

9.3 Establishing the compressed air

connection . . . . . . . . . . . . . . . . . . 20

9.4 Condensate . . . . . . . . . . . . . . . . . 21

9.5 Electrical installation . . . . . . . . . . . 21

9.6 Overtemperature protection . . . . . 22

Usage

10 Operation . . . . . . . . . . . . . . . . . . . . . . . 23

10.1 On/Off switch . . . . . . . . . . . . . . . . 23

10.2 Manual venting . . . . . . . . . . . . . . . 23

10.3 Unit with castors . . . . . . . . . . . . . . 23

11 Maintenance. . . . . . . . . . . . . . . . . . . . . 24

11.1 Maintenance schedule . . . . . . . . . 24

11.2 Disinfecting and cleaning the sur-

faces . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting

12 Tips for operators and service techni-

cians. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Appendix

13 Information about EMC in accord-

ance with EN 60601-1-2 . . . . . . . . . . . . 28

13.1 General notes . . . . . . . . . . . . . . . . 28

13.2 Abbreviations . . . . . . . . . . . . . . . . 28

13.3 Guidelines and manufacturer's in-

formation . . . . . . . . . . . . . . . . . . . 28

EN

Contents

Important information

1 About this document . . . . . . . . . . . . . . . 3

1.1 Warnings and symbols . . . . . . . . . . 3

1.2 Copyright information . . . . . . . . . . . 4

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Intended use. . . . . . . . . . . . . . . . . . 4

2.2 Improper use . . . . . . . . . . . . . . . . . 4

2.3 General safety information. . . . . . . . 4

2.4 Specialist personnel . . . . . . . . . . . . 5

2.5 Electrical safety. . . . . . . . . . . . . . . . 5

2.6 Essential performance character-

istics. . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Notification requirement of seri-

ous incidents . . . . . . . . . . . . . . . . . 5

2.8 Only use original parts. . . . . . . . . . . 5

2.9 Transportation and storage . . . . . . . 6

2.10 Disposal . . . . . . . . . . . . . . . . . . . . . 6

Product description

3 Overview. . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Scope of delivery . . . . . . . . . . . . . . 7

3.2 Spare parts and accessories. . . . . . 7

4 Technical data . . . . . . . . . . . . . . . . . . . . 8

4.1 Basic data . . . . . . . . . . . . . . . . . . . 8

4.2 Variants. . . . . . . . . . . . . . . . . . . . . . 9

4.3 Declaration of conformity . . . . . . . 10

5 Operation . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 Unit details . . . . . . . . . . . . . . . . . . 11

5.2 Pneumatics plan . . . . . . . . . . . . . . 12

5.3 Main air supply . . . . . . . . . . . . . . . 13

5.4 Standby mode . . . . . . . . . . . . . . . 13

5.5 Device label . . . . . . . . . . . . . . . . . 14

6 Type plate. . . . . . . . . . . . . . . . . . . . . . . 16

Assembly

7 Tools required. . . . . . . . . . . . . . . . . . . . 17

8 Requirements . . . . . . . . . . . . . . . . . . . . 17

8.1 Installation/setup room . . . . . . . . . 17