2. INTRODUCTION

2-1. Introduction

Thank you for your choice, this “DN511A” Industrial Digital Weighing Indictor..

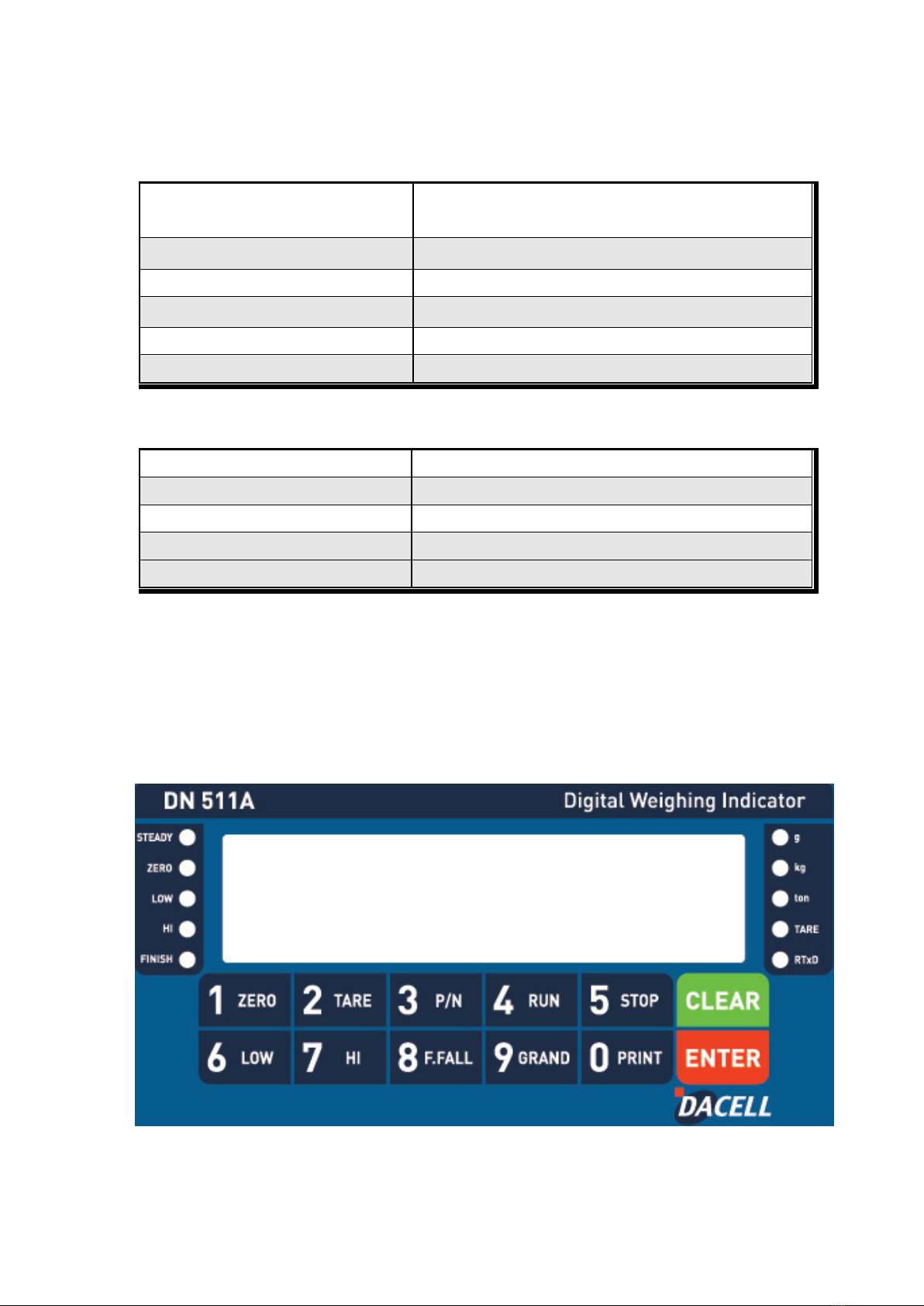

This “DN511A” model is control purpose application usage Digital Weighing Indicator, with

powerful communication performance.

With 4pcs control relay outputs and High Speed A/D conversion performance will lead you to

precise weighing process.

This “DN511A” Weighing Indicator is control purpose application model, and it can be used for

most kinds of control applications.

Please review this instruction Manual and learn more about information about “DN511A”.

Enjoy your process efficiency with “DN511A” Weighing Indicator..

2-2. Cautions

1). Don’t drop on the ground or avoid serious external damage on item.

2). Don’t install under sunshine or heavy vibrated condition.

3). Don’t install place where high voltage or heavy electric noise condition.

4). When you connect with other devices, please turn off the power of item.

5). Avoid from water damage.

6). For the improvement of function or performance, we can change item specification without

prior notice or permission.

7). Item’s performance will be up-dated continuously base on previous version’s performance.

8) The quantity of load cell to connect is max. 6pcs.

2-3. Features

1). All Modules and Option Cards are isolated to maximize accuracy and performance.

2). External input terminal inside.

3). By using “Photo-Coupler” on each module(Option, Analog board, In/Out), we improved

“Impedance problem”, “Isolation ability among inputs”, “Leading power problem”, and

“Noise covering function”.

4). Data back-up function, when the sudden power off

5). Polycarbonate film panel, strong against dust and water

6). RS-232C (Com. Port1) is standard installed.

8). Variable options(Order in advance)

2-4. Box Contents

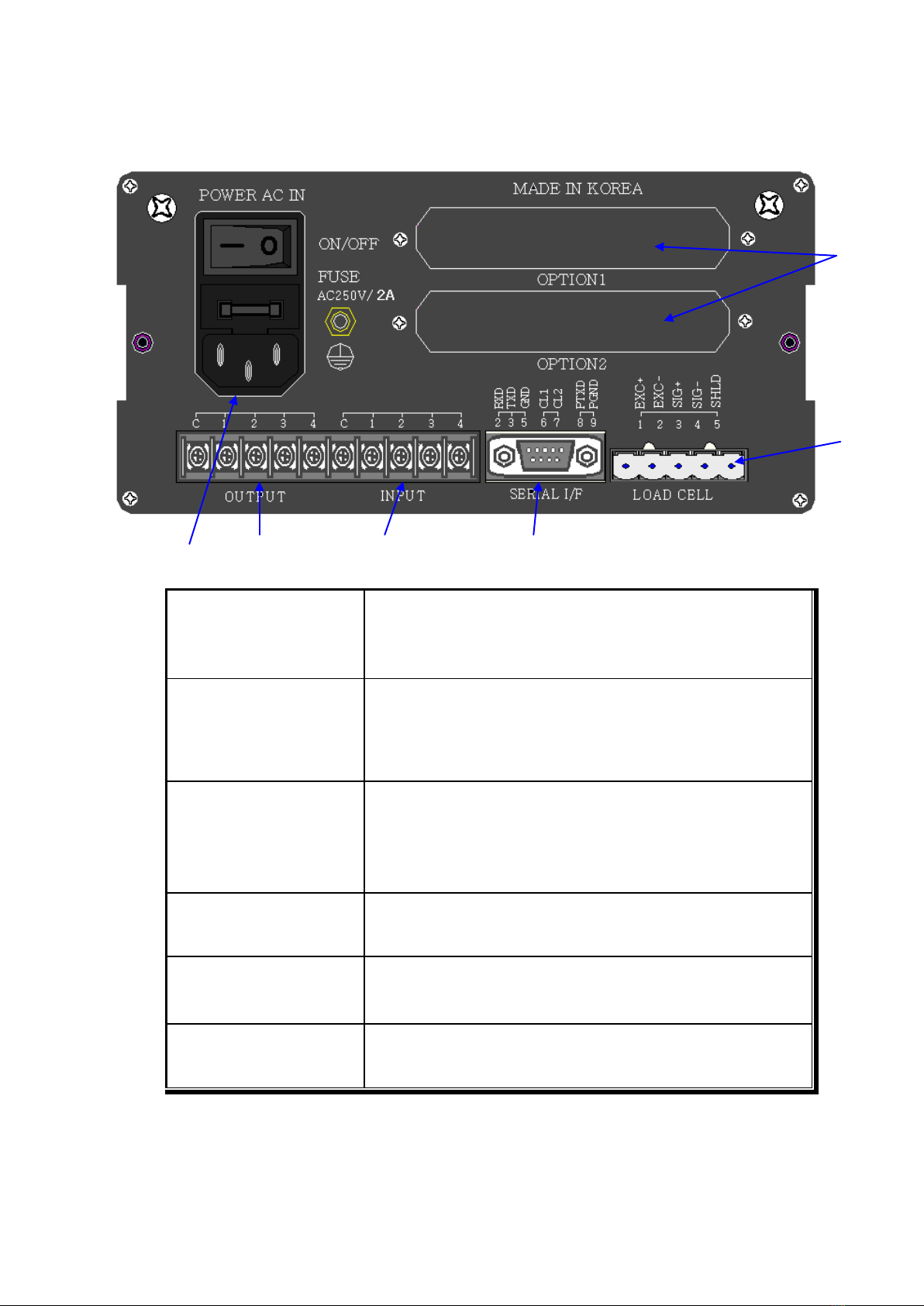

1). Power Cable(1pcs) / Fuse(2pcs) / Load cell Connector(1pcs) / Manual(1pcs)

Cautions

!

3/ 49