IM 735-4 • MICROTECH II CHILLER UNIT CONTROLLER 4 www.DaikinApplied.com

Recognize Safety Symbols, Words and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner and installer’s responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the

risk of property damage and/or product damage, serious

personal injury or death. Improper installation, operation and

maintenance can void the warranty.

Cautions indicate potentially hazardous situations, which can result in

personal injury or equipment damage if not avoided.

Static sensitive components. Can cause equipment damage.

Discharge any static electrical charge by touching the bare metal inside the

control panel before performing any service work. Never unplug cables,

circuit board terminal blocks, or power plugs while power is applied to the

panel

Warnings indicate potentially hazardous situations, which can result in

property damage, severe personal injury, or death if not avoided.

Dangers indicate a hazardous situation which will result in death or

serious injury if not avoided. Electric shock hazard. Can cause personal

injury or equipment damage. This equipment must be properly grounded.

Connections and service to the MicroTech II Unit Controller must be

performed only by personnel knowledgeable in the operation of the

equipment being controlled.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with this instruction manual,

may cause interference to radio communications. It has been tested and

found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a

commercial environment. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be required

to correct the interference at his or her own expense. Daikin disclaims any

liability resulting from any interference or for the correction thereof.

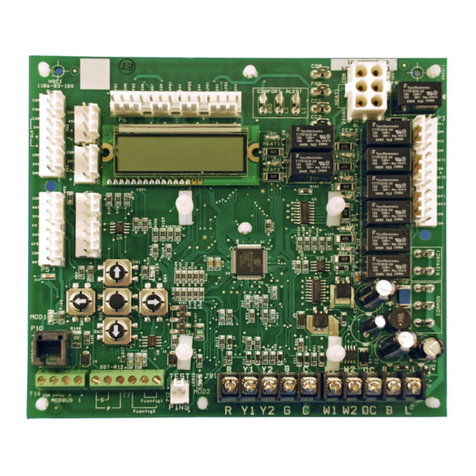

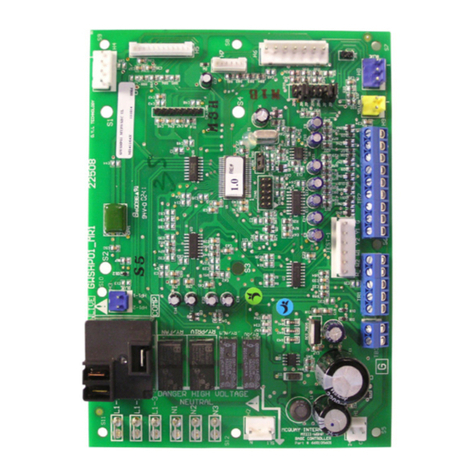

The communication module connects the

MicroTech II chiller unit controller to a building automation

system (BAS). This interface enables the exchange of

variables between the unit controller and a

Operating Network or LON.

Features

• Integration into a building automation and control system

via

• Installed with LonMark®

• Network controller (Neuron chip) handles the complete

network protocol and user application

• LEDs that indicate communication status and network

activity

• commissioning

tools such as Echelon’s®LonMaker®software

• Circuit board components enclosed in protective housing

and inserts into the unit controller

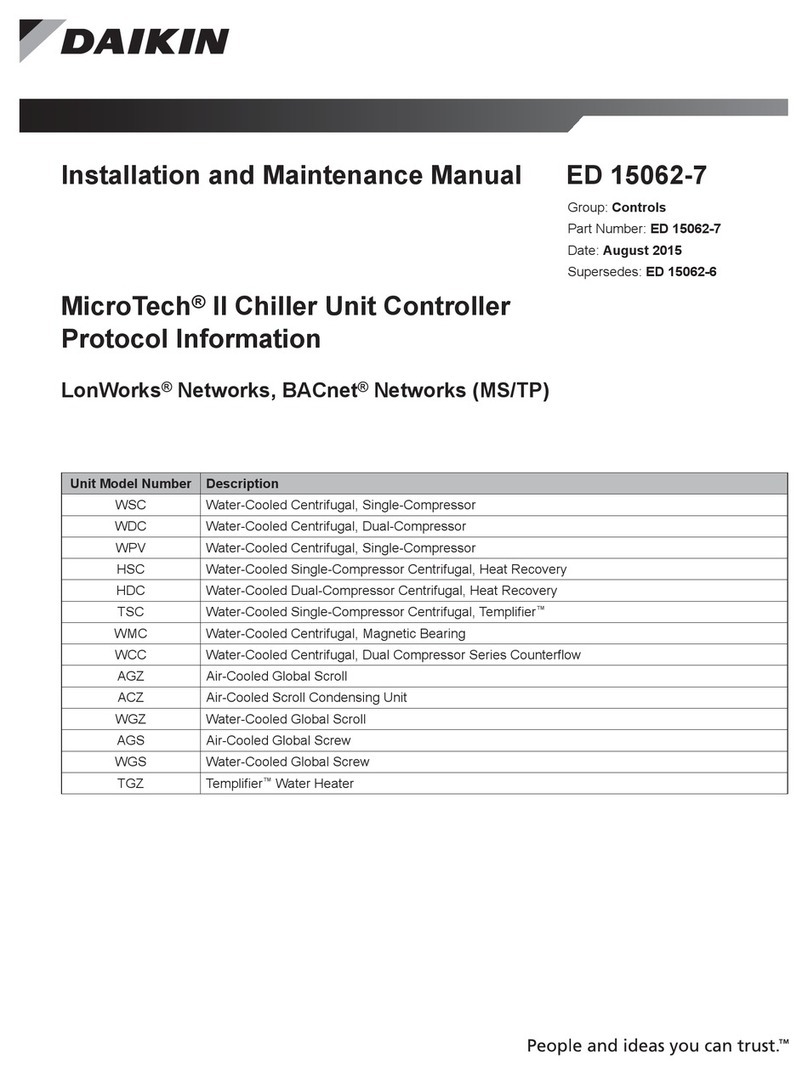

The following section provides a summary of technical data

and conformance to agency listings.

Dimensions 2 ” x 1 ” (60 x 30 mm)

Temperature 32 - 149°F (0 - 65°C)

Humidity <80% RH

Temperature -4 - 158°F (-20 - 70°C)

Humidity <80% RH

Power DC 5 V (+5% / –5%)

Network

Network cable LON interface: Plug-in terminals 2 wires,

interchangeable

Bus connection/

Transceiver Galvanically isolated, 78k baud TP/FT-10 transceiver

data

memory

Network connector 3-pin (GND, A, and B) network connector plug

Ferrite enclosure Snap-on ferrite core as optional attachment to the

network cable for noise reduction

US UL 873

Canada CSA C22.2 No. 24-93