ASTAT XL Service Manual Contents

Contents

1Caution Statements................................................................................................................................. 2

1.1 Electrical Shock Risk ........................................................................................................................................................................................2

1.2 Power-up procedure.......................................................................................................................................................................................3

1.3 Stored charge .....................................................................................................................................................................................................3

1.4 Short circuit..........................................................................................................................................................................................................3

1.5 Disposal Instructions.......................................................................................................................................................................................3

2Functional Tests ....................................................................................................................................... 4

2.1 Power Circuit Test.............................................................................................................................................................................................4

2.2 Start Performance Test..................................................................................................................................................................................4

2.3 Run Performance Test....................................................................................................................................................................................5

2.4 Bypass Contactor Test ...................................................................................................................................................................................5

2.5 Control Input Test .............................................................................................................................................................................................5

2.6 After Repair Tests..............................................................................................................................................................................................5

3Troubleshooting ....................................................................................................................................... 7

3.1 Protection Responses.....................................................................................................................................................................................7

3.2 Trip Messages .....................................................................................................................................................................................................7

3.3 General Faults...................................................................................................................................................................................................11

3.4 SCRs .......................................................................................................................................................................................................................13

4Service Instructions ............................................................................................................................... 14

4.1 QLxxB0023D to QLxxB0053D (G1B).......................................................................................................................................................15

4.2 QLxxB0076D to QLxxB0105D (G1B).......................................................................................................................................................16

4.3 QLxxB0145D to QLxxB0220D (G2B).......................................................................................................................................................17

4.4 QLxxB0255D to QLxxB0425D (G3B).......................................................................................................................................................18

4.5 QLxxX0255D (G3C)..........................................................................................................................................................................................19

4.6 QLxxB0500D to QLxxB1000D (G4B).......................................................................................................................................................20

4.7 QLxxX0360D to QLxxX0930D (G4C).......................................................................................................................................................21

4.8 QLxxX1200D to QLxxX1600D (G5C).......................................................................................................................................................22

5Spare Parts .............................................................................................................................................. 23

5.1 Main Control PCB ............................................................................................................................................................................................23

5.2 Model PCB...........................................................................................................................................................................................................25

5.3 Backplane PCB .................................................................................................................................................................................................26

5.4 Bypass Driver PCB ..........................................................................................................................................................................................27

5.5 SCRs and SCR Connections .......................................................................................................................................................................28

5.6 Power Assemblies...........................................................................................................................................................................................30

5.7 Fans........................................................................................................................................................................................................................31

5.8 Snubber Assemblies ......................................................................................................................................................................................32

5.9 Current Transformers ...................................................................................................................................................................................33

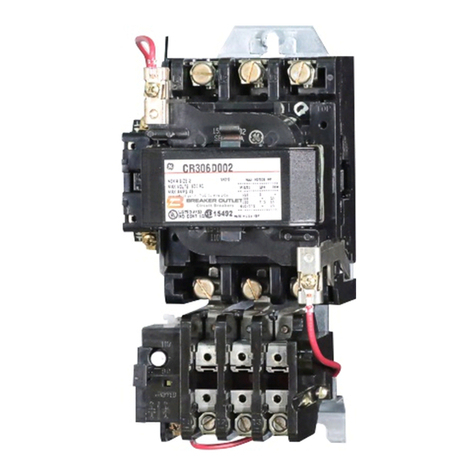

5.10 Bypass Contactors .........................................................................................................................................................................................34

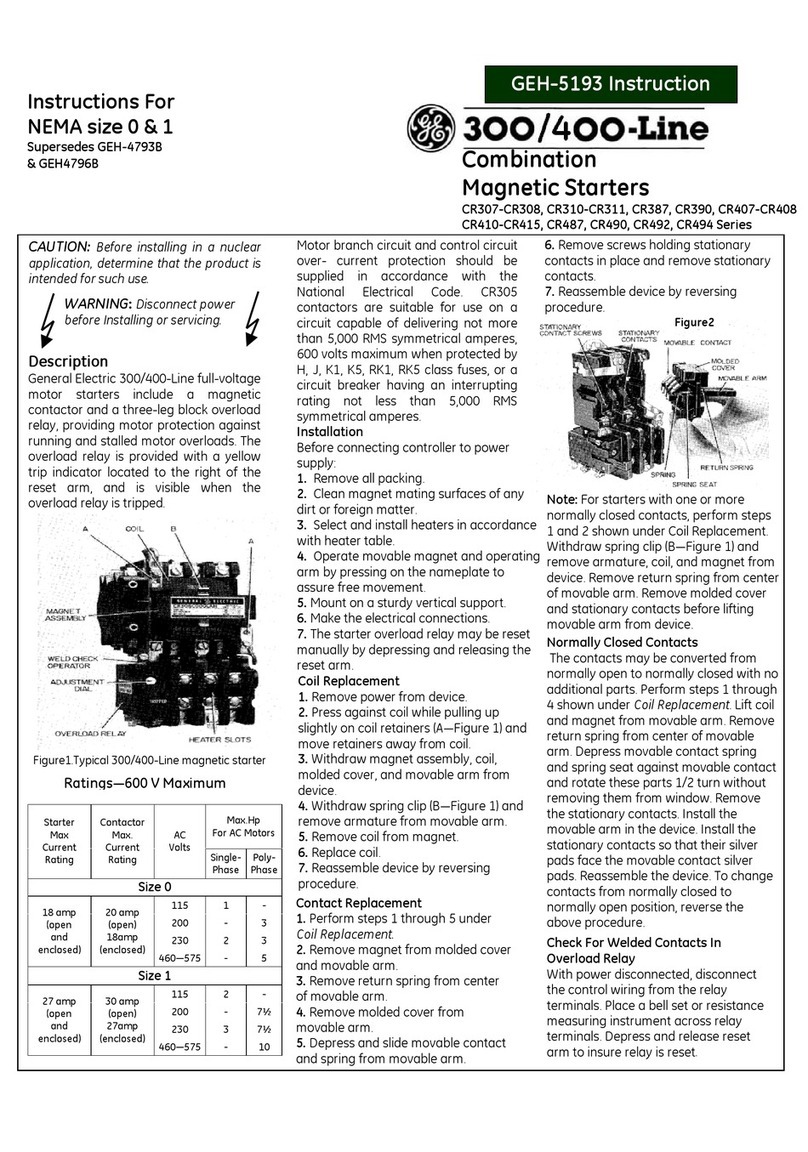

5.11 Plastics..................................................................................................................................................................................................................35

5.12 Busbars ................................................................................................................................................................................................................36

5.13 Other Spare Parts ...........................................................................................................................................................................................38

6Appendix .................................................................................................................................................. 39

6.1 Bolt Tightening Torques...............................................................................................................................................................................39

DET-813 1