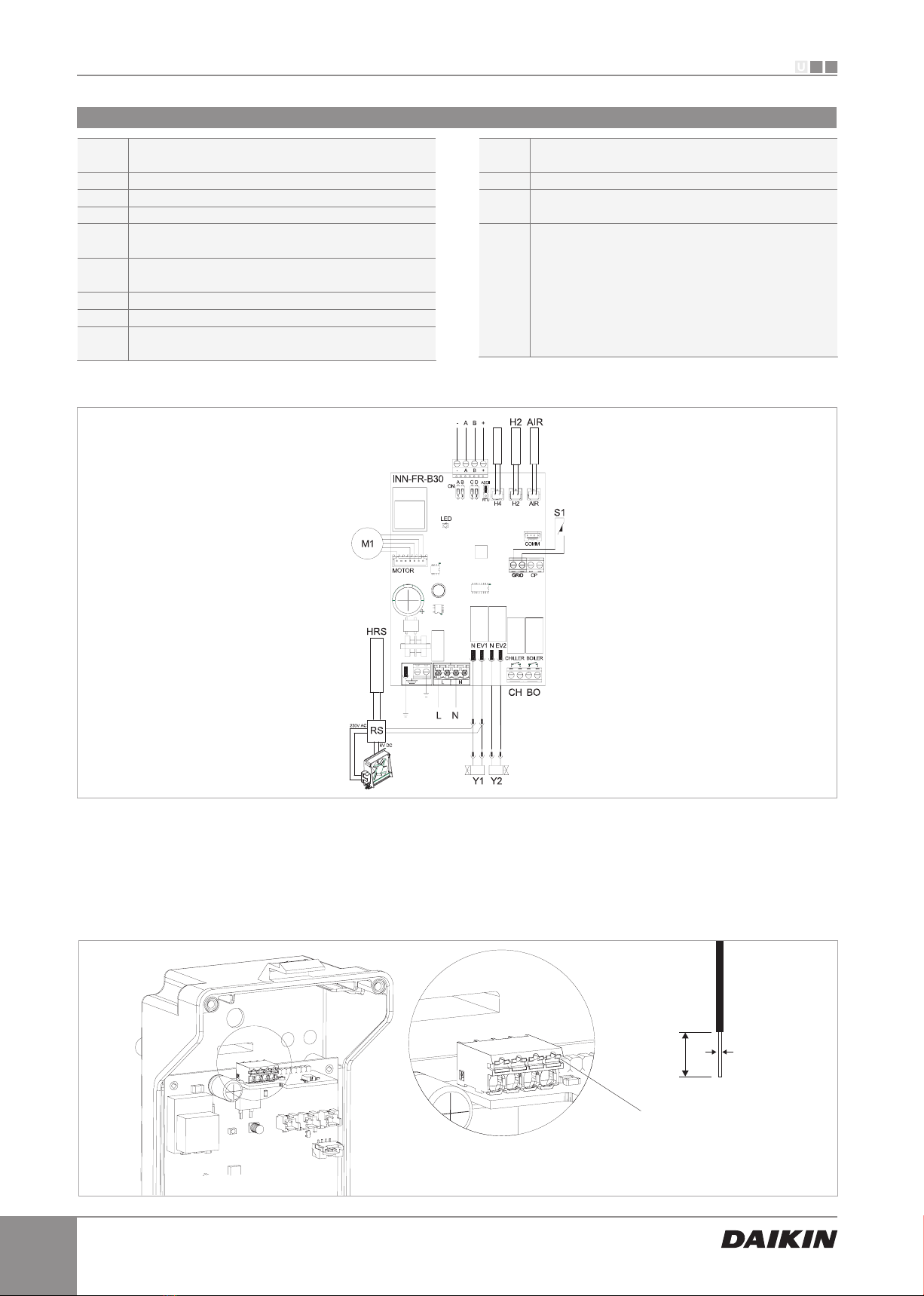

Daikin Altherma EKRTCTRL1 User manual

Other Daikin Heater manuals

Daikin

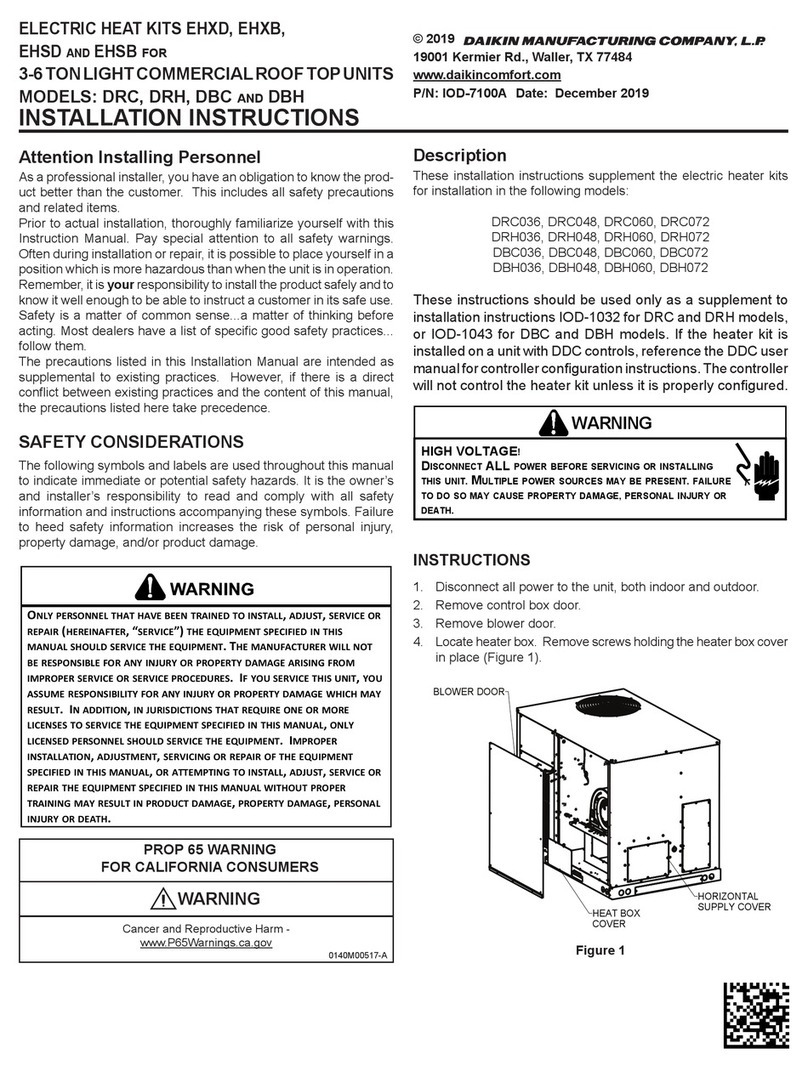

Daikin DRC User manual

Daikin

Daikin EHXD User manual

Daikin

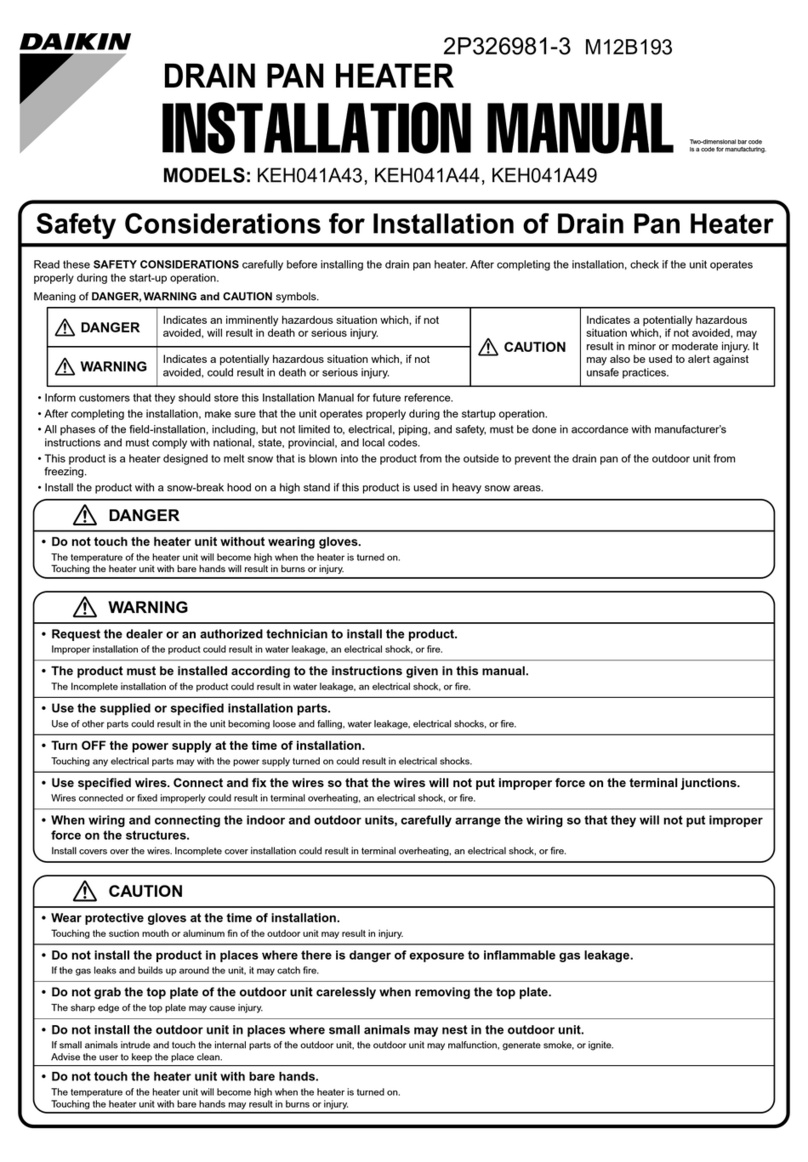

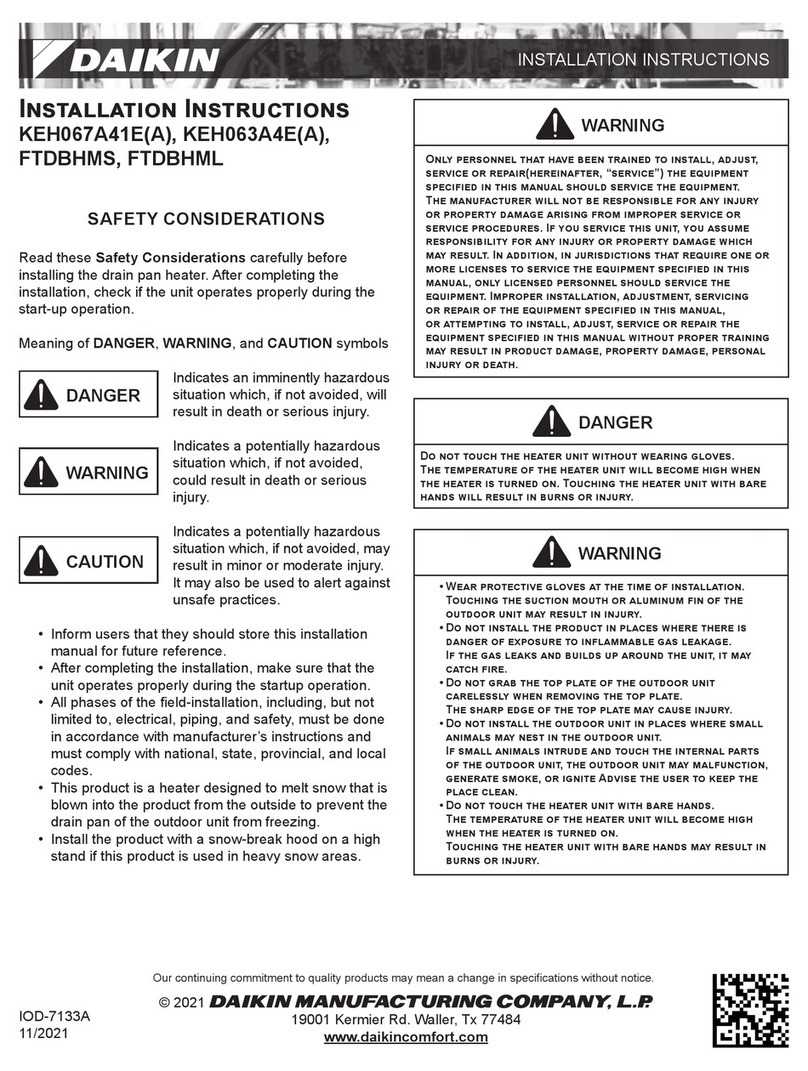

Daikin KEH067A41E(A) User manual

Daikin

Daikin Altherma 3 GEO Product information sheet

Daikin

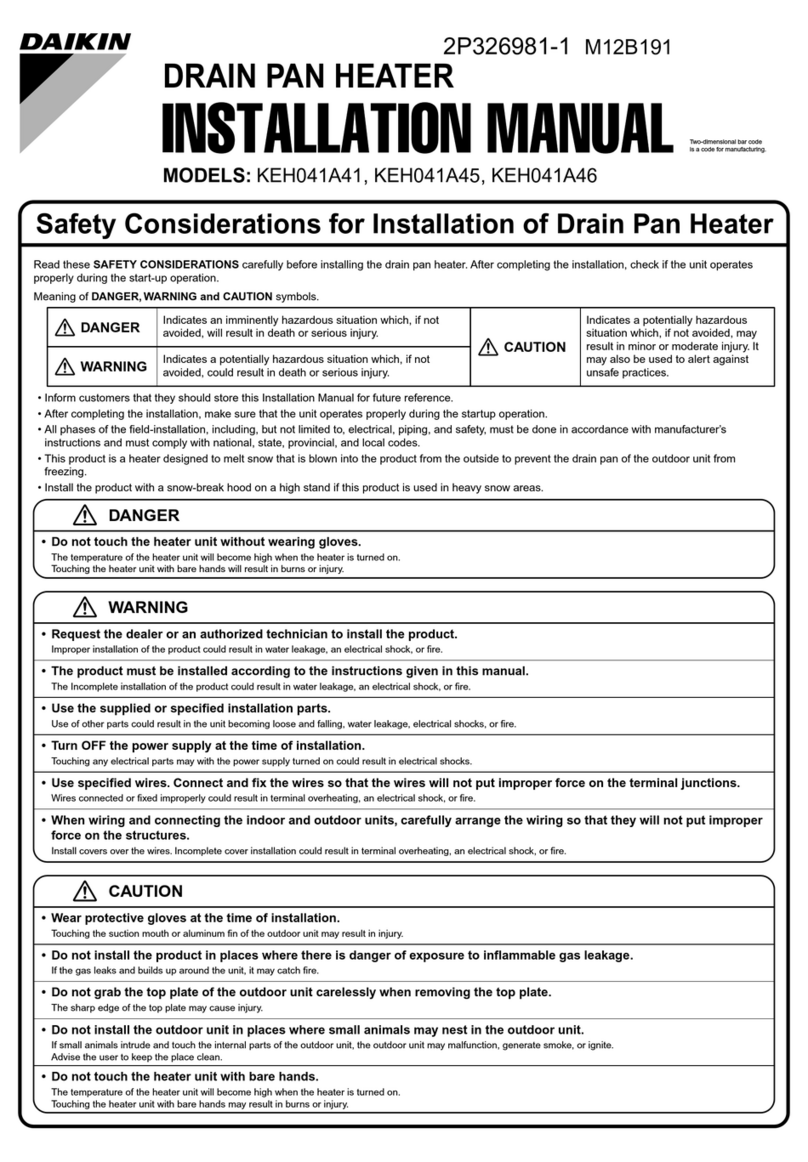

Daikin KEH041A41 User manual

Daikin

Daikin REYQ8-48PY1B User manual

Daikin

Daikin FWXV15AVEB User manual

Daikin

Daikin KEH094A41E User manual

Daikin

Daikin KEH041A42 User manual

Daikin

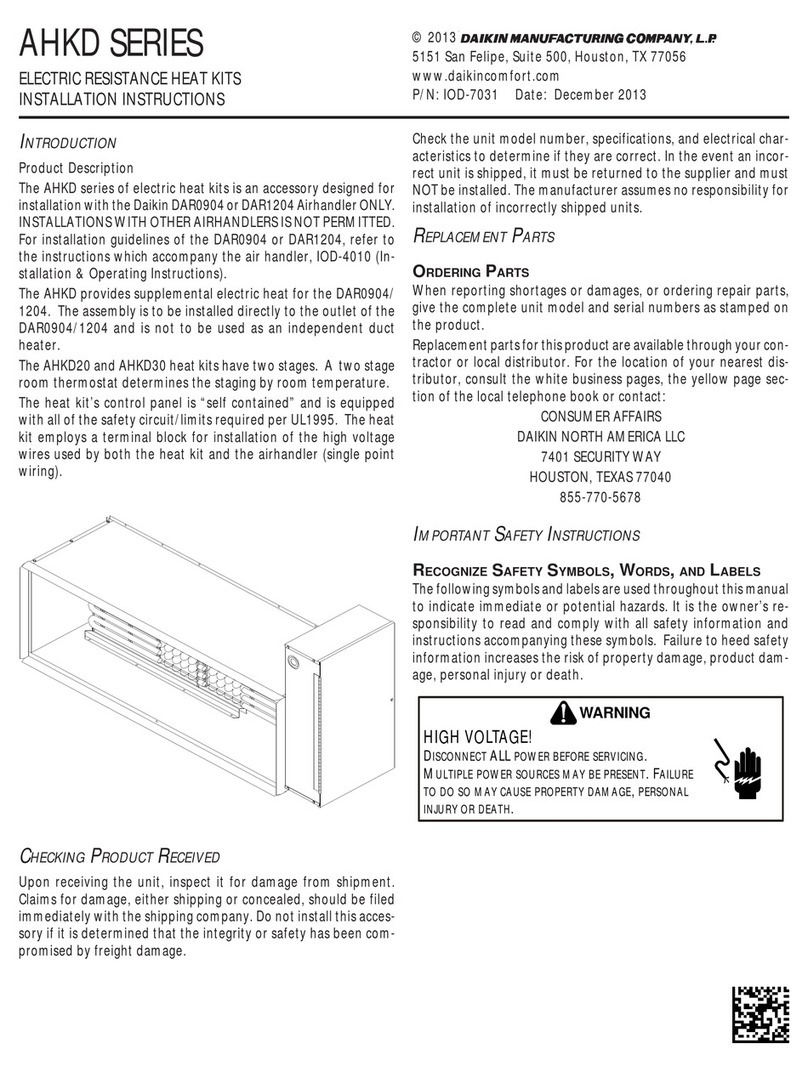

Daikin AHKD 20 User manual

Popular Heater manuals by other brands

oventrop

oventrop Regucor Series quick start guide

Blaze King

Blaze King CLARITY CL2118.IPI.1 Operation & installation manual

ELMEKO

ELMEKO ML 150 Installation and operating manual

BN Thermic

BN Thermic 830T instructions

KING

KING K Series Installation, operation & maintenance instructions

Empire Comfort Systems

Empire Comfort Systems RH-50-5 Installation instructions and owner's manual

Well Straler

Well Straler RC-16B user guide

EUROM

EUROM 333299 instruction manual

Heylo

Heylo K 170 operating instructions

Eterna

Eterna TR70W installation instructions

Clarke

Clarke GRH15 Operation & maintenance instructions

Empire Heating Systems

Empire Heating Systems WCC65 Installation and owner's instructions