137

GB

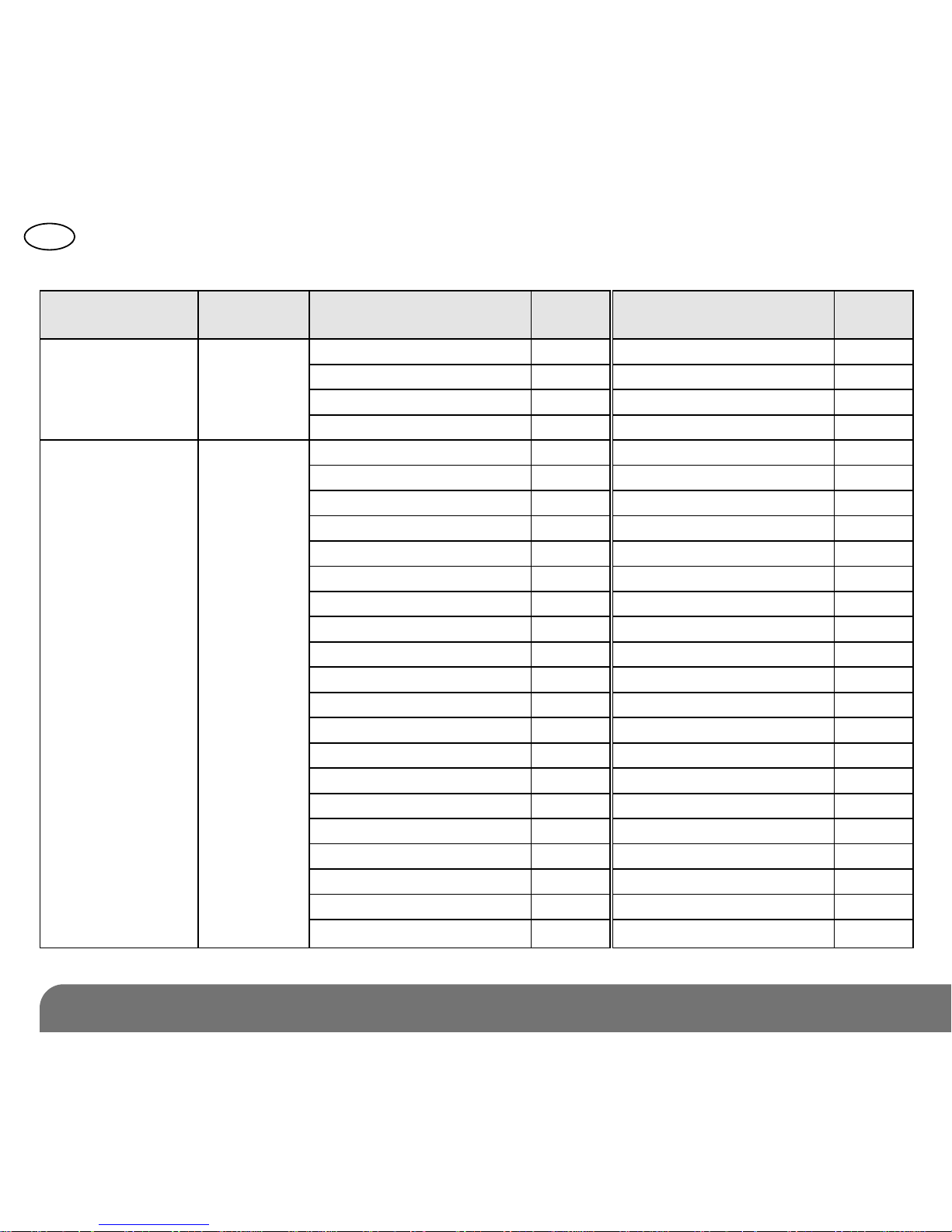

3. D fault configuration

The external universal transmitter is

factory-configured for use with terminal

block n° 1.

If this default configuration is suitable

for the application intended, programme

the transmitter to be recognised by the

control panel.

By default: intrusion detection

application on terminal block n° 1

• type of external sensor: NC (default

parameter value = 7),

• detector type: detector not protecting an

entrance to the home (default parameter

value = 1),

• 90 sec. inhibition after each detection:

inhibition enabled (default parameter

value = 2),

• alarm level: triggering on intrusion (default

parameter value = 1).

4. Appr ntissag

The external universal transmitter is

programmed so that a loop is recognised

by the control panel. According to the

application, each loop will be identified

either as a detector or as a control unit loop.

1. To programme the external universal

transmitter, the control panel must be

in installation mode. If it is not, ask the

user to press the following sequence on

the control panel keypad:

then:

IMPORTANT: in all other cases in which

terminal block n° 1 is used, or when a

technical probe needs to be connected, the

terminal block must first be configured

before being programmed on the control

panel. In this case refer to the Advanced

configuration operations chapter.

IMPORTANT: the control panel indicates

there is an error by emitting 3 short beeps.

When this happens programming should be

carried out again from the start.

IMPORTANT: during recognition program -

ming, the product to be programmed for use

with the control panel does not need to be

placed next to it. In fact, we recommend you

place the product at a short distance from

the control panel (at least 2 meters away).

master code

engineer installer code