MAN#650074:A

The gauge can also be mounted into a Dakota Digital CUP-3001, it will include a mounting block

with a long stainless screw. A bracket for your handle-bar size will also be required. Remove two nuts and

U-clamp from the gauge. Slip the mounting block over the studs and secure it with the two nuts. Once

the cup is mounted to the location of your choosing, and the wires are run through the bottom of the cup

you can slide the HLY-3027 into the cup and secure it with the screw through the tip of the cup.

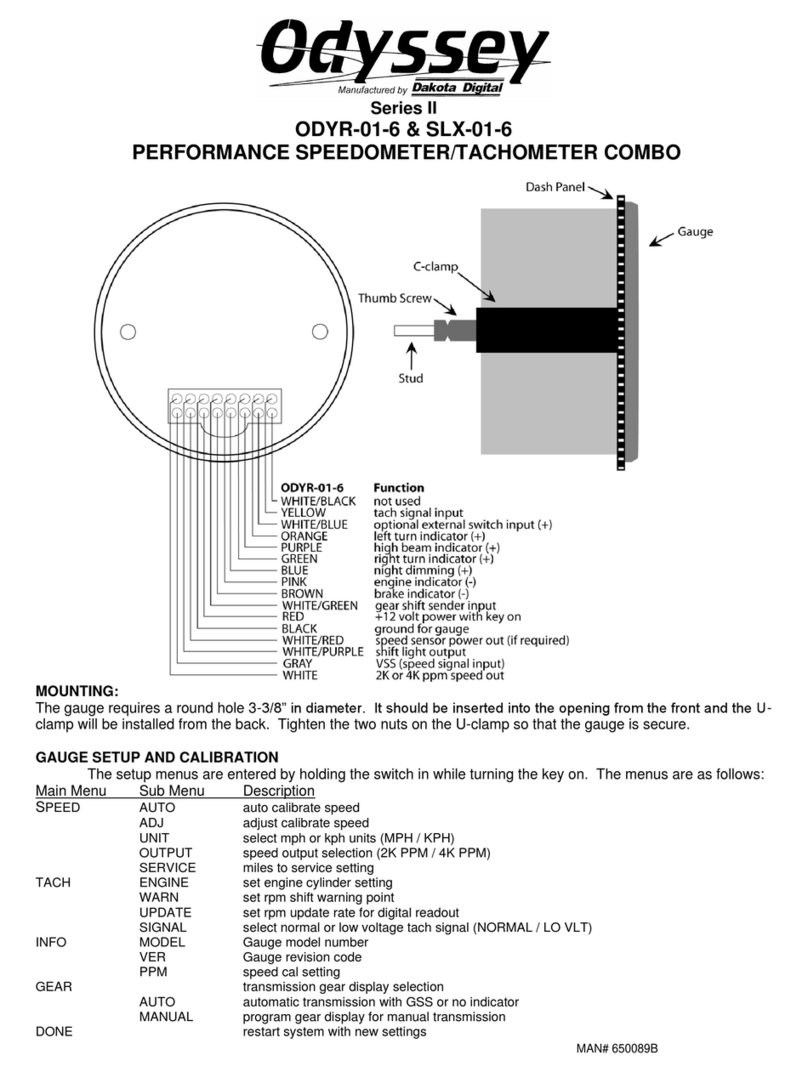

Introduction:

This Odyssey Series II gauge from Dakota Digital, Inc. incorporates the reliability and quality of

our standard gauges, along with several unique features and easy mounting. These features include:

Industry standard 2-1/16” gauge size.

Weather-proof construction.

250-18,000 rpm range with 10 rpm resolution. (100 rpm res. above 10,000)

Adjustable cylinder selection (1-15).

Adjustable warning point to flash the gauge readout.

High rpm recall.

Microprocessor stabilized readings.

Night dimming with lens label lighting.

Non-Glare, high contrast lens

High Visibility VFD display for sunlight readability.

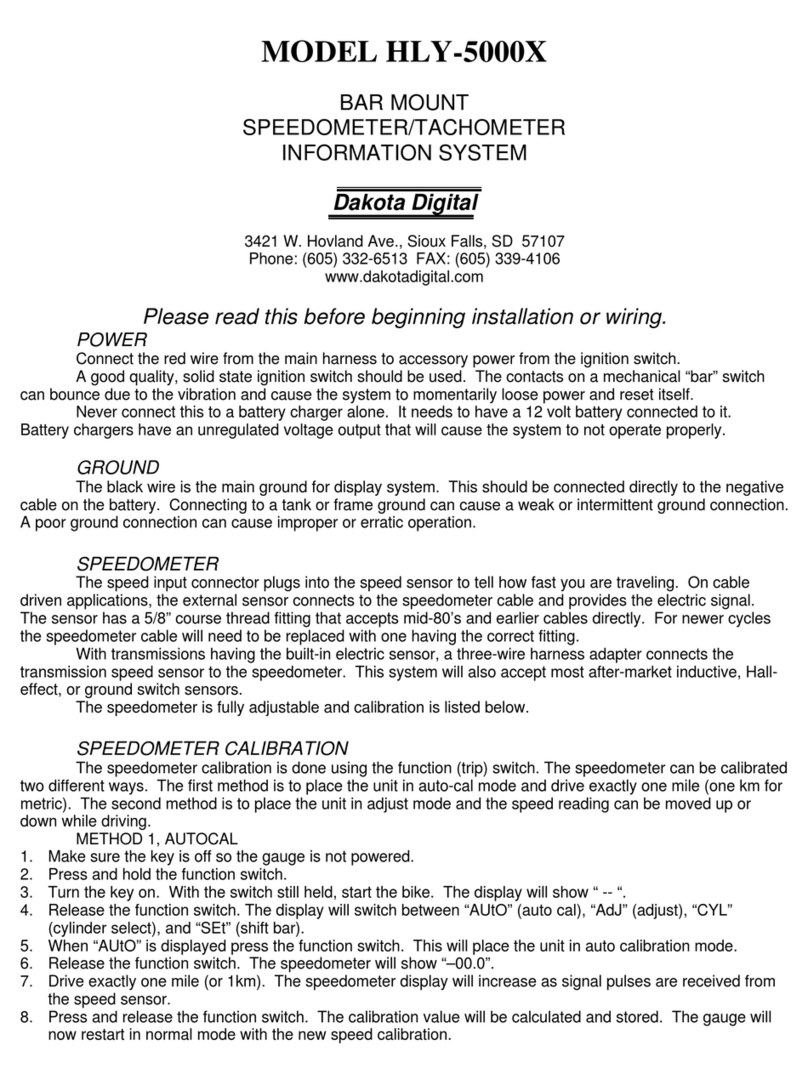

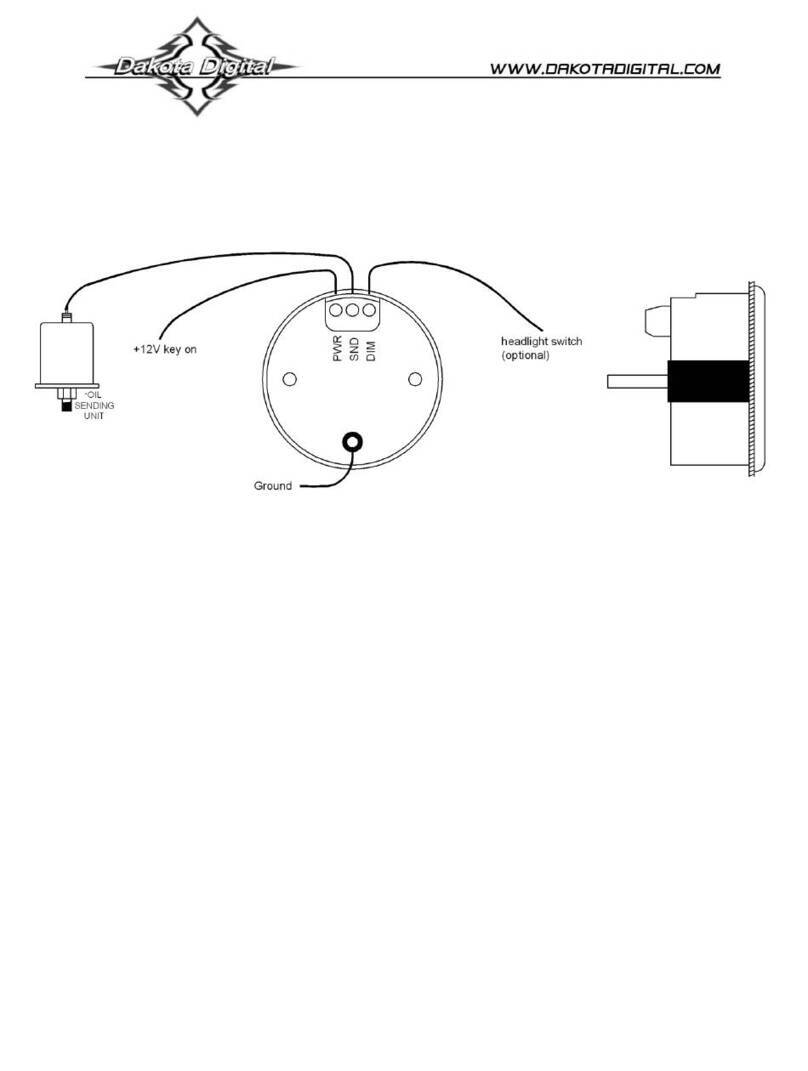

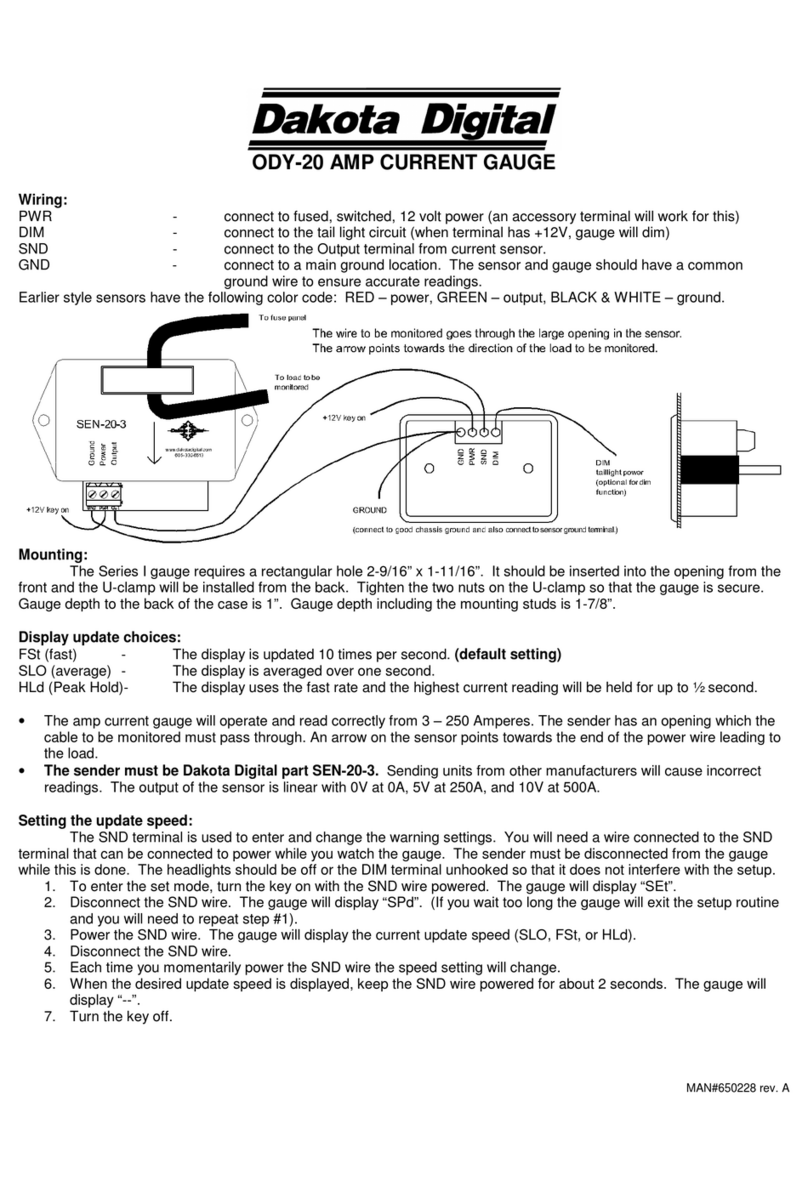

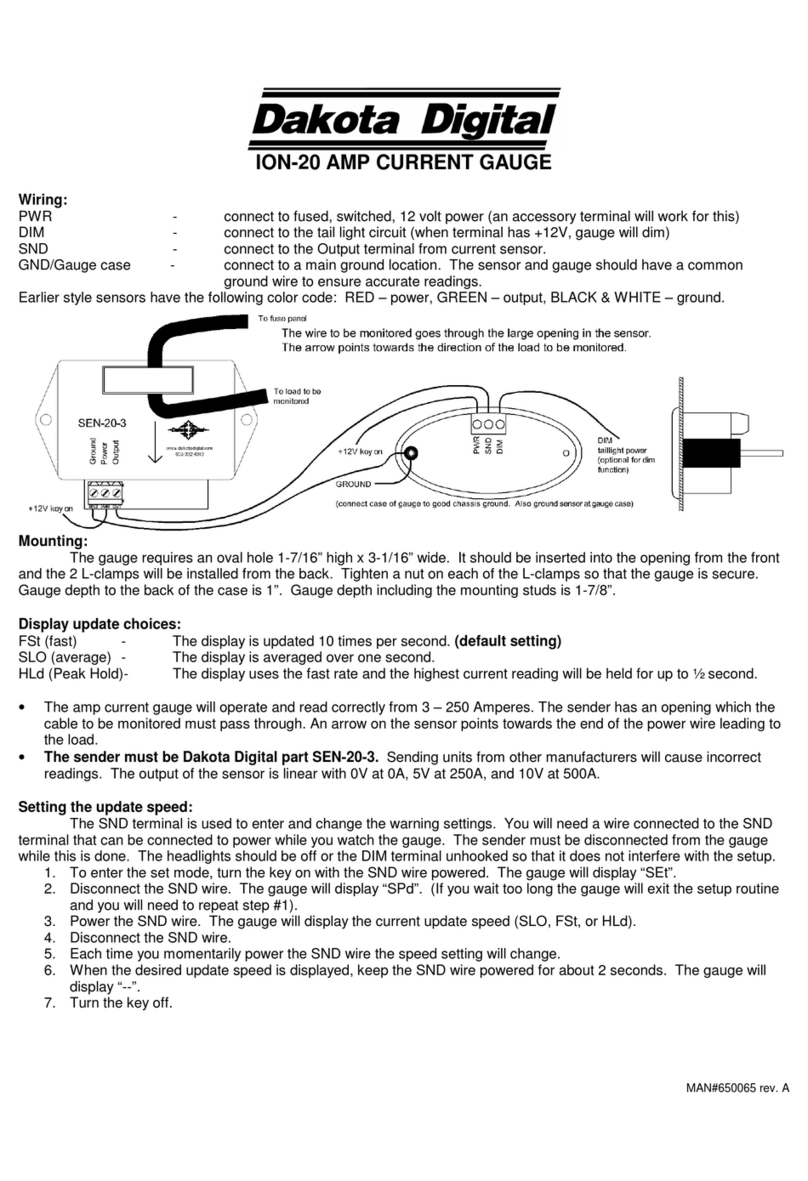

POWER

Connect the red wire from the main harness to accessory power from the ignition switch.

Never connect this to a battery charger alone. It needs to have a 12 volt battery connected to it.

Battery chargers have an unregulated voltage output that will cause the system to not operate properly.

GROUND

The black wire is the main ground for the gauge. A poor ground connection can cause improper

or erratic operation. The black wire loops over to the top screw on the back of the case. This ensures a

good case ground connection.

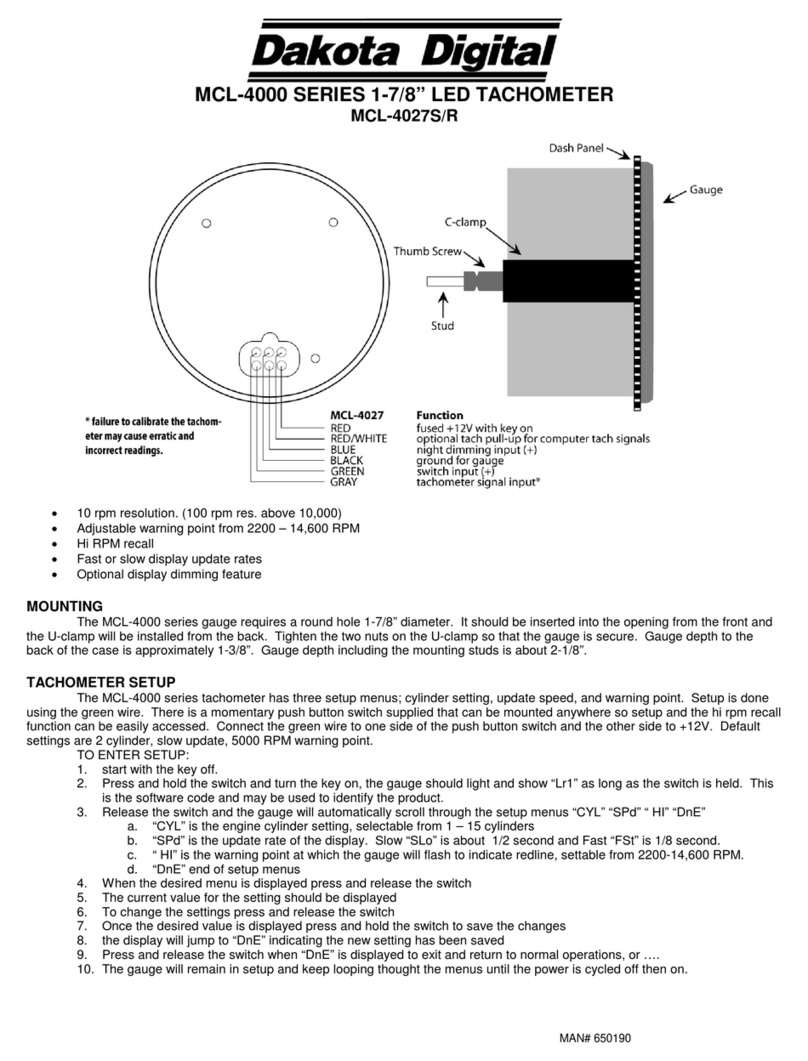

TACHOMETER

The gray wire connects to the vehicle tach signal. On point type and pointless distributors connect

to the negative side of the coil. This will sometimes be labeled TACH or DIST. On distributorless ignition

systems, connect to the tach output wire or to the negative wire of one of the coils.

For tach signals integrated into a vehicle wiring harness, consult a service manual to determine

the color code and location of the tachometer signal. The tachometer signals from some engine

computers require a weak 12 volt pull-up for correct operation of the gauge. Tie the gray and white/red

wires together if this is needed.

The tachometer is adjustable from 1 to 15 cylinder signals and calibration is discussed below.

The gauge displays the engine rpmx10 from 250 –9990 and rpmx1000 for 10,000 –18,000.

2500 rpm would be displayed as “250” and 11,400 rpm would be displayed as “11.4”. The decimal point

indicates the reading has changed from rpmx10 to rpmx1000.

The gauge can be set for a slow update, which changes the displayed reading every ½ second, or

for a fast update, which changes the displayed reading every 1/8 second. The slow update rate is

recommended for most applications since rapidly changing numbers can be difficult to read.

For 2004+ Harley and 2003 V-Rod

The tachometer signal will come from the negative side of the ignition coil. Blue/Orange for the front

cylinder, Yellow/Blue for the rear cylinder, connect the tachometer input to only one of these two wires, set the

tachometer for a 1 cylinder signal, refer to Steps 4 through 7 of the setup procedure.

FUNCTION SWITCH/RECALL HIGH RPM

The function switch is connected with one wire to a 12 volt source and the other wire to the green

wire from the tachometer harness. The function switch is used for calibration and to recall the highest rpm

reached since the last reset. Pressing the function switch while the gauge is running will display “HI” and

then the current high rpm. This will repeat every 2 seconds. Holding the function switch for 8 seconds will

reset the high rpm.

The high rpm recall is updated every 1/8 second regardless of the display update rate. This

allows it to catch the highest rpm which might be missed at the slow update rate.