– i –

Table of Contents

1 Introduction.........................................1

How to Use This Manual ............................1

General Summary .....................................2

Operation ...................................................2

2 Component Description and Theory

of Operation........................................3

Sign Controller............................................3

LED Modules...............................................4

LED Diagnostics..........................................4

Power Supplies ...........................................4

Cooling .......................................................4

Light Sensors ...............................................4

3 Mechanical Installation .....................5

Lifting the Sign ............................................5

Mounting Methods ....................................5

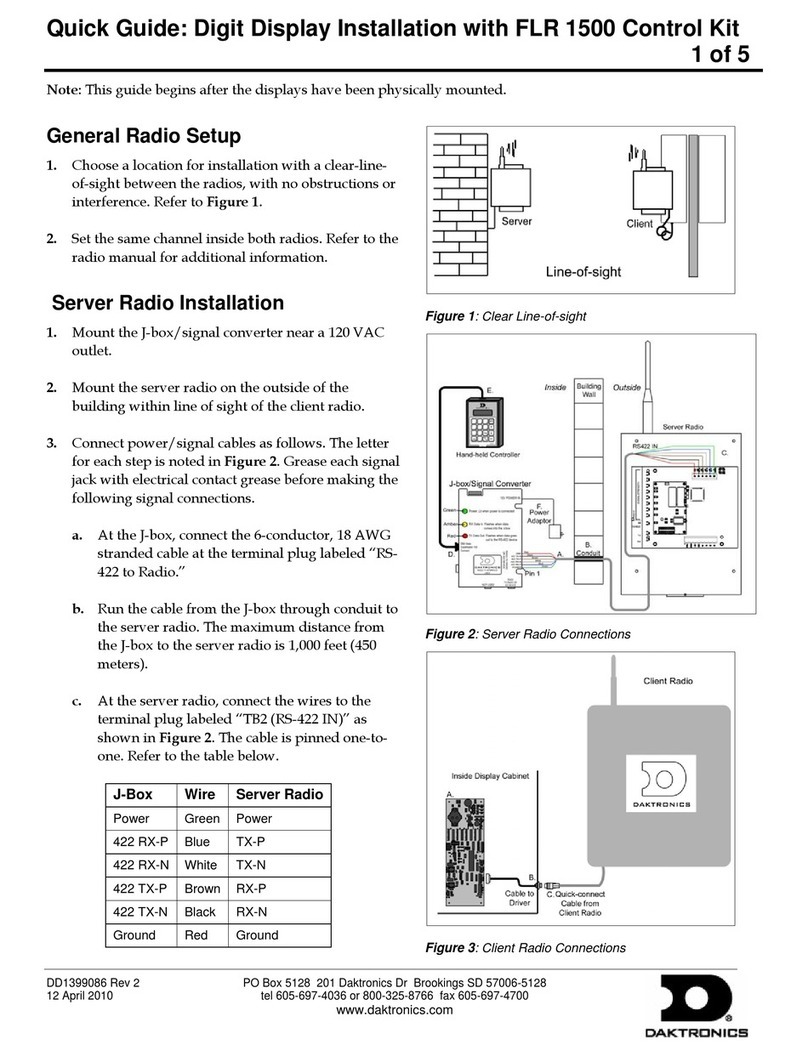

4 Electrical Installation ..........................6

Getting Started ..........................................6

Conduit.......................................................6

Grounding ..................................................6

Power Installation.......................................7

Sign Communication ................................7

Default Speeds ..........................................7

Conduit Sealing ........................................7

First Time Turn On ......................................7

5 Maintenance and Troubleshooting ..8

Getting Started ..........................................8

Service and Diagnostics ...........................8

Sign Controller Replacement...................8

Accessing the Internal Components ......9

Replacing a Module .................................9

Replacing a Power Supply .......................9

Ventilation Systems (With Fans and

Filters) ........................................................10

Replacing a Ventilation Fan...................10

Routine/Preventative Maintenance ....11

Sign Cabinet Inspection .....................11

Sign Controller ......................................11

Structural Inspection ...........................11

Photo Sensor Assembly Inspection ....11

LED Cleaning.........................................11

Ventilation System Inspection.............11

Routine/Preventative Maintenance

Checklist ..................................................12

Troubleshooting of the Variable Speed

Limit Sign ...................................................12

6 Replacement Parts and Repair &

Exchange Programs .........................14

Daktronics Exchange and Repair and

Return Programs ......................................14

Exchange Program ..............................14

Before Contacting Daktronics.............14

Repair & Return Program........................15

Shipping Address..................................16

E-mail.....................................................16