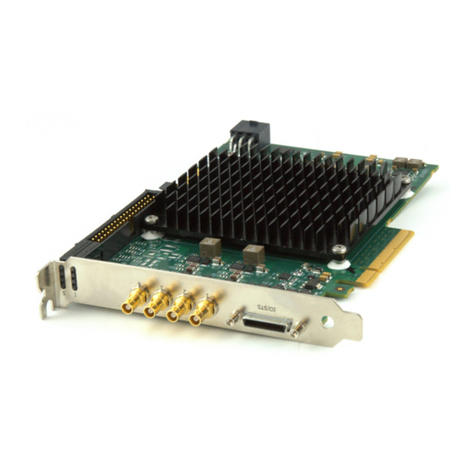

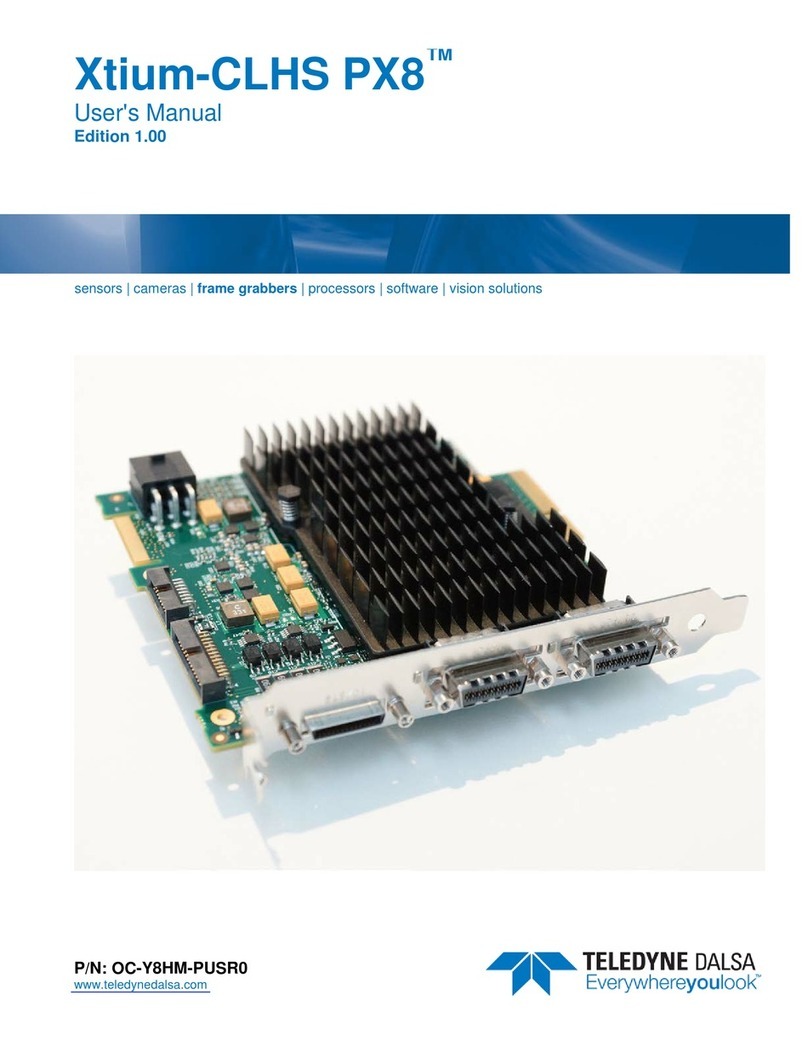

Xtium-CL PX4 User's Manual Overview

7

About the Xtium-CL PX4 Frame Grabber

Series Key Features

•Compliant with Camera Link specification version 2.0

•Uses a PCIe x4 Gen2 slot to maximize transfers to host computer buffers

•Acquire from Monochrome, RGB, Bayer and Bi-Color cameras, both area scan and linescan

•Supports multiple tap formats, in multiple pixels depths

•Pixel clock range from 20 to 85 MHz

•Output lookup tables

•White Balance Gain for RGB pixels

•Vertical and Horizontal Flip supported on board

•External Input Triggers and Shaft Encoder inputs, along with Strobe outputs

•Supports a number of acquisition events in compliance with "Trigger to Image Reliability"

•RoHS compliant

•Supports Power Over Camera Link (PoCL)

See “Technical Specifications” on page 60 for detailed information.

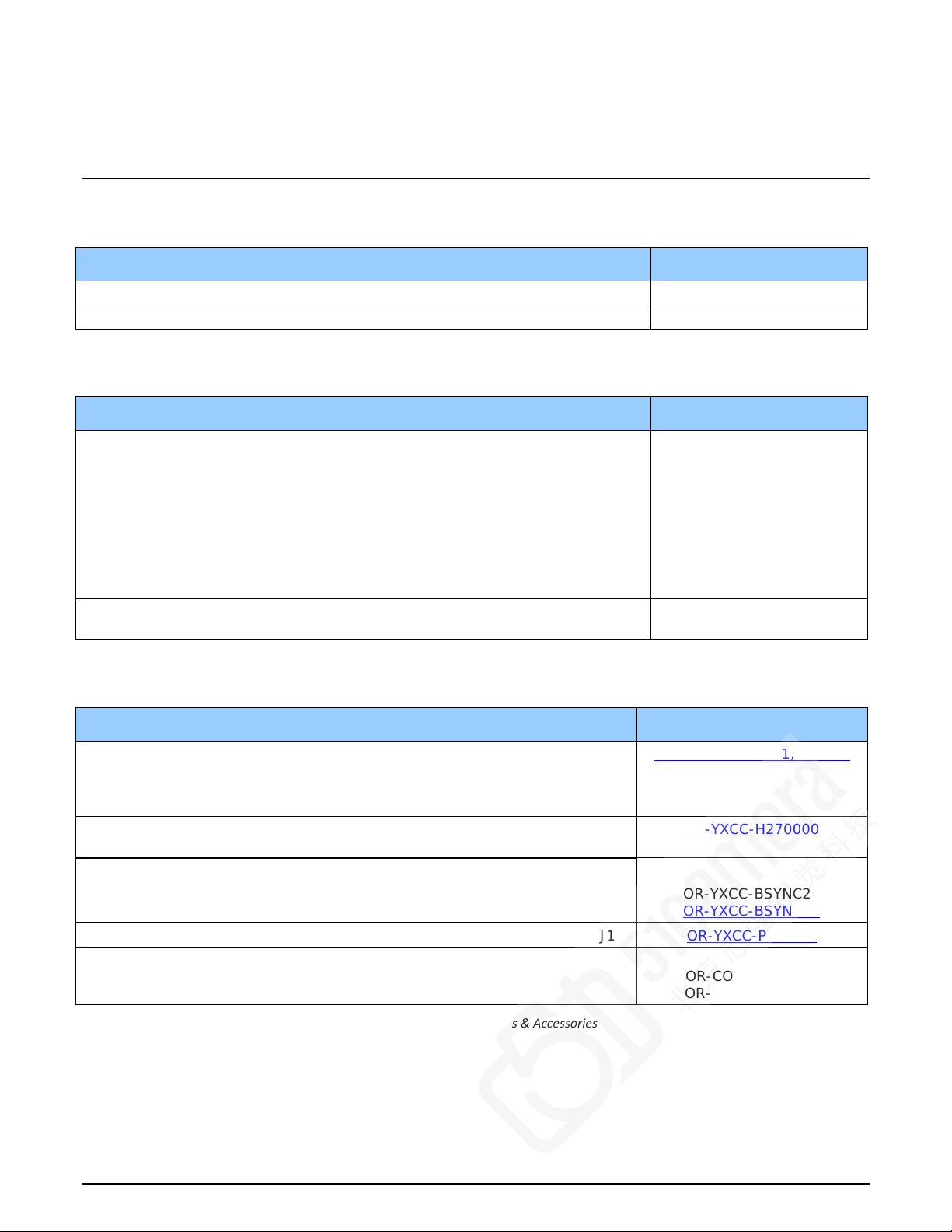

User Programmable Configurations

Use the Xtium-CL PX4 firmware loader function in the Teledyne DALSA Device manager utility to

select firmware for one of the supported modes. Firmware selection is made either during driver

installation or manually later on (see "Firmware Update: Manual Mode" on page 11).

Full Configurations: Firmware choices are:

•One Full Camera Link Input with up to 8 Taps parallel (installation default selection):

Support for 1 Base, 1 Medium or 1 Full Camera Link camera, 1 tap segmented, 2 taps

alternate, or 2/3/4/8 taps parallel — monochrome.

•Support for 1 Base or 1 Medium Camera Link camera, 1 tap and 2 taps parallel RGB.

•One Full Camera Link Bayer Input with up to 8 Taps parallel:

Support for 1 Base, 1 Medium or 1 Full Camera Link Bayer camera, 1 tap segmented, 2 taps

alternate, or 2/3/4/8 taps parallel. Note that horizontal flipping is not available with this

configuration.

•One 80-bit Camera Link Input:

Support for one 10 Tap @ 8-bit monochrome, one 8 Tap @ 10-bit monochrome camera, one

80-bit packed RGB, or one 80-bit packed Bi-Color camera.

•One 80-bit Camera Link Bayer Input:

Support for one 10 Tap @ 8-bit Bayer camera or one 8 Tap @ 10-bit Bayer camera. Note that

horizontal flipping is not available with this configuration.

ACUPlus: Acquisition Control Unit

ACUPlus consists of a grab controller, one pixel packer, and one time base generator. ACUPlus

delivers a flexible acquisition front end and supports pixel clock rates of up to 85MHz.

ACUPlus acquires variable frame sizes up to 64KB per horizontal line and up to 16 million lines per

frame. ACUPlus can also capture an infinite number of lines from a line scan camera without losing

a single line of data.