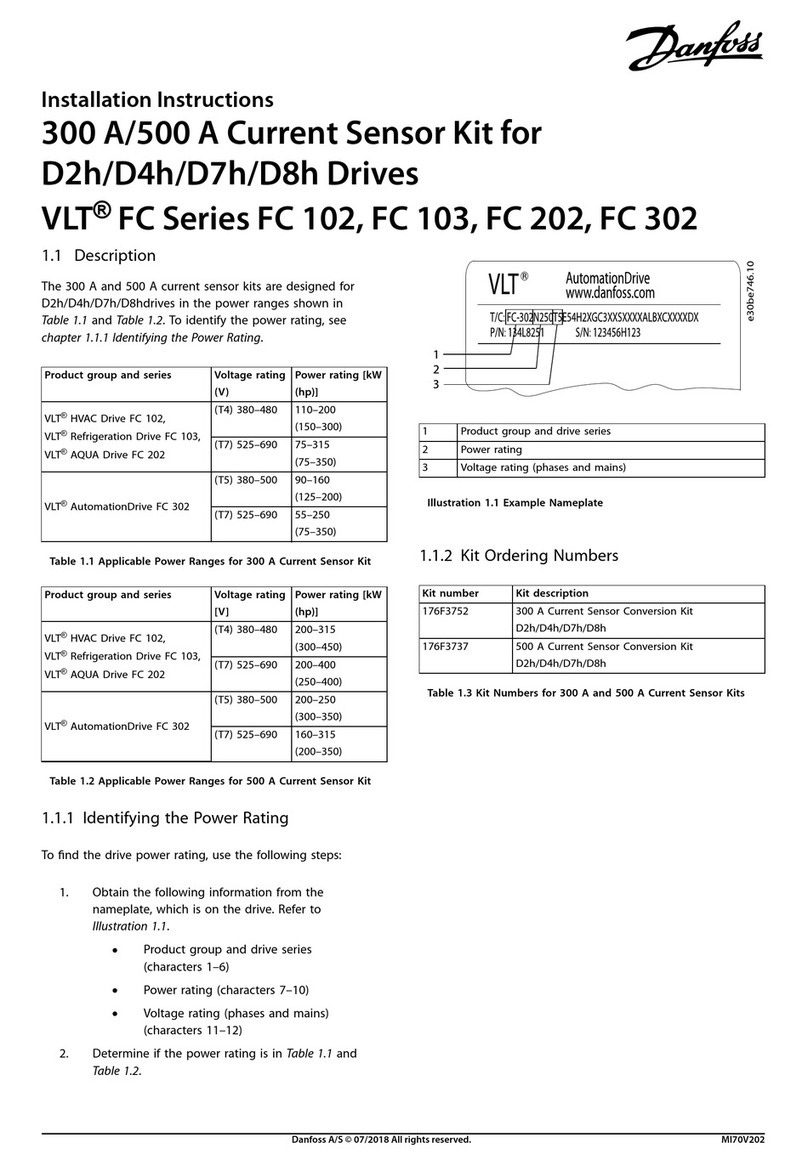

1.

-

-

-

-

-

-

-

-

-

-

-

2 Disassembly

2.1 Safety Information

NOTICE

QUALIFIED PERSONNEL

Only qualified personnel are allowed to install the parts described in these installation instructions.

Disassembly and reassembly of the drive must be done in accordance with the corresponding service guide.

Use the standard fastener torque values in the service guide, unless the torque value is specified in these instructions.

WARNING

ELECTRICAL SHOCK HAZARD

VLT® FC series drives contain dangerous voltages when connected to mains voltage. Improper installation, and installing or serv-

icing with power connected, can cause death, serious injury, or equipment failure.

Only use qualified electricians for the installation.

Disconnect the drive from all power sources before installation or service.

Treat the drive as live whenever the mains voltage is connected.

Follow the guidelines in these instructions and local electrical safety codes.

WARNING

DISCHARGE TIME (20 MINUTES)

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait 20 minutes after power has been removed before performing service or repair work can result in death or serious

injury.

Stop the motor.

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

DC-link connections to other drives.

Wait 20 minutes for the capacitors to discharge fully before performing any service or repair work.

Measure the voltage level to verify full discharge.

NOTICE

ELECTROSTATIC DISCHARGE

Electrostatic discharge can damage components.

Ensure discharge before touching internal drive components, for example by touching a grounded, conductive surface or by

wearing a grounded armband.

2.2 Removing the AC Input Busbars

To remove the AC input busbars, use the following steps. The AC input busbars can look different when the drive includes extra

input options, such as an RFI filter or AC fuses. Illustration 1 shows the AC input busbars with no input options. Illustration 2 shows

the AC input busbars with optional RFI filter and AC fuses.

Procedure

Remove the air baffle by removing 4 screws (T25) and 2 lower screws (T40).

If the brake option is present, there are no lower screws.

AN275538690239en-000101 / 130R0721 | 3Danfoss A/S © 2022.11

Disassembly

300 A Current Sensor Kit for D1h/D3h/D5h/D6h Drives

Installation Guide