Danfoss Series 90 User manual

Other Danfoss Controllers manuals

Danfoss

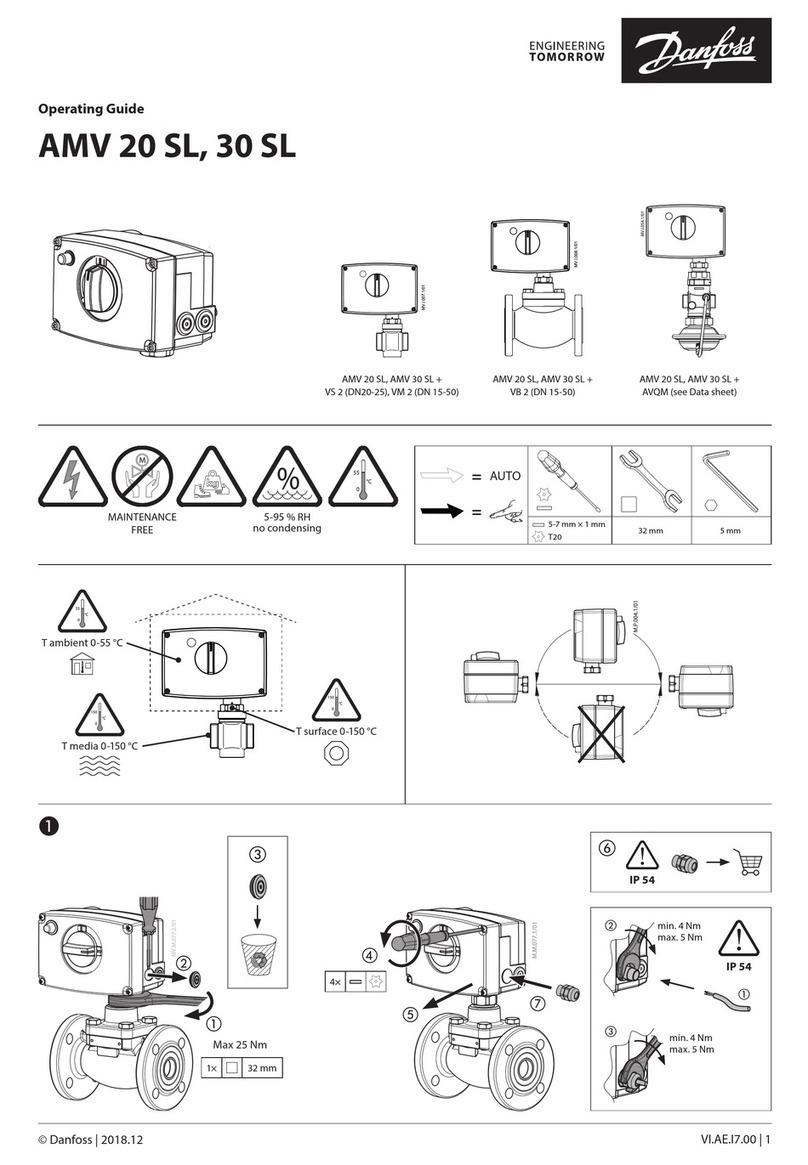

Danfoss AMV 20 SL User manual

Danfoss

Danfoss VLT MCD 201 User manual

Danfoss

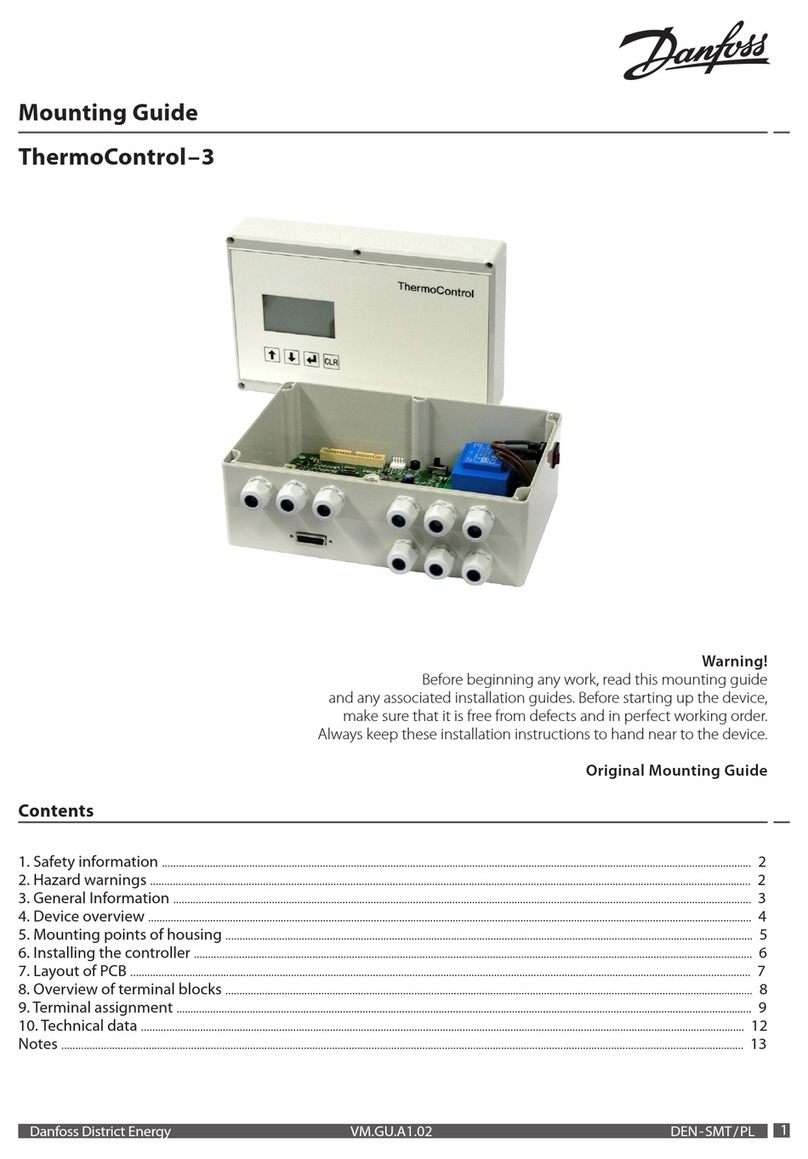

Danfoss ThermoControl-3 Installation instructions manual

Danfoss

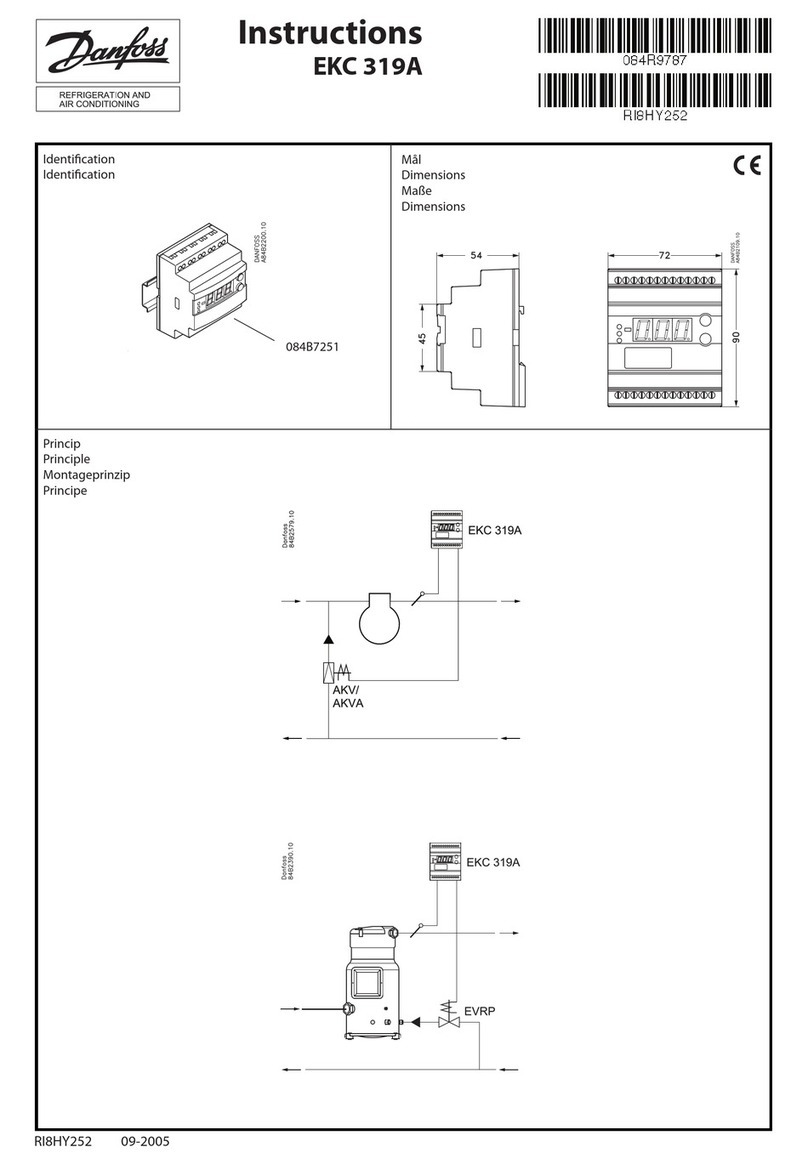

Danfoss EKC 319A User manual

Danfoss

Danfoss ERC 112D User manual

Danfoss

Danfoss CCR3+ User manual

Danfoss

Danfoss VLT HVAC Drive FC 102 User manual

Danfoss

Danfoss Old ICAD 600 series User manual

Danfoss

Danfoss EKC 202D User manual

Danfoss

Danfoss VLT AutomationDrive FC 301 User manual

Danfoss

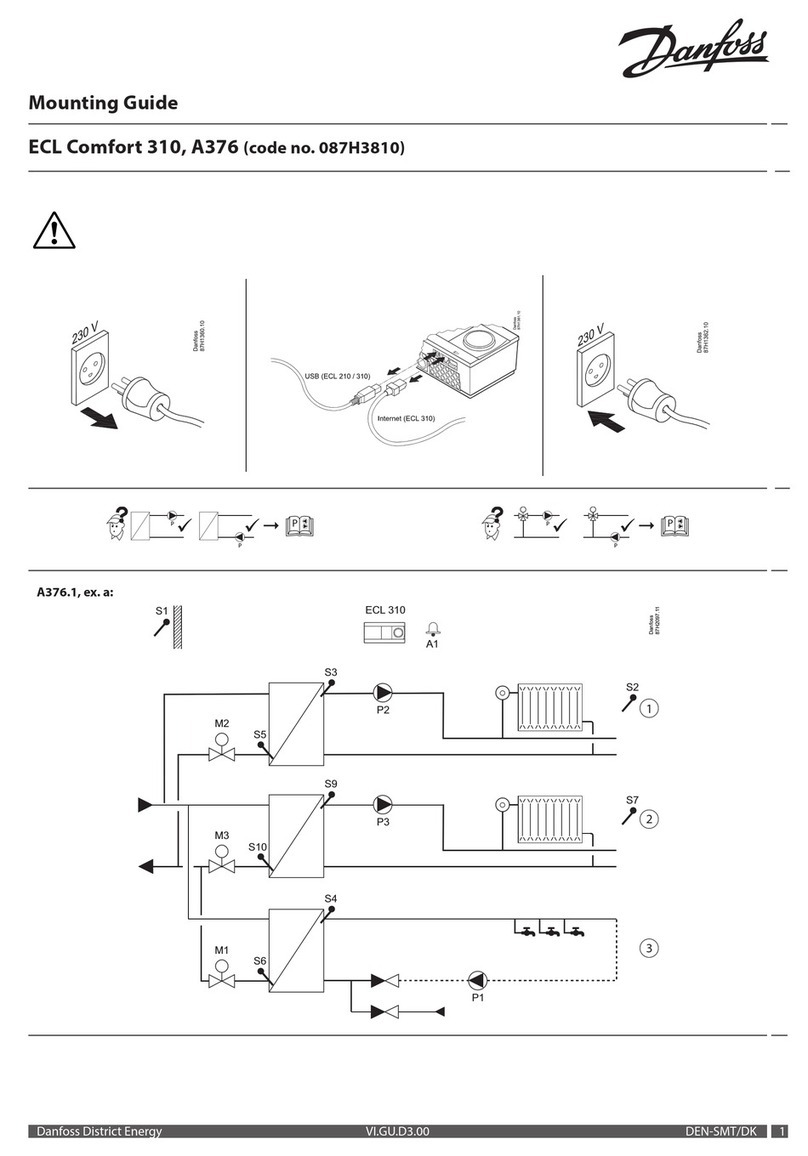

Danfoss A376 Series Installation instructions manual

Danfoss

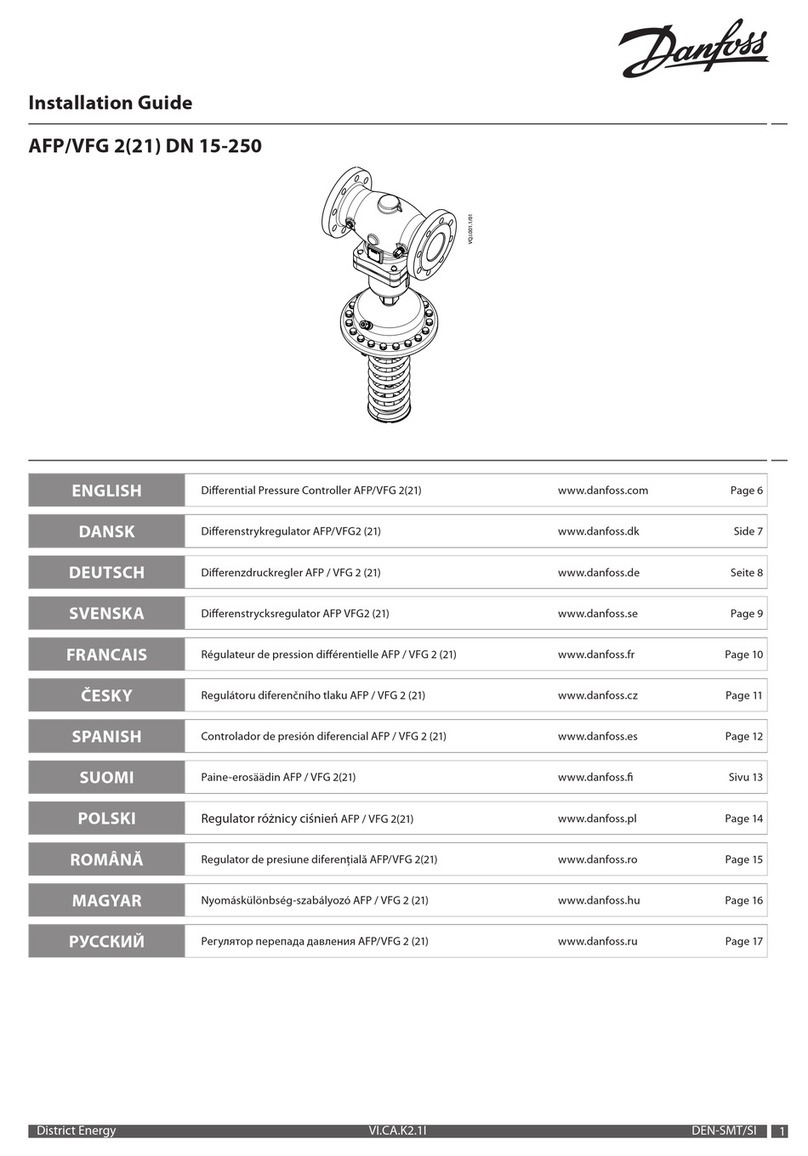

Danfoss AFP Series User manual

Danfoss

Danfoss ERC 213 User manual

Danfoss

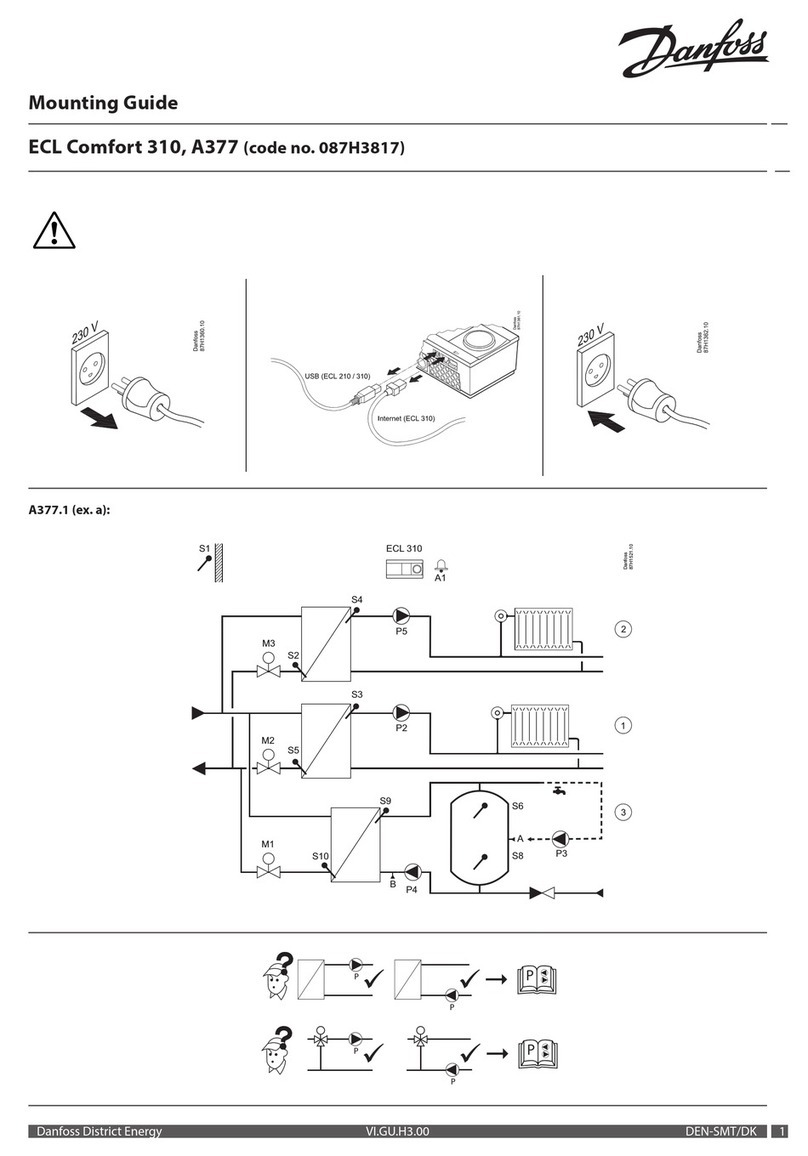

Danfoss A377.1 Installation instructions manual

Danfoss

Danfoss PLUS+1 Series Manual

Danfoss

Danfoss ICAD 600A User manual

Danfoss

Danfoss ECL Comfort 296 User manual

Danfoss

Danfoss EKE 1A User manual

Danfoss

Danfoss VLT AutomationDrive FC 302 User manual

Danfoss

Danfoss ISD Encoder Box User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions