Danfoss ERC 213 User manual

Other Danfoss Controllers manuals

Danfoss

Danfoss AK-CC55 User manual

Danfoss

Danfoss AMD 613 User manual

Danfoss

Danfoss 140F1089 User manual

Danfoss

Danfoss MCA 123 POWERLINK User manual

Danfoss

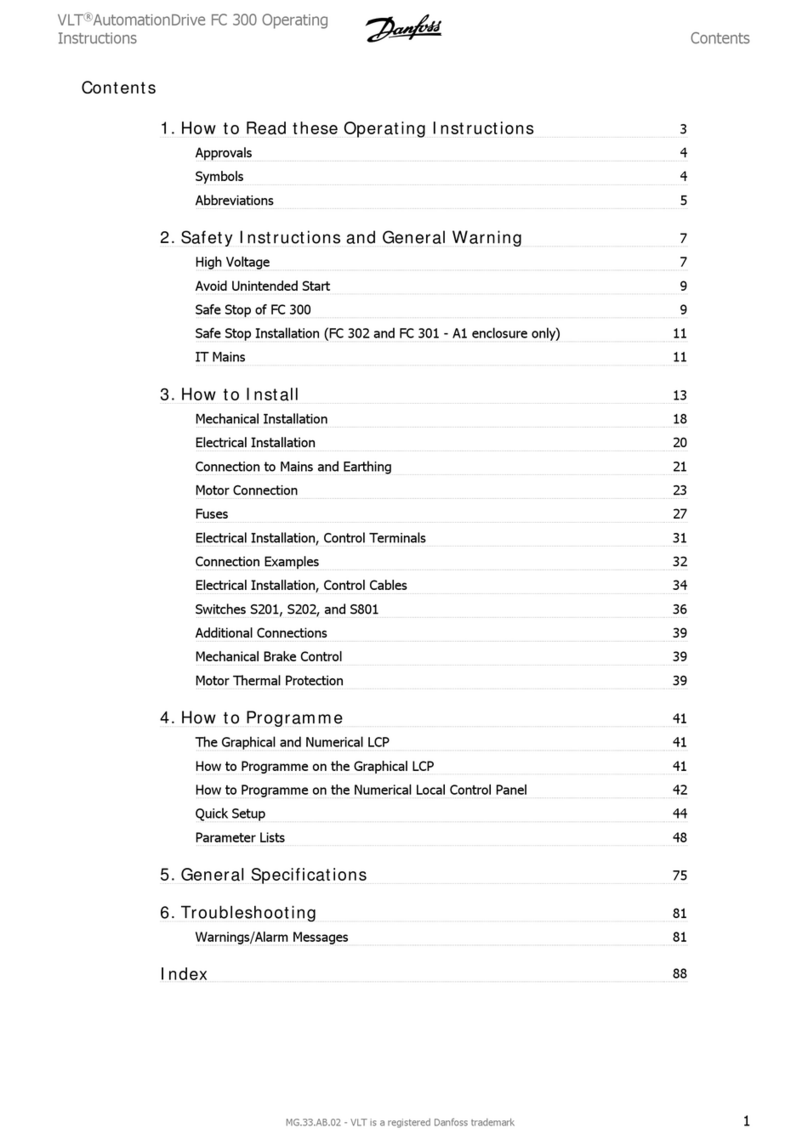

Danfoss VLT AutomationDrive FC 300 User manual

Danfoss

Danfoss DEVIreg Multi User manual

Danfoss

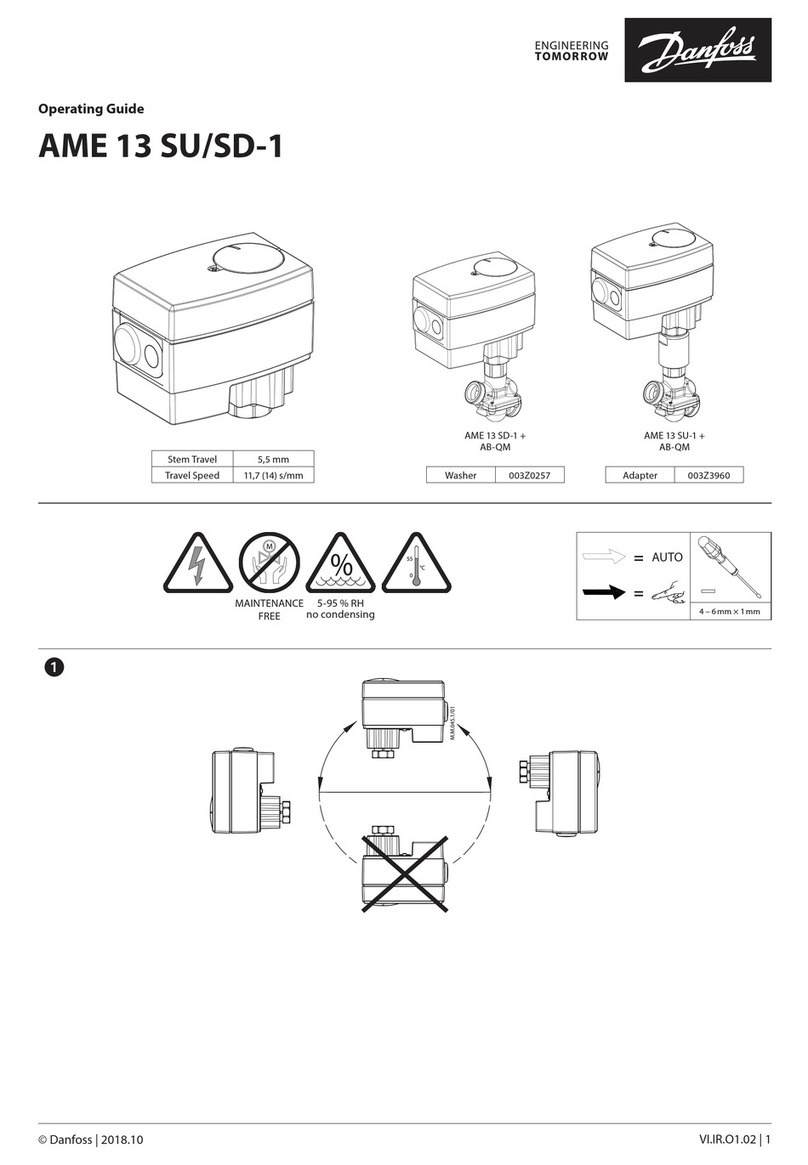

Danfoss AME 13 SU-1 User manual

Danfoss

Danfoss PVE 4 Series User manual

Danfoss

Danfoss NovoCon S Digital User manual

Danfoss

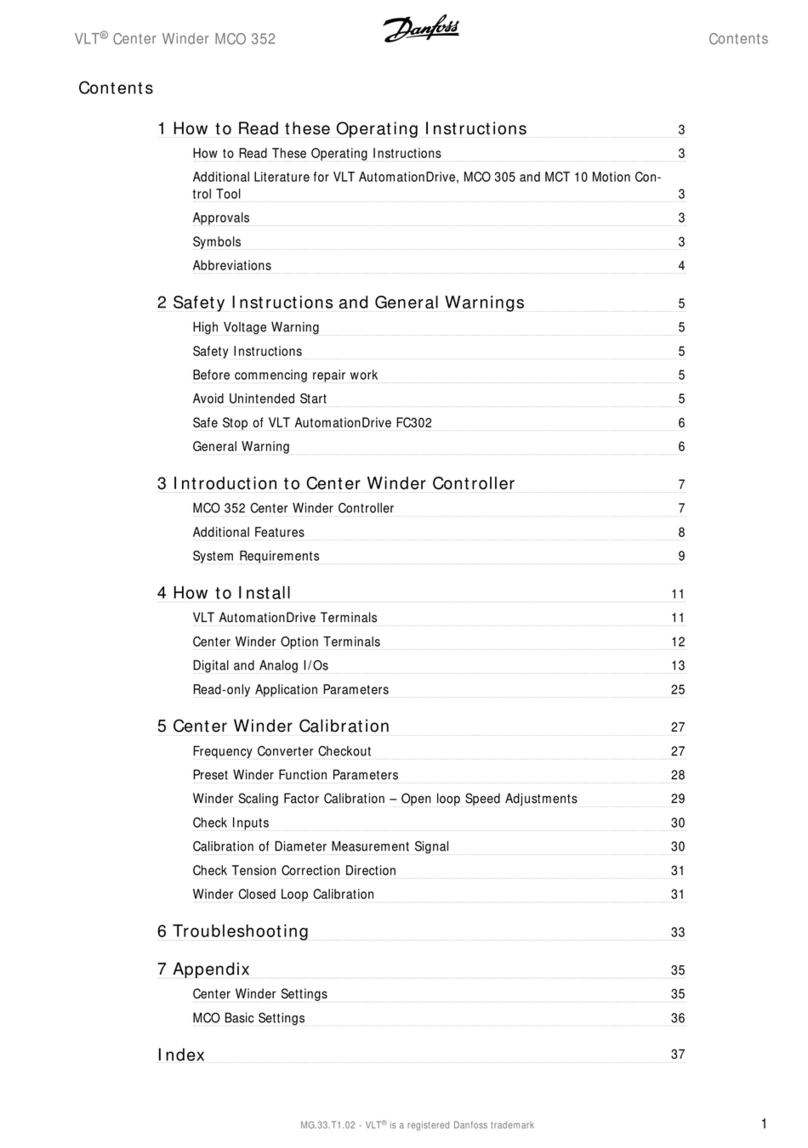

Danfoss VLT Center Winder MCO 352 User manual

Danfoss

Danfoss AK-CC 450 User manual

Danfoss

Danfoss AMV 110 NL User manual

Danfoss

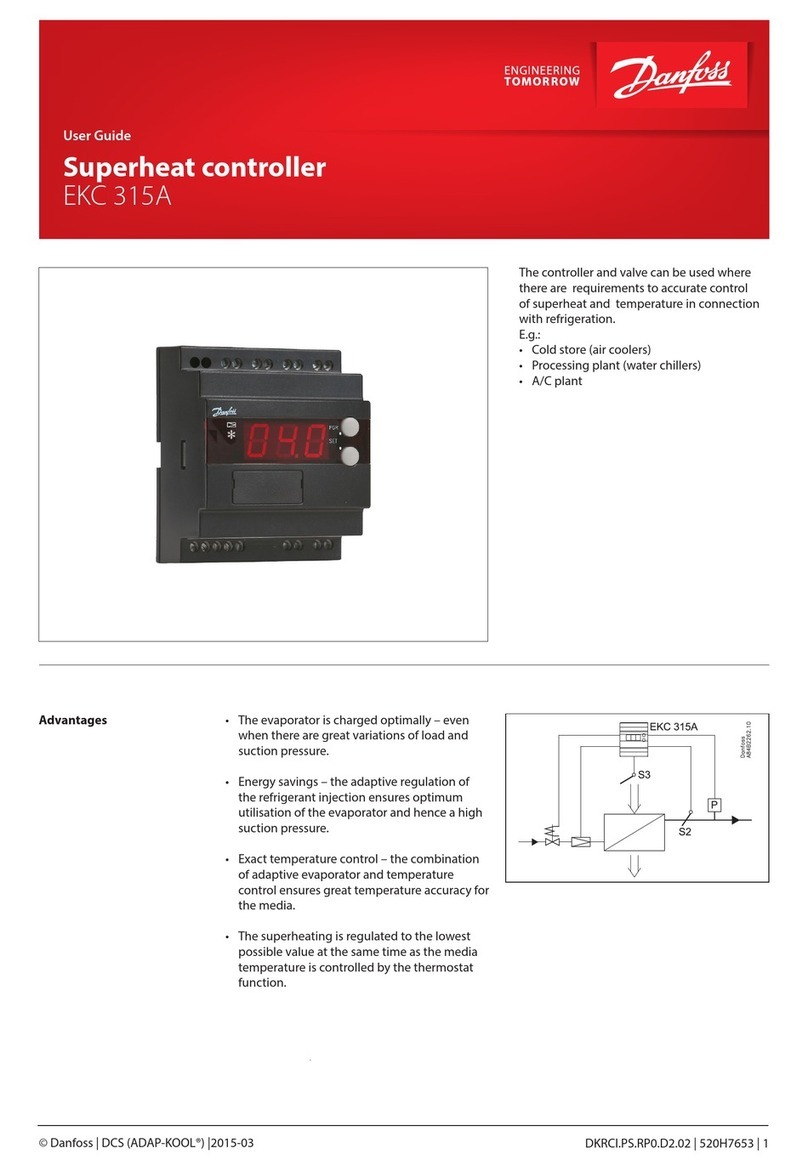

Danfoss EKC 315A User manual

Danfoss

Danfoss ERC 213 User manual

Danfoss

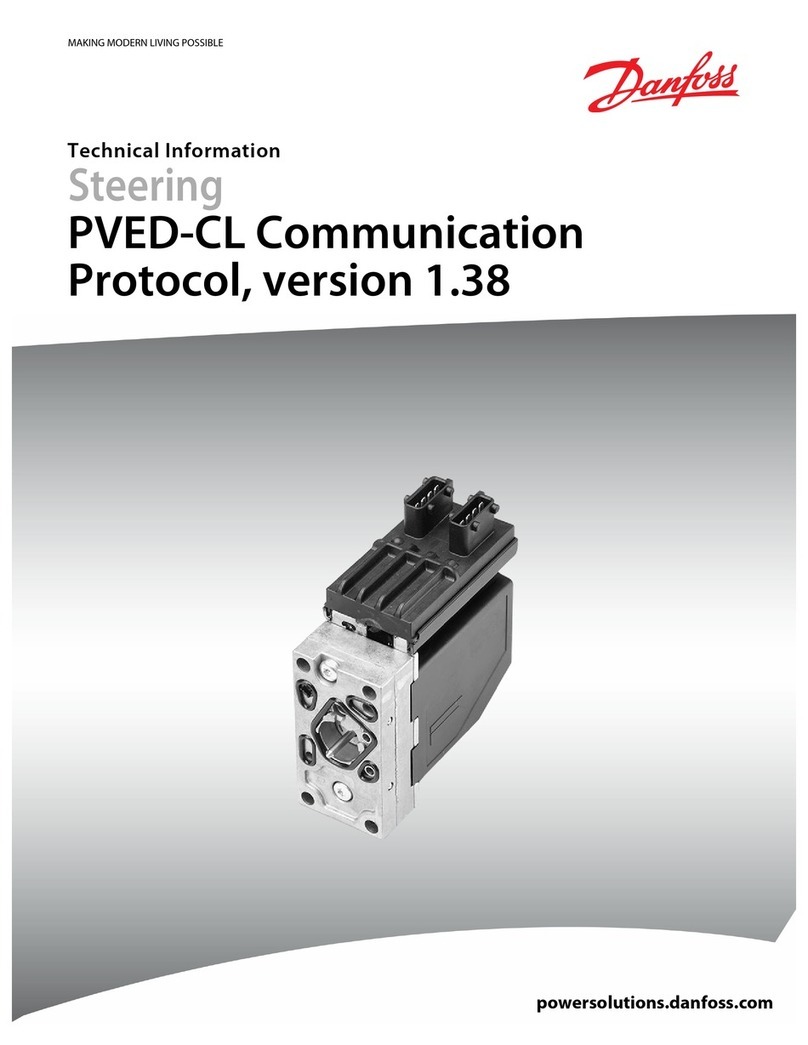

Danfoss pved-cl Manual

Danfoss

Danfoss DEVI DEVIreg Hotwater User manual

Danfoss

Danfoss ERC 214 User manual

Danfoss

Danfoss VLT HVAC Drive FC 102 Operating instructions

Danfoss

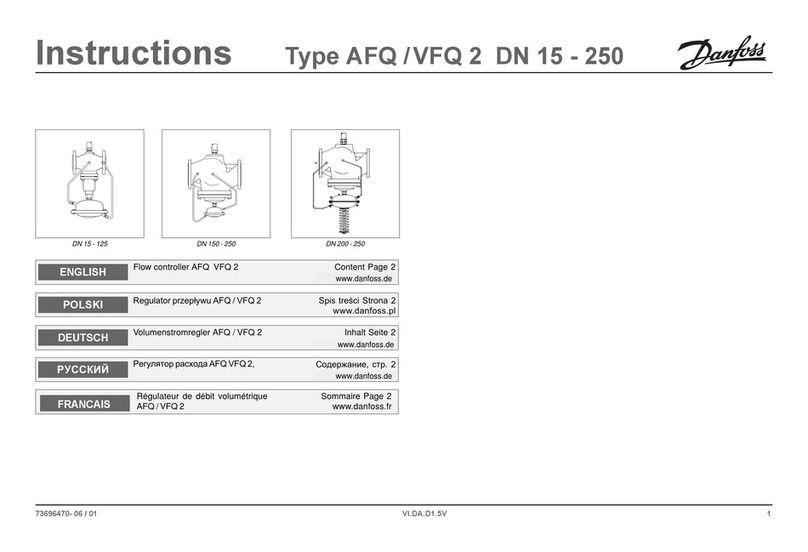

Danfoss AFQ 2 User manual

Danfoss

Danfoss EIM 336 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions