Danfoss VLT 4000 User manual

Other Danfoss DC Drive manuals

Danfoss

Danfoss VLT AutomationDrive FC 302 Operating instructions

Danfoss

Danfoss VACON 3000 User guide

Danfoss

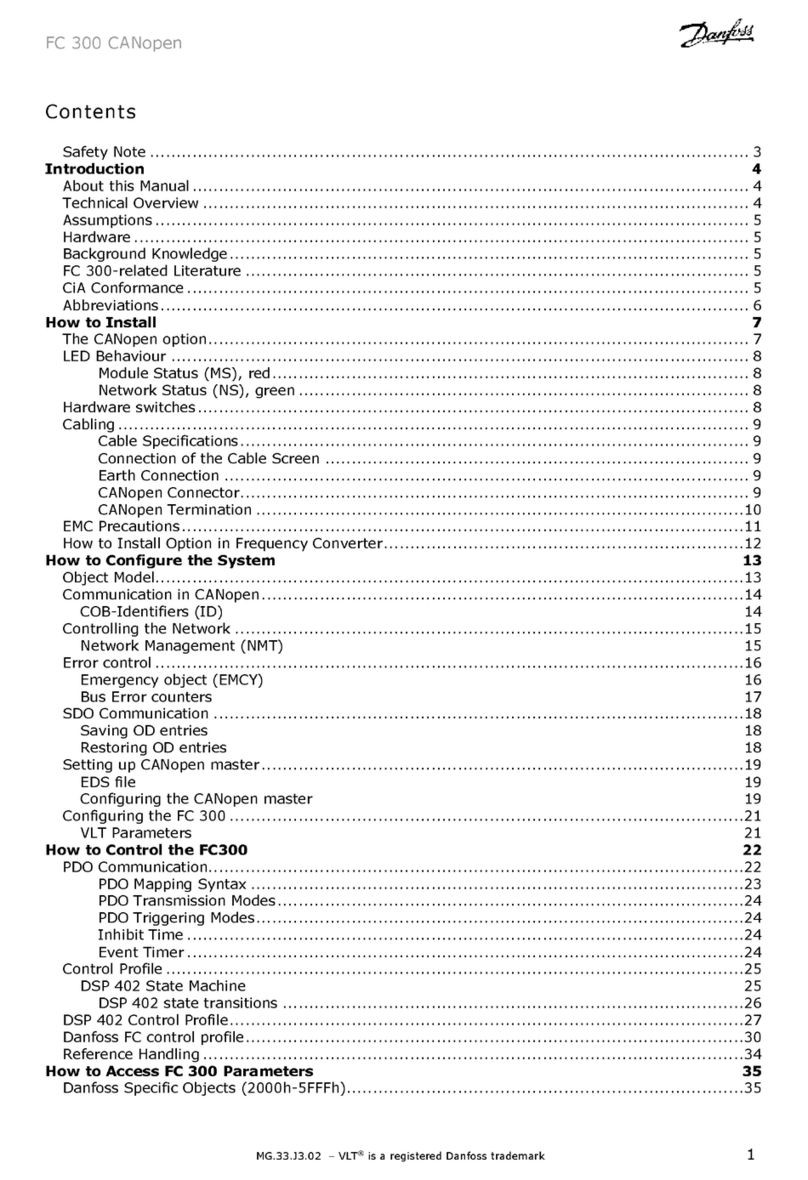

Danfoss FC 300 User manual

Danfoss

Danfoss FC 300 Series Operating instructions

Danfoss

Danfoss VLT AutomationDrive EZ FC 321 User manual

Danfoss

Danfoss VLT AutomationDrive FC 300 Guide

Danfoss

Danfoss VLT HVAC Drive FC 102 User manual

Danfoss

Danfoss VLT HVAC Drive FC 102 User manual

Danfoss

Danfoss vlt aqua User manual

Danfoss

Danfoss VLT Midi Drive FC 280 Operating instructions

Danfoss

Danfoss VLT AQUA Drive FC 202 Guide

Danfoss

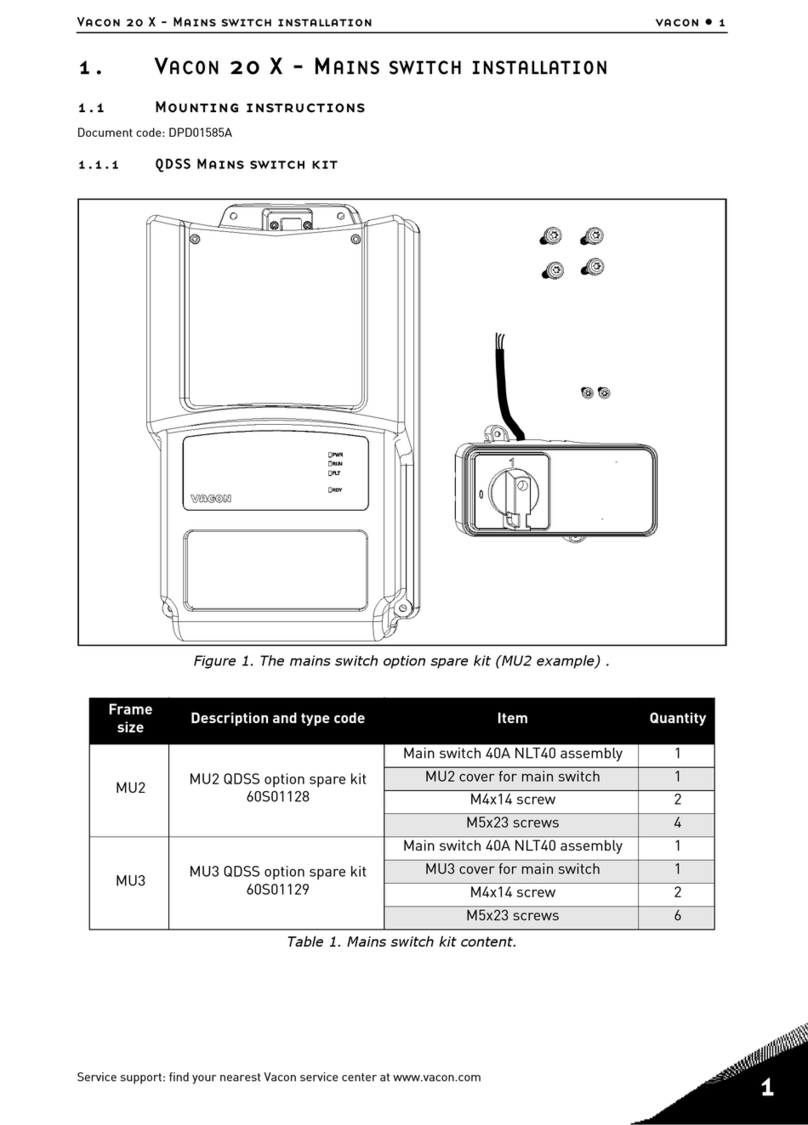

Danfoss VACON 20 X User manual

Danfoss

Danfoss VLT series User manual

Danfoss

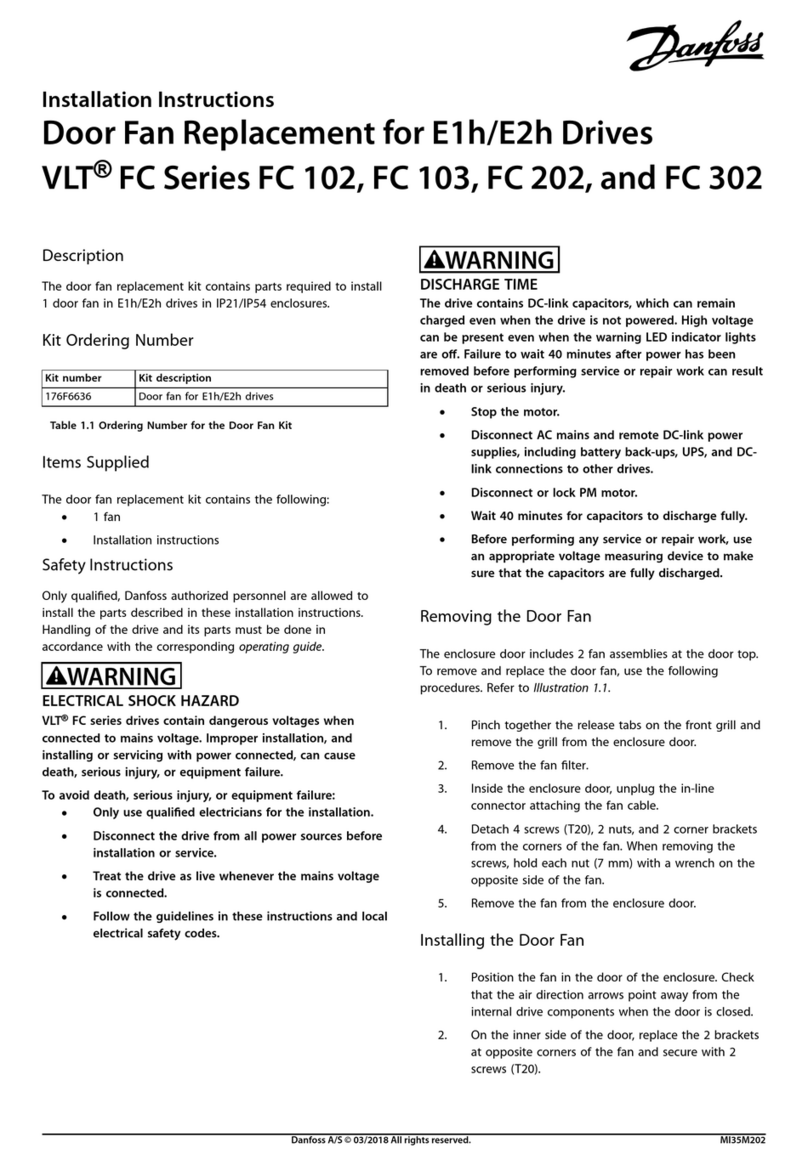

Danfoss 176F6636 User manual

Danfoss

Danfoss VLT User manual

Danfoss

Danfoss VLT HVAC Basic Drive FC 101 User manual

Danfoss

Danfoss VLT Midi Drive FC 280 User manual

Danfoss

Danfoss VLT HVAC Drive FC 102 Operating instructions

Danfoss

Danfoss VLT 4000 VT User manual

Danfoss

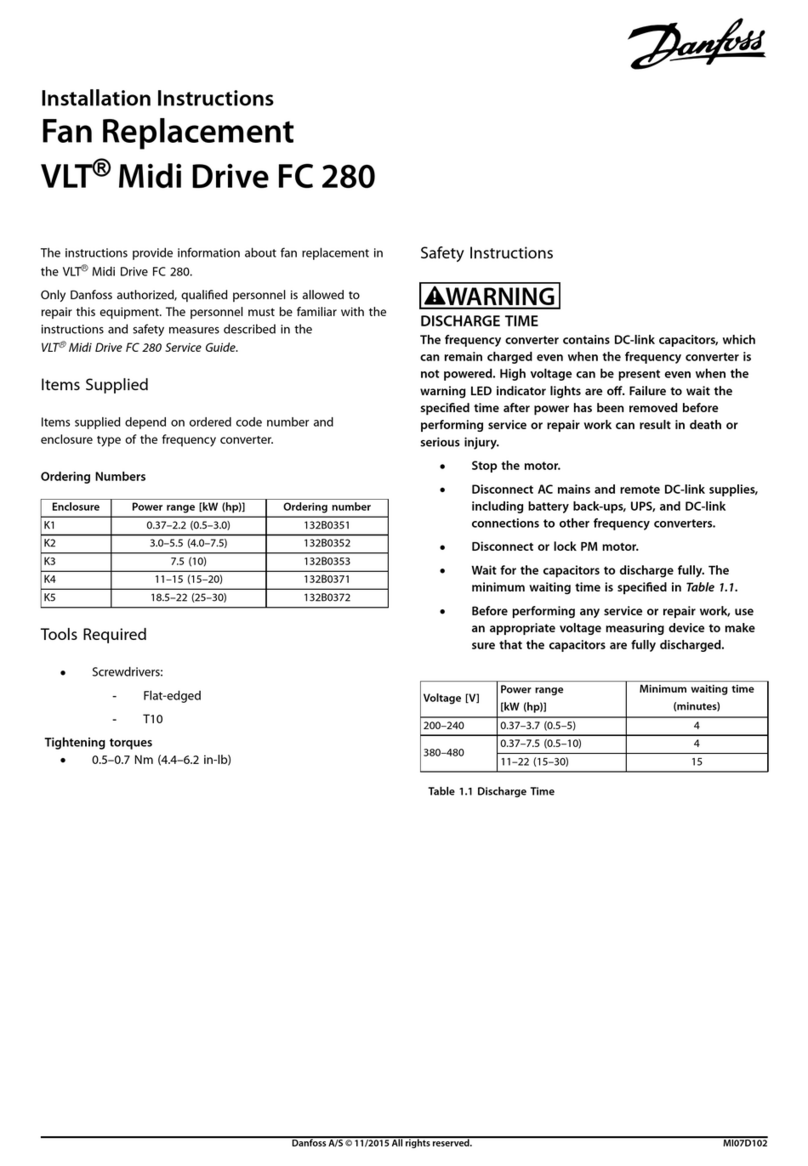

Danfoss VLT DriveMotor FCP 106 Operating instructions