1.5.2.2 EMC Directive

The purpose of the EMC (electromagnetic compatibility)

Directive is to reduce electromagnetic interference and

enhance immunity of electrical equipment and instal-

lations. The basic protection requirement of the EMC

Directive is that devices that generate electromagnetic

interference (EMI), or whose operation could be aected

by EMI, must be designed to limit the generation of

electromagnetic interference. The devices must have a

suitable degree of immunity to EMI when properly

installed, maintained, and used as intended.

Electrical equipment devices used alone or as part of a

system must bear the CE mark. Systems do not require the

CE mark, but must comply with the basic protection

requirements of the EMC Directive.

1.5.2.3 Machinery Directive

The aim of the Machinery Directive is to ensure personal

safety and avoid property damage to mechanical

equipment used in its intended application. The Machinery

Directive applies to a machine consisting of an aggregate

of interconnected components or devices of which at least

1 is capable of mechanical movement.

Drives with an integrated safety function must comply with

the Machinery Directive. Drives without a safety function

do not fall under the Machinery Directive. If a drive is

integrated into a machinery system, Danfoss can provide

information on safety aspects relating to the drive.

When drives are used in machines with at least 1 moving

part, the machine manufacturer must provide a declaration

stating compliance with all relevant statutes and safety

measures.

1.5.2.4 ErP Directive

The ErP directive is the European Ecodesign Directive for

energy-related products. The directive sets ecodesign

requirements for energy-related products, including

frequency converters. The directive aims at increasing

energy eciency and the level of protection of the

environment, while increasing the security of the energy

supply. Environmental impact of energy-related products

includes energy consumption throughout the entire

product life cycle.

The RCM Mark label indicates compliance with the

applicable technical standards for electromagnetic compat-

ibility (EMC). An RCM Mark label is required for placing

electrical and electronic devices on the market in Australia

and New Zealand. The RCM Mark regulatory arrangements

only deal with conducted and radiated emission. For

frequency converters, the emission limits specied in

EN/IEC 61800-3 apply. A declaration of conformity can be

provided on request.

1.5.3 UL Compliance

Illustration 1.2 UL

NOTICE

The VLT®Advanced Harmonic Filter AHF 005/AHF 010

460 V/60 Hz and 600 V/60 Hz types are UL-listed at UL

le no. E134261 (NMMS.E134261).

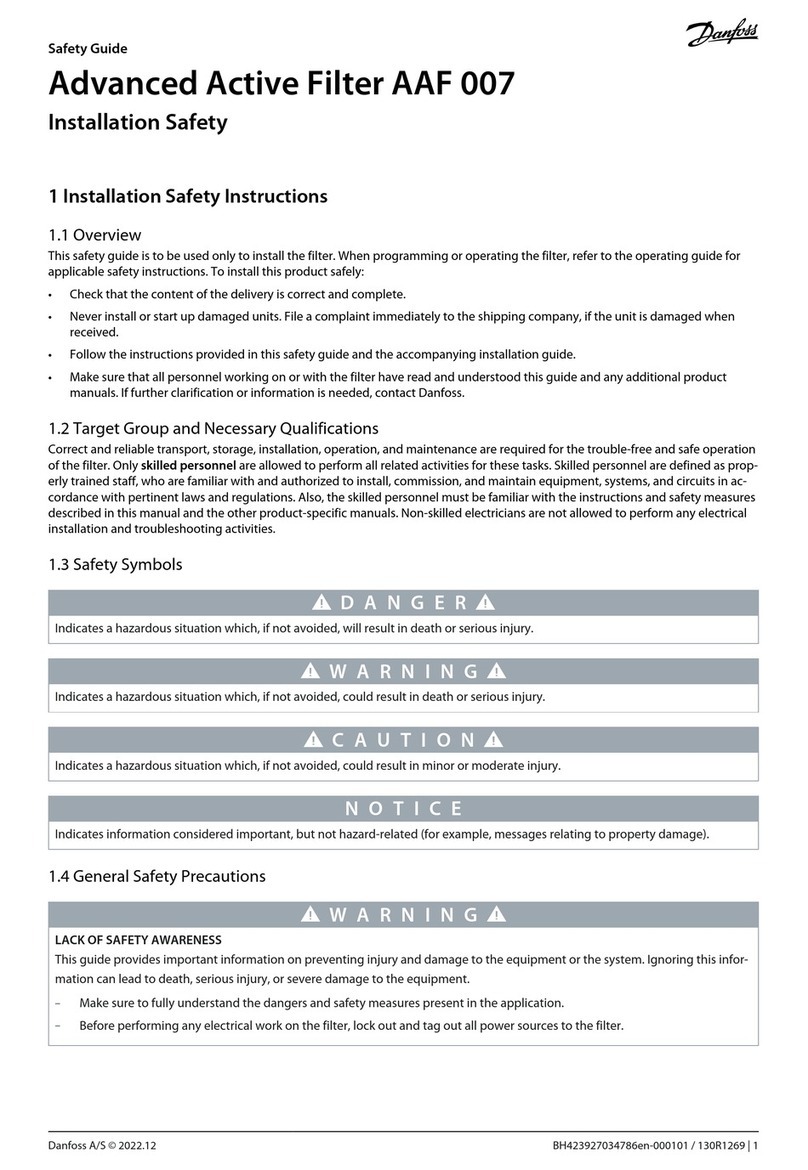

1.6 Safety

1.6.1 General Safety Principles

If handled improperly, drives have the potential for fatal

injury as they contain high voltage components. Only

qualied personnel are allowed to install and operate the

equipment. Do not attempt repair work without rst

removing power from the drive and waiting the

designated amount of time for stored electrical energy to

dissipate.

Strict adherence to safety precautions and notices is

mandatory for safe operation of the drive and lter.

1.6.2 Qualied Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the trouble-

free and safe operation of the lter. Only qualied

personnel are allowed to install or operate this equipment.

Qualied personnel are dened as trained sta, who are

authorized to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Also, the qualied personnel must be familiar

with the instructions and safety measures described in this

manual.

WARNING

IMPROPER INSTALLATION

Improper installation of the lter or the frequency

converter may cause death, serious injury, or equipment

failure.

•Follow this design guide and install according

to National and Local Electrical Codes.

Introduction VLT®Advanced Harmonic Filter AHF 005/AHF 010

6 Danfoss A/S © 05/2019 All rights reserved. MG80C602

11