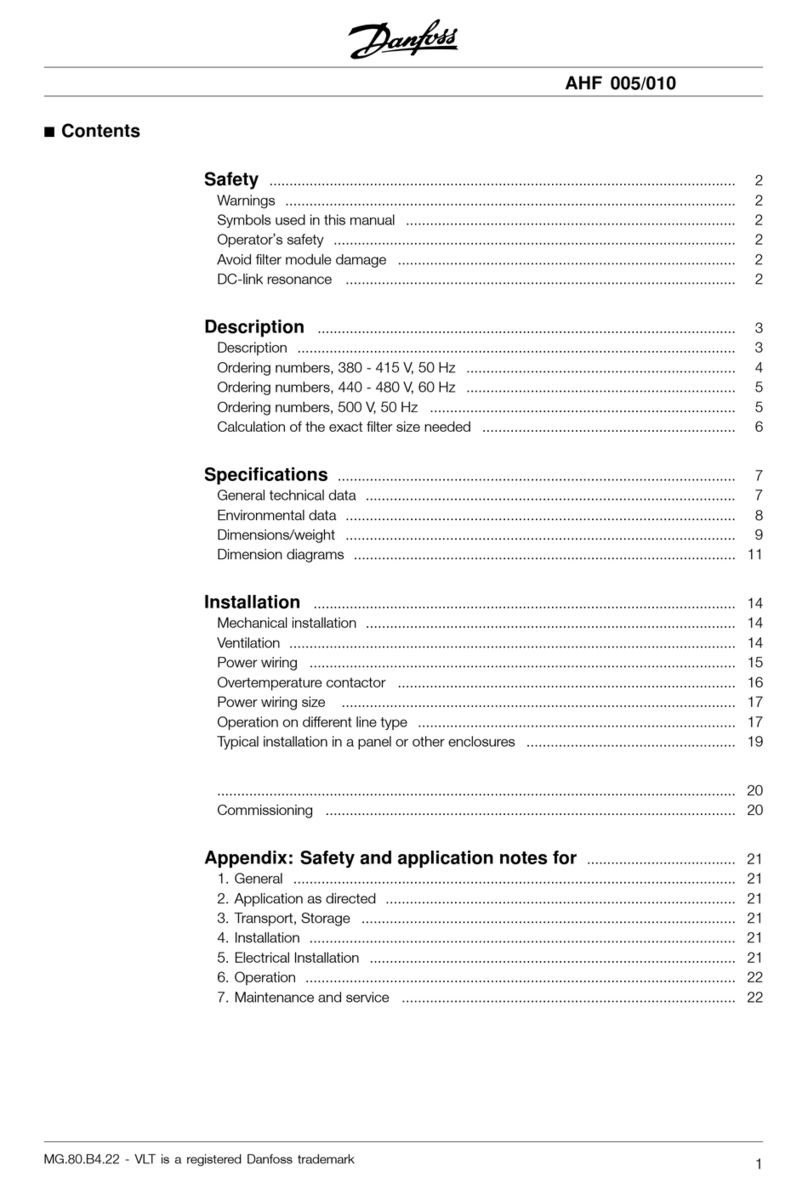

1 Introduction

The purpose of this manual is to provide detailed technical

information and instructions to enable a qualified

technician to identify faults and perform repairs on VLT®

Advanced Active Filters in D- and E-frame sizes. It covers

both the stand alone active filter (AAF) and the filter

portion of the VLT®Low Harmonic Drive (LHD).

This manual provides the reader with a general view of the

filter's main assemblies and a description of the internal

processing. With this information, technicians should have

an understanding of AAF operation for troubleshooting

and repair.

This manual provides instructions for the active filter

models and voltage ranges described in Table 1.1.

1.1 VLT Active Filter Product Overview

VLT®Active Filter AAF006 is a device for harmonics and

reactive current mitigation. The unit is designed for instal-

lation in various applications or combined with a

Adjustable frequency drive as a packaged low harmonic

drive solution. The AAF measures the current signal via

external transducers and counteracts the unwanted

elements of the measured current. The unwanted elements

are programmable via the LCP. The active filter can

compensate all harmonics until 40th harmonics at the same

time in an overall compensation mode or until the 25th

harmonics individual selected down to specified value set

via the LCP. The unit is also capable of correcting reactive

currents to harmonize the current and voltage phases,

creating a displacement power factor close to 1. The AAF

also balances the current loads equally on all three phases.

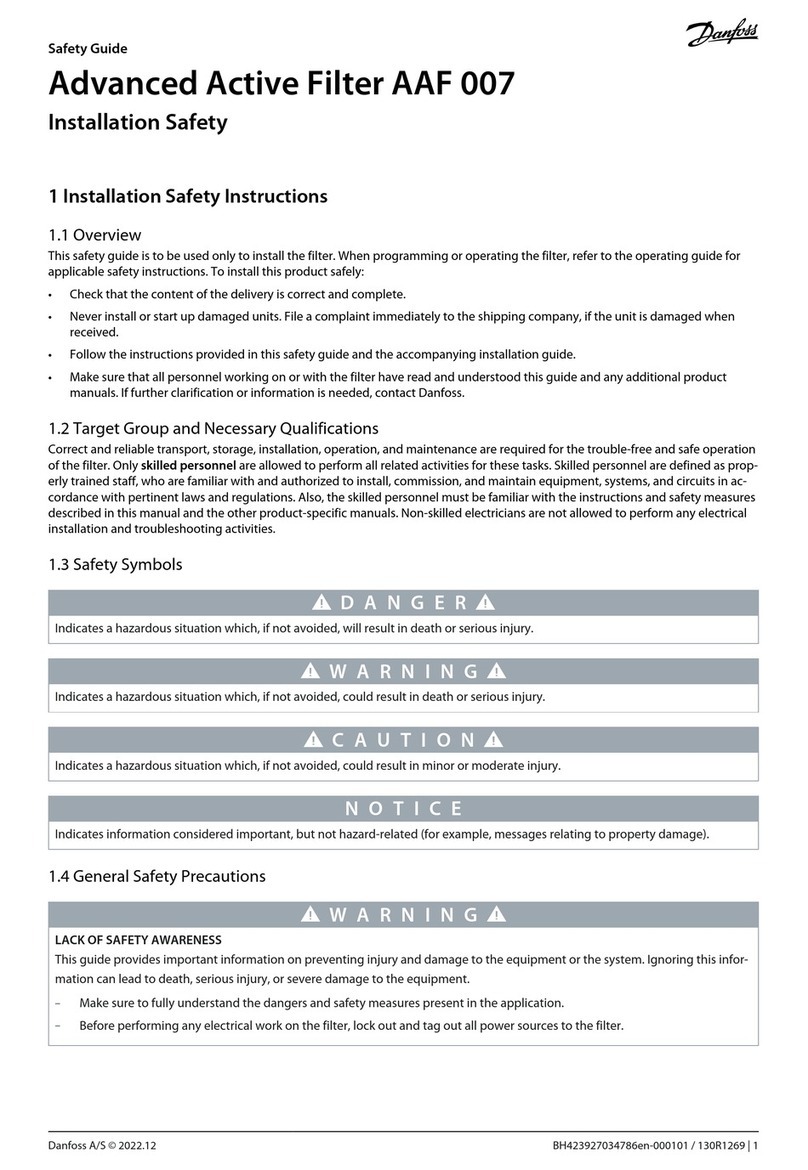

1.2 For Your Safety

1.2.1 Warnings

CAUTION

Active filters contain dangerous voltages when connected

to line power. The connected current transducers may also

hold dangerous voltages when connected. Only a

competent technician should carry out service.

WARNING

For dynamic test procedures, line power is required and all

devices and power supplies connected to line power are

energized at rated voltage. Use extreme caution when

conducting tests in a powered unit. Contact with powered

components could result in electrical shock and personal

injury.

1. DO NOT touch electrical parts of the filter or

external current transducers when connected to

line power. After removing power from line

power, wait 20 minutes for D-frame and 40 for E-

frame units before touching any electrical parts.

2. When any repair or inspection is made, line

power must be disconnected.

3. The STOP key on the control panel does not

disconnect line power.

4. When servicing external current transformers

(CTs), remove power completely from the

connection point on both line power and

secondary side of the CTs.

5. Use a shorting connector on the secondary side

of customer-supplied external current

transformers (CTs) whenever current is present on

the line power (primary side) and the AFC card is

NOT wired to the external CT terminals.

1.3 Electrostatic Discharge (ESD)

CAUTION

When performing service, use proper ESD procedures to

prevent damage to sensitive components.

Many electronic components within the unit are sensitive

to static electricity. Voltages so low that they cannot be

easily detected can reduce the longevity and performance

of the AAF, or completely destroy sensitive electronic

components.

Introduction VLT Advanced Active Filter AAF006 D and E Frames Service Manual

MG90Z122 - VLT®is a registered Danfoss trademark 1-1

11