Notice is hereby given that thi s owner' s manu al is part of the ar ticl e owned in whole by the

manu fact urer , known as indicat ed by this discl aimer and all illust ration s within the manu al. All

righ ts for manu fact uri ng and reprod ucing of such ar ticl es or any part thereof ar e reser ved by the

manu fact urer . Nei ther sai d article no r any part thereof may be manu fact ured or reprod uce d in any

way exc ept by the written authori zat ion from the manu fact urer . All prop riet ary rights and

inform ation are the sol e prop erty of the manu fact urer .

DISCLAIMER

LIMITED WARRANTY

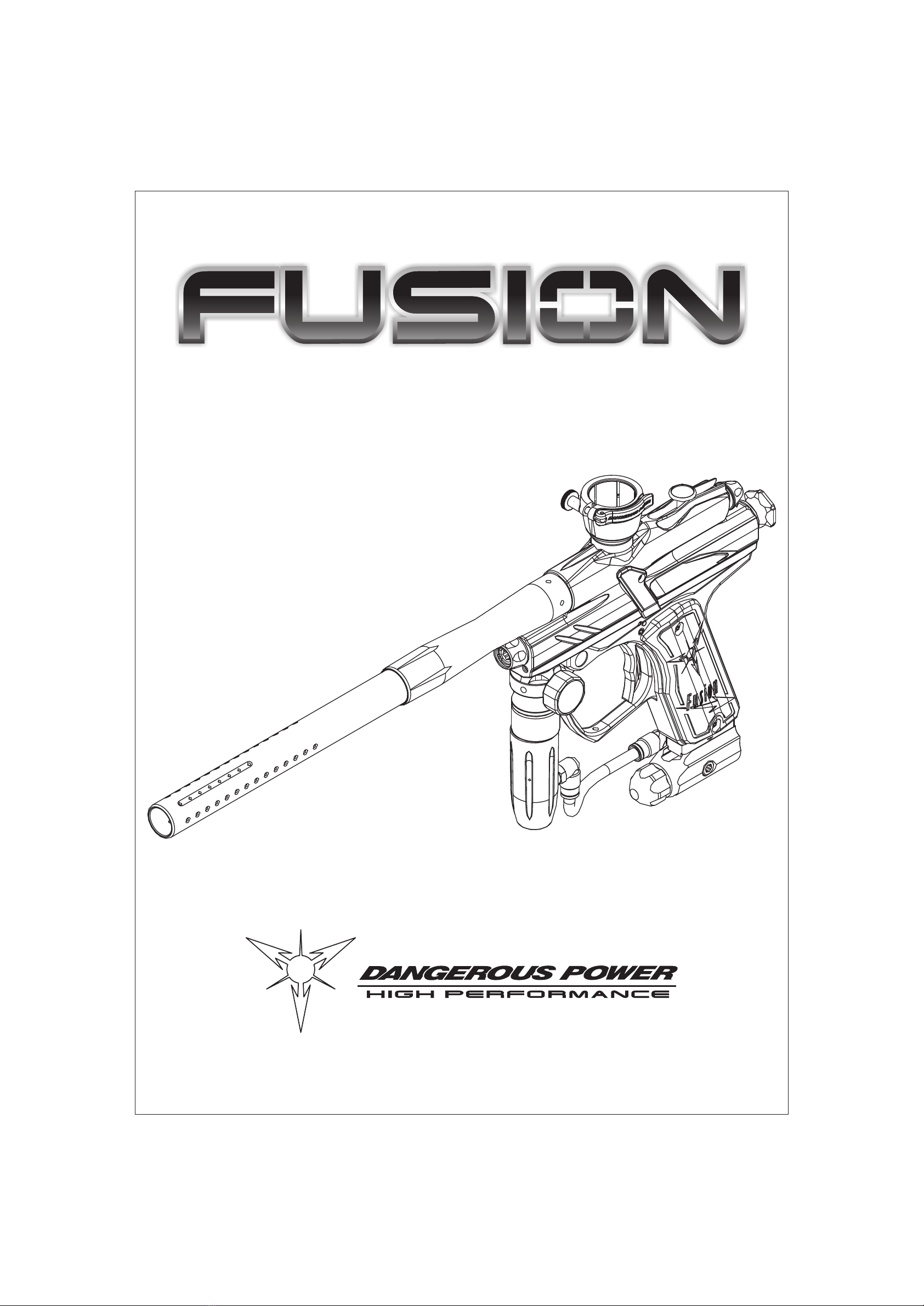

DANGEROUS POWER war rants this Fusi on paint ball marker , to the ini tial retail purcha ser , to be

free from defect in ori gi nal materials and /or workm ansh ip for twelve (12) months from the ori ginal

date of pu rcha se with the follow ing exc epti on s: (a) Dispo sabl e part s (batt eries, o-r ing s, seal s, micro

switch, ai r press ure hose, rubber and /or plast ic mat erial part s, etc.) are not included in thi s limited

warranty . (b) Elect ronic part s on thi s marker are fully warranted for 30 day s from the ori gi nal date of

purcha se. (c) Bol t and striker syst ems of this marker are ful ly war ranted for 6 months from the ori ginal

date of pu rcha se. (d) Surf ace dam age s (scr atche s and nicks) or oper ation failure du e to acci den t, neg lect ,

modificat ion, normal wear , oper ator error, mai ntena nce by any on e other than an authori zed dea ler or

age nt, misuse, improp er disass embly and reassem bl y, and at tempt s made to dri ll ho les or remove met al

from the exter nal surf aces which cou ld redu ce the saf et y and /or perf orm anc e of thi s marker are no t

cov ered under this limited warranty . Purchaser is respo nsi ble for all rend ered ser vices not cov er ed under

this limited warranty , includi ng any app licab le shi pp ing cost s, labo r, and /or inst allation. DANGEROUS

POWER reser ves the right to deter mine the legit imacy of claimed defect ive ori ginal part s and their

eligi bility for cov erage under the terms of thi s warranty .

DANGEROUS POWER , its authori zed dea lers, affi liates, and /or age nts, will not be held liable

under this warranty , stat e, fede ral, or com mon law for any prod uct failure, personal inj ury, or

prop erty dam age resul ting from improp er use and /or alter ation of thi s prod uct. Any attempt to alter

the trigg er assem bly will inst antl y void yo ur war ranty and may resul t in ser ious injury. Any attempt

to alter basi c marker part s witho ut pri or written con sent from the manu fact urer will resul t in

autom atic defaul t of all exp ressed warranti es. Paint ball mar kers are no n-r efun dab le and are not

sub ject to exc han ge from manu fact urer .

This limited warranty is no n-t ransfer able and is vali d only upon present ation of a com pl eted warranty

regis tration card and ori ginal proo f of purcha se. There are no other warranti es or guar antees , exp ressed

or implied, made by the manu fact urer on this paint ball marker.

4

TM

TM

TM