PAGE 2 05776-1198 <90-00124>

NOTE: This section lists the different options available for this product. To order any of the avail-

able options, contact Dantel Inside Sales through our toll-free number, 1-800-432-6835.

OPTION NUMBER FEATURES

B18-05776-00 Wired only. No modules

B18-05776-01 Wired shelf equipped with one 46105 Dual VF 64Kb Channel module; one 44022 Subscriber

Line Interface module; and one 44118 4W/4W VF Bridge.

B18-05776-02 Equipped the same as the -01 option above; less the 46105.

ORDERING INFORMATION

GENERAL DESCRIPTION

This shelf is designed to be a 4-wire analog or digital order

wire assembly (OW). It is wired for:

♦44022-00 (A17-44022-00) Subscriber Line Interface module

♦44118-00 (A17-44118-00) 4W/4W VF Bridge

♦46105-00 (A17-46105-00) Dual VF 64 Kb Channel module.

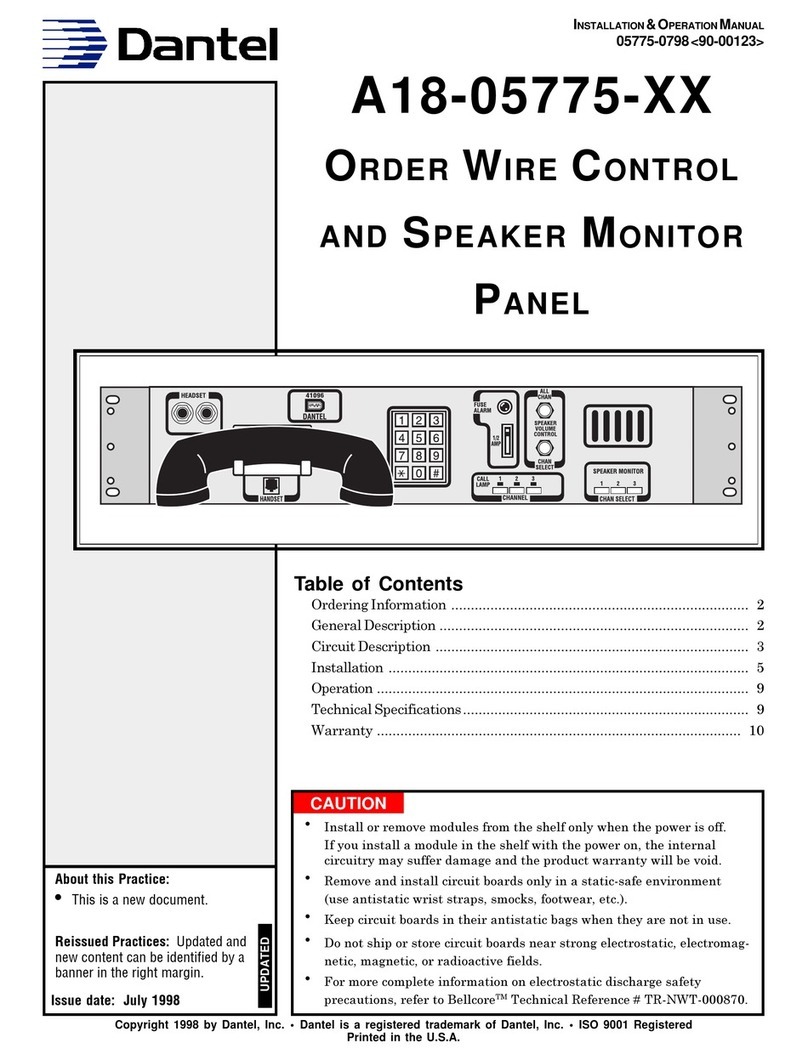

The 05776 is equipped to use a 4-wire telephone such as the

A23-00010-20 or an A18-05775-00 3 channel OW speaker moni-

tor panel. No DTMF decoding is provided for this unit. DTMF

signaling is only used to get access to the VNET interface to the

PBX.

The unit is designed as a party-line system so that a caller, on

the OW channel, will simply speak into the handset and call who

he wants to talk to. The same is true from a call coming in from

the Off-Net package. The Off-Net unit associated with this

system will be the VNET PBX assembly A18-05774.

The 05776 operates from -21 to -56 volts with levels of +7 to

-16 dBm on any port of the 44118 VF bridge. In this application

all ports of the bridge will be set for -16 dBm on the transmit

ports and +7 dBm on the receive ports. The OW interface will be

made up of:

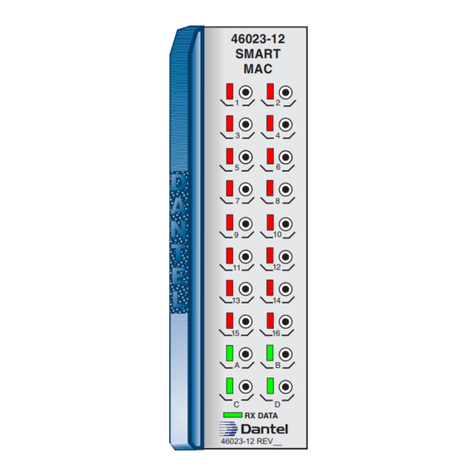

♦A 46105-00 Dual VF card in slot 1 (J1)

♦A 4118-00 4w/4w bridge in slot 2 (J2)

♦A 44022-00 subscriber line interface in slot 3 (J3).

NOTE:

With the release of the

B18-05776-XX Universal Order-

wire assembly, the A80-00630-00

M lead interface module has

been added.

This assembly will allow for con-

trol of M lead devices that re-

quire RS-232 or RS-449 RTS

leads to enable the 64 kb chan-

nels. The interface module can be

provisioned so that the on-hook

idle condition is normal low or

normal high.

UPDATED

NEW NOTE