DAS AP-BLOT User manual

das

srl

Viale Tivoli Km 18,642 – 00018 Palombara Sabina (Roma) - Italy

Tel (+39) 0774 66840 – 0774 637070 - Fax 0774 634039

E- m a i l : i nf o@dasitaly c o m - h t t p : / / www dasit a l y c o m

AP

APAP

AP-

--

-BLOT

BLOTBLOT

BLOT

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

SERVICE MANUAL

This manual contains DAS reserved information All rights reserved Unauthorized copying of this manual or parts

is prohibited

AP Blot– SERVICE MANUAL

SECTION 0

INTRODUCTION

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 3

Ed.

Index

Indice

Date

Data

Description

Descrizione

Execution

Elaborazione

Verification

Verifica

Approval

Approvazione

0 Rev 00

29 04 08

Issue

0 Rev 01

02 04 09

General revision

Important Notes:

To avoid errors durin maintenance and repairs, carefully read the entire manual before

attemptin any work on the instrument.

Pay particular attention to the “GENERAL SAFETY WARNINGS” in Section 1 and follow instructions for specific

operations precisely as indicated in this manual

AP Blot– SERVICE MANUAL

SECTION 0

INTRODUCTION

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 5

CONTENTS

SECTION 1 GENERAL SAFETY ............................................................................................................................. 9

1.1.

GENERAL

SAFETY

WARNINGS

AND

SYMBOLS.............................................................................. 11

1.2.

INSTRUMENT

USE

AND

CONDITIONS............................................................................................... 11

1.3.

INTENDED

USE/USERS

OF

THE

INSTRUMENT................................................................................. 11

SECTION 2 INSTALLATION AND TECHNICAL SPECIFICATIONS ........................................................... 13

2.1.

INSTALLATION ...................................................................................................................................... 15

2.2.

WORK

AREA............................................................................................................................................ 16

2.3.

TECHNICAL

SPECIFICATIONS ............................................................................................................ 16

SECTION 3 MAINTENANCE PROCEDURES .................................................................................................... 17

3.1

SYSTEM

ARCHITECTURE ........................................................................................................................ 19

3.2

REMOVING

WORK

AREA......................................................................................................................... 21

3.2.1.

REMOVING WORK AREA .................................................................................................................... 21

3.2.2.

Removing shaking plane......................................................................................................................... 23

3.3

DILUTOR

UNIT ........................................................................................................................................... 2

3.3.1.

DES RIPTION OF HOW IT WORKS ................................................................................................... 24

3.3.1.1.

Dilutor Unit......................................................................................................................................................2

3.3.1.2.

Dilutor mechanism ...........................................................................................................................................25

3.3.1.3.

Valve mechanism/Syringe................................................................................................................................25

3.3.1. .

Pump Unit ........................................................................................................................................................26

3.3.1.5.

Probe ................................................................................................................................................................27

3.3.1.6.

Probe Wash Basin ............................................................................................................................................27

3.3.1.7.

Dilutor Unit PCB Electrical Diagram...............................................................................................................28

3.3.1.8.

Dilutor unit hydraulic component diagram.......................................................................................................29

3.3.2.

REGULAR DILUTOR UNIT MAINTENAN E ...................................................................................... 30

3.3.2.1.

Visual checks ...................................................................................................................................................30

3.3.3.

SUBSTITUTING DILUTOR UNIT OMPONENTS.............................................................................. 31

3.3.3.1.

Substituting valve – syringe – dispensation probe tubing.................................................................................31

3.3.3.2.

Substituting valve mechanism..........................................................................................................................32

3.3.3.3.

Substituting 3-way Electro valve......................................................................................................................32

3.3.3. .

Substituting 3-way valve mechanism ...............................................................................................................32

3.3.3.5.

Substituting Peristaltic Pump Tubing...............................................................................................................33

3.3.3.6.

Substituting Dilutor Motor ...............................................................................................................................3

3.3.3.7.

Substituting Opto SIDILOP PCB.....................................................................................................................35

3.3.3.8.

Substituting INTERFA2 PCB ..........................................................................................................................35

3.3.3.9.

Substituting probe wash basin ..........................................................................................................................35

3. .

X–Y

AXIS ................................................................................................................................................. 36

3.4.1.

DES RIPTION OF HOW IT WORKS ................................................................................................... 36

3. .1.1.

X – Y axis movement mechanism....................................................................................................................36

3. .1.2.

X- Y axis Electrical Functions Diagram...........................................................................................................37

3.4.2.

REGULAR MAINTENAN E FOR X–Y AXIS ........................................................................................ 38

3. .2.1.

Cleaning X-Y axis tracks..................................................................................................................................38

3. .2.2.

Check belt tension ............................................................................................................................................38

3. .2.3.

Check condition of flat cables ..........................................................................................................................38

3.4.3.

ALIBRATING X–Y AXIS SETTINGS ................................................................................................... 38

3. .3.1.

X and Y axis belt tension..................................................................................................................................38

3.4.4.

Substituting X–Y AXIS PARTS ............................................................................................................... 39

3. . .1.

Substituting X-axis Movement Motor..............................................................................................................39

3. . .2.

Substituting Y-axis Movement Probe Motor.................................................................................................... 0

3. . .3.

Substituting Opto XGOLAV (X-axis movement) PCB.................................................................................... 0

3. . . .

Substituting X-axis movement belt .................................................................................................................. 1

3. . .5.

Substituting Flat Cables.................................................................................................................................... 1

3. . .6.

Substituting X-Y axis movement flat cables .................................................................................................... 1

3. . .7.

Substituting INTEROP2 PCB (Y-axis movement)........................................................................................... 2

3.5.

Z1

-

Z2

AXIS ............................................................................................................................................. 3

3.5.1.

DES RIPTION OF HOW IT WORKS ................................................................................................... 43

3.5.1.1.

Z1 - Z2 axis movement mechanism.................................................................................................................. 3

3.5.1.2.

Z axis electrical circuit diagram .......................................................................................................................

3.5.2.

REGULAR Z AXIS MAINTENAN E...................................................................................................... 45

3.5.2.1.

Z

2

axis movement control................................................................................................................................. 5

3.5.3.

Z-AXIS ALIBRATION .......................................................................................................................... 45

3.5.4.

SUBSTITUTING Z

1

and Z

2

AXIS PARTS ............................................................................................... 46

3.5. .1.

Substituting Z

1

Axis probe................................................................................................................................ 6

3.5. .2.

Substituting Z

1

Axis probe motor..................................................................................................................... 7

AP Blot– SERVICE MANUAL

SECTION 0

INTRODUCTION

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 6

3.5. .3.

Substituting Z

2

Axis probe ............................................................................................................................... 7

3.5. . .

Substituting Z

2

Axis probe motor..................................................................................................................... 8

3.6.

SHAKING

PLANE.................................................................................................................................... 9

3.6.1.

DES RIPTION OF HOW IT WORKS ................................................................................................... 49

3.6.1.1.

Shaking plane movement mechanism .............................................................................................................. 9

3.6.1.2.

Shaking plane circuit diagram ..........................................................................................................................50

3.6.2.

MAINTENAN E AND SHAKING PLANE ALIBRATION................................................................... 51

3.6.3.

SUBSTITUTING SHAKING PLANE OMPONENTS........................................................................... 51

3.6.3.1.

Substituting Shaking Plane Motor....................................................................................................................51

3.6.3.2.

Substituting opto PCBs ....................................................................................................................................52

3.7.

CAMERA .................................................................................................................................................. 53

3.7.1.

DES RIPTION OF HOW IT WORKS ................................................................................................... 53

3.7.2.

AMERA MAINTENAN E .................................................................................................................... 54

3.7.2.1.

Checking USB cable connection ......................................................................................................................5

3.7.2.2.

Cleaning lens....................................................................................................................................................5

3.7.3.

ALIBRATE AMERA........................................................................................................................... 54

3.7.4.

SUBSTITUTING AMERA AND/OR PARTS ........................................................................................ 54

3.7. .1.

Substituting camera ..........................................................................................................................................5

3.7. .2.

Substituting camera lens...................................................................................................................................55

3.7. .3.

Substituting camera USB cable ........................................................................................................................55

3.7. . .

Substituting LED light bar................................................................................................................................55

3.8.

OPTICAL

SENSORS ................................................................................................................................ 56

3.8.1.

DES RIPTION OF HOW OPTI AL SENSORS FUN TION ............................................................... 56

3.8.2.

REGULAR MAINTENAN E .................................................................................................................. 56

3.8.2.1.

Cleaning opto ...................................................................................................................................................56

3.8.2.2.

Checking procedure..........................................................................................................................................56

3.8.3.

HE KING DISTAN E FOR OPTO OUPLERS (X AXIS) ................................................................ 57

3.8.4.

HE KING DISTAN E FOR OPTO OUPLERS (Y AXIS) ................................................................ 58

3.9.

USB

COMMUNICATION ........................................................................................................................ 59

3.9.1.

DES RIPTION OF HOW IT WORKS ................................................................................................... 59

3.9.2.

HE K FUN TIONALITY ................................................................................................................... 59

3.9.3.

REPLA ING DILAP21 and SIR4MOT P Bs ........................................................................................ 60

3.10.

DILUTOR

COMMAND

LIST................................................................................................................... 61

3.11.

HYDRAULIC

CIRCUIT

DIAGRAM ....................................................................................................... 66

3.11.1.

REGULAR MAINTENAN E .............................................................................................................. 67

3.11.2.

SUBSTITUTING HYDRAULI IR UIT OMPONENTS............................................................... 67

3.11.2.1.

Electro-valve substitution.................................................................................................................................67

3.12.

SUMMARY

OF

REGULAR

MAINTENANCE ....................................................................................... 68

3.12.1.

DILUTOR UNIT ................................................................................................................................. 68

3.12.2.

X–Y AXIS ............................................................................................................................................ 68

3.12.3.

Z2 AXIS............................................................................................................................................... 68

3.12.4.

SHAKING PLANE .............................................................................................................................. 68

3.12.5.

AMERA ............................................................................................................................................ 68

3.12.6.

OPTI AL SENSOR............................................................................................................................. 68

3.12.7.

HYDRAULI IR UIT...................................................................................................................... 68

SECTION 4 CALIBRATION PROCEDURES (XCALIB) ................................................................................... 69

.1.

INSTALLING

SOFTWARE ..................................................................................................................... 71

.2.

OPERATING

MENU ................................................................................................................................ 72

.3.

DESCRIPTION

OF

MENU

FUNCTIONS ................................................................................................ 73

. .

INSTRUMENT

BAR................................................................................................................................. 7

.5.

SETTINGS ................................................................................................................................................ 75

4.5.1.

HARDWARE ONFIGURATION .......................................................................................................... 75

4.5.2.

Language................................................................................................................................................ 76

4.5.3.

ommunication port............................................................................................................................... 76

4.5.4.

Serial number ......................................................................................................................................... 77

.6.

WORK

AREA............................................................................................................................................ 78

.7.

MAIN

FUNCTIONS.................................................................................................................................. 79

4.7.1.

Tank level Sensors.................................................................................................................................. 79

4.7.2.

Dispensation Test ................................................................................................................................... 79

4.7.3.

Dilution Test........................................................................................................................................... 79

4.7.4.

Movement Test........................................................................................................................................ 80

4.7.5.

Print Preview.......................................................................................................................................... 82

4.7.6.

Print........................................................................................................................................................ 82

4.7.7.

Turn Light On......................................................................................................................................... 83

4.7.8.

lose Function ....................................................................................................................................... 83

AP Blot– SERVICE MANUAL

SECTION 0

INTRODUCTION

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 7

4.7.9.

Exit ......................................................................................................................................................... 83

.8.

DILUTOR.................................................................................................................................................. 8

4.8.1.

alibrate probe positions....................................................................................................................... 84

4.8.2.

alibrate probe height ........................................................................................................................... 89

4.8.3.

alibrate LT ........................................................................................................................................... 91

4.8.4.

alibrate shaking plane ......................................................................................................................... 93

4.8.5.

alibrate syringe.................................................................................................................................... 95

4.8.6.

alibrate SUL ........................................................................................................................................ 98

4.8.7.

Wash basin test....................................................................................................................................... 99

4.8.8.

Prime .................................................................................................................................................... 101

4.8.9.

alibrate camera.................................................................................................................................. 102

4.8.10.

alibrate parameters........................................................................................................................ 104

4.8.11.

Home................................................................................................................................................. 105

4.8.12.

Turning motors off ............................................................................................................................ 105

4.8.13.

Reset.................................................................................................................................................. 105

.9.

? ............................................................................................................................................................... 106

4.9.1.

Instrument information......................................................................................................................... 106

4.9.2.

Software component information ......................................................................................................... 107

4.9.3.

About .................................................................................................................................................... 107

SECTION TROUBLE SHOOTING ................................................................................................................... 109

5.1

DILUTION

/

DISPENSATION................................................................................................................... 111

5.2

X

-

Y

-

Z

MOVEMENTS............................................................................................................................. 112

5.3

CAMERA.................................................................................................................................................... 112

SECTION 6 SCHEMATIC DIAGRAMS.............................................................................................................. 113

AP Blot– SERVICE MANUAL

SECTION 1

GENERAL SAFETY

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 9

SECTION 1

GENERAL SAFETY

AP Blot – SERVICE MANUAL

SECTION 1

GENERAL SAFETY WARNINGS

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 11

1.1. GENERAL SAFETY WARNINGS AND SYMBOLS

In this manual the following symbols stand for danger or warnings:

General DANGER symbol which indicates that a serious safety risk can occur if

instructions and warnings are not followed

Indicates ELECTRICAL VOLTAGE which could cause death upon contact Covers

with this symbol can only be removed and replaced by qualified personnel and only

after electrical power has been disconnected

Indicates that the instrument uses reagents and corrosive, irritating or noxious

DANGEROUS CHEMICAL SUBSTANCES which could damage health

Indicates that the instrument deals with potentially infectious samples (e g body

fluids such as urine) which could cause INFECTION/CONTAMINATION Always

observe general safety precautions when any of these biological substances are

present

Indicates that not following the correct instructions could damage instrument and/or

its proper functioning

Indicates that important information concerning the instrument or a Section of the

document should be read carefully

1.2. INSTRUMENT USE AND CONDITIONS

The instrument is intended for use in the following working conditions:

− as In Vitro Diagnostic (IVD) medical device as specified in the technical data

− with chemical reagents and accessories supplied and/or declared compatible with instrument

− at a specific temperature and humidity levels as specified in this manual

− not to be used and powered in a potentially explosive or fire hazardous environment

This instrument should only be used as described in this manual

Any other use has to be regarded as improper

1.3. INTENDED USE/USERS OF THE INSTRUMENT

The instrument should only be used for the intended purpose and in perfect technical conditions, only by

qualified personnel following strict safety procedures and regulations for accident prevention

This manual contains instructions for qualified personnel:

− Only Qualified Technicians are entitled to service and repair the instrument with original spare

parts and after appropriate training

Modifications of the instrument are not allowed. The user is liable for any improper

modifications and any subsequent consequences.

For extraordinary maintenance - request Specialized Technicians with authorised equipment and

original spare parts from authorised service centers

AP Blot – SERVICE MANUAL

SECTION 2

INSTALLATION AND TECHNICAL SPECIFICATIONS

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 13

SECTION 2

INSTALLATION AND TECHNICAL SPECIFICATIONS

AP Blot – SERVICE MANUAL

SECTION 2

INSTALLATION AND TECHNICAL SPECIFICATIONS

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 15

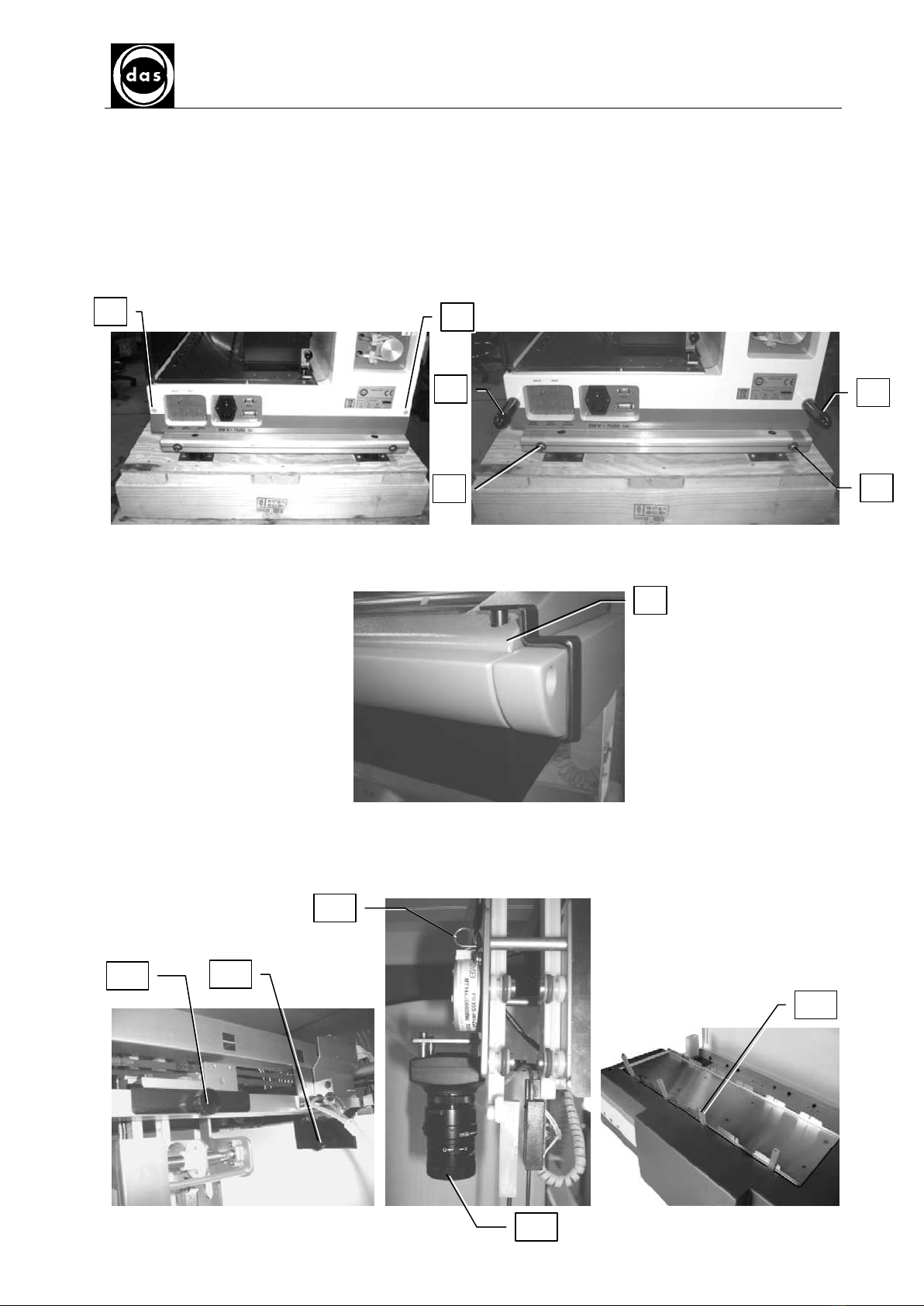

2.1. INSTALLATION

The instrument is packed with a wooden box To unpack the instrument follow the instructions described below:

a) Remove the 2 plastic covers (1-2) from the instrument right side and the other ones from the left side Screw

in the 4 handles on both sides (3-4) for manual instrument placement Once in position remove the handles e

put back in place the plastic covers

b) Remove the 4 screws that hold the instrument on to the wood base (5-6)

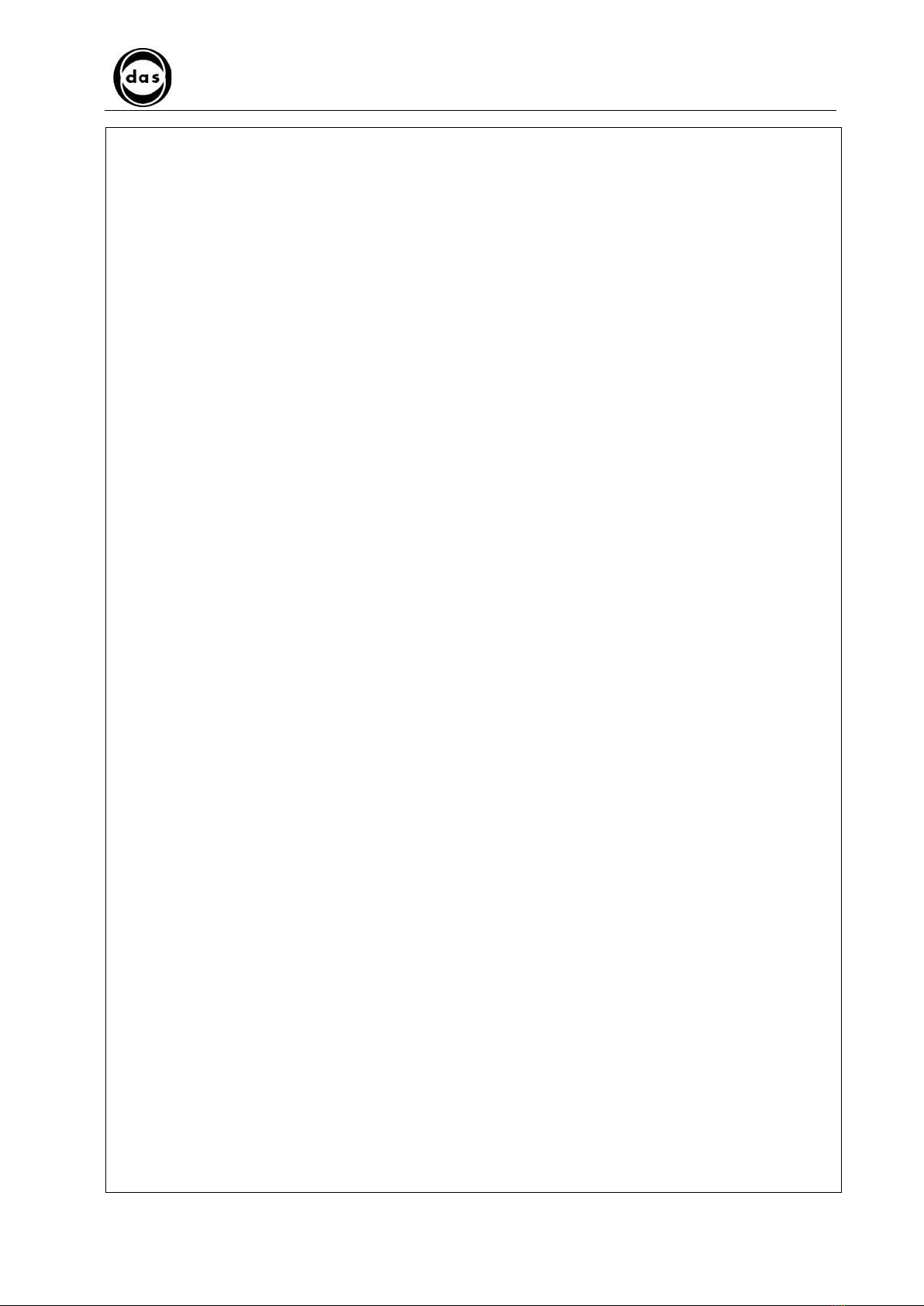

c) Remove screw and bracket (7), screw in the same place using the screw removed before

d) Remove, - screw and bracket (7), screw in the same place the enclosed screw in the bag

e) Remove screws (8,9,10) and related brackets

f) Remove the Z block holder (11) as indicated

g) Remove the protection cap from the camera (12)

h) Remove the blocking tools (13) from the oscillating plane

7

10

8

12

9

11

2

3

4

5

6

1

AP Blot – SERVICE MANUAL

SECTION 2

INSTALLATION AND TECHNICAL SPECIFICATIONS

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Pag 16

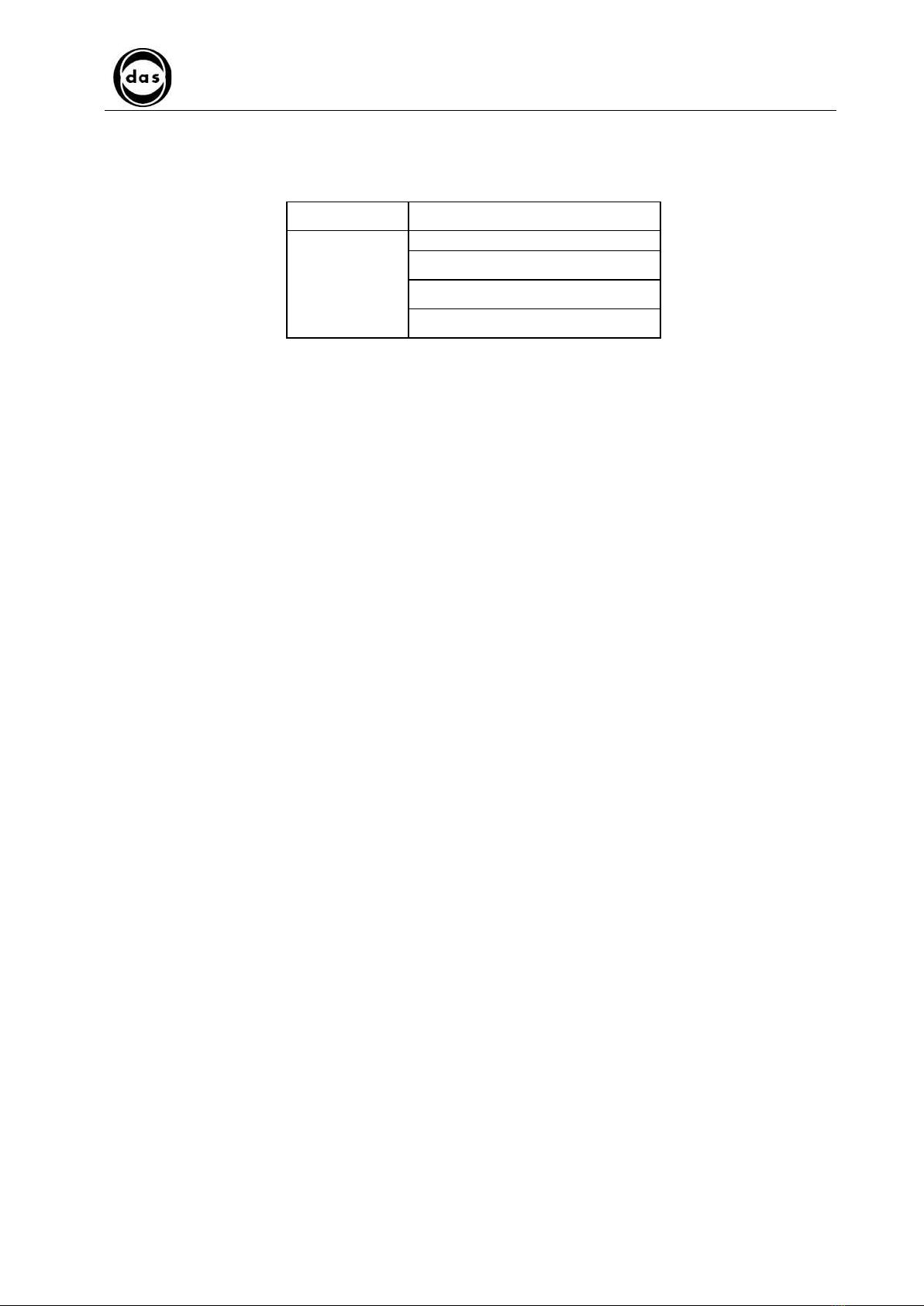

2.2. WORK AREA

AP-Blot work area showing the various components:

Probe washing

basin 48 position Sample rack Reagent and control rack Tanks

Camera Calibration area Strip holder rack

Fig 1 - AP-Blot Work Area

2.3. TECHNICAL SPECIFICATIONS

Sample rack 48 sample tubes (Ø 13mm)

Reagent rack 6 x 100ml vials and 8 control positions

Liquid Containers 2 tanks for wash buffer and waste Both with liquid level sensors

Strip Holders 6 slides (8 strips per slide) to process up to strips on oscillating plane

Dispensation System 1 dispensation and 1 aspiration probe

Strip Washing Liquid dispensation and aspiration via two instrument probes

Image acquisition system High Resolution Colour Camera (3 3 Megapixels) mounted above Probes

Dispensation Up to 2500 µl with a 1 µl resolution

Software Windows 2000 and XP compatible to set up work list, reports and result archive

Loading work lists and transmit results via Host Computer interface (LIS)

Minimum C Requirements − 200 MB free hard disk space

− CD-Rom reader

− RAM 512 MB

− Pentium 4

− Standard video card:VGA 1024x768 16 million colours

− Free USB 2 0 port

ower Requirements 230/115 VAC, 50-60Hz, 150W

Optional Bar Code Reader (BCR) for samples with position ID

Measurements 79 x 61 x 65 h (in cm)

Weight 71 Kg

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Page 17

SECTION 3

MAINTENANCE PROCEDURES

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Page 19

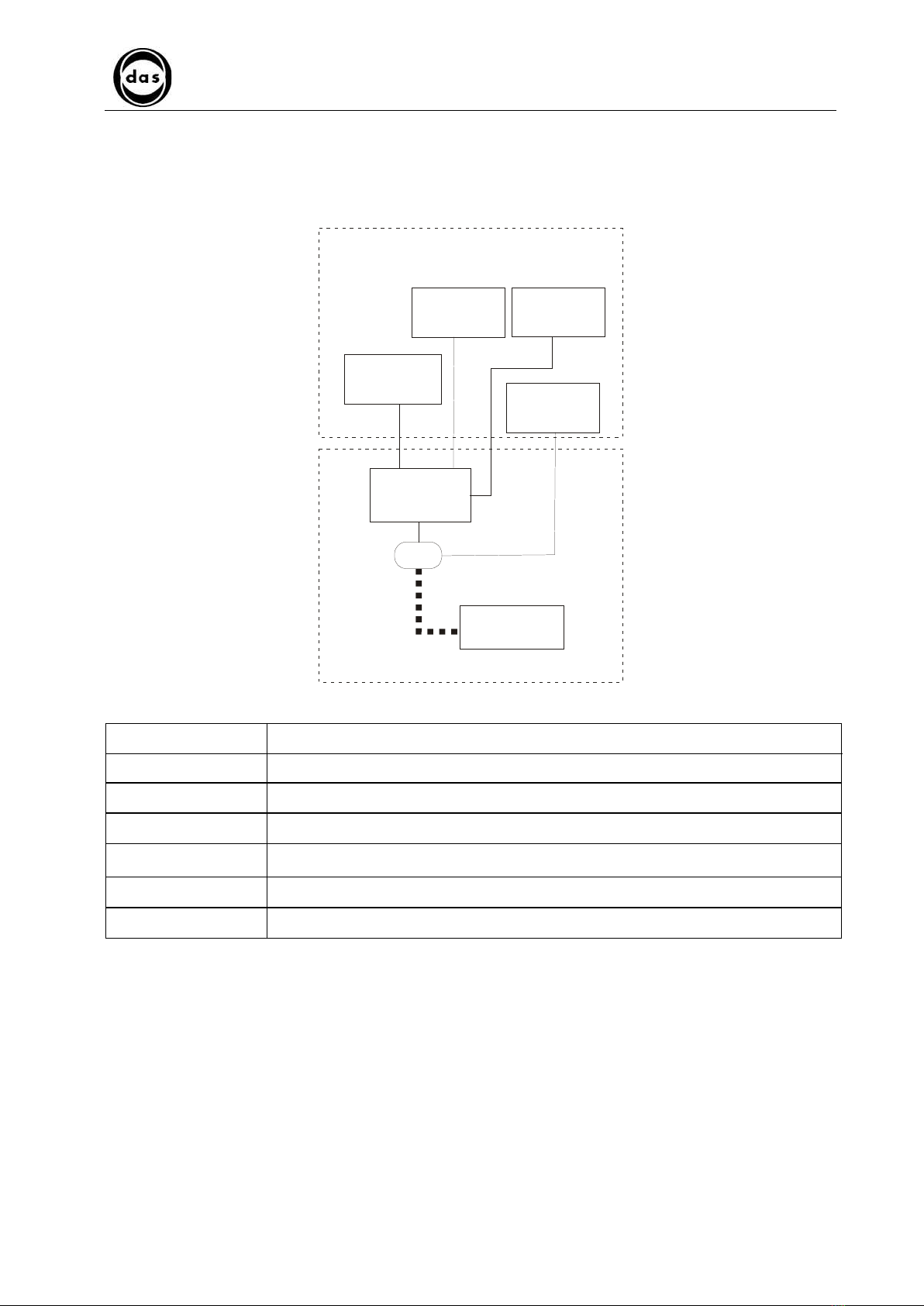

3.1 SYSTEM ARCHITECTURE

The system architecture is illustrated in the following diagram and described in table below:

Control and check board

Function group

Z1, Z2 AXIS

DIL P21

X-Y AXIS

Personal

Computer

USB

DILUTOR

UNIT

SHAKING PLANE

CAMERA

Functional unit Description

X – Y Axis The X-Y axis movement mechanism moves probe arms over work area with precision

Z

1

Axis The Z

1

axis raises and lowers dispensing probe over work area

Z

2

Axis The Z

2

axis raises and lowers aspiration probe over work area

Dilutor unit The dilutor unit aspirates and dispenses samples, calibrators, controls, and generally all

reagents It also washes Z1 axis probe internally and externally

Shaking Plane The shaking plane shakes the 6 slides holding the strips to be processed

Camera The camera acquires the images of the processed strips

AP Blot - SERVICE MANUAL

SECTION 3

MAINTENANCE PROCEDURES

Doc N° MDS-AP-26-00-02

Rev 01

Date: 02 04 2009

Page 20

The AP Blot communicates with the PC via a serial connection: between the Dilutor PCB and the PC

The units controlled by the PCB are:

PCB Unit

X – Y Axis

Z

1

– Z

2

Axis

Dilutor unit

DILA 21

Shaking plane

Table of contents

Popular Laboratory Equipment manuals by other brands

Dosmatic

Dosmatic Superdos 45 0.3% PAA operating manual

Velp Scientifica

Velp Scientifica AREC.T instruction manual

Endress+Hauser

Endress+Hauser Analytik Jena CyBio SELMA user manual

Endress+Hauser

Endress+Hauser asp-port d 2 Installation and operating instructions

IKA

IKA C 7010 operating instructions

Thermo Scientific

Thermo Scientific FT 6060 operating instructions

NPI

NPI ISO-STIM 01B Operating instructions and system description

Tuttnauer

Tuttnauer 2340E Operation & maintenance manual

Fisher Scientific

Fisher Scientific Finnpipette II Instructions for use

Rosemount

Rosemount 700XA quick start guide

InfiRay

InfiRay MH25 user manual

Thermo Scientific

Thermo Scientific 2115 Series operating manual