Terragene Bionova MiniPro User manual

WARNING: this product contains dry natural rubber

Rev. 11 | February 2022

Bionova® MiniPro

Auto-reader

for Hygiene Monitoring systems

Bionova® MiniPro

Index

4 Composition

4 Product description

4 Indications for use

4 Features

5 Safety information

5 Symbols

6 Operating conditions

6 Powersupplyspecications

6 Environment operating conditions

6 Regulatory compliance

7 Product Compatibility and Incubation programs

7 Bionova®MiniPro Incubation Programs

7 Bionova®MiniPro Auto-reader compatible indicators

7 Instructions for use

7 Start-up

10 Interpretation of results of PRO1 indicators

12 Disposal

12 Reprinting of results

12 Remaining incubation time

12 Audible alarm

12 Cancel reading

12 Temperature monitoring

12 Thermalpaperspecications

12 Paper roll replacement

13 Set-up Mode

13 Time setting Mode

13 Additional features

13 Firmware update

14 Bionova® Cloud Environment

14 Threshold Mode selection for PRO1 Indicators

15 ISO 15883-5:2021 Threshold Mode

15 ISO15883-5Workow

17 Bionova®Cloud Surface Eye Mobile App advanced features

17 Cleaning and maintenance

18 Troubleshooting

19 Warranty

19 Term

19 Limitation of liability

19 Technical assistance

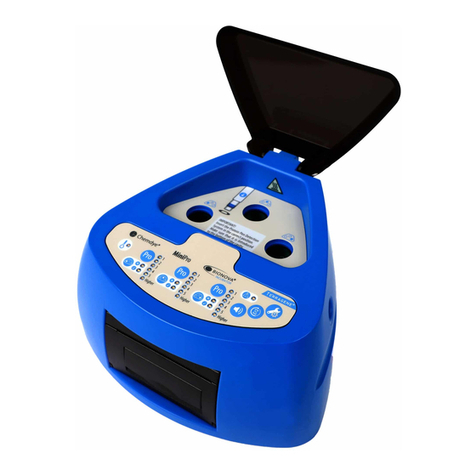

4 Bionova® MiniPro

Composition

Product description

Bionova®MiniPro Auto-reader has been designed for the

automatic readout of Terragene®Chemdye®Hygiene Monitoring

System PRO1 Indicators (PRO1 Protein Pen Indicators) appropriate

for surface cleaning and contamination control applications.

Bionova®MiniPro Auto-reader incubates at 60 °C and performs

a quantitative analysis over the Chemdye®PRO1 Protein Pen

Indicators, adjusted by a BSA (Bovine Seric Albumin) reference

curve. Bionova®MiniPro allows the incubation and readout

of 3 independent Chemdye®PRO1 Indicators simultaneously.

Bionova® MiniPro quantitative analysis has a detection limit of

0.5μgandaquanticationrangefrom1to50μgofequivalent

BSA Protein. The results are indicated with a resolution

of 0.1 μg, with an accuracy greater than 90 % in the whole

quanticationrange(IC95%).

Bionova®MiniPro Auto-reader also provides a printed ticket

each time an automatic readout is completed for recording

the results. This allows for easy result management, for

documentation compliance and safekeeping.

Do not place a new Protein Pen until the Temperature is stable

and the Temperature Stability Indicator stops blinking.

Indications for use

Terragene®Bionova®MiniPro incubator incubates at 60 °C

and reads the Terragene®Chemdye®Hygiene Monitoring

System Indicators at the times prescribed in the User Manual.

Features

1 Protective Cover

2 Incubation Area

16

17

18

1

2

3

4

5

67

8

9

10

11

12

13

14

15

Bionova® MiniPro 5

Important

Direct current

For indoor use only

Keep away from sunlight

Batch code

Manufacturer

Separate collection for waste of electrical and

electronic equipment

To avoid risks and/or damaging the device:

For indoor use only.

Do not place the Auto-reader in a room exposed to direct

sunlight or to high luminous intensity lamps.

Do not place the Auto-reader near devices that emit strong

electromagneticelds.

Do not use the Auto-reader on leaned surfaces or on

surfaces that are subject to shocks, vibrations,temperature or

high relative humidity.

Disconnect the power cord before cleaning.

Do not use abrasive, corrosive cleaners or disinfectants.

Do not immerse into any liquid . Do not pour any liquid inside.

Make sure the Auto-reader is connected to an appropriate

electrical mains outlet socket.

Use only the included power supply (AC power adapter), power

supply’s AC plug, power supply cords, and USB cable. Verify that

all the included elements are in good condition on daily basis. If

any of them is damaged, discontinue their use. The use of cables,

adapters, cords, and/or power supplies dierent from the ones

includedmaycauseres,electricalshocks,orevenphysicalinjuries.

Do not plug any devices into the Auto-reader’s USB port other

than a personal computer (PC). The PC has to be compliant with

IEC60950-1, IEC 62368-1 or comparable, with safety extra-low

voltages on its USB ports. Ask a qualied technician to verify

device compatibility. Attaching any other device to the USB port

may damage the Auto-reader and may not be safe for the user.

Do not attempt to repair the Auto-reader by yourself, that

could lead to major and irreversible damages to the device. In

case of device malfunction, contact your local distributor for

further assistance.

To avoid risks and/or damaging the device:

For indoor use only.

Safety information

Symbols

Operating relative humidity

Operating temperature

Caution, Warning, Attention - Refer to the

Instructions for use

Caution: Hot surface

3Control Panel

4Cavity for Paper

5Thermal Printer

6Temperature Stability Indicator

7Attention Indicator Light

8Incubation Position

9Start Incubation Program Button / Time Left

10 Red LED Indicator / Protein level above Threshold (HTM01-

01 Threshold mode) / Protein level above 1ug (ISO 15883-5

Threshold mode)

11 Green LED Indicator / Protein level below Threshold (HTM01-

01 Threshold mode)/ Protein level below 1ug (ISO 15883-5

Threshold mode)

12 Quantitative Protein Level LED Indicators

13 Alarm Cancellation Button

14 Reprint of Results

15 Configuration / Paper Traction Button

16 Hole for External Temperature Control

17 Input for Power Supply Plug (12 Volts DC)

18 USB Port

80 %

30 %

10 ºC

30 ºC

LOT

6 Bionova® MiniPro

Safety information

Do not place the Auto-reader in a room exposed to direct

sunlight or to high luminous intensity lamps.

Do not place the Auto-reader near devices that emit strong

electromagneticelds.

Do not use the Auto-reader on leaned surfaces or on

surfaces that are subject to shocks, vibrations,temperature or

high relative humidity.

Disconnect the power cord before cleaning.

Do not use abrasive, corrosive cleaners or disinfectants.

Do not immerse into any liquid . Do not pour any liquid inside.

Make sure the Auto-reader is connected to an appropriate

electrical mains outlet socket.

Use only the included power supply (AC power adapter),

power supply’s AC plug, power supply cords, and USB cable.

Verify that all the included elements are in good condition on

daily basis. If any of them is damaged, discontinue their use.

The use of cables, adapters, cords, and/or power supplies

dierent from the ones included may cause res, electrical

shocks, or even physical injuries.

Do not plug any devices into the Auto-reader’s USB port

other than a personal computer (PC). The PC has to be

compliant with IEC60950-1, IEC 62368-1 or comparable, with

safety extra-low voltages on its USB ports. Ask a qualied

technician to verify device compatibility. Attaching any other

device to the USB port may damage the Auto-reader and may

not be safe for the user.

Do not attempt to repair the Auto-reader by yourself, that

could lead to major and irreversible damages to the device. In

case of device malfunction, contact your local distributor for

further assistance.

To reduce the risks associated with contaminated

surfaces with protein levels outside the user-defined

threshold:

Please read, understand, and follow the Instructions for Use

of each Protein Pen before its incubation.

Do not remove the Protein Pen before the Auto-reader

reportsthenalreadoutresult.Checktheprintedticket.

To avoid a potentially hazardous situation:

Avoid contact with the hot metal block inside each incubation

position.

Donotinsertyourngers,oranyotherelement,insidethe

incubation positions.

Place only compatible indicators inside the incubation positions.

IMPORTANT

Do not use this product in a manner not specified by

Terragene S.A., otherwise the protection provided by the

product might be affected.

Only Terragene S.A. authorized personnel can access

or service the internal components of the Auto-reader.

Parts or components inside the Auto-reader should not be

manipulated by the user.

Operating conditions

Power supply specifications

Input parameters Operating conditions Units

Voltage range (100-240) AC Volts

Frequency 50/60 Hertz

*Current 0,5 Amperes

Output parameters Values Units

Voltage 12 DC Volts

**Current 2 Amperes

* 1 Ampere in USA and Canada.

** 3 Amperes in USA and Canada.

Terragene®S.A. recommends the use of UPS instead of

voltage stabilizers, since they fulfill two functions: to stabilize

and maintain the energy during a power outage.

Environment operating conditions

Environmental Operating Units

conditions conditions

Altitude 3500 (max.) Meters

Operation temperature 10-30 Celsius

RelativeHumidity30-80%

Installation/Over-voltage category II

Degree of contamination 2

Storagetemperature10-30%

Voltage 12 DC Volts

Regulatory compliance

Bionova®MiniPro Auto-reader complies with the following

standards and directives:

Electrical Safety IEC 61010-1

IEC 61010-2-010

Bionova® MiniPro 7

Safety information

Low Voltage Directive

2014/35/EU

Electromagnetic EN 61326-1

Compatibility (EMC) EMC Directive 2014/30/EU

European Commission RoHS Directive 2011/65/EU

WEEE Directive 2012/19/EU

Bionova®MiniPro Auto-reader do not represent

photobiological risk and do not generate dangerous optical

radiation in any of its normal operation conditions as per the

requirements of IEC 62471 Standard.

Designed under Quality Management System standards ISO

13485:2016/NS-EN ISO 13485:2016.

Instructions for use

Start-up

1|Place the Bionova®MiniProAuto-readeronarmsurface,free

from vibrations, away from direct sunlight, currents of hot or cold

air, chemical and corrosive or ammable substances. Do not

place the Auto-reader in a way that disconnection of the power

supply’sACplugfrommainscouldbedicult.Leaveaspaceof

at least 10 cm from the Auto-reader to the closest wall. Do not

move the Auto-reader periodically or during its use. Connect the

Auto-reader to a secure and stable electrical mains outlet socket.

Do not wet or heat the device. If liquid is spilled on the

Auto-reader, disconnect it and follow the instructions on the

Cleaning and maintenance section.

2|Power on your Bionova®MiniPro by connecting the power

supply’s AC plug to mains and then connect the plug at the

other end of power supply to the rear of the Auto-reader.

Before power on, verify that all incubation positions are empty.

If the blue attention light starts blinking after powering on the

incubator, check that the printer door is tightly closed and

that the printer has paper. If not follow the instructions in the

Replacement of the paper roll section.

3|Set the incubator internal clock to correspond to your local time

(seecongurationmethodsintheTime setting mode section).

All devices are manufactured with the following settings:

Time zone: UTC +0:00

Printing language: English

If you want to change the time zone, or the printing language

refer to Modication of time zone, or Modication of printing

language on the Set-up mode section.

4|Select your preferred Protein Quantication Threshold

Mode for your Auto-reader between the two Threshold

modes available: Threshold based on HTM01-01 Standard, or

Threshold based on ISO 15883-5:2021 standard.

Product Compatibility and

Incubation programs

Bionova® MiniPro Incubation Programs

The following incubation programs are available for your

Bionova®MiniPro. Verify which incubation programs are

available for your country checking the Indications for Use

section.

Temperature Time Incubation

selection selection program

60 ºC PRO (4 min) PRO at 60 °C

To select the appropriate incubation program for the Indicator

you are planning to use, follow each Indicator’s Instructions

for use.

Select the appropriate incubation program before the

incubation of any Indicator.

Bionova® MiniPro Auto-reader compatible indicators

We develop new Indicators for extending the features of our

Auto-readers regularly. Please check out your Auto-reader’s

compatibility matrix on www.terragene.com/minipro tond

out all compatible indicators for your device.

8 Bionova® MiniPro

An incubation position can not be enabled before the incubation

temperature is stable and the Auto-test has been carried out

successfully. Please wait until both processes are completed

before placing an indicator on an incubation position.

8|Use a compatible Chemdye®PRO1 indicator to take a

sample from the surface to be analyzed. Make sure to follow

the indicator’s instructions for use while taking the sample. A

summary of the swabbing process is also detailed one Figure 1.

9|After a sample from the swabbing surface has been taken,

place the PRO1 indicator into the enabled incubation position.

Insert the indicator fully inside the incubation position, as

shown on the Auto-reader’s label. When the indicator is on the

correct position, the indicator can not be rotated. (Figure 2).

Make sure that the solution is correctly mixed and the reading cone

hasasucientamountofsolutionbeforestartinganincubation.

Make sure that the indicator’s swab is not inside the reading

cone before starting an incubation.

10|Once the indicator is placed on the incubation position,

press and hold the button for 1 second to start the

incubation and readout process. Once the process start, the

positive and negative indicators will start to

blink and will keep blinking throughout the whole incubation

and readout process. Wait until the incubation and readout

process is completed before removing the indicator.

Do not move or remove or change the Indicator placement

once a reading process has begun, as it could lead to errors in

the incubation and/or readout process.

11|Once the incubation and readout process is completed, the

positive and negative indicators will stop

blinking and the Auto-reader will indicate the µg of protein

quantity found in the sample by turning on the corresponding

Quantitative Protein Level LED Indicator. A ticket will be

printed as well detailing the protein quantity along with other

useful information related to the readout process.

The protein quantity found on the sample is also used to

obtain and inform a readout result depending on the Protein

QuanticationThresholdModeandthresholdvaluesselected

on your Auto-reader. Please refer to the Interpretation of

Instructions for use

For selecting a Threshold mode and a Threshold value, please

follow the indications detailed on Threshold Mode selection on

Bionova®Cloud Environment section.

All devices are manufactured with the following settings:

Default Threshold Mode: HTM 01-01

Default Protein Threshold: 1 µg

Make sure that the selected Protein Quantication Threshold

Mode is according to your needs before performing an incubation.

The Threshold Mode can not be changed during ongoing readings.

5|Wait until the temperature stability indicator stops blinking

for the incubator to reach a steady working temperature.

Do not place an indicator on an incubation position before the

incubation temperature is stable.

6|Once the temperature stability indicator remains stable,

a one-time automated test to check each position internal

status will be carried out (Auto-test).

Once the Auto-test is complete, the green negative indicator

light will turn on to indicate that the position can be used to

perform a reading. Otherwise, the red positive indicator light

will turn on to indicate that an error has occurred.

When the incubator detects an error in a position, the position

will be disabled to guarantee the reliability of the results and it

cannot be used to perform any further readings.

To indicate that a position has been disabled, the red positive

indicatorlightwillblinkindenitely.

For the correct performance of the auto-test keep the

protective cover closed when the Auto-test is running.

7|After the Auto-test, readings can be initiated on any

incubation position if the position is not disabled. Choose one

of the incubation positions to start an incubation. Press and

hold the button of the chosen position for 1 second to

enable the position’s readout mode. The Auto-reader will emit

a short beeping sound and the 1 µg quantitative protein level

led indicator will blink for a moment. After that, two short

beeping sounds will be emitted indicating that the incubation

position is enabled and ready to start an incubation.

Bionova® MiniPro 9

results of PRO1 indicators section for more information.

After a Readout result is informed remove the indicator from

the incubation position an press the button once to reset

the incubation position to its stand-by state.

Note: The color of the solution on the PRO1 indicator can

be used for a qualitative reading only if the protein pen is

removed when the program ends. An audible alarm will be

seto30secondsbeforetheendoftheincubationprogram

to warn the operator that the incubation time is close to be

completed. If the protein pen is not removed as soon a result

is informed the color of the solution will continue to evolve.

12|To save the printed ticket. Pull upward for the paper to be

cut with the serrated edge of the printer.

Note: If there is no paper for ticket printing, the blue attention

light will start blinking. To replace the paper, follow the

instructions in the Paper roll replacement section. After the

paper has been replaced, you can reprint the last 3 readout

results following the Reprinting of Results section instructions.

Figure 1

A

Remove swab and add the moisturizer

B

Swab the desired surface by applying a strong pressure

C

Place the swab back into the device

Instructions for use

D

Activate

E

*Reference

volume

Shake downwards vigorously until the solution turns to green

and reaches the readout cone reference volume

F

Shake for 15 seconds with the swab inside the readout cone

G

Slide swab upwards without completely removing

H

Again, shake downwards vigorously and reach the readout

cone reference volume

10 Bionova® MiniPro

I

*Reference

volume

Readout cone without swab

J

Incubate immediately and read

Figure 2

Impossible

to rotate

Insert to

the bottom

Insert the pen on the incubation/reading position

Interpretation of results of PRO1

indicators

OnceaPRO1Indicatorreadoutprocessisnished,theAuto-

reader will inform the equivalent µg of protein quantity found

on the sample using a BSA (Bovine Seric Albumin) calibration

curve through the Quantitative Protein Level LED Indicators

and through a printed ticket.

The protein quantity found on the sample is also used

to obtain and inform a readout result depending on the

Threshold mode and threshold values selected on your Auto-

reader. Such readout result can be either Positive or Negative

for HTM01-01 Threshold Mode, or Negative, Alert, or Action for

ISO 15883-5 Threshold Mode.

Note: To select a Threshold mode and its values please

refer to the Threshold Mode selection on Bionova®Cloud

Environment section.

Instructions for use Readout results for HTM01-01 Threshold Mode

HTM01-01 Threshold Mode is the default Protein

QuanticationThresholdmodeofyourAuto-reader.

HTM01-01 guidelines indicates the use of a single protein

quantitythresholdtoevaluatecleaningecacy.Theguidelines

recommends that the residual protein level upper limit of

acceptable protein contamination after processing is 5 µg BSA

equivalent per instrument side, indicating as well that lower

levels may be recommended for particular applications.

Important: Refer to the HTM01-01 guidelines for detailed

information on how to implement the standard to your processes.

If HTM01-01 Threshold Mode is selected as the readout

threshold mode on your Auto-reader, each time a readout is

completed the protein quantity will be informed through the

Quantitative Protein Level LED Indicators and a printed ticket:

POSITIVE CANCELEDNEGATIVE

1 µg

2 µg

3 µg

4 µg

5 µg

Approximate amounts of BSA expressed in µg.

If the protein quantity detected on the sample is lower than

the selected threshold, a Negative readout result will be

informed and the Auto-reader will turn on the Green LED

indicator. If the quantity detected is greater than the selected

threshold, a Positive readout result will be informed and the

Auto-reader will turn on the Red LED indicator. The readout

result will be detailed on the printed ticket as well.

Furthermore, if the Auto-reader is connected to the Bionova®

Cloud Environment, the readout results can be found on the

Hygiene Monitoring > Finished web page of Bionova® Cloud

Web interface.

Bionova® MiniPro 11

Take action immediately whenever a POSITIVE Readout

Result is informed as this indicate that the protein quantity

founddoesnotcomplywiththeuserdenedqualitystandards

set for the cleaning process.

Readout results for ISO 15883-5 Threshold Mode

TheISO15883-5:2021standardindicatestheuseoftwodierent

protein quantity thresholds to evaluate cleaning ecacy: An

Action threshold, and an Alert threshold. ISO 15883-5 based

thresholds are expressed as ratios in µg/cm2 units that relates

protein quantity found in a sample (µg) and the swabbing surface

(cm2) on which the sample was taken. According to the standard,

eachthresholdhasdierentimplications:

Alert threshold: The alert levels are the target levels of

cleaning ecacy that the cleaning process should achieve.

Recommended threshold value 3µg/cm2. Lower values may be

recommended for particular applications.

Action threshold: The action levels are the maximum criteria

for acceptable cleaning ecacy during testing of a sample.

Recommended threshold value 6.4µg/cm2. Lower values may

be recommended for particular applications.

Values between the two thresholds should be investigated,

but are considered to pass cleaning requirements.

Important: Refer to the ISO 15883-5:2021 standard for

detailed information on how to implement the standard to

your processes.

If ISO 15883-5 Threshold Mode is selected as the readout

threshold mode on your Auto-reader, each time a readout is

completed the protein quantity will be informed by the Auto-

reader through the Quantitative Protein Level LED Indicators

and through a printed ticket:

Instructions for use 1 µg

2 µg

3 µg

4 µg

5 µg

Approximate amounts of BSA expressed in µg.

Also, as a quick visual cue of the protein quantity found on the

sample, the device will turn on the Red LED Indicator if the

protein quantity is above 1 µg, or the Green Indicator if the

protein quantity is below 1 µg.

Important: Please keep in mind that according to ISO 15833-

5:2021 standard the protein quantity found in a sample (in µg)

needs to be related to the swabbed surface area to obtain

a readout result (in µg/cm2) that can be comparable with the

selected Alarm and Alert thresholds (also in µg/cm2).

Once the protein quantity in the sample has been obtained

by the Auto-reader, and the swabbed surface information has

been obtained with the Bionova®Antinova APP. The information

isnallylinkedtogetherbytheBionova®Cloud Environment to

inform the readout result. Please refer to ISO 15883-5:2021 on

Bionova®Cloud Environment section for a step by step guide to

upload and link data on Bionova®Cloud Environment.

Once the data has been linked, the readout result will be

shown on the Hygiene Monitoring > Finished tab of Bionova®

Cloud Web Interface. Depending on the threshold values

selected, the informed readout result can be as follows:

If the protein quantity found on the swabbed surface (µg/cm2) is

below the Alert Threshold. The readout result will be informed

as NEGATIVE.

If the protein quantity found on the swabbed surface (µg/cm2)

is above the Alert Threshold but below the Action Threshold.

The readout result will be informed as ALERT.

If the protein quantity found on the swabbed surface (µg/cm2) is

above the Action Threshold. The readout result will be informed

as ACTION.

Take action immediately whenever an ACTION Readout

Result is informed as this indicate that the protein quantity

founddoesnotcomplywiththeuserdenedqualitystandards

set for the cleaning process.

Disposal

Discard the PRO1 indicator according to your country’s sanitary

12 Bionova® MiniPro

regulations. It is not possible to use or incubate a PRO1 indicator

more than once. Please refer to the PRO1 instructions for use.

Reprinting of results

The Auto-reader allows reprinting of the last 3 results. For

reprinting the results, press the button for 3 seconds.

Remaining incubation time

Bionova®MiniPro Auto-reader allows you to verify the remaining

incubation time in every reading position by ticket printing.

Whenever a reading process is in course, press and hold the

button for 3 seconds. A ticket will print, informing reading

position, incubation program and remaining incubation time.

To verify remaining incubation time of 2 or more readings in

course, press 2 buttons simultaneously; the device renders

a ticket, informing remaining incubation time of all positions.

Audible alarm

An audible alarm will sound every time a positive result is

detected in Bionova®MiniPro Auto-reader. The alarm allows

the user to immediately detect a positive result without the

need to visually control the device. The alarm can be canceled

by pressing the button.

Cancel reading

The user can cancel a reading of any of the 3 positions by

simultaneously pressing and holding for 3 seconds the

button of the chosen position and the button. Once a

reading is canceled a ticket will be printed.

Temperature monitoring

Bionova®MiniPro Auto-reader features an automated internal

temperature control. If the incubation temperature falls

outsideofthespecied rangeof60±2ºC,thetemperature

stability indicator light will start to blink. The incubation

temperature can be externally monitored by placing an

external thermometer in the hole for external temperature

control located at the back of the device.

Thermal paper specifications

Recommended paper: JUJO AF50KSE3 thermal paper or similar

Instructions for use (order code ICTP).

Paper width : 57 mm

Maximum paper thickness: 60 g/m2

Maximum diameter size: 23 mm

Paper roll replacement

1|To replace the paper roll, pull the handle on the printer

door. Open the cover and remove the empty roll.

2|Place the new paper roll with the outer side up.

3|Close the printer cover by pressing on the sides of the lid.

Note: You can check the correct paper replacement by

pressing the button to advance the paper a few

centimeters.

Set-up Mode

Bionova®MiniProfeaturesacongurationmodethatenables

you to set the printing language and the date format and time

zone in the device. To enter Set-up Mode, turn on the Auto-

reader while holding down the button . The red and green

LEDs in the three positions will remain on, indicating that the

device is in this mode. The printer will render a ticket indicating

Bionova® MiniPro 13

that it is in Set-up Mode.

To change the date format, time zone and printing language,

please follow the instructions listed below. When nished,

restart the computer to exit Set-up Mode.

Modification of date format and time zone

The date format and time zone modication function allows

changing the date format and time zone of the device to suit

better the local characteristics of your country.

To make these changes, start your device in Set-up Mode (See

Set-up Mode section) and press the button.

The green light indicator corresponding to incubation position

1 will start blinking. In addition, the current date format will be

printed in order to set a reference value.

Three types of date format are available: DD/MM/YY, MM/DD/

YY and YY/MM/DD.

Note: The default date format is DD/MM/YY.

Press the or button to move back and forth between

each of the 3 available options. After 2 seconds, a ticket with

the selected format will be printed to set a reference.

To save the selected date format, press and hold the

button for 3 seconds. To exit without saving the changes,

disconnect the device.

Once the date format has been modied and saved,

the incubator will enter Time Zone modication Mode

automatically. The current date (with the previously selected

format) and the current time will be printed to set a reference.

To subtract hours, press the button as many times as

necessary. To add hours, press the button as many times

as necessary. After 2 seconds, a ticket will be printed, informing

the selected time zone.

To conrm the change, hold down the button for 3

seconds. To discard the changes, unplug the incubator from

the power source.

Note: The green light indicator corresponding to incubation

position 1 will stop blinking once both, the date format, and time

zonemodicationsaresaved.

Modification of printing language

This functionality allows changing the language that appears

on the tickets. To make this change, the device must be started

in Set-up Mode (see Set-up Mode), then press the button .

The current language and list of available languages will be

printed to establish a reference. Press the button to scroll

up and the button to scroll down. After 2 seconds, a ticket

will be printed informing the selected language.

Toconrmthechange,pressandholdthe button for 3

seconds. To discard the change, unplug the Auto-reader from

the power source.

Time setting mode

Modification of the time using the Bioupdate® software

Connect the auto-reader via the USB port to a PC and Run

Bionova®Bioupdate Firmware Upate Utility. Select the Auto-

reader and press the Clock Sync button, the auto-reader

internal time and date will be synchronized with the PC’s

current time and date. Synchronization can only be done as

long as there is not an ongoing reading.

Modification of the time using Bionova® Cloud Agent

Connect the auto-reader via the USB port to a PC and run

Bionova®Cloud Agent. Select the Auto-reader and press the

Clock Sync button, the auto-reader internal time and date

will be synchronized with the PC’s current time and date.

Synchronization can only be done as long as there is not an

ongoing reading.

Additional features

Firmware update

Bionova®MiniPro Auto-reader allows the update of its

rmware (program inside the Auto-reader that controls and

denes its dierent features) by using Bionova®Bioupdate

rmwareupdate utility. Bionova®Bioupdate connects to the

Internet to verify, download, and install, the latest rmware

version available for your Auto-reader. The update process

only lasts a few seconds and is carried out without the loss

of any Auto-reader’s data. Please visit www.terragene.com/

software to download Bionova®Bioupdate.

Update process

Before updating the device, make sure that the Bionova®

Cloud Agent is closed. Power Off the Incubator for five

seconds, afterwards Power On the Incubator and follow the

next steps:

1|Using the included USB cable, connect your Bionova®MiniPro

to a PC where Bionova®Bioupdate has been previously

installed. Make sure the PC has a working Internet connection.

2|Run Bionova®Bioupdate.

3|Select the Auto-reader from the list and press the Start

14 Bionova® MiniPro

Bionova® Cloud Environment

The new Bionova®Cloud environment is a Cloud based solution

that integrates the information generated by Terragene®

electronic devices with an easy-to-use Web App for the

traceability of sterilization and disinfection control applications.

The Bionova®Cloud environment is composed by two main

components: the Bionova®Cloud Traceability Software which

is a Web Based application, and the Bionova®Cloud Agent

which is a Microsoft™ Windows App that acts as an interface

between the Terragene®compatible devices and the web

based application.

Bionova®Cloud Traceability Software allows to manage

and store the readout results of Self-contained biological

indicators and Hygiene Monitoring System Indicators in a

secure and user-friendly way.

Bionova®Cloud Traceability Software allows matching the

information of an Indicator result with the sterilizer or washing

machine used, the operator, cycle characteristics, and all

relevant information for allowing each institution achieve

reliable documentation compliance and safe-keeping.

The Bionova®Cloud Agent handles all communications with

Terragene®compatible electronic devices and the Host PC

where the Agent App runs.

Bionova®Cloud Agent then acts as an interface between

the Terragene®compatible devices and the Bionova®Cloud

Traceability software and sends the information generated from

the devices to the Microsoft™ Azure powered Cloud server where

the Traceability Software Web App runs and stores the information.

The user can then access to the Cloud saved information

through any device with a compatible web browser.

To access to the Bionova®Cloud Environment please visit

www.terragene.com/bionova-cloud.

Threshold Mode selection for

PRO1 Indicators

Bionova®Cloud Environment allows the selection of the

ProteinQuanticationThresholdModeandThresholdvalues

throughout its web interface.

Important: Threshold Mode selection is only available for the

latestsrmwareversions.UpdateyourAuto-reader’srmware

before carrying out any of the steps below. Please refer to the

Firmware update section for more information

1|Connect your Auto-reader to a PC where Bionova®Cloud

Agent is installed.

2|Run and Log-in to the Bionova®Cloud Agent. Wait until the

Agent lists the incubator.

3|Access as the Administrator user to the Bionova®Cloud

Environment Web interface.

4|Go to the Conguration > Parameters section tab on the

Bionova®Cloud Web Interface left side menu.

5|Select the Threshold working mode for your Auto-reader:

HTM01-01 or ISO 15883-5. Save the selected mode clicking

on the SAVE button.

6|Select the Threshold values for the selected mode. Save the

selected Threshold values by clicking on the SAVE button.

If the process is carried out successfully your Auto-reader will

Additional features

button to update.

4|Wait until the software indicates that update process

has been completed. The Auto-reader will print an update

conrmationticket.Ifitwasalreadyuptodate,theticketwill

not be printed.

Note: This process must be repeated every time that a new

rmware version is available, this will be informed in the

Terragene S.A. Website.

Bionova® MiniPro 15

print a ticket detailing the Threshold Mode selected.

ISO 15883-5:2021 Threshold

Mode

The new ISO 15883-5:2021 Standard implements new

recommendations for taking action based on the ndings of

hygiene monitoring indicators. One of the major features of

this new revision of the standard is that the protein quantities

measured when swabbing an instrument must be related to

the swabbing surface in which the sample was taken for correct

decision making over decontamination and washing equipment.

To obtain an estimation of the Swabbing surface area, the

new Bionova®Cloud Surface Eye Mobile App was designed.

The Surface Eye Mobile App is a new proprietary application

developed by Terragene®compatible with Android OS that

allows the user to obtain an estimation of an instrument’s

swabbed surface using complex machine learning

technologies in a few simple steps. The App also implements

seamlessly integration with the Bionova®Cloud Environment.

Linkingproteinquanticationreadoutdata(inµg)informedby

an Auto-reader, and swabbing surface data (in cm2) informed

by the Surface Eye App, throughout the Bionova®Cloud

Environment allows the creation of ratios of protein quantities

and swabbing surface area (in µg/cm2) that can be compared

with ISO 15388:2021 style thresholds.

ISO 15883-5 Workflow

Take the following steps for linking protein quantication

readout data and swabbing surface data through the Bionova®

Cloud Environment.

A) Set-up

1|Set-up your Auto-reader for ISO 15883-5 Threshold Mode.

Please refer to the Threshold Mode selection on Bionova®

Cloud Environment section for more information.

2|Download the Bionova®Cloud Surface Eye APP from Google

Play Store on your Android compatible device.

Important: Make sure your Android device has a working

camera for the Surface Eye App to work as intended.

B) Login and authentication

1|Log-in to the Bionova®Cloud Agent on the PC connected to

your PRO1 Indicator Auto-reader.

2|Log-in to the Bionova®Cloud Surface Eye APP with the same

credentials used on the Bionova®Cloud Agent.

3|Log-in to the Bionova®Cloud Web Interface with the same

credentials used on the Bionova®Cloud Agent.

C) Swabbing and surface estimation

1|Set the instrument to be swabbed over the Surface Eye

Card. Please keep in mint that the swabbing area must be

fully contained on the card for the Surface Eye APP to properly

estimate the swabbing surface area.

2| Tap on the icon, and align the 3 position markers

from your phone screen with the 3 position markings on the

Surface Eye card. Once the position markers are aligned, the

App will take a photo automatically.

3|Select the area of the instrument to be swabbed and tap

on the icon.

4|The APP will automatically select and estimate the surface

(cm2) of the selected swabbing area.

Bionova® Cloud Environment

16 Bionova® MiniPro

It is a good practice to standardize the swabbing area for

each instrument. Dening and using the same swabbing

area for a given instrument allows the sampling process to

be repeatable through time and deliver valuable statistical

information.

Important: According to ISO 15883-5:2021 Standard, the

recommended values for the Alert and Action threshold

are 3 µg/cm2 and 6,4 µg/cm2, respectively. As both ratios

relate protein quantity of a sample to the swabbing surface

from which the sample is taken, please make sure to use

standardized surfaces on the range of 1 to 7 cm2. The use of

higher swabbing surfaces (>7,6 cm2) imply that the protein

quantitytodenetheactionthresholdwouldbeabovethe50

µg of the PRO1 Hygiene Monitoring System quantization range

and thus cannot be properly used.

5|Deneaninstrumentcodeandadescriptiontofullyidentify

the swabbing area and the surface acquisition details.

Note: Choose a descriptive code and description for the

instrument so its easier to link the surface data with the

protein readout information later on the Bionova Cloud

Environment.

6|Check the Both sides check-box if you plan to swab both

sides of the instrument. Checking the button will duplicate

the selected swabbing area to account for the double sided

swabbing procedure.

7|Once ready, tap the icon. The APP will upload all the

surface information to your Bionova®Cloud Environment

account.

8|The surface acquisition details can be edited from the Apps’

home menu swiping the instrument code to the left.

D) PRO1 Indicator incubation and readout

1|Follow the instructions for use of your PRO1 Indicator to take

a protein sample of the selected instrument.

Important: Make sure to swab evenly the same surface area

that was selected on the Surface Eye App.

Important: Make sure you swab both sides of the instrument

if the Both sides check-box was selected on the Surface Eye

APP.

2|Carry out the incubation and readout of the PRO1 Indicator

as described on the Instructions for Use section of this manual.

Wait for a readout result to be informed.

E) Linking protein readout information and swabbing

surface information

1|Once the Readout result is informed by the Auto-reader.

Go to the Hygiene Monitoring > Finished tab on the Bionova®

Cloud Web Interface right side menu and ll in the PRO1

Indicator readout information.

2|Click on the Assign Area button and select the surface

acquisition data details of the swabbed surface.

Important: Make sure the surface acquisition information

corresponds to the protein readout data so that the correct

ratios can be obtained. To check if the surface information

is the correct one, click on the magnifying glass to view

the swabbing surface image saved on he Bionova®Cloud

environment.

3|Click the Conrm button to save the details, or the Conrm

and move to saved button to save the details and move the

readout to the Bionova®Cloud Database accessible through

Dashboard > Saved section tab on the Bionova®Cloud Web

Interface left side menu.

Bionova® Cloud Environment

Bionova® MiniPro 17

Bionova® Cloud Surface Eye

Mobile App advanced features

Redefining the swabbing area of an instrument

You can redene a previously saved surface area of an

instrument on the Surface Eye app, and take a new photo to

assign a new swabbing area to the instrument. For this swipe

left on the instrument code, and tap the icon. Take a new

photo and select the new swabbing area.

Editing an instrument code and description

You can edit the details of any of the instrument codes

previously saved on the Surface Eye app. For this swipe left on

the instrument code, and tap the icon.

Conversion of ISO 15883-5 thresholds

Once a swabbing surface area has been saved and assigned

to an instrument on the Surface Eye App, the details of the

surface can be accessed by taping the instrument code.

On the details screen, the Alert and Action Thresholds (in

µg/cm2) as dened on the Bionova®Cloud Environment,

are converted and shown to the user as protein quantity

thresholds (µg) for the selected surface.

This allows for direct visual comparison between the protein

quantity found on the sample as informed on the Auto-reader

printed ticket, and the protein quantities that correspond to

thealertandactionthresholdsforthedenedswabbingarea.

Cleaning and maintenance

Cleaning and decontamination of external surfaces

Disconnect the power supply cable and the USB cable from

the Auto-reader. If the device is hot, wait until it has cooled

down before handling it.

Cleanthe external surfacesof the device usinga microber

cloth moistened with a solution of mild dish washing

detergent and water. Wring the cloth so it is damp but not

dripping before cleaning, and wipe the outer surfaces of the

Auto-reader. Afterwards, moisten a clean microber cloth

with water only, and repeat the procedure until all traces

of detergent are removed from the external surfaces of the

device. After cleaning, allow the Auto-reader to air dry for at

least 1 hour before connecting the power supply cable or the

USB cable again.

This cleaning procedure can be followed whenever considered

appropriate.

This cleaning procedure must be followed every time a spill

occurs on any of the external surfaces of the Auto-reader.

If further cleaning is required, or if you have doubts about

the cleaning agents you may use, please contact your local

distributor.

Do not clean the internal parts of the device.

Do not pour or immerse the device into any liquid. Do not

allow any liquid to run inside the device during its cleaning.

Maintenance

Bionova®MiniPro does not require routine maintenance.

18 Bionova® MiniPro

Troubleshooting

Fault

The Auto-reader does not start.

The Auto-reader informs an error

in an incubation position during

“Autotest”.

The Auto-reader informs an error

in an incubation position during

“Autotest”.

An incubation can not be run in a

Protein Pen incubation position

(position’s red light is on).

The Auto-reader does not run an

incubation in any position.

Is not possible to change

temperature and/or time setting.

It’s not possible to start a protein

pen incubation (Pen not valid

ticket).

The Auto-reader does not detect

the protein Pen (Pen not detected

ticket).

The printer does not print (blue

attention light blinks quickly).

The printer releases unprinted

paper.

The Auto-reader can not be

updated.

The Auto-reader is not detected by

Bionova® Cloud Agent.

Possible cause

Power supply is not connected.

A indicator is placed in the incubation

position during the Autotest.

Dust particles might be obstructing the

readout mechanism.

Position disabled. Error in that position

during “Autotest”.

Incubation temperature not stable.

Ongoing reading.

Protein pen condition is not appropriate

for its incubation

Protein pen is not correctly placed in the

incubation position.

The printer cover is not tightly closed.

Printer without paper.

Paper roll is not placed correctly.

Bionova®Cloud Agent is being run.

The Auto-reader is turned off / The Auto-

reader is not connected to the PC.

Action

Check that the power supply is connected

to a proper mains. Check that the DC

plug of the power supply is connected to

the rear of the Auto-reader.

Check that every incubation position is

empty during the Autotest.

Avoid using the Auto-reader in dusty

environments. Use air to dust-off inside

a position. Do not insert solid objects.

Once cleared, restart the Auto-reader.

Make sure that the position is empty

when starting the Auto-reader. Once

cleared, restart the Auto-reader.

Wait until temperature is stable before

any incubations.

Wait for any incubation to complete, and

try again.

Make sure that the solution on the reading

coneissucient.Makesuretheindicator

solution is not overly saturated or already

changing its color (i.e., not green).

Do not incubate an indicator twice.

Please follow the Indicator Instructions

for use before its incubation.

Make sure the indicator is fully placed

at the bottom of the incubation position

before its incubation.

Check that the cover is tightly closed.

Place a new paper roll in the right direction.

Place the paper according to the

directions on the Replacement of the

paper roll section.

Close Bionova® Cloud Agent and restart

the Auto-reader.

Follow the directions on the Start-up

section to set-up the device properly.

Bionova® MiniPro 19

Warranty

Terragene S.A. guarantees both the quality of the product

material components and the quality of its manufacturing

process. Should any material or manufacturing faults be

detected within the warranty period, the only obligation of

Terragene S.A. will be product repairing or substitution.

Term

The warranty period for electronic products marketed by

Terragene®will be 1 (one) year from the date of first use of the

product, and may never be extended beyond the product’s

useful life -5 (five) years from its manufacture-.

Limitation of liability

Terragene S.A. shall not be held liable for any loss or damage

that result from the unsuitable use of the equipment,

negligence or user’s full responsibility.

Technical assistance

Terragene S.A.

Ruta Nacional Nº 9, KM 280 - CP 2130.

Parque Industrial Micropi - Alvear - Santa Fe - Argentina.

Other manuals for Bionova MiniPro

1

Table of contents

Other Terragene Laboratory Equipment manuals

Terragene

Terragene IC10/20FRT Instruction manual

Terragene

Terragene BIONOVA MiniBio User manual

Terragene

Terragene Bionova MiniPro User manual

Terragene

Terragene Bionova IC10/20FRLCD User manual

Terragene

Terragene Bionova IC10FR User manual

Terragene

Terragene Bionova IC10FR User manual

Terragene

Terragene UVFlow User manual

Terragene

Terragene Trazanto User manual

Terragene

Terragene Trazanto User manual

Terragene

Terragene BIONOVA MiniBio User manual